The 13-8 PH Stainless Steel is a top-tier heat-treated alloy that has good corrosion resistance and serves as a versatile steel in high-risk industries. The alloy finds applications from aircraft controls to the assembly of board components for medical devices due to its corrosion-free and wear-resistant properties. What appear to be the special features of 13-8 PH stainless steel that make people use this material frequently? The following text will explore in great detail what 13-8 ph stainless steel specifications are in place. The properties that enable it to be used uniquely for many purposes whether you are a technical professional, an engineer, or merely a layperson who is fascinated with the products that make the world tick, such a treatise can be of great help as it explains in lengthy detail why grade 13 8ph stainless steels have such a large part to play in the manufacture of products today.

Specifications of 13-8 PH Stainless Steel

Alloy 13-8 PH is a precipitation-hardening stainless steel known for its high strength, exceptional toughness, and excellent corrosion resistance. The alloy has the following essential characteristics:

- Chemical Composition: The alloy in discussion contains mainly iron, with chromium in the range of 12.25–13.25%, nickel at approximately 7.5–8.5%, and small amounts of aluminum, molybdenum, and titanium.

- Mechanical Properties: It offers high tensile strengths of up to 205 ksi, along with higher levels of hardness, making it suitable for these types of applications.

- Corrosion Resistance: Unlike standard hardenable alloys, this requires high levels of corrosion resistance even in harsh application environments.

- Heat Treatment: This material is strengthened and hardened through a simple heat treatment process, allowing for versatile application in manufacturing components for various purposes.

- Operating Temperatures: The Grad13 8PH alloy describes a range of applications in which a material retains its functional properties, ranging from cryogenic to approximately 600°F (316°C).

It is therefore recommended in numerous applications, including aerospace, medical, and high-performance industries, for these properties.

Chemical Composition of 13-8 PH

Grade 13-8Ph is characterized as a grade of steel that falls under the category of stainless steel with precipitation-hardenable properties. This steel is of very high grade due to the balance among strength, toughness, and corrosion resistance achieved through a constrained composition that enhances these properties. Its proposed chemistry is given below, along with the approximate percentage schedule.

| Element | Percentage Range | Function |

|---|---|---|

| Fe (Iron) | Balance | This component applies as a principal one in the composition |

| Cr (Chromium) | 12.25 – 13.25% | This element has high corrosion resistance and also contributes to higher strength |

| Ni (Nickel) | 7.50 – 8.50% | This element increases tenacity as well as resistance to corrosion |

| Mo (Molybdenum) | 2.00 – 2.50% | It combats corrosion caused by pitting and crevices which in turn increases strength |

| Al (Aluminum) | 0.90 – 1.35% | It is fundamental in a precipitation-hardening mechanism |

| Ti (Titanium) | ≤ 0.10% | It serves to reduce the grain size and improve the strength |

| Mn (Manganese) | ≤ 0.10% | Is responsible for maintaining the structure in place |

| Si (Silicon) | ≤ 0.10% | It improves resistance to oxidation |

| C (Carbon) | ≤ 0.05% | Prevents precipitation of carbides and loss of corrosion resistance |

| P (Phosphorus) | ≤ 0.01% | Within limits to ensure proper structure |

| S (Sulfur) | ≤ 0.008% | Maintained at very low values to prevent inclusions formation |

The iron alloys resulting from these components exhibit efficient mechanical properties, excellent corrosion resistance, and durable performance under varying conditions. These special properties enable the use of steel grade 13-8PH, which is required in various areas of activity involving tension, notably aerospace production, surgical devices, and other high-strength industries, thanks to its stable structures.

Mechanical Properties of 13-8 PH Stainless Steel

Withstanding the mechanical performance requirements, 13-8 PH stainless steel is a suitable material. A more detailed description of the five key mechanical properties is given below.

| Property | Value Range | Description |

|---|---|---|

| Tensile Strength | 170-210 ksi (1172-1448 MPa) | The ultimate value depends on heat treatment conditions |

| Yield Strength | 140-200 ksi (965-1379 MPa) | Withstanding the stress that materials conventionally have excellent elasticity |

| Hardness | 38-47 HRC | Minimum hardness required to sustain high service loads |

| Elongation at Failure | 10-14% | Adequate ductility even for large loads |

| Fracture Toughness (KIC) | ~50 ksi√in (55 MPa√m) | For the H950 condition, it trades off strength and crack propagation |

All these properties present in 13-8 PH stainless steel enable it to be used effectively in high-pressure situations, thus ensuring physical integrity and the ability to withstand failure without any doubt.

Heat Treatment Processes for 13-8 PH

In the treatment sequence of 13 (grad13) 8PH stainless steel, heat treatment is very significant as it helps to get the desirable mechanical properties in this steel.

Solution Annealing

- Temperature: Normally carried out in the range of 1,900°F (1,038°C)

- Process: After attaining the solution annealing temperature, the alloy is held at this temperature to dissolve precipitates into solid solutions and to form a uniform structure. Afterwards, the part goes into cooling, either by natural air or by shortage of time, with some rapid technique. The purpose of this is to prepare the material for aging treatment.

Air Hardening

- Temperature: Maintained Within (1,875°F ) 1,025°C- 1,050°C (1,925°F) range

- Process: After reaching the desired temperature range, the alloy is air-cooled. This is done because warping and distortion are also minimized, and allows one to attain a stable microstructure when needed for carrying out further aging.

H950 Aging Treatment

- Temperature: Heat at 510°C (950°F) for 4 hours, after which cooling is conducted by air.

- Purpose: With this aging process, there is an enhancement of strength without a high compromise on ductility that facilitates the attainment of the H950 condition properties, which are relatively balanced.

Double Aging Process

- Temperature Ranges: The alloy undergoes a double aging process at different temperatures (for example, 1,150°F and then 950°F).

- Purpose: Such treatment is preferable for those constructions that are highly stressed, nevertheless. I would explain that in such instances, it gives more dimensional stability and also better mechanical characteristics.

Cryogenic Treatment (Optional)

- Temperature: Cooling down to extremely low temperatures, such as -100°F to -300°F (-73°C to -184°C).

- Purpose: These enhance wear resistance and stress-relieving effects in such applications when dimensions and microstructures are of utmost importance.

The flexibility of these procedures offers a range of functionalities geared towards meeting specific requirements for necessary mechanical properties, such as strength, ductility, and the ability to withstand erosion. The heat treatment processes can be speculated and designed suitably as per the requirements of the goals, such as meeting the demands of aerospace, automotive industries, and any other high-performance sector.

Applications of 13-8 PH Stainless Steel

Aerospace Components

Stainless steel 13-8 PH is one of the most common materials used in the aerospace sector, primarily due to its high strength-to-weight ratio and excellent resistance to stress corrosion cracking. It is extensively used in the production of structural parts of aircraft, landing gears, and engine components.

Medical Equipment

Due to its excellent corrosion resistance and standard biocompatibility, this alloy is well-suited for use in surgical instruments, dental instruments, and orthopedic implants.

Nuclear and Power Generation

The high tensile strength and resistance to chloride stress corrosion of 13-8 PH steel make it appropriate for power plant applications, including nuclear power reactors, where it can be reliably used in severe operating conditions.

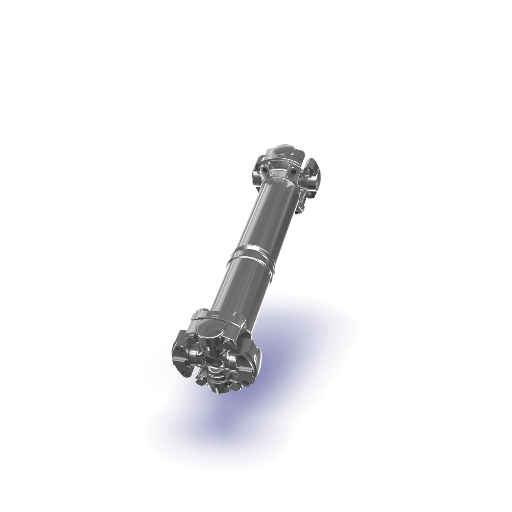

Oil and Gas Industry

Grad13 8ph is a steel that resists chlorites and stress corrosion very well. Therefore, such steel may be applied in oil and gas drilling operations where risers must withstand high axial loads, together with high internal pressure imposed by drilling mud. This material is often used in downhole tools, valves, and drilling components because it can withstand very high stress or corrosive environments, which are usually associated with oil or gas exploration.

Automotive Components Used in High-Stress Applications

In more sporty applications of the automotive industry, grade 13-8PH stainless steel is utilized in manufacturing parts such as drive shafts, gears, and suspension parts, which require high impact strength and fatigue resistance.

Industry Uses of 13-8 PH

Components of the Aerospace Industry

One of the fields that uses the grad13-8PH extensively is aviation, where it is used for the construction of landing gear, complex structures, and fixings. In all aspects of aviation, particularly in harsh environments where failure is not tolerated, 13-8PH overperforms as it has the highest working to weight ratio of any material, as well as good fatigue properties, and is extremely rust-free.

Medical Uses

13-8 PH has many medical applications, including surgical tools, skeletal system implants, and dental instruments, because of its compatibility with the body and slight degradation from wear or chemicals that patients or tools are expected to be subjected to. Therefore, the application materials inside those precision and durable equipment are designed for an environment where they last long, fail easily, and cause no problems.

Energy Sector

High temperature applications include various components of a power unit, such as compressor blades and rotors. Downtime and man-hours are reduced in energy generation plants where equipment is in use, due to this material’s high mechanical strength and long-term stability.

Application in Marine Science

For naval and marine industries, there is little or no application of 17-7 PH, but all of the applications include the use of 13-8 PH, and besides propeller shaft, rudder, submersible pumps housings, which are in a salt environment and are made of 13-8 stainless steel. The fragility of 13-8 PH stainless steel makes it ideal for exposure in a saltwater environment over a much longer duration.

Defense and Military Equipment

Defense and military equipment, for the reasons presented above, can never be considered complete without grade 13-8PH stainless steel, which is used in aerospace applications, including missile navigation parts, gun shells, and armoring. In cases where there is no compromise on safety and performance, the use of this steel and its layers is applicable mainly due to the steel’s impact resistance.

Typical Applications for Round Bar

Aerospace Sector

Round bars are in high demand in the aerospace industry, primarily due to their exceptional strength and superb corrosion resistance. Materials such as titanium and stainless steel alloys, including grade 13-8PH, are also suitable for making critical parts like landing gears, bolts, and shafts for jet engines. Available market data estimates that by 2030, the global market for aerospace-grade metal round bars will be worth $ 16 billion, thanks to advancements in airplane production and a greater emphasis on the use of lightweight materials.

Automobile Industry

The round bars serve several functional purposes in vehicles by producing components such as gear shafts, axles, and suspensions. They are essential in a vehicle’s functionality and in maintaining its durability as they are exact in size and other physical aspects. As electric vehicles (EVs) continue to enter the market, there is a growing preference for materials such as aluminum round bars due to their lighter weight, which helps improve vehicle efficiency and reduce emissions.

Construction Industry

In their function within constructions, round bars are used to reinforce concrete structures or to make various types of frameworks. They can appear in residential projects, commercial projects as well as in infrastructure construction. In terms of construction activities, it can be observed that the global report related to steel rebars, including round bars, revealed more than $200 billion by 2022, while promising to expand at a 4.7% CAGR over 2030 owing to the increasing urbanisation and development of infrastructure in countries.

Oil and Gas Industry

Round bars, specifically stainless steel or superalloy round bars, are essential components in the oil and gas industry, used in applications such as drilling rig parts, pipelines, and valves. Due to their high pressure and corrosion-resistant nature, these products are ideal for many oil and gas applications. With a rising demand for energy globally, the forecast for stainless steel round bars within the oil and gas application rises.

Medical Instruments

Precision round bars also find use in hospitals, where they are utilized to manufacture surgical tools, orthopedic implants, and medical instruments. Titanium and stainless steel round bars are widely used because they provide excellent biocompatibility and do not corrode easily, making them very durable. The trend towards enhanced healthcare facilities is boosting the need for medical-grade round bars as many investments are made in the health sector.

Round bars are universal, as they can be used in multiple industries. Therefore, they have facilitated most technological, infrastructural, and innovative developments on a global scale. Recently, many stainless steel products are now manufactured using metals with grades such as 13-8PH, as it contains these elements. Round steel of this type exhibits significant resistance to distortion, corrosion, and heat, in addition to being fatigue-resistant. This ultimately further implies that companies specializing in production and manufacturing have gone one step further – ensuring that all the round bars used are strong, durable and tough enough to stand the test of time – in retrospect, since time immemorial there have always been round bars made out of different materials, and other processes formulated for ensuring their strength and durability.

Advantages of Using 13-8 PH Stainless Steel

| Key Advantage | Description |

|---|---|

| High Strength | Exceptional tensile and yield strength |

| Corrosion Resistance | Resists rust and chemical exposure |

| Heat Treatability | Properties are adjustable via heat treatment |

| Excellent Toughness | Maintains toughness under heavy loads |

| Fatigue Resistance | Withstands repeated stress cycles |

| Dimensional Stability | Minimal expansion under temperature changes |

| Moderate Magnetism | Slightly magnetic after hardening |

| Weldability | Suitable for inert gas welding processes |

| Versatile Applications | Used in aerospace, marine, and medical fields |

Material and Grade Insights

Grade 13-8PH stainless steel has a martensitic structure and belongs to the premium category of stainless steel due to its excellent mechanical properties, including strength, toughness, and resistance to corrosive agents. Due to its ability to withstand even the most challenging conditions, it is preferred in both the aerospace industry and the medical field. The material’s precipitation hardening feature provides a balance of strength and toughness, and therefore is used in precision components and other applications that require such characteristics.

Overview of Grade 13-8

When discussing 13-8PH stainless steel, this material is a precipitating martensitic stainless steel in UNS S13800. However, this precipitation hardening alloy differs from regular martensitic stainless steel in that it is strengthened after being placed in use, rather than before, and is also rugged and highly corrosion-resistant.

This alloy was initially designed for use in the aviation industry but is now also sought after by other sectors, as it can withstand more mechanically challenging conditions.

Important Characteristics:

- Toughness and High Tensile: The grade 13-8 steel can achieve a strength of above 200 ksi (N/sq. inch × 10^3) at 750°F, while also resisting cracking.

- Corrosion Resistance: More than the standard stain, especially steel, it is good in the presence of water or sufficiently mild chemicals.

- Precipitation Hardening: Metals such as this alloy can be subjected to heat treatment to achieve specified conditions, including H950, H1025, and H1075. The purpose of these treatments, which further heat the metallic component, is to enable it to perform specific functions based on its industry. This performance includes enhancing one or more of the atmospheric conditions, increasing resistance to certain chemicals, and so on.

Some of the typical uses include:

- Aviation: Components such as aircraft parts, landing gears, and assemblies rely on this type due to its extreme mechanical strength.

- Health Care: This technology is especially trusted in the hands of surgeons and other critical instruments.

- Nuc and Chem Industries: Due to corrosion threats, safety components and some critical parts are made of this material, which provides safety effectiveness.

Heat Processing:

- The 13-8PH alloy is heat-treated to strengthen it for its particular usage.

- H950 condition is the highest known strength condition, and it is also moderately challenging.

- H1025 is used in many structural applications. It provides a good strength-to-corrosion-resistance ratio.

- H1075 and H1150 are the conditions that provide excellent ductility and toughness.

The unique characteristics of Grad13 8PH stainless steel, through its fantastic combination of properties, explain why it has remained at the forefront among component materials for harsh environmental conditions to this day. Its multiple uses and stability boosts make it complementary rather than optional in applications needing reasonable or moderate parameters of this head-splitting aspect.

Understanding UNS S13800

Grad13 8PH, as well as UNS S13800, is a grade of precipitation hardenable martensitic alloy produced for higher strength, good corrosion resistance, and greater toughness. I believe this material is commonly utilized in the areas of defense, chemistry, and medical surgery due to its unique properties, making it an exceptionally good material that performs well in severe conditions. It possesses an optimum set of properties that makes it essential in critical applications where greater strength and agility are needed.

Comparison with Other Stainless Steel Grades

| Property | 13-8 PH Stainless Steel | 17-4 PH Stainless Steel |

|---|---|---|

| Chromium Content | 13% | 17% |

| Nickel Content | 8% | 4% |

| Molybdenum Content | 2% | 0% |

| Copper Content | 0% | 4% |

| Strength | Higher | High |

| Toughness | Higher | Moderate |

| Corrosion Resistance | Good | Very Good |

| Heat Treatability | Yes | Yes |

| Weldability | Good | Moderate |

| Applications | Aerospace, High-Stress | Aerospace, Chemical Processing |

Size and Availability of 13-8 PH Round Bar

Stainless steel types 13-8PH rods and bars are available in various diameters for different applications and industries. The arsenal often ranges from 0.25 inches to 12 inches in diameter, but custom diameters can also be ordered from the producer or vendor. The bars are either standard length or can be cut to meet the project’s requirements. The distributors can be different, but are available consistently with any metal due to the heavy usage, bearing in mind the aerospace and medicinal industries. This is why, for a specific order, it is advisable to call the relevant companies to check the availability and delivery times.

Standard Sizes of 13-8 PH Round Bar

13-8-ph round bars are produced in various standardized sizes, making them suitable for numerous industrial applications. Such standard sizes encompass both small and large diameters, allowing for use in various engineering applications. Some of the popular sizes in stock are as follows:

Diameter Range:

- Small Sizes: 0.25″ (6.35 mm) concurrently up to 1.00″ (25.4 mm)

- Medium Sizes: grad13 8ph 1.25″ (31.75mm) along with 4.0″ (101.6 mm)

- Large Sizes: 4.50″ (114.3 mm) to 6.00″ (152.4 mm) plus

Standard Lengths:

- The most common lengths are 10 feet (3 meters) or 12 feet (3.6 meters); however, other lengths can be arranged upon request.

Surface Finish:

- Both annealed and machined finishes are typically available, making the material suitable for a wide range of applications.

As listed previously, these sizes have already been extensively applied in the aerospace, medical, or chemical industries, citing the presence of high tensile strength, resistivity, and workability. Customers with specific needs may purchase sizes that differ from those defined by manufacturers, and additional operations, such as the centerless grinding method and forging, may be applied.

Further size availability and specifications can be obtained from steel producers themselves, or distributors, where stock for particular items is requested to be checked. A number of other online resources, such as those available on supplier websites or product pages, have more detailed size charts to refer to.

Sources for Purchasing 13-8 PH Stainless Steel

The material named as grad13 8ph is in great demand across numerous industries and therefore, there exist multiple companies all over the world that are engaged in its trade. Below are some of the sources and information that may be of interest.

Atlantic Stainless Co., Inc.

The company – Atlantic Stainless, whose primary thrust is stainless steel materials, offers grade 13 8ph alloys in various available forms (bars, sheets, or plates). They also provide cutting to lower dimensions and same-day deliveries on both small and large orders.

Alloy Metals Company

This provider specializes in aerospace materials and, therefore, is an appropriate source of 13-8 PH stainless steel. Products are available in various thicknesses and sizes, adhering strictly to AMS and other standards.

Online Metals

Online Metals offers 13-8 PH Stainless Steel in small quantities to customers who may wish to conduct prototyping or other less complex tasks. The website provides some information on product details, cost, and shipping.

Continental Steel & Tube Co.

Coxsco has been providing Ferrous and Non-Ferrous Metal Supplies to Loosing and the surrounding counties for over 30 years. The bar, wire, and plate forms of 138 PH stainless steel are supplied by Continental Steel. All materials are fully certified to meet ASTM and AMS standards.

International Marketplaces

Sell sites like Alibaba, and ThomasNet are replete with vendors who supply 13-8 ph steel in different forms and shapes grad13 8ph steel. These platforms are exceptionally efficient in determining the cost and availability across many other countries and resorts.

Additional Considerations

Meaningful Documentation of the alloy’s composition must accompany any forged Grade 13-8PH stainless steel for sale. It must come from the supplier. Such grades of stainless steel are very popular in the aviation, naval, or other high-strength applications, and hence it is essential to make sure that the material supplied meets the requirements of AMS 5629, which is another name for ASTM A564. If the geometry is also provided, it is possible to request it in the state of H950 or H1025, which are methods of heat treatment that determine the condition to which the steel will be subjected. There are also many things you can easily find online, from specification tables to contacting the supplier’s service representatives if you are unable to obtain what you want.

Industry Standards and AS9100 Compliance

Monitoring whether aviation production complies with all applicable regulations and standards is one of the most essential approaches to guarantee high quality, which consumers expect, safe production, which authorities expect, and operational equipment, which the airline provides. Conformance and compliance requirements for various industries, including customers in the aerospace industry, are explained through the most prevalent quality management system, namely the AS9100 Guidelines. Importantly, five aspects of the compliance system and supporting systems are addressed below:

AS9100 Quality Management System

The standard applies to businesses that may undertake the design, manufacture, or any other stage of developing aerospace parts. These procedures are strategically documented to enhance the quality of processes and minimize the likelihood of harm during production.

AMS 5629 Specifications

The revised Temple Alloy Spec, AMS 5629, describes the chemical composition and characterization of metallic alloys, including steel, used for critical engineering applications such as aerospace.

ASTM Standards A-564 are in effect

The conversation needs to be enriched with relevant information and in a manner that helps students appreciate the practices being put in place in far-off lands. These standards apply to precipitation-hardening stainless steels, a type of steel primarily favored for manufacturing strength-critical aerospace components. They also provide mechanical properties, subdivision, and treatment processes utilized.

Certification Requirements of the FAA

These products are designed and manufactured in accordance with FAA regulations, which mandate the airworthiness standards for the systems and components used in building aircraft.

Integration of ISO 9001

In this regard, it is critical that processes should work on the principle of cohesiveness so that two different quality systems can be used, AS9100, which is based on ISO 9001, and allows for compatibility within multi-industry quality systems, but with additional demands for aerospace.

By following the provided guidelines and standards, manufacturers can ensure the consistency of the product and guarantee its safety and conformity throughout the aviation industry’s operational activities.

References

- University of North Texas Digital Library

Development of New Stainless Steel Covering Period

This document discusses the mechanical properties of precipitation-hardened steels, including 13-8 PH. - Defense Acquisition University (DAU)

High-Cycle Fatigue Behavior of Precipitation-Hardened Stainless Steel Alloys

This paper explores the fatigue behavior of PH 13-8 Mo in various environments. - Penn State University – Materials Science Research

Control of Grain Structure, Phases, and Defects in PH Stainless Steels

This research paper provides insights into the grain structure and mechanical properties of 13-8 PH stainless steel.

Frequently Asked Questions (FAQ)

In grade 13-8 PH stainless steel, what are the alloy requirements?

This type of material is classified as a martensitic precipitation-hardening stainless steel alloy, characterized by high impact strength and toughness. The alloy has a low carbon content and is primarily used in the aerospace industry due to its excellent toughness and fair resistance to corrosion.

Are there different uses for 13-8 PH stainless steel?

Composites and custom shapes, especially in detailed aspects of the aviation systems, also employ 13-8 PH. This necessity enables the development of enhanced structures, such as aircraft and other high-altitude installation units.

How about the physical or metallurgical properties of 13 8ph substance?

13-8 PH is characterized by high strength, good ductility, high resistance to wear, and an extra high tensile strength. However, it can also be used to enhance commonplace steels, typically through a precipitation-hardening and vacuum melting process, for increased toughness.

What qualities distinguish the chemical characteristics of 13-8 PH stainless steel?

Iron, chromium, nickel, and molybdenum, broken into smaller elements, form the primary chemical compound of the 13-8 PH that contains. High strength and corrosion resistance are significant characteristics of the chemical mixture, particularly under limiting exposure conditions.

What is the Thermal Treatment of 13-8 PH Comprehending Stainless Steel?

The thermal treatment of 13-8 PH stainless steel consists of a set of procedures that include aging the material at specific temperatures, aiming to achieve improved property levels. The strength and toughness of this material are typically achieved through H950 and H1000 heat treatments.

In what sizes and forms is the 13-8 PH stainless steel produced?

There is a wide variety of 13-8 PH stainless steel that comes in several sizes and forms, including sheets and plates. The products are manufactured to ensure that the requirements of the particular applications are met; hence, the performance is optimal.

What are the qualities of 13-8 PH stainless steel that can be used in the aerospace industry?

The high strength, good toughness and good resistance to corrosion of 13 8 ph stainless steel makes it one of the most preferred material in this case of extreme condition that comes with aerospace applications because of its application. This metal is chosen here because in the harsh environmental conditions, its structural properties are preserved.

Where and how do we use 13-8 PH stainless steel?

Using the 13-8 PH stainless grade offers numerous benefits. High strength, moderate ductility, and toughness characterize this. The martensitic nature of this steel, however, allows for effective hardening and hence it finds application especially when critical components that require high performance are needed.