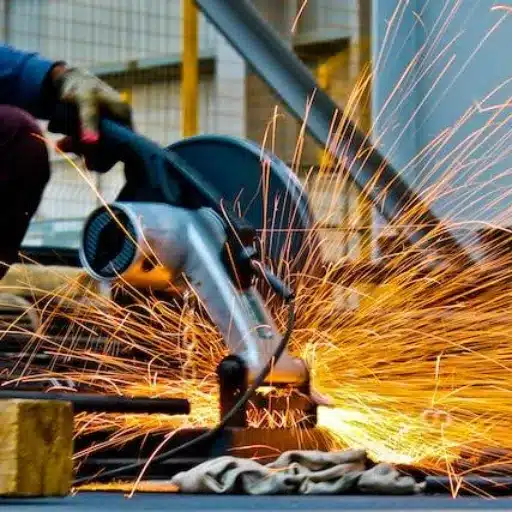

Cutting the sheets of stainless steel is a method that could be quite complicated, demanding the appropriate arsenal of tools, techniques, and professionals to attain both the precision and the efficiency. It does not matter whether you are a veteran metalworker or a DIY beginner; it is important to be aware of the whole process of slicing stainless steel in order to not make very costly errors and to get the quality you want. This manual will lead you through the indispensable stages, from the right tools to the recommended methods by the industry. You will not only acquire the knowledge but also the skill to carry out your operations on cutting stainless steel. Let us then get going with the splitting of the metal sheets for your work into the rightly sized pieces!

Introduction to Cutting Stainless Steel

A Cutting Techniques Understanding Significance

Cutting stainless steel is an accurate skill that needs a deep knowledge of the methods to get the best results. Stainless steel is very tough and not easy to corrode, but its strength also makes it difficult to cut unless the right technique is used. The use of the proper cutting techniques is the key to reducing material waste, cutting production costs, and getting a clean and polished finish.

Based on the statistics of the industry, the use of improper methods can cause discoloration due to heat, burrs, and even damage to the blade. For example, laser cutting, which is a well-known method, can create smooth edges, but may need careful tuning to avoid burning and distortion. Moreover, the mechanical methods like sawing or shearing are best for heavy sheets but require very good care in tool selection and maintenance to avoid warping of the material or wearing out of the tool.

Stainless Steel Sheet Applications Overview

Architecture and Construction

Stainless steel sheets have been widely used in buildings and constructions as an aesthetically pleasing and strong material. Their resistance to corrosion makes them suitable for building exteriors, roofs, and ornamental features. A study shows that the worldwide stainless steel industry was worth $111.8 billion in 2022, with the building industry being the major consumer.

Transport and Automotive

Cutting stainless steel sheets are critical in the production of car exhaust systems, body frames, and decorative trims. Their property of enduring high temperatures and resisting wear guarantees the effectiveness and durability of vehicles. Additionally, auto manufacturers take advantage of the material’s recyclability to achieve environmental goals.

Medical Devices

High hygienic standards make stainless steel sheets vital in the medical sector. The production of surgical tools, hospital beds, and dentist’s instruments is done with them because of their non-porous nature and easy sterilization. The medical device market is increasingly promoting the development of stainless steel devices owing to the progress in healthcare.

Methods for Cutting Stainless Steel

Laser Cutting: Precision and Efficiency

Laser cutting has become one of the most sophisticated and effective methods for processing stainless steel plates. The use of concentrated laser beams provides a very high level of accuracy and a very short time of processing, which in turn makes it an important option for manufacturing sectors that need detailed designs or very close tolerances. The latest figures show that laser cutting can reach a cutting tolerance of ±0.002 inches, thus allowing the production of components that are precise to the limit of their dimensions.

One of the main benefits of laser cutting is its versatility in the context of different thicknesses of stainless steel. For example, the current laser cutting installations can cut metals ranging in thickness from 0.5 mm to 30 mm depending on the output power of the laser. The thick material is handled by high-power CO2 or fiber lasers that are capable of delivering outputs of over 12 kW, and the precision of the cuts is maintained while the roughness at the edges is reduced.

Plasma Cutting: Versatility and Speed

Cutting with plasma is one of the most versatile and fast methods that are basically used for the cutting of electrically conductive materials such as steel, aluminum, brass, and copper. The process is cutting by means of a jet of plasma, which as a consequence is very hot and very fast, melting and ejecting the metallic material, thus making the cuts by using very fast and clean technology. Also, the cutting of the above-mentioned materials is as fast as 1/16 inch for the thinnest ones and 2 inches for the thickest ones among standard thicknesses.

One benefit that cutting with plasma is very much recognized for is its incredible cutting speed. Based on the latest industry statistics, a plasma cutter is able to complete a 1.5-fold higher processing rate of the material than the so-called traditional methods, specifically oxy-fuel cutting which is the slowest of all, depending on how thick the material is. A case in point is that a plasma cutter of 200 amps can slice through half-inch steel at around 60-75 inches per minute. Such rapidity makes it become the preferred option for industries requiring fast manufacturing processes like construction, production, and maintenance.

Advantages and Disadvantages of Each Method

Pros and Cons of Laser Cutting

✓ Pros of Laser Cutting

High Precision and Accuracy

Laser cutting is the method which is known to be extremely precise, allowing for tolerances as small as ±0.001 inches. This property makes it very appropriate for intricate designs and the complex cutting of shapes, thus guaranteeing that less material is used.

Efficiency and Speed

Modern laser cutting machines, powered by sophisticated technology, are able to work on different materials at very high speeds. For instance, some of the high-powered machines can cut through steel of 0.12 inches thickness at the rate of 400-600 inches per minute (IPM), which is a great speed that considerably lessens the time taken for production.

Versatility

The laser beam can be used to cut various substances such as metals (steel, aluminum, and titanium), plastics, wood, and even composite materials. Furthermore, it can accurately cut through different thicknesses of materials without major changes in machine settings.

✗ Cons of Laser Cutting

High Initial Investment

The initial cost of acquiring and installing a laser cutting system can be very high. An industrial-grade laser cutter usually costs between $50,000 and $500,000, based on its power and features. This could be a problem for small companies or new ventures.

Material Limitations

Laser cutting, while very flexible, nevertheless cannot be used for reflective materials like copper and brass as these materials will scatter the laser beam thereby lowering efficiency.

Energy Consumption

Laser cutters especially the high-powered ones can consume a lot of energy. For instance, a 3,000-watt laser cutter may use up to 18 kWh of power per hour based on the usage which will consequently make its operational cost higher than that of some other cutting methods.

Pros and Cons of Plasma Cutting

✓ Pros

High Speed and Efficiency

The plasma cutting method is much quicker than the traditional ones and, particularly, the cutting of thin and medium-thick metals will benefit the most from this new technology. For example, a state-of-the-art plasma cutter can cut 1/2-inch thick steel at a maximum rate of 20 inches per minute.

Versatility

Metallic and non-metallic materials of various thicknesses and types can be plasma cut. That is, the process is steel, stainless steel, aluminum, brass, and copper, thereby making it applicable to manufacturing, automotive, and other industries.

Precision and Clean Cuts

The use of modern CNC plasma cutters makes it easy to get very precise cuts, which lead to very clean edges and very little waste of material. The width of the kerf is small, so the need for post-processing is also small.

✗ Cons

Limited Cutting Thickness

In general, plasma cutters are most able to cut through thin or moderately thick metals. For example, they are very good at cutting through 2-inch-thick materials, yet the cutting of thicker materials may require other techniques like oxy-fuel or waterjet cutting.

Heat-Affected Zone (HAZ)

The plasma arc’s remarkable heat can result in a heat-affected zone that might change the characteristics of the metal next to the cut, making it weaker in some applications.

Consumable Costs

Regular replacement of consumables such as electrodes and nozzles is necessary for plasma cutting systems to operate. The constant use of the equipment may eventually lead to higher operating costs as well.

Selecting the Right Tools for Cutting Stainless Steel

Factors to Consider When Choosing Tools

Material Thickness

The thickness of the material have a great impact on stainless steel cutting tools selection. Very thin materials (less than 0.25 inches) are best cut with fiber lasers that can work fast, up to 140 inches per minute. For cutting metals with thickness of 12 inches or more, the preferred method is waterjet cutting which can overcut with no heat distortion.

Type of Finish Required

Different methods produce different types of finishes on stainless steel. Among the cutting methods, laser cutting is the one that gives the smoothest and cleanest edges and it does not need much post-processing. Waterjet cutting also gives very precise cuts but it may leave a matte edge and this could be an advantage for making a non-aesthetic application.

Production Volume

In case of a high-production environment, fiber lasers are the best option as they provide the speed and automation needed to meet large-scale production requirements. On the other hand, for custom or low-volume projects, the plasma or waterjet cutting are the ones that allow more flexibility with less investment in machinery.

Expert Tips for Optimal Cutting

💡 Material Selection and Preparation

Before the beginning of the cutting process, make sure that the material is clean, free of any residues, and properly fixed. Waterjet cutting is perfect for working with delicate materials such as composites or laminated sheets because of its non-invasive yet exact movement. On the other hand, fiber laser cutting with its capability of high energy absorption becomes the best technique for cutting stainless steel and aluminum metals fast and effectively.

⚡ Optimize Cutting Speed

Speed of cutting has a direct effect on precision and quality of the edge. High-density power in fiber lasers allows them to cut up to 60 meters per minute for thin metals. Nevertheless, for thicker materials, slower waterjet cutting with the right settings will produce clean and uniform edges. Adapting the speed to the thickness and type of material not only prevents loss of material but also yields the best results.

🎯 Choose the Right Nozzle and Settings

The quality of the cut is highly influenced by the size of the nozzle and the positioning of the focus in fiber laser cutting. An off-position focal point will diminish accuracy and increase the width of the kerf. Waterjet cutting, on the other hand, dictates that the orifice and mixing tube be in prime working order; if they are worn out, pressure and abrasive flow consistency may be affected which will result in a decrease in accuracy.

Reference Sources

-

TBK Metal

Article: 6 Reasons to Buy Custom-Cut Stainless Steel Sheet

This source discusses the benefits of custom-cut stainless steel sheets, highlighting their suitability for industrial and design purposes. -

Fortune Business Insights

Report: Stainless Steel Sheet Market Size & Growth Analysis [2030]

This market analysis provides insights into the growth and demand for stainless steel sheets, emphasizing their widespread industrial applications. -

Steelway Laser Cutting

Guide: Best Practices for Cutting Stainless Steel

This guide explains the best methods for cutting stainless steel, such as CNC laser cutting, and discusses its precision and efficiency.

Frequently Asked Questions (FAQs)

❓ Cutting stainless steel of what thickness is the easiest?

Actually, the general rule is that the cutting of stainless steel gets easier with the decreasing thickness of the gauge, 16 gauge and 18 gauge being the lowest. Jigsaws or handheld metal shears can easily handle the cutting of a 16-gauge stainless steel sheet; however, even stronger tools like saws and band saws will be necessary for cutting effectively the thickest stainless steel.

❓ How to cut a stainless steel sheet in a straight line?

To accomplish a straight cut of the stainless steel sheet, the first step is to fix the sheet with a clamp and then put a straight edge as a guide. Accuracy can be ensured by marking the cutting line with a scribing tool. A jigsaw or a circular saw can be utilized in conjunction with the guide for making a straight and clean cut.

❓ Is cutting stainless steel with a saw the only option?

No, cutting stainless steel with a saw is not the only option as metal shears or a handheld grinder can also suffice as alternatives. Nonetheless, the cut made by these methods might not be as precise as that of a saw. If you need to make multiple cuts in small pieces or if the shape is intricate, using a jig could be beneficial for guiding the cuts produced by these tools.