Stainless steel is well-known for being sleek, relatively unbreakable, and resistant to rust, making it ideal for everything from appliances to industrial equipment. Stainless steel has a reputation for being a strong material, but questions about it still arise. Can it tarnish? Can it lose its shine? This article covers all the basics while uncovering the facts. We’ll look at the stainless steel’s durability and the conditions under which tarnishing can occur. By the end, you’ll have understood the properties of stainless steel and its maintenance tips sufficient to help retain its beauty and functionality.

What Causes Tarnish on Stainless Steel?

When the protective layer of chromium oxide is vulnerable to external conditions, it leads to tarnish. This can be due to exposure to harsh chemicals, prolonged contact with saltwater, and high humidity. Moreover, scratches and/or surface damage can cripple corrosion resistance, allowing for oxidation. Neglecting basic maintenance, such as washing off dirt, grime, or grease, contributes to tarnishing, along with a lack of attention. Maintaining the stainless steel’s luster is possible with proper care and regular cleaning.

Understanding the Chromium Content in Stainless Steel

Chromium gives stainless steel its vital corrosion-resistant qualities, explaining why it is found in that alloy. Stainless steel requires, at a minimum, 10.5 percent Chromium, which binds itself to oxygen in the environment and creates a stable surface layer of chromium oxide. This form of oxide is protective in nature and limits rust formation even if the surface is damaged. To maintain the surface protective layer, substances like harsh chemicals and abrasives must be avoided. Regular cleansing helps the chromium retain its protective qualities.

How Does Stainless Steel React with the Environment?

Stainless steel withstands most damage due to environmental factors owing to the chromium found in the alloy, which makes up 10.5 percent to 30 percent of its volume. A surface layer of chrome oxide is formed, which prevents both oxidation and corrosion. This layer of chrome oxide, which is passive, is capable of self-repairing even when it is scratched. However, in places where chloride levels are higher, like in Marine environments, pitting corrosion becomes a threat, especially in lower grades of molybdenum, 304 stainless steel, for instance. By using more alloyed steels like 316 stainless, which contain 2 -3 percent molybdenum, resistance to such corrosion increases.

Stainless steel’s ability to withstand severe heat is a remarkable feature. Austenitic grades can tolerate temperatures up to 1,400°F (760°C) without considerable damage, and their resistance to cryogenic temperatures makes them ideal for use in extremely cold environments. Its strength, in concert with its recyclability, makes stainless steel an eco-sensitive material option in numerous sectors.

Is Corrosion a Form of Tarnish?

Corrosion and tarnishing are both important forms of deterioration that are related but differ slightly from each other. Tarnishing occurs from the combination of certain environmental factors, such as oxygen, sulfur, or moisture, which results in a thin layer of discoloration on the surface. It does cosmetically affect nonferrous metals such as silver and copper, but usually does not disintegrate the structural strength of the material itself.

The term corrosion pertains to the destruction of a material, usually a metal, that is a result of an electrochemical reaction with some constituents of the environment, such as water, oxygen, or even acids. This would usually be much more than a superficial reaction and more likely to lead to some significant destruction to the structure in question. Iron rusting is a prime example of this, where the iron goes through the reaction of oxygen and water, yielding iron oxides or rust.

Some notable pointers that would fit into the collision versus tarnish comparison are:

- Exposure to Oxygen: Both will go through oxygen, however more often than not for corrosion a form of electrolyte for example water would need to be present.

- Type of Material: While tarnish affects alloy materials primarily non ferrous, corrosion can damage both ferrous and non ferrous metals.

- Surrounding Elements: Corrosion takes place more vigorously when it is humid or acidic, whereas tarnishing is driven by mere exposure to air and sulfur compounds.

- Rate of Reaction: Generally, tarnish develops over time at a slower rate, whereas, in extreme environments, corrosion may happen more quickly.

Grasping this information is important for metalworking industries to make good decisions concerning the methods used for metal treatment as well as its preservation.

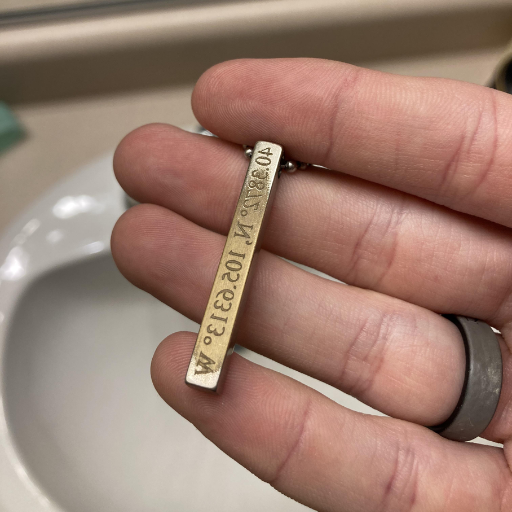

Can Stainless Steel Jewelry Tarnish?

The composition of stainless steel jewelry contains chromium, which explains why it is highly resistant to tarnish. Due to the presence of chromium, stainless steel develops a protective oxide layer on its surface, which prevents it from reacting with air and sulfur compounds that usually tarnish the jewelry. Although stainless steel is not immune to discoloration under extreme conditions, due to its low maintenance needs, it is an excellent choice for everyday wear.

Impact of Contact with Water and Chlorine

Stainless steel is known to be highly resistant to tarnish and corrosion, but prolonged exposure to water and chlorine might have some impact. From my experience, water alone does not create many issues, but chlorine, particularly in swimming pools, gradually weakens the protective oxide layer over time. To maintain the splendid appearance of stainless steel, it is ideal to rinse and dry the jewelry after contact with chlorinated water. This helps achieve optimum durability, shine, and luster.

How Nickel and Molybdenum Affect Stainless Steel Jewelry

Nickel and molybdenum have a significant effect on the performance and durability of stainless steel jewelry. My understanding is that nickel is implicated in the manufacturing process, which contributes to smooth and shiny finishes as well as enhanced corrosion resistance. It is known that some people can be allergic to nickel. Molybdenum, on the other hand, increases the strength and resistance of stainless steel against pitting and cracking, which is useful in more demanding environments. If properly balanced, these elements guarantee that stainless steel jewelry is appealing and remains durable over time.

Why Stainless Steel Jewelry is Considered Low Maintenance

Stainless steel jewelry is classified under low-maintenance wear because it is scratch, tarnish, and corrosion resistant. This makes it perfect for daily wear. Unlike other softer metals, it doesn’t need constant cleaning or special attention. A soft cloth wipe is more than enough to keep it shining. Sweating or exposure to water doesn’t diminish its luster. Such resilience, coupled with ease of care, makes it an attractive, practical, and enduring addition to any jewelry collection.

How to Clean Your Stainless Steel and Prevent Tarnish?

Like gold, stainless steel does not require excessive maintenance, however, frequent sanitizing will prevent hand and wrist infections that may arise from dirt buildup. The process of cleaning stainless steel jewelry begins by soaking the necklace in warm water mixed with a mild detergent. Mords and crevices can be scrubbed with a brush. Finally, rinse the necklace under warm water and dry with a soft cloth. Jewelry should be placed in an air-sealed box to prevent tarnishing. Remember, stainless steel jewelry should not be soaked in any cleaning materials.

Effective Use of Stainless Steel Cleaners and Polishing Techniques

When cleaning the surface of stainless steel, always select products labeled for stainless steel, as using any other product may result in damage to the surface. Using a soft and non-scratching cloth or sponge that follows the direction of the grain work for applying cleaning products yields the best results. For tougher stains, a paste-like mixture of baking soda and water can serve as a non-reactive scrub. After scrubbing, rinse thoroughly with clean water and dry the surface immediately with a cloth that does not leave lint to avoid water spots.

Polishing can be done with purpose-made stainless steel polish or a mixture of olive oil combined with vinegar and restores shine. Buffing requires moderate pressure aided by placing a bit of the mixture on a microfiber cloth to make the surface shine. For efficient polishing, refrain from using steel wool or other scratching resources as they make the surface rough. Use moderate force, but only after sufficient checks confirm it is indeed absent from the section where the polish will be applied.

Preventive Measures: Avoiding Scratches and Abrasive Materials

To keep scratches at bay and preserve the shine of stainless steel surfaces, polish using soft microfibers cloth or sponges rather than steel wool and scouring pads. All other tools with hard, coarse materials that may etch or damage the stainless steel surface must also be avoided. Furthermore, care should be taken while selecting cleaning agents; neutral pH solutions, mild detergents, and specialty cleaners meant for stainless steel are great options. Avoid harsh chemicals, as they contain chlorides that may cause pitting and corrosion over time.

When it comes to cleaning, follow the steel’s natural grain to prevent fine scratches and achieve a polished look. Residue from cleaning materials tends to encourage staining, while hard water left on the steel can lead to dullness. To enhance clarity, completely rinse the vessel with water, then wipe the surface clean with a soft, dry cloth.

For technical specifications, the following restrictions should be imposed:

- To prevent damage to the surface, cleaning tools should have material hardness lower than 200 HV (Vickers Hardness).

- Cleaning aids should have less than 250 parts per million (ppm) chloride content in order to reduce risk of corrosion.

- To avoid the formation of mineral deposits, water used for rinsing should preferably have a hardness level lower than 80 mg/L (ppm) as calcium carbonate.

Stainless steel can maintain its durability, shine, and resistance to scratches for a long period of time with regular cleaning and proper care.

Using Soap and Water vs. Baking Soda for Cleaning

Cleaning stainless steel is something that can be achieved using soap, water, or even baking soda—both have their pros and cons. For regular maintenance, a mixture of soap and warm water works best because it’s effective, easy to apply, and doesn’t scratch the surface of the steel. On the other hand, stains and grease buildup are easily removed using baking soda. It can be applied with a soft cloth or sponge, otherwise known as the gentle touch. I turn to soap for maintenance and baking soda for spot cleaning. Both methods ensure that the surface is clean while preserving the surface of the stainless steel.

Is Stainless Steel Jewelry Safe for All Environments?

Most people can wear stainless steel jewelry without any worries due to its corrosion resistance and durability. This metal can be exposed to sweat, water, and even humidity for long durations and will not rust or tarnish, making it great for daily wear. However, wearing this jewelry in chlorinated water or around strong cleaning agents can be damaging. To keep the durability of this jewelry, you need to clean and store it properly when it is not being worn.

Effects of Wearing Jewelry in the Ocean

Depending on the ocean water temperature, wearing jewelry can have varying impacts based on its material composition. For example, its salinity can be aggressive towards sterling silver, corroding or tarnishing it quickly; saltwater is known to be highly corrosive, while lower quality metals tend to tarnish easily. In contrast, gold, especially above 18K, does not corrode as easily, although dulling of the surface over time due to exposure to salt and sand is still possible. Better options for saltwater wear are stainless steel and titanium due to the protective oxide layers they possess.

Things To Keep An Eye On:

- Chloride in Seawater: Approximately 19,400 ppm; can lead to accelerated damage on certain metals.

- pH Values: Usually range from 7.8 to 8.4; extended contact with some metals might influence oxidation.

- Water Movement: The movement of water and sand can cause abrasions, resulting in scratches on softer metals such as silver and gold.

- Salinity in Seawater: Roughly 35 parts per thousand; tends to prolong damage to metals.

To avoid the worst outcome, carefully removing jewelry before going for a swim and rinsing it with regular water after exposure can reduce damage.

Comparing Stainless Steel to Sterling Silver Jewelry

While both sterling silver and stainless steel are well-liked for jewelry, they vary in composition, tarnishing, care, and maintenance. Stainless steel is an alloy of iron, chromium (minimum of 10.5%), and sometimes nickel oxide or molybdenum, giving the metal remarkable corrosion and tarnishing resistance. Furthermore, it is highly durable and scratch-resistant, requiring little upkeep. On the other hand, sterling silver consists of 92.5% silver alongside 7.5% other metals, usually copper, which enhances its strength and durability. Unfortunately, sterling silver can easily tarnish from oxidation when exposed to air or moisture.

Jewelry Durability

- Stainless Steel: Highly resistant to scratches and any other form of environmental damage, making it ideal for daily use jewelry.

- Sterling Silver: Softer and more delicate than stainless steel, increasingly prone to scratches and deformation with frequent use.

Jewelry Corrosion Resistance

- Stainless Steel: With its chromium content, it is resistant to rust or any other form of oxidation as it forms a protective oxide layer. Can withstand humid places, as well as water exposure.

- Sterling Silver: With time, silver is prone to compromising its state due to sulphur compounds found in air or water, turning into a blackened color.

Weight & Aesthetic Appeal

- Stainless Steel: Typically heavier, stainless steel is modern and industrial in appearance and comes in polished or brushed finishes.

- Sterling Silver: Sterling Silver is lighter in weight and offers a shine that is classic and elegant, though it needs a bit more care to keep it that way.

Hypoallergenic Properties

- Stainless Steel: Contains nickel, which can cause allergic reactions to some people. Check ‘surgical grade’ stainless steel if you want a hypoallergenic option.

- Sterling Silver: Hypoallergenic for most people, but some may be irritated by alloys that have a higher content of copper.

Price Comparison

- Stainless Steel: Stainless Steel is the least expensive as it is readily available and cheaper to produce.

- Sterling Silver: Sterling silver is more costly because it contains more silver, which is a precious metal.

Think of your budget, intended use, and aesthetic preference while choosing between the two. For low-maintenance and durable jewelry, go with stainless steel. For those looking for something elegant and timeless, sterling silver is perfect.

What Makes Stainless Steel a Popular Material?

A low-cost material because of its relative strength, stain-resistant steel has gained widespread applications in everyday life. This is because it is easily maintained, doesn’t rust or corrode, and retains its shape even after years of use. Furthermore, its resistance to deformation makes it easily moldable into jaw-dropping designs—from intricate jewelry to sturdy industrial tools.

The Role of Protective Layer in Rust Resistance

The protective layer provides significant aid in rust resistance, preventing moisture from coming in contact with the underlying steel, which stops rust. Rust is steel’s primary problem. The layer made up of chromium oxide forms naturally when stainless steel comes into contact with air. What I find amazing is that the layer can self-repair when damaged. This makes it low-maintenance and protects it from corrosion.

Exploring Different Grades of Stainless Steel

Stainless steel has many grades, all classified according to their performance parameters and needs. These are usually divided into four main types:

- Austenitic Stainless Steel

Exhibiting excellent corrosion resistance and high ductility, this type is often found in kitchen utensils, construction, and in the medical industry.

- Typical Grades: 304, 316

- Key Properties: Non-magnetic, with high chromium (18-20%) and nickel (8-10%) contents, great weldability.

- Applications: Food marine environments, parts processing (316 because of its Chloride resistance).

- Ferritic Stainless Steel

Good self-contained corrosion, superior thermal conductivity are the hallmarks of ferritic stainless steel and thus it’s used for automotive and industrial machinery components.

- Typical Grades: 430, 409

- Key Properties: Low nickel content, non-magnetic, moderate with lower chromium (12-17%) corrosion resistance, low cost.

- Applications: Sinks, home appliances.

- Martensitic Stainless Steel

Known for withstand gave high strength and wear resistance. Thus, sustaining to factors of mechanical capabilities is helpful.

- Typical Grades: 410, 420

- Key Properties: Moderate corrosion resistance, magnetic, and high carbon content enhance hardness.

- Applications: Valves, surgical equipment.

- Duplex Stainless Steel

Duplex grades have remarkable strength along with best resistance to corrosion because of their combination with austenitic and ferritic steels.

- Typical Grades: 2205, 2507

- Key Properties: Among Duplex Stainless Steel grades, they are defined as having a high strength-to-weight ratio, resistance against disintegration due to stress, balanced chromium and nickel content (22-25% and 4-7% respectively).

- Chemical plants, oil and gas pipelines, seawater desalination systems.

Choose a grade based on the degree of corrosion resistance and mechanical properties. The grade should meet the economical and environmental requirements for the application.

Benefits of Resistance to Tarnish and Corrosion

The self-repairing corrosion shield offers enhanced economic value, making it ideal for use in demanding environments. Failing equipment in chemical processing can lead to undue downtime, making more reliable corrosion-resistant devices a necessity. Coupled with low susceptibility to corrosion while housing external elements like marine water, a tarnish-proof outer layer greatly increases appeal while making it a great defensive component.

References

- The Pros and Cons of Stainless Steel Jewelry – Discusses the durability and tarnish resistance of stainless steel jewelry.

- Does Stainless Steel Jewelry Tarnish? Ways to Prevent It – Explains the conditions under which stainless steel might tarnish and how to prevent it.

- Does Stainless Steel Tarnish? – Revealing Key Facts – Provides insights into the protective chromium oxide layer that prevents tarnishing.

Frequently Asked Questions (FAQ)

Q: Does stainless steel tarnish over time?

A: Stainless steel does not tarnish easily because it is known for its resistance to rust and corrosion. It contains at least 10.5% chromium, which reacts with oxygen to form a protective layer of chromium oxide, preventing tarnishing.

Q: Why is stainless steel a popular material for jewelry?

A: Stainless steel is a popular material for jewelry because it is resistant to corrosion, durable, and hypoallergenic. It is also less expensive than precious metals like silver and gold, making it an attractive option for many.

Q: How should I care for stainless steel to prevent tarnishing?

A: To maintain its appearance and prevent tarnishing, clean stainless steel with warm water and a soft cloth. For deeper cleaning, use a gentle polishing cloth. Avoid exposing the metal to harsh chemicals and chlorinated water.

Q: Is it true that stainless steel jewelry is safe to wear?

A: Yes, stainless steel jewelry is safe to wear because it is hypoallergenic and does not corrode or stain easily. It is an excellent choice for those with sensitive skin.

Q: Can stainless steel discolor or stain?

A: While stainless steel is resistant to discoloration and staining, improper care, exposure to harsh environments, or certain chemicals can cause tarnished stainless steel. However, with proper care, it can last a long time without issues.

Q: What are the different types of stainless steel used in jewelry?

A: There are several types of stainless steel, including 304 and 316L. 316L is often used in jewelry as it is more resistant to corrosion and hypoallergenic, making it ideal for daily wear.

Q: How does chromium in stainless steel prevent tarnishing?

A: Chromium in stainless steel reacts with oxygen to form a thin, protective layer of chromium oxide. This layer helps resist rust and corrosion, ensuring the metal remains shiny and untarnished.

Q: Can stainless steel corrode under certain conditions?

A: Although stainless steel is resistant to corrosion, it can corrode if exposed to harsh chemicals or environments for extended periods. However, with proper care and maintenance, it can remain in excellent condition.

Q: What should I do if my stainless steel jewelry becomes tarnished?

A: If your stainless steel jewelry becomes tarnished, clean it with warm water and a soft cloth. For more stubborn stains, use a polishing cloth designed for stainless steel. Avoid abrasive cleaners that could damage the metal.