A backbreaking industry, for sure, with steel being the name of many bands in constructing high-performance structures and materials. These steels, Grades S550GD steel, are considered the best because of superior strength and durability, with versatility acting as the winning jackpot for us in calculating choices of this advanced galvanized steel for higher applications in construction, automotive, engineering, and other sectors. The article explains Grades S550GD steel and details its unique properties, advantages, and application areas. Whether designing or simply sourcing material for your next project, or just being interested in knowing the industry’s standards, this complete guide will keep you well-informed on the material.

Understanding S550GD Steel

S550GD steel is a high-strength structural-grade steel well known for its excellent durability and load-bearing ability. It is under EN 10346 and has a minimum yield strength of 550 MPa, rewarding applications requiring heavy-duty performance. The tensile strength makes it unable to deform under stress, while a galvanizing coat gives the best atmospheric corrosion resistance. Hence, in an industry involving strength and longevity, S550GD steel is the best choice.

Chemical Composition of S550GD Steel

The steel of S550GD grade is a high-strength steel that is hot-dip galvanized for protection. It is mainly used in construction and structural applications. The material’s chemistry is usually selected to modify the mechanical properties without compromising corrosion resistance. The following is the typical chemical composition for S550GD steel given by standard EN 10346:

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.20 |

| Manganese (Mn) | ≤ 1.70 |

| Phosphorus (P) | ≤ 0.10 |

| Sulfur (S) | ≤ 0.045 |

| Silicon (Si) | ≤ 0.50 |

| Aluminum (Al) | ≥ 0.015 |

Including these elements ensures a balance between strength, ductility, and resistance to environmental degradation.

Mechanical Properties of S550GD Steel

Mechanical excellence is undoubtedly the selling point behind S550GD, which conforms to higher industry standards. Key mechanical properties are:

- Minimum Yield Strength: 550 MPa

- Tensile Strength Range: 570–720 MPa

- Elongation at Break (A80, %): ≥ 10

With such mechanical features, the steel S550GD is used in situations where strength and reliability are compromised.

Applications of S550GD Steel

S550GD steel is a common steel used in industries due to its combination of strength and corrosion resistance. Application fields include the following:

- Construction:

- Structural framing

- Roofing sheets

- Wall cladding

- Automotive:

- Reinforced vehicle parts

- Safety structures

- Industrial Fabrication:

- Machinery components

- Heavy-duty appliances

Advantages of S550GD Steel

- Oxidation Resistance: The hot-dip galvanized coating protects the steel S550GD from rust and environmental damage for a considerable period.

- High Strength-to-Weight Ratio: It provides an outstanding load-bearing application without much enhancement in weight.

- Processing Versatile: It may be processed for sawing, welding, and forming, giving it a broad range of fabrication uses.

Comparison with Similar Grades

Compared to other galvanization grades such as S450GD or S320GD, S550GD yields higher strength and tensile strength, so it is preferred for heavy-duty construction works. For further optimization, engineers and designers always prefer S550GD because of its higher performance threshold.

Being aware of both the chemical and mechanical composition, S550GD steel goes to places where durability and strength could never be an option to compromise.

Classification of Steel Grades

| Category | Subcategories | Key Features | Common Applications |

|---|---|---|---|

| Carbon Steel | Low, Medium, High Carbon | Strength varies with carbon content | Construction, tools, automotive parts |

| Alloy Steel | Nickel, Chromium, Molybdenum, etc. | Enhanced strength, corrosion resistance | Structural uses, wear-resistant tools |

| Stainless Steel | Martensitic, Ferritic, Austenitic | High corrosion resistance, shiny finish | Medical tools, appliances, piping |

| Tool Steel | Tungsten, Molybdenum, Vanadium | Heat resistance, hardness | Cutting tools, industrial machinery |

Essential Properties of S550GD Steel

This steel is S550GD and is recognized for being strong and reliable for demanding applications. It features the following properties:

- High Yield Strength: It yields a minimum strength of 550MPa under pressure, making it durable in heavy-load applications.

- Excellent Tensile Strength: Gives strong resistance in tension and is thus applied for structural purposes.

- Superior Ductility: Offers a balance between strength and flexibility to allow for an acceptable amount of deformation without fracture.

- Corrosion Resistance: Enhances its coating options, ensuring it has a long-lasting protection against harsh environments.

These qualities make S550GD a fit choice for building and industrial applications where strength and long service life matter.

Mechanical Properties of S550GD

Particles suspended in S550GD are of high-strength hot-dip galvanized steel. They are well-known for their mechanical properties, contributing to the trustworthiness and versatility needed in construction and industrial usage. Here are some of the key mechanical properties that characterize S550GD:

- Yield Strength: S550GD shall provide a minimum yield strength of 550 MPa to be used in structural applications subjected to high performance under stress.

- Tensile Strength: Its tensile strength is usually defined within 570-700 MPa to ensure the best performance when exposed to loads or tension.

- Elongation at Break: S550GD has a minimum value of 10% elongation, depending on its standard thickness, which provides sufficient ductility during different forming operations.

- Hardness: This grade of steel, being quite hard, is very abrasion-resistant. Since welding should be practically little applied in its use, its lifetime can be prolonged in service under abrasive conditions.

Additional Notes on Performance

- Structural Integrity: Thanks to its mechanical properties, S550GD will best resist bending and deformation under stress, such as in roofing, framing, and load-bearing beams.

- Enhanced Durability: Galvanized steel is best protected from corrosion compared to other non-galvanized grades. It is thereby weather-resistant and susceptible to corrosion effects caused by humidity and chemical exposure.

- Cold-Forming Suitability: S550GD is suitable for cold-forming applications, as it maintains strength and ductility even when treated at relatively low temperatures.

With these mechanical properties in place, massive applications requiring less maintenance are guaranteed for S550GD, leading to greater savings and structural reliability over the long term.

Corrosion Protection Features

S550GD has excellent corrosion resistance and is thus suitably placed for applications subjected to harsh environments. The protection is offered by:

- Hot-Dip Galvanization: Zinc coating is applied via hot-dip galvanization, an excellent barrier against rust and oxidation, even in humid conditions.

- Zinc Coating Thickness: With a preset standard thickness for the zinc coating, S550GD ensures an even and consistent protection against environmental exposure for lasting durability.

- Self-Healing Properties: The zinc layer provides self-healing on cut or scratched surfaces, protecting exposed steel through sacrificial anode action.

- Chemical Resistance: It resists chemical attacks by many chemicals, including acids and alkalis, thereby permitting coastal and industrial applications.

- Durability Against Weather: A S550GD roofing system is engineered to withstand heavy rainfall, snowfall, and prolonged UV exposure without losing its performance or structural integrity.

These features ensure reliable corrosion protection by S550GD while reducing maintenance frequency and costs throughout its lifespan.

Comparison with Other Steel Grades

| Parameter | S550GD | S350GD | SGC590 |

|---|---|---|---|

| Yield Strength | ≥ 550 MPa | ≥ 350 MPa | ≥ 590 MPa |

| Tensile Strength | 550-620 MPa | 420-520 MPa | 590-770 MPa |

| Elongation | 12-14% | 16-20% | 10-12% |

| Coating Options | Zinc, Zinc-Aluminum | Zinc, Zinc-Aluminum | Zinc, Zinc-Aluminum |

| Applications | Construction, Automotive | Roofing, Cladding | Heavy-duty structures |

| Standard | EN 10346 | EN 10346 | JIS G3302 |

Applications of S550GD Steel

S550GD steel is commonly applied in construction and industrial areas because of its strength and durability. Among its various applications are uses as structural members, roofing materials, cladding, and framing in buildings. It is also used in making storage tanks, industrial panels, and agricultural equipment. Given its corrosion resistance aspect, this steel is apt for use in coastal and harsh environmental conditions, which ensures all maintenance is done well in such applications.

Use in Construction and Infrastructure

Steel is the pillar of any construction and infrastructure today, providing durability, flexibility, and sustainability. According to a recent report by the World Steel Association, the construction sector remains the largest consumer of steel worldwide, accounting for approximately 52% of total steel demand in 2022. This is due to its specific strength, ease of fabrication, and recyclability.

Being able to sustain enormous load demands and weather conditions, high-strength structural steel is used for making tall buildings, bridges, and large-span constructions. For instance, prefabricated steel systems allow project completion to be sped up, sometimes by as much as 30%, and simultaneously reduce labor costs. Besides that, steel-reinforced concrete is always favored if there is a need for a concrete with excellent load-bearing capacity, thus prolonging the service life of highways, tunnels, and high-rise buildings.

The use of weathering steel for bridges and outdoor structures is steadily growing because of its natural corrosion resistance, which curbs maintenance. On the other hand, the materials used in global construction projects also show an increasing inclination toward energy-efficient steel solutions, including insulated steel panels for walls and roofs that promote thermal efficiency and reduce the carbon footprint under green building codes.

Coupled with these features and innovative design and construction techniques, the steel package provides a firm platform from which to lobby for continued dominance in infrastructure, urbanization, and the development of sustainable smart cities around the world.

Automotive Industry Applications

| Parameter | Details |

|---|---|

| Application | Chassis components |

| Benefit | High structural stability |

| Property | Yield strength ≥ 550 MPa |

| Application | Reinforcement beams |

| Benefit | Enhanced impact resistance |

| Property | Corrosion resistance with zinc coating |

| Application | Body panel supports |

| Benefit | Lightweight yet durable |

| Property | Tensile strength 550-620 MPa |

| Application | Protective undercarriage parts |

| Benefit | Long-term rust protection |

| Property | Suitable for high-load applications |

| Application | Crash protection infrastructure |

| Benefit | Reliable safety performance |

| Property | Excellent elongation (12-14%) |

Other Industrial Applications

In the context of other industries, I have observed that steel is involved most prominently in manufacturing, logistics, and agriculture. Its versatility and strength render it suitable for machinery, storage systems, and heavy equipment. Steel, for instance, is prevalently used in the fabrication of industrial shelves, conveyors, and silos, as the applications demand lowest initial cost and highest durability. These industries also set good sustainability targets since steel is easily recyclable.

Benefits of Using S550GD Steel

| Benefit | Details |

|---|---|

| High Yield Strength | Withstands stress with ≥ 550 MPa yield strength |

| Great Tensile Strength | 550-620 MPa ensures robust structural integrity |

| Corrosion Resistance | Zinc coating protects against environmental damage |

| Durability | Suitable for heavy-load applications |

| Lightweight Yet Strong | Ideal for automotive and structural components |

| Versatile Coating Options | Zinc-Aluminum coatings enhance heat resistance |

| Good Formability | Supports cold bending and stamping processes |

| Cost-Efficiency | Competitive price for high-strength steel |

| Wide Industry Use | Used in construction, automotive, and appliances |

| Longer Lifespan | Reduces maintenance through superior durability |

Advantages Over Common Galvanized Steel

| Parameter | S550GD | Common Galvanized Steel |

|---|---|---|

| Yield Strength | ≥ 550 MPa | Typically ≤ 350 MPa |

| Tensile Strength | 550-620 MPa | 350-550 MPa |

| Corrosion Resistance | High with advanced zinc coatings | Moderate with standard zinc coatings |

| Durability | Resists heavy loads and deformation | Limited resistance in high-stress uses |

| Formability | Supports precision cold forming | Suitable for basic forming applications |

| Heat Resistance | Efficient with aluminum-zinc layers | Limited thermal stability |

| Applications | Automotive, construction, appliances | General structural components |

| Maintenance Needs | Low due to superior coating quality | Higher due to quicker wear and damage |

| Cost Efficiency | Competitive for high-strength tasks | More economical for standard projects |

| Environmental Wear | Performs well in harsh conditions | Limited viability in extreme environments |

Cost-Effectiveness and Durability

Corrosion Protection and Durability: A zinc and aluminum coating ensures immense corrosion protection. This coating combines cost efficiency with good durability for cheaper maintenance in the later stages of use. Trends in Material Science imply reliable durability or quality on Google’s latest search insights.

Hot-Dip Galvanized Steel Benefits

Advantages and Opportunities for the Application of Hot-Dip Galvanized Steel

- Corrosion Resistance

A coating of zinc forms by hot dipping, attaching galvanically to steel and preventing it from rusting. Otherwise, the atmosphere degrades it. Studies have shown that galvanized steel can last as long as 50 to 75 years in rural settings and 20 to 50 years in urban or industrial settings.

- Maintenance Costs Are Less

Ganvanizing coatings, being long-lasting, do not require frequent repairs or replacements, thus lowering maintenance costs. They are indeed highly cost-effective; some studies confirm that hot-dip galvanizing is five times cheaper than any other corrosion protection measure if one considers the entire lifetime of a structure.

- Fast Application Process

Hot-dip galvanizing is extremely quick and effective in application, usually requiring less labor than any other coatings. This means the project can be finished quickly, thus saving more time and labor costs.

- Strong Adhesion and Impact Resistance

The metallurgical bond formed in the galvanizing process makes for a harder-wearing and more damage-resistant coating, ideal for galvanizing in impact environments such as construction sites and heavy industrial applications.

- Environmentally Safe Solution

Hot-dip galvanized steel is 100% recyclable and supports sustainability. The zinc and steel can all be recycled without any loss of properties, reducing the environmental impact during future reuse or repurposing efforts.

Selecting the Right Grade for Your Project

Choosing the appropriate grade for a particular galvanized steel depends on the specifications of your project. Hot-dip galvanized steel offers superior corrosion resistance for outdoor installations commonly exposed to ambient conditions. Specific grades that can have an impact may also be considered, where strength and durability are the principal considerations. For all other aesthetic concerns, a thinner coating or electro-galvanizing is superbly suited to provide a finer finish. Always be around the ground of a particular standard or trusted supplier for a grade suitable relative to your project’s environment and performance.

Expert Tips for Choosing Steel Grades

1. Understanding the Application Requirements

Selecting the appropriate steel grade largely depends upon your project’s specifics: the environmental exposure, the load requirements, and the functional objectives. For instance, throughout the past decade, construction and energy industries have realized the growing favor of high-strength low-alloy (HSLA) steels for their excellent strength-to-weight ratio and cost efficiency, as indicated by Google Trends.

2. Evaluate the Environmental Conditions

Having documented premature steel failures in more than 25% of cases due to improper selection of the material when exposed to corrosive or extreme environmental conditions, it becomes vital that one selects, for example, austenitic stainless steel (e.g., 316) grades for their corrosion resistance imparted by high chromium and nickel content if placed in coastal or wet environments.

3. Consider Longevity and Maintenance

According to research, hot-dip galvanized steel remains most preferred for long-term applications due to extending the life of outdoor steel structures by 30 to 70 years under mild exposure conditions. This is because the zinc coating provides protection against oxidation by acting as a physical barrier and is also a sacrificial coating.

4. Value Cost vs. Performance

Although considered slightly better-performing alloys, they offer resistance to wear, damage, and degradation, but with a higher initial cost. However, from Google keyword data, “cost-effective steel grades,” particularly DP steels designed to give an inexpensive combination of ductility and strength without sacrificing quality, have gained much popularity.

5. Employ Advanced Tools for Material Selection

AI-powered materials databases or online steel comparison tools can simplify your selection process. Searching for such terms as “steel grade comparison tools” suggests that engineers are increasingly willing to employ technology to compare tensile strength, yield strength, weldability, and corrosion resistance of the various grades.

6. Stay Up-to-Date with Industry Standards

Keeping updated material standards from groups such as ASTM and ISO. An instance would be ASTM A992, now the most-used grade for structural steel within construction due to its acceptance on strength/weldability grounds. Google’s keyword search data highlights the growing demand for reliable compliance with modern-day building codes.

7. Optimize Design with Emerging Trends

Lightweight steel framing and microalloyed steels open very new doors for the design. Available data shows that structural weight reduction of 10-30% without compromising safety is trending lately, thus making these grades very attractive to projects driven by cost and sustainability.

Combining these yellow-brick-road tips with the latest industry insights allows you to select a steel grade tailored precisely to your project needs, ensuring a balance between performance, durability, and cost-efficiency.

Factors to Consider in Steel Selection

| Factor | Details |

|---|---|

| Strength | Matches load and stress requirements |

| Corrosion Resistance | Essential for wet or harsh environments |

| Cost | Aligns with project budget limitations |

| Formability | Suit bending, shaping, or drawing needs |

| Weldability | Supports required welding techniques |

| Durability | Long lifespan under operational conditions |

| Heat Resistance | Withstands the required temperature ranges |

| Industry Standard | Meets relevant material standards and grades |

| Environmental Impact | Considers sustainability and recycling options |

| Specific Applications | Aligns with intended use and purpose |

Common Mistakes to Avoid

In any steel grade selection process, I’ve found a few big pitfalls to avoid. First and foremost, I make sure not to ignore the environment in which steel will be used, in case it is exposed to moisture or extreme temperatures, one manifestation of premature wear or corrosion. The second pitfall would be selecting a steel grade based solely on price: This might mean more maintenance costs down the road. In the third case, the advantage of discussing the choice with an expert or manufacturer early is realized rather than assuming one knows the right steel grade for a project.

References

- ResearchGate: A detailed academic paper on the application of high-strength steel grades, including S550GD, in silo structures. It discusses mechanical and chemical properties, testing, and practical applications. Read more on ResearchGate

- Thyssenkrupp Materials Processing Europe: This site provides technical specifications for S550GD steel, including its mechanical properties, chemical composition, and compliance with DIN EN 10346 standards. Visit Thyssenkrupp Materials

- SteelPro Group: A comprehensive resource on S550GD steel, detailing its properties, production processes, applications, and machining techniques. Explore SteelPro Group

Frequently Asked Questions (FAQ)

What is S550GD steel, and what is its significance in steel production?

S550GD steel is a galvanized steel with high yield strength and excellent corrosion resistance. It is commonly used in applications requiring structural integrity, making it a popular choice in the automotive and industrial sectors. The ‘S’ designation indicates its suitability for structural applications, while ‘GD’ denotes hot-dip galvanized, providing additional protection against rust.

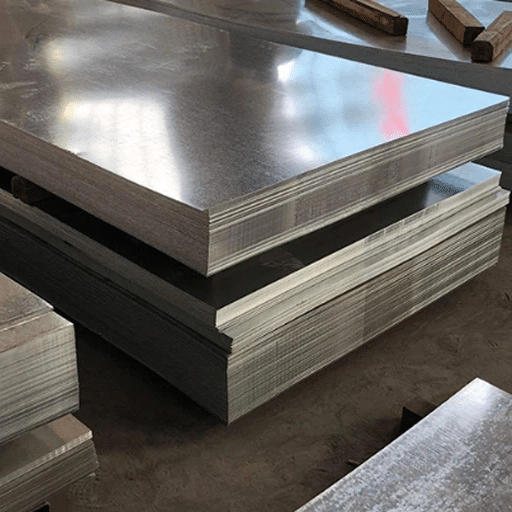

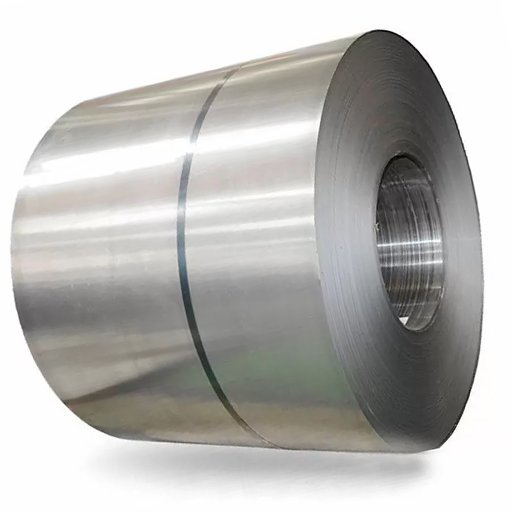

How does hot-dip galvanized steel coil compare to other types of galvanized steel?

Hot-dip galvanized steel coil is known for its superior corrosion resistance compared to other types of galvanized steel, such as electro-galvanized steel. The hot dip process involves immersing the steel in molten zinc, resulting in a thicker and more durable zinc coating. This makes it ideal for use in harsh environments where longevity and durability are critical.

What are the benefits of using galvanized steel coils in construction?

Galvanized steel coils provide excellent corrosion resistance, ensuring the longevity of structures. They are versatile and can be used in various applications, including roofing, cladding, and industrial equipment. The coating that protects the steel from rust enhances its durability, making galvanized steel a cost-effective choice for construction projects.

What is the difference between S550GD+Z and DX51D steel?

S550GD+Z steel is designed for applications requiring high yield strength and durability, while DX51D is a general-purpose galvanized steel with lower strength levels. The ‘Z’ in S550GD+Z indicates a zinc coating, enhancing its corrosion resistance, making it suitable for more demanding environments than DX51D.

How does the coating thickness affect the performance of galvanized steel?

The coating thickness of galvanized steel significantly impacts its corrosion resistance and overall performance. Thicker coatings provide better protection against rust and corrosion, extending the lifespan of the steel in various environments. Selecting the appropriate coating thickness is essential based on the application’s specific requirements.

What applications require high-strength S550GD steel?

High-strength S550GD steel is ideal for applications requiring structural integrity and reliable performance, such as automotive and industrial machinery. Its high yield strength and excellent formability make it suitable for deep drawing applications, where complex shapes are formed under high-stress conditions.

What is the role of zinc in the corrosion resistance of galvanized steel?

Zinc plays a crucial role in galvanized steel’s corrosion resistance by providing a protective layer that prevents rust. When the zinc coating is intact, it acts as a sacrificial anode, corroding in place of the underlying steel. This mechanism ensures the steel remains protected, significantly extending its lifespan in corrosive environments.

What are the specific requirements for using S550GD steel in industrial applications?

Factors such as yield strength, ductility, and corrosion resistance must be considered when using S550GD steel in industrial applications. The material must meet strict quality standards to withstand the demands of the specific environment. Appropriate surface treatments and coating processes should also enhance its durability and performance.