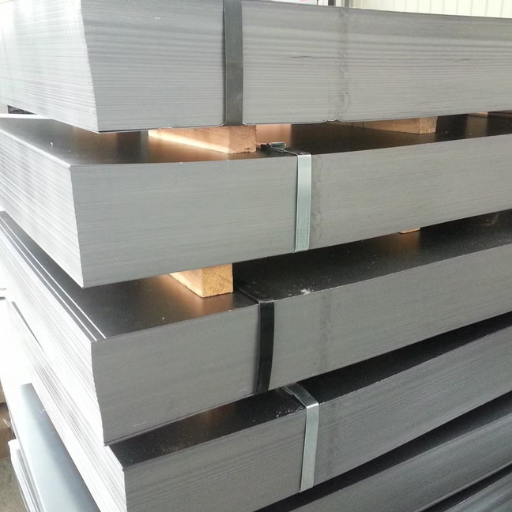

Materials are chosen based on durability, strength, and performance in construction and manufacturing. One such material that has gained immense popularity is S320GD—a premium grade of coated structural steel. Known for its good mechanical properties and versatility, S320GD finds application in various uses ranging from roofing systems to structural frameworks. This article will shed light on the key features of the S320GD grade, its advantages, and how the special coating helps protect it from environmental factors leading to corrosion. Whether you are a professional in the business or just a curious mind willing to know the science of high-performance materials, this guide will equip you with some useful insight to understand better S320GD and its crucial importance in the modern engineering world.

What Are the Mechanical Properties of S320GD?

This grade is eminently superb with regard to mechanical performance and is, therefore, widely applicable in structural uses. With very high values of yield strength and tensile strength, it is durable and, therefore, able to resist stressed deformation. It also possesses good elongation properties, under dynamic stresses, so that the steel can maintain the integrity of its structure. In addition, its impact resistance holds out against the strain of harsh environmental conditions, which commonly renders it into a very versatile steel in construction.

Exploring the Yield Strength of S320GD

| Key Point | Details |

|---|---|

| Material Number | 1.0250 |

| Standard | EN 10346 |

| Yield Strength | ≥ 320 MPa |

| Tensile Strength | 390-530 MPa |

| Elongation at Break | ≥ 17% |

| Chemical Composition | C ≤ 0.20%, Si ≤ 0.60%, Mn ≤ 1.70% |

| Coating Options | Z, ZF, ZA, ZM, AZ, AS |

| Corrosion Resistance | Enhanced by zinc coating |

| Applications | Construction, automotive, appliances |

| Thickness Range | 0.40-4.00 mm |

| Width Range | Up to 1,620 mm |

Understanding Elongation and Formability

In steel materials, elongation and formability are essential aspects determining mechanical performance. Elongation at break is considered the ability of the material to stretch until it breaks and is, thus, used to qualify ductility. A material with an elongation value of more than 17% stands for a good relationship between strength and ductility and is, therefore, suitable for high-demand forming processes.

Formability is a material’s capacity to undergo deformation without cracking or failure; this property, however, depends on different factors, such as chemical composition, microstructure, and processing methods. The material exhibits commendable formability, with its optimized chemical composition (≤0.20% C, ≤0.60% Si, ≤1.70% Mn), especially when it is combined with advanced coating grades like Z (zinc) or ZM (zinc-magnesium), which improve formability-related surface performance.

This specification guarantees that the material can withstand processes like deep drawing, bending, or stamping without failure in advanced technological applications in the automotive and construction fields. According to more recent research, steels with a greater elongation value and tensile strength under control (those within this material’s 390-530 MPa range) provide a higher flexibility in forming complex parts. Innovative surface treatments further contribute to preserving the integrity of the steel during deformation, especially under highly stressed manufacturing conditions.

The combination of higher elongation values and good formability characteristics makes this material adaptable to various applications while maintaining dimensional and structural integrity.

How Do Mechanical Properties Affect Structural Applications?

Mechanical properties such as strength, ductility, hardness, and toughness directly govern a material’s ability to withstand loads, resist deformations, and remain durable under certain structural applications for performance and safety against different conditions.

How Does the Chemical Composition of S320GD Compare to Other Steel Grades?

S320GD steel chemical composition is tailor-made for high durability and corrosion resistance, and is thus great for structural applications. It usually has low carbon, manganese, phosphorus, and sulfur levels to strike a balance between strength and workability. S320GD has improved galvanization properties from the zinc coating, granting higher protection against environmental wear and corrosion when compared with other steel grades like S235 or S355. This particular patch of qualities gives it a set of features that make it an apt choice in construction and in fabrication.

The Role of Chromium and Other Alloys

Chromium is a key component for high-performance manufacturing that lends steel and other alloys their properties. When chromium is added to steel, the overall corrosion resistance is enhanced by depositing a thin film of chromium oxide on the material surface. These chromium-rich alloys—stainless steel being typical, with at least 10.5% chromium—are thus ideal for applications requiring resilience against moisture, chemicals, and high temperature.

Apart from corrosion resistance, chromium is also involved in industrial tools and machinery’s hardening and wear resistance mechanisms. Current materials science data indicate that steel with a chromium content of 12%-18% significantly increases durability, allowing it to withstand the harshest atmospheric conditions.

Other alloying elements, such as nickel, molybdenum, and vanadium, can be combined with chromium to adjust properties in specific ways. For example, nickel increases toughness and ductility, and molybdenum increases resistance to pitting and crevice corrosion, particularly in marine environments. These alloys are then used to develop materials for critical industries like aerospace, automotive, construction, and medical devices requiring strength and time.

These modernized alloy developments are pushed ahead by growing demand from around the world. Stainless steel production reached over 56 million metric tons per year by 2022, which speaks volumes about the importance of chromium and related alloys across industries.

Impact of Chemical Composition on Corrosion Resistance

The relative chemical composition of an alloy determines the corrosion resistance of a compound, the latter functioning in an elementary fashion to protect an alloy against undesirable agents in the external environment. Below is a description of five most common elements and their respective influence on corrosion resistance:

- Chromium—Chromium remains the most important element for corrosion resistance in stainless steel. It forms a passive surface oxide layer that inhibits further oxidation. Therefore, alloys generally contain at least 10.5% chromium to afford adequate corrosion resistance.

- Nickel – Adding nickel provides stability and toughness and resists pitting and crevice corrosion, especially in marine and acidic environments.

- Molybdenum—Molybdenum offers some pitting resistance in chloride environments like seawater. Alloys with 2-3% molybdenum do well in high salinity.

- Carbon – Carbon is required for strength; however, high-carbon steels are comparatively less corrosion resistant, as chromium retention is reduced due to the formation of chromium carbides. Carbon content is kept low in stainless steels, such as low-carbon grades, to maintain good corrosion resistance.

- Nitrogen—Nitrogen increases stainless steel’s resistance to pitting and crevice corrosion, particularly in duplex grades. In addition, nitrogen ensures enhanced mechanical properties, combining strength and ductility.

By carefully adjusting these element percentages, the engineers can develop specific alloys for special environments and operational requirements, where best performance and high life should be ensured.

Comparing Carbon Content in Different Steel Types

| Steel Type | Carbon Content Range (%) | Key Characteristics | Common Applications |

|---|---|---|---|

| Low Carbon Steel | 0.04 – 0.30 | Ductile, easy to weld, low strength | Cutting tools, springs, and masonry nails |

| Medium Carbon Steel | 0.31 – 0.60 | Stronger, harder, less ductile | Automotive parts, gears, axles |

| High Carbon Steel | 0.61 – 1.50 | Very hard, brittle, wear-resistant | Cutting tools, springs, masonry nails |

| Ultra-High Carbon Steel | 0.96 – 2.10 | Extremely strong, brittle | Knives, truck springs, cutting tools |

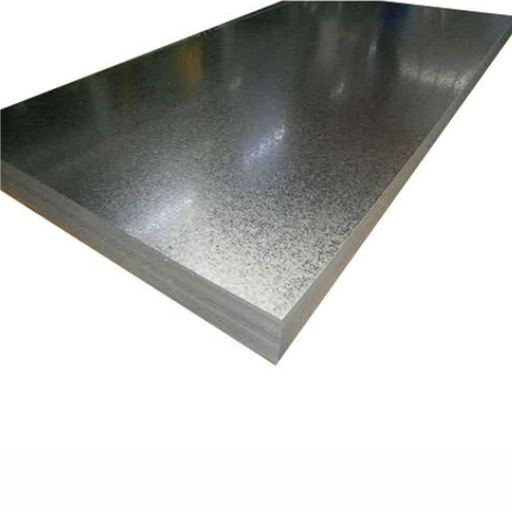

What Is the Galvanize Coating Process for S320GD?

The galvanization process for the coating of S320GD involves the application of a protective zinc layer onto the steel surface to keep it safe from corrosion. Usually, this is done through hot dip galvanizing, in which steel is subjected to cleaning, fluxing, and immersion in a bath of molten zinc. The zinc coating metallurgically bonds to the surface of the steel and becomes a strong barrier against degradation by moisture in the environment or air. Hence, the protection conferred from rusting extends to longevity and resilience of the material during application.

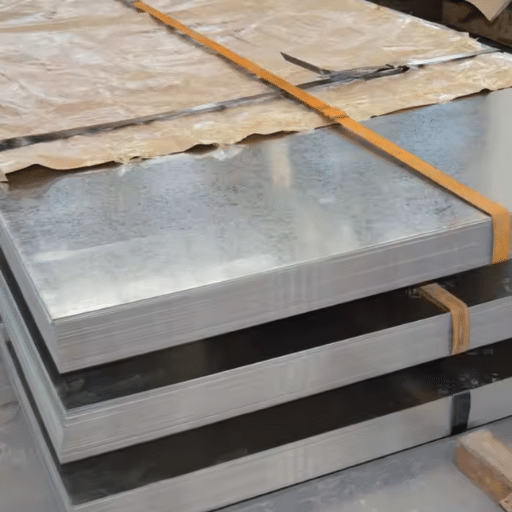

Understanding Hot-Dip Galvanized Steel

Essentially, hot-dip galvanized steel assures myriad benefits, and, consequently, it garners widespread consideration in various industries. Mainstream publicity often targets corrosion protection as the main selling point for galvanized steel. Galvanized coatings are found to vary in longevity by exposure conditions. For instance, studies have shown galvanized coatings to last more than 50 years in rural environments, while in industrial and marine settings, they last over 20 years. Thus, the lifespan of these galvanized coatings is enough to minimize maintenance costs, creating a real economic option for infrastructure and construction projects.

Similarly, a significant advantage of hot-dip galvanizing is that it provides uniform coverage, even on edges and corners where other coatings would thin out. The metallurgical bonding of zinc and steel results in a hard layer that does not break easily when undergoing transportation or installation. Galvanized steel can be recycled, making it fit perfectly for sustainability goals, decreasing the environmental impact of big projects.

Applications and Industry Usage

Thanks to its lasting qualities, several highly catalytic applications of hot-dip galvanized steel have made it universally desired in bridge construction, highways, power transmission towers, and outdoor equipment. According to figures from World Industry Reports, about 40 million tons of zinc are consumed annually, about half of which is used in galvanizing.

Galvanized steel is also widely used in the automotive industry to rust-proof body panels and structural members so that vehicle parts enjoy a longer life. Similarly, it finds application in agriculture in the construction of machinery, fencing, and storage tanks that resist inclement weather.

Key Performance Data

- Corrosion Resistance: Tests show that, on average, galvanizing delays corrosion by 30-75% compared to other coating methods.

- Thickness Consistency: The zinc coating usually ranges between 45 to 85 microns on coating, adjusted per application requirements and exposure conditions.

- Economic Impact: Switching to hot-dip galvanized steel saves every company about 20-30% in repair and maintenance costs over the steel’s lifetime.

- Durability: According to AGA research, galvanized steel can retain its structural integrity in temperatures ranging from -40°F to 392°F.

All in all, combining time-tested data with new advances in hot-dip galvanizing technology, this material boasts being the backbone of all well-built, sustainable infrastructures for the future.

Benefits of Coated Structural Steels in Corrosive Environments

| Key Benefit | Description |

|---|---|

| Corrosion Resistance | Protects steel from rust and oxidation. |

| Extended Lifespan | Increases durability and service life. |

| Cost-Effective | Reduces maintenance and replacement costs. |

| Barrier Protection | Prevents contact with corrosive elements. |

| Aesthetic Appeal | Offers color options for better design. |

| Environmental Adaptability | Performs well in diverse conditions. |

| Cathodic Protection | Sacrificial layer protects exposed steel. |

| Improved Safety | Prevents structural failures due to corrosion. |

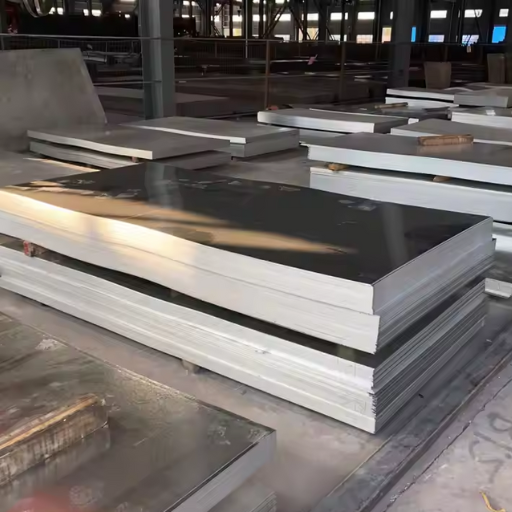

How Does S320GD Fit into the Structural Steel Market?

S320GD is imperative for acceptance in the structural steel market because of its perfect balance of strength, durability, and diversity. The high yield strength of S320GD makes it suitable wherever load-bearing capability is in use. On the other hand, S320GD sustains corrosion-resistance properties that prolong its life in different environmental conditions. It is further capable of deformation to be shaped for all construction and other manufacturing uses as demanded by any industrial steel solution that needs to be reliable and adaptable. These essential features put S320GD on the list of first choices for infrastructure, automotive, or industrial projects.

Comparison of Common Steel Grades

| Steel Grade | Carbon Content (%) | Key Features | Common Applications |

|---|---|---|---|

| A36 | Low (≤ 0.3%) | Ductile, weldable, affordable | General construction, bridges |

| A572 | Low (≤ 0.3%) | High strength, good ductility | Beams, columns, girders |

| A992 | Low (≤ 0.3%) | High strength, seismic resistance | High-rise buildings, bridges |

| 304 SS | Low (≤ 0.08%) | Corrosion-resistant, durable | Kitchenware, medical devices |

| 4140 | Medium (0.3–0.6%) | Strong, wear-resistant | Automotive, machinery parts |

| D2 Tool | High (0.6–1.5%) | Hard, abrasion-resistant | Cutting tools, dies |

Applications of S320GD in Automotive and Construction

| Industry | Application | Key Features |

|---|---|---|

| Automotive | Car body panels | High strength, corrosion resistance |

| Frames and reinforcements | Durable under mechanical stress | |

| Underbody parts | Protection against harsh environments | |

| Construction | Roofing and wall cladding | Weather-resistant, long-lasting |

| Structural beams and columns | High load-bearing capacity | |

| Interior partitions | Easy to shape and install | |

| Drainage systems | Long-term durability in severe weather | |

| Solar mounting systems | High strength, low maintenance | |

| Sandwich and composite panels | High rigidity and durability |

What are the DIN and EN standards for S320GD?

S320GD is a type of structural steel in wide applications in construction and fabrication.

- DIN Standard: According to DIN EN 10346, S320GD is a technical delivery condition applicable to continuously hot-dip coated steel flat products.

- EN Standard: Under the EN Standard system, S320GD is also governed by EN 10346, which identifies it as a galvanized steel grade with a minimum yield strength of 320 MPa.

These standards were established to guarantee uniform quality and performance for structural applications.

Understanding DIN Tolerances and Specifications

| Category | Key Points |

|---|---|

| Definition | DIN ensures standardization in Germany. |

| Purpose | Promotes quality, safety, and efficiency. |

| Linear Tolerances | Fine: ±0.05mm, Coarse: ±0.2mm (varies). |

| Angular Tolerances | Fine: ±1°, Coarse: ±3° (varies). |

| Form Tolerances | Includes straightness, flatness, etc. |

| Position Tolerances | Covers symmetry, perpendicularity, etc. |

| Voluntary Use | Standards are not legally mandatory. |

| Global Role | DIN aligns with ISO and CEN standards. |

Key Aspects of EN 10346 and 1.0250

| Aspect | Details |

|---|---|

| Standard | EN 10346 |

| Material Grade | 1.0250 (S320GD) |

| Coating Types | Zinc, Zinc-Iron, Zinc-Aluminum, Zinc-Magnesium |

| Thickness Range | 0.20 mm to 3.0 mm |

| Applications | Construction, Automotive, Appliances |

| Yield Strength | Minimum 320 MPa |

| Tensile Strength | Minimum 390 MPa |

| Elongation | Minimum 17% |

| Corrosion Resistance | Proportional to coating thickness |

| Surface Finishes | Regular, Minimized, Zero Spangle |

How Standards Affect Weld and Structural Integrity

Basically, standards work to ensure that the weld and structural integrity are intact by providing clear guidelines and specifications that I can depend on during design and manufacture. They maintain consistency, help to reduce the chance for errors, and allow one to maintain safety based upon acceptable tolerance levels and material properties. From my point of view, these standards are something I must respect to ensure that the structures and welds are all at the quality level that is required, are sufficiently durable, and capable of performing as expected, minimizing the risk factor and enhancing reliability in general.

References

- SteelNumber: Provides detailed chemical composition and classification of S320GD steel according to EN standards. Visit SteelNumber1.

- SteelOrbis: Offers a global steel grade equivalency chart, including S320GD and its equivalents. Visit SteelOrbis2.

- Shangang Steel Supply: Features a comprehensive comparison of galvanized steel material standards, including S320GD. Visit Shangang Steel Supply3.

Frequently Asked Questions (FAQ)

Q: What is the S320GD grade in structural steels?

A: The S320GD grade refers to a type of coated structural steel with a yield strength of at least 320 MPa, commonly used for its good strength and formability. It is often utilized in a range of industries, including construction and manufacturing.

Q: How is S320GD steel typically coated?

A: S320GD steel is commonly coated through a continuous hot-dip process, using materials like zinc or a zinc-iron alloy (ZF) for corrosion protection. This coating enhances the steel’s durability in harsh environments.

Q: What are the common applications of S320GD steel?

A: S320GD steel is widely used in constructing roofs, enclosures, and other structural components due to its good weldability, strength, and corrosion resistance. Its high-quality finish makes it suitable for both visible and structural applications.

Q: What are the dimensional specifications for S320GD steel coils?

A: S320GD steel coils are available in various thicknesses, typically ranging from 0.35 mm to 0.50 mm. These coils are produced to meet specific industry standards and dimensional requirements.

Q: How does the zinc coating on S320GD steel improve its properties?

A: The zinc coating on S320GD steel provides better corrosion resistance, significantly enhancing the steel’s longevity and performance in harsh environments. This is crucial for maintaining the integrity of structures exposed to the elements.

Q: What standards govern the production of S320GD steel?

A: The production of S320GD steel is regulated by standards such as EN 10147, which specify the chemical composition, mechanical properties, and coating requirements to ensure consistent quality and performance.

Q: Can S320GD steel be used for welding applications?

A: Yes, S320GD steel offers good weldability, making it suitable for various welding applications in construction and manufacturing. Its low-carbon content and specific alloying elements facilitate welding processes.

Q: What is the significance of the longitudinal and coil terms in relation to S320GD steel?

A: Longitudinal refers to the orientation of the steel grain structure, which can impact its mechanical properties. Coils denote the form in which the steel is supplied, allowing for efficient transportation and processing in manufacturing.

Q: How does the base material of S320GD steel contribute to its characteristics?

A: The base material of S320GD steel, typically a low-carbon steel, balances strength and ductility. This makes it ideal for forming and shaping processes while maintaining structural integrity.

Q: What role does manganese play in S320GD steel?

A: Manganese is an essential alloying element in S320GD steel, contributing to its strength and toughness. It also aids in the steel’s ability to undergo annealing processes, improving its overall mechanical properties.