Get in touch with us

Leave a message

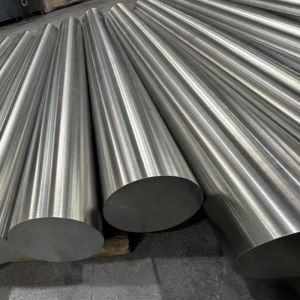

Our premium Hastelloy materials deliver exceptional performance in the most aggressive environments. As leading superalloy manufacturer, we provide various Hastelloy grades including the renowned Hastelloy C series, engineered for ultimate corrosion resistance and high temperature stability. Each Hastelloy composition is optimized for specific industrial challenges, offering cost-effective solutions across chemical processing, aerospace, and marine applications.

Hastelloy alloys adhere to standards like ASTM B574 (bars) and ASME SB-575 (plates), with grades classified by composition and purpose. Key Hastelloy grades include Hastelloy C276, Hastelloy C22, Hastelloy C2000, and Hastelloy B-3, each optimized for specific environments—think High Temperature Alloys for aerospace or Corrosion Resistant Alloys for acids.

| Type | Composition (Key Elements) | Characteristics | Common Grades |

|---|---|---|---|

| B-Series | Ni (65%), Mo (28-30%) | High resistance to reducing acids | B-2, B-3 |

| C-Series | Ni (50-60%), Cr (15-22%), Mo (13-16%) | Versatile corrosion resistance | Hastelloy C276, C22, C2000 |

| G-Series | Ni (40-45%), Cr (22-30%), W | Phosphoric acid resistance | G-30, G-35 |

| X-Series | Ni (44%), Cr (22%), Fe (20%) | High-temp strength, oxidation | Hastelloy X |

Hastelloy shines where others fail—think Hastelloy C276 in wet chlorine or Hastelloy C22 in mixed acids.

| Property | Behavior | Key Elements | Notes |

|---|---|---|---|

| Corrosion Resistance | Exceptional in acids (HCl, H2SO4) | Ni, Mo, Cr | Strong in reducing/oxidizing media |

| Oxidation Resistance | Stable up to 1200°C (2200°F) | Cr, Fe | Ideal for High Temperature Alloys |

| Magnetism | Non-magnetic | Ni dominance | Useful in sensitive equipment |

| Heat Resistance | Good to 538-982°C (1000-1800°F) | Mo, W | Varies by grade |

| Property | Hastelloy (C276) | Stainless Steel (316) | Notes |

|---|---|---|---|

| Tensile Strength | 690-930 MPa | 515-690 MPa | Hastelloy outshines in stress |

| Yield Strength | ≥ 310 MPa | ≥ 205 MPa | Superior load-bearing capacity |

| Hardness (Brinell) | ≤ 220 HB | ≤ 217 HB | Comparable, but Hastelloy resists corrosion |

| Elongation | ≥ 40% | ≥ 40% | Excellent ductility for forming |

Hastelloy shines across industries:

Hastelloy uses span wherever durability meets corrosion.

Despite its strengths, Hastelloy isn’t flawless:

Hastelloy excels in corrosive settings:

Welding Hastelloy requires precision:

These ensure Hastelloy metal retains its properties.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.