Get in touch with us

Leave a message

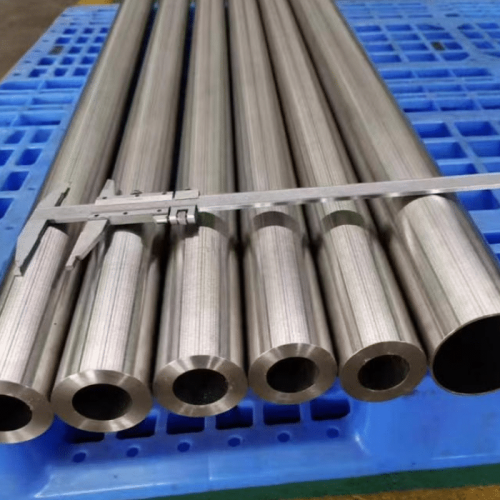

Stellite8 Cobalt Alloy Tube is a high-performance chromium cobalt nickel alloy designed for exceptional durability, corrosion resistance, and thermal stability. Produced by our trusted China manufacturer, this cobalt alloy steel excels in demanding industrial applications, offering unmatched reliability due to its optimized cobalt alloy composition.

Inquire about competitive pricing for Stellite8 Cobalt Alloy Tube through our website or customer service portal. Pricing is customized based on specifications, order volume, and delivery terms. Connect with our China-based manufacturing team for a tailored quote.

Stellite8 Cobalt Alloy Tube is valued for its versatile cobalt alloy uses across industries, including:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance (approx. 48-53%) |

| Chromium (Cr) | 27-31% |

| Tungsten (W) | 8-10% |

| Nickel (Ni) | 1-3% |

| Carbon (C) | 0.8-1.2% |

| Iron (Fe) | ≤3% |

| Others | ≤1% (Si, Mn, etc.) |

| Property | Value |

|---|---|

| Tensile Strength | 900-1050 MPa |

| Yield Strength | 600-750 MPa |

| Elongation | 12-18% |

| Hardness (HRC) | 36-42 |

| Density | 8.5 g/cm³ |

The cobalt alloy properties of Stellite8 provide excellent resistance to acids (e.g., sulfuric, hydrochloric) and alkalis, making it suitable for corrosive environments. Avoid prolonged exposure to strong oxidizing agents like nitric acid. Stellite8 Cobalt Alloy Tube adheres to environmental standards, but cobalt recycling is recommended due to resource scarcity.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.02-0.06 |

| 10% Sulfuric Acid | 0.06-0.12 |

| 10% Hydrochloric Acid | 0.1-0.25 |

Stellite8itled for TIG (Tungsten Inert Gas) and plasma arc welding to ensure robust joints. Preheating to 150-250°C minimizes cracking risks. Fabrication methods include:

The Stellite8 Cobalt Alloy Tube from this China manufacturer is top-notch. Its corrosion resistance in harsh fluids is impressive, and delivery was prompt.

David L.

Oil and Gas Engineer

We rely on these tubes for handling aggressive chemicals. The cobalt alloy properties ensure long-term reliability, and the factory’s support is excellent.

Sarah M.

Chemical Plant Manager

The Stellite8 Cobalt Alloy Tube performs exceptionally in seawater environments. It’s a durable solution for our offshore projects.

James R.

Marine Engineer

A: Stellite8 has lower carbon and tungsten content than Stellite 4, offering better ductility and slightly less wear resistance.

A: It’s used in oil and gas, aerospace, chemical processing, and marine industries for its durability.

A: Yes, up to 1150°C, but oxidation risks increase beyond this limit.

A: Yes, it complies with global regulations; recycling is advised due to cobalt scarcity.

A: TIG and plasma arc welding are recommended for strong, reliable welds.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.