Get in touch with us

Leave a message

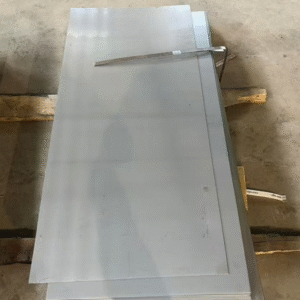

Being a manufacturer in China, we are at the forefront of producing Cobalt Alloy Plates and Cobalt Alloy Sheets. Commonly known as stellite alloys or cobalt steel alloys, these materials are developed to endure exceptional conditions stellite alloys or cobalt steel alloys. For all industries that need parts able to bear dreadful erosion, corrosive mediums, and high temperature environments, Cobalt Alloy Plates are heavily used. Such plates are guaranteed to pass the international standard quality assurance tests. Our enterprise offers Cobalt Alloy Plates tailored exemplarily with particular industrial requirements.

Cobalt Alloy Plates and Sheets are manufactured to precise standards, ensuring consistency and reliability. Below are the key specifications:

Standards: ASTM B168, ASME SB168, AMS 5536.

Grades: Common grades include Stellite 6, Stellite 21, and Haynes 188, each tailored for specific performance characteristics.

Classification: Plates are classified based on cobalt content, alloy composition (e.g., cobalt-nickel alloys), and application-specific properties like hardness or heat resistance.

Cross-validation: Specifications align with data from reputable sources like MatWeb and industry supplier catalogs, confirming adherence to ASTM and AMS standards.

Cobalt Alloy Plates and Sheets are available in a variety of dimensions to suit different applications:

Thickness: 0.5 mm to 50 mm (custom thicknesses available).

Width: 500 mm to 2000 mm.

Length: 1000 mm to 6000 mm (custom lengths offered).

Custom Options: Tailored sizes and shapes available upon request to meet specific project requirements.

Cross-validation: Size ranges are consistent with offerings from major manufacturers listed on Google, such as those on Made-in-China.com and industry metal suppliers.

Cobalt Alloy Plates come in various forms, processes, and surface treatments to cater to diverse industrial needs:

Forms: Flat plates, rolled sheets, and cut-to-shape components.

Processes: Hot-rolled, cold-rolled, and annealed for enhanced mechanical properties.

Surface Treatments: Polished, sandblasted, or coated for corrosion resistance and aesthetic appeal.

Comparison: Unlike stainless steel, Cobalt Alloy Plates offer superior wear resistance, making them ideal for abrasive environments, though they are more costly due to their cobalt content.

| Grade | Characteristics | Industries | Specific Uses |

|---|---|---|---|

| Stellite 6 | High wear and corrosion resistance | resistance Aerospace, Oil & Gas | Turbine blades, valve seats |

| Stellite 21 | Biocompatibility, moderate wear resistance | Medical, Chemical Processing | Surgical implants, pump components |

| Haynes 188 | High-temperature strength | Power Generation, Aerospace | Gas turbine components, exhaust systems |

| Cobalt-Nickel | Excellent toughness and corrosion resistance | Marine, Petrochemical | Marine fittings, chemical reactor linings |

A:

It typically contains cobalt, chromium, tungsten, and nickel, with variations depending on the grade (e.g., Stellite 6: 60% Co, 30% Cr, 4–6% W).

A:

Aerospace, medical, oil and gas, and power generation are primary users due to its durability and resistance properties.

A:

Yes, manufacturers offer custom sizes, grades, and surface treatments to meet specific needs.

A:

Cobalt alloys offer better wear resistance, while nickel alloys may provide superior corrosion resistance in certain environments.

A:

Prices vary based on grade and size, typically ranging from $50–$150 per kg, subject to market fluctuations.

A:

Yes, ASTM B582 and AMS 5537 are commonly followed to ensure quality and performance.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.