Get in touch with us

Leave a message

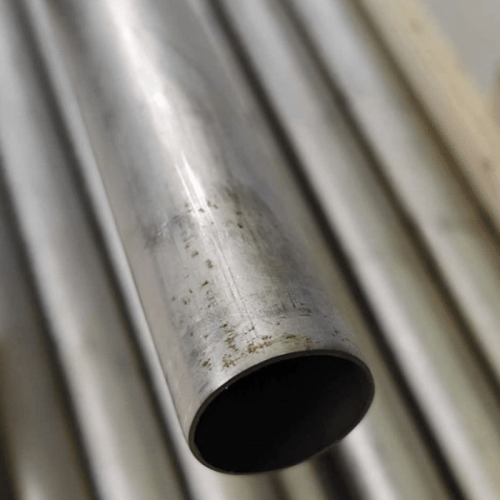

Stellite4 Cobalt Alloy Pipe, a premium chromium cobalt nickel alloy, is engineered for extreme durability and resistance to wear, corrosion, and high temperatures. Manufactured by our trusted China enterprise, this cobalt alloy steel is ideal for demanding industrial environments, offering superior performance in applications requiring robust material properties. Its unique cobalt alloy composition ensures longevity and reliability, making it a top choice for industries worldwide.

For competitive pricing on Stellite4 Cobalt Alloy Pipe, contact our sales team through our website or customer service portal. Pricing terms are tailored to order volume, specifications, and delivery requirements. Reach out today to discuss your needs with our China-based manufacturing experts.

The versatile Stellite4 Cobalt Alloy Pipe is widely used across industries due to its robust cobalt alloy uses. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance (approx. 50-55%) |

| Chromium (Cr) | 28-32% |

| Tungsten (W) | 12-15% |

| Nickel (Ni) | 0.5-2% |

| Carbon (C) | 0.9-1.4% |

| Iron (Fe) | ≤3% |

| Others | ≤1% (Si, Mn, etc.) |

| Property | Value |

|---|---|

| Tensile Strength | 950-1100 MPa |

| Yield Strength | 650-800 MPa |

| Elongation | 10-15% |

| Hardness (HRC) | 38-44 |

| Density | 8.6 g/cm³ |

The cobalt alloy properties of Stellite4 ensure excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it suitable for harsh chemical environments. However, prolonged exposure to highly oxidizing acids like nitric acid may require careful monitoring. Stellite4 Cobalt Alloy Pipe complies with environmental regulations, but recycling is recommended due to cobalt’s limited availability.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.01-0.05 |

| 10% Sulfuric Acid | 0.05-0.1 |

| 10% Hydrochloric Acid | 0.1-0.2 |

Stellite4 Cobalt Alloy Pipe supports multiple welding methods, including TIG (Tungsten Inert Gas) and plasma arc welding, to ensure strong joints. Preheating to 200-300°C is recommended to prevent cracking. Fabrication techniques include:

The Stellite4 Cobalt Alloy Pipe from this China manufacturer exceeded our expectations. Its corrosion resistance in acidic environments is outstanding, and the custom specifications were delivered on time.

John D.

Petrochemical Engineer

These tubes handle corrosive chemicals flawlessly. The cobalt alloy composition is top-quality, and the manufacturer’s service is reliable.

Anna T.

Chemical Plant Supervisor

The durability of Stellite4 Cobalt Alloy Pipe in seawater conditions is unmatched. It’s a reliable choice for offshore projects.

Michael T.

Marine Engineer

A: Stellite4 has a higher tungsten content, enhancing wear resistance compared to alloys like Stellite 6, making it ideal for abrasive environments.

A: Petrochemical, aerospace, power generation, and marine industries rely on its durability and corrosion resistance.

A: Yes, it performs well up to 1200°C, but oxidation risks increase beyond this temperature.

A: It meets environmental standards, but recycling is advised to reduce cobalt impact.

A: TIG and plasma arc welding are recommended for strong, reliable joints.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.