It might appear to be an overwhelming job to cut stainless steel sheets due to their strong and long-lasting characteristics. Nonetheless, clean and accurate cuts can be obtained easily with proper tools and methods, and this is true for both DIY hobbyists and professionals. This manual will help you make the right choice by showing you the most effective ways and the safest and best manner to deal with stainless steel. If your aim is to create elaborate patterns or simple cuts, you will learn about the necessary tools, the accuracy guaranteeing tips, and mistakes to avoid. So, keep reading if you want to know all the information required to turn your stainless steel cutting projects into a successful one.

Introduction to Cutting Stainless Steel

Importance of Proper Cutting Techniques

Proper cutting methods for stainless steel are of utmost importance for assuring safety and operation efficiency at the same time. Stainless steel, being a tough and multipurpose material, is not very easy to handle if the wrong methods are applied. Ineffective practices can result in various problems such as distortion of material, ragged edges, and sometimes even damage to the cutting tools. Manufacturers and industry specialists claim that using improper methods can increase the amount of waste by as much as 25%, thus, wasting time and resources which is a big problem in big projects.

Stainless steel cutting is characterized by the need for precision, as the aesthetic aspect of just mated with the material is often critical for the application. Research has shown that straight, clean cuts minimize the risk of the weak points forming in the material, thus, enhancing its integrity and lifespan. Moreover, using high-quality cutting tools like carbide-tipped blades or plasma cutters leads to even smoother results. Further studies indicate that the practice of using a slow and even cutting speed will effectively manage the problem of heating-up which is a cause of discoloration and impaired strength of the steel.

Use Cases of Stainless Steel Sheets

Stainless steel sheets are among the most diverse materials in use and are not limited to factories, but their properties of durability, anti-corrosiveness, and attractiveness are among the main reasons they are widely accepted across various industries. The building and construction industry is the main market where stainless steel sheets are being applied for cladding, roofing, and structural parts. Current industry statistics indicate that the consumption of stainless steel in construction provides for about 10% of the overall global demand which implies the material is indispensable in terms of the aesthetics, functionality, and service life of modern architecture and infrastructure works.

In the same context, stainless steel sheets remain heavily utilized in the manufacture of household appliances like refrigerators, ovens, and dishwashers, also taking advantage of their sanitary nature, and premium appearance. The global market for home appliances has been recently valued at over $ 500 billion, and stainless steel was the material of choice for many manufacturers.

Essential Tools and Equipment for Cutting Stainless Steel

Recommended Tools for Cutting Stainless Steel Sheets

1. Plasma Cutters

Plasma cutters are very efficient tools in the hands of those who like working with stainless steel sheets and come to dealing with the kinds of cuts that are only possible with a gas that is electrically ionized. To get there, these machines use the ionized gas and thus can perform the task of cutting the metal at high speed and with great precision. The latest plasma cutters are capable of going through sheets of stainless steel with thickness up to 1.5 inches. The combination of speed and accuracy makes them suitable for industrial and commercial operations. In line with industry reports, the trend of plasma cutter adoption gained momentum, as the development of new and more efficient ones reduced the operational costs further and made the tools even more powerful.

2. Circular Saw with Carbide-Tipped Blade

If you are cutting stainless steel sheets for medium- to small-scale projects then the solution is the circular saw fitted with a carbide-tipped blade. This technique really produces straight and clean cuts the best. Blade technology has come up with a new level of durability where carbide tips last much longer than old-fashioned steel blades, thus making it an economical choice for heavy-duty use.

3. Angle Grinders

Angle grinders are powerful and versatile; portable ones can be used outdoors for cutting thin stainless steel plates. With the use of the right cutting disc, the machines can deliver quick, clear and precise cuts. The quality of discs, especially the abrasive stainless steel cutting wheels, assures endurance and smooth cutting. Angle grinders of the modern day have advanced in vibration control and power efficiency, making them comfortable and safe to use.

Comparing Manual vs. Electric Tools

| Tool Type | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Manual Tools |

|

|

Small tasks, delicate work, situations requiring portability |

| Electric Tools |

|

|

Large-scale projects, repetitive tasks, professional work |

Step-by-Step Guide for Different Cutting Methods

How to Cut Stainless Steel Sheets Using a Saw

1Select the Appropriate Saw and Blade

To cut metal or stainless steel, a circular saw or jigsaw fitted with a top-quality blade designed for this purpose is the best option. It’s the carbide-tipped blades or blades with the indication “ferric metal cutting” that come highly recommended as they are long-lasting and quite timesaving at the same time. When dealing with heavy sheets, the angle grinder with a cut-off wheel attachment can also be an option.

2Hold the Stainless Steel Sheet in Position

When clamping, be sure to apply enough pressure so that the stainless steel sheet does not move at all. If the sheet is not firmly held, it may result in improperly cut pieces and will also increase the likelihood of injuries. Plus, it should always be the case that the cutting area has free movement and no obstructions.

3Draw Your Cutting Line

Take a ruler and fine-point marker or a scribe to make a very clear and precise line on the metal sheet that shows where it is going to be cut. With this line as a guide, you will be able to cut with precision.

4Oil the Cutting Edge

Cutting oil drops need to be applied along the line that has already been marked. The lubrication acts to lessen the friction between the blade and the metal, as well as the heat generated, which are some of the main causes of blade wear, thus extending the life of the blade and also resulting in a smoother finish.

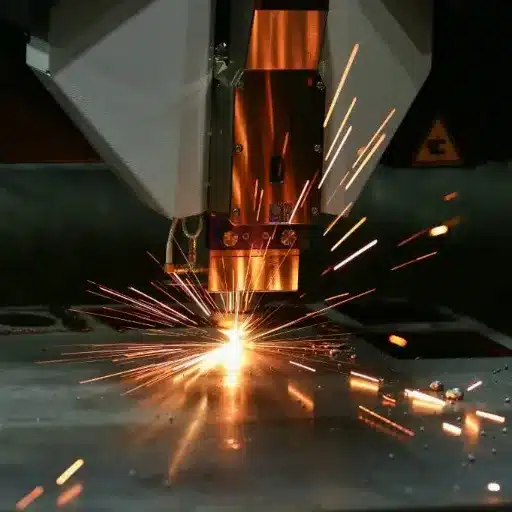

Stainless Steel Laser Cutting

Laser cutting is now a very effective and precise way of processing stainless steel, especially when it comes to complicated designs and fast production. The method employs a concentrated laser to either soften, oxidize, or evaporate the material which results in very neat and clean cuts with almost no distortion. Along with the latest trends in laser technology, the new machines can cut stainless steel up to 0.25 inch (6 mm) thick while maintaining high precision.

For instance, it is common for industrial fiber lasers to provide a maximum cutting speed of 400 IPM for very thin stainless steel sheets (around 0.04 inch or 1mm thick), but this will ultimately depend on the machine used and the material being cut. Moreover, CO2 laser cutting is quite effective for thicker grades of stainless steel giving an excellent edge quality albeit at a slightly slower rate of work. These systems tend to produce a cutting tolerance of ±0.002 inches which is ideal for various sectors like aerospace, medical instruments, and beautiful designs that require high accuracy.

Key Performance Specifications:

- Maximum Thickness: Up to 0.25 inch (6 mm)

- Cutting Speed: Up to 400 IPM for thin sheets (1mm thick)

- Cutting Tolerance: ±0.002 inches

- Applications: Aerospace, medical instruments, intricate designs

Safety Precautions When Cutting Stainless Steel

Safe Operating Procedures

⚠️ Risk Assessment

Before any cutting operations are started, a comprehensive risk assessment should be conducted. OSHA regulations suggest that recognizing hazards like sharp edges, flying debris, and equipment breakdowns can halve workplace accidents. It is also a good practice to constantly renew assessments as this would make sure that new risks are properly managed.

🔧 Routine Maintenance and Inspections

Regular maintenance of cutting machines is decisive in avoiding accidents. Research has shown that through routine checks, 70% of accidents involving machines can be prevented. Always inspect the equipment for wear and tear or potential hazards, adhering to the manufacturer’s recommendations.

🎓 Training and Certification

Employees must be trained in the safe operation of machines and the proper handling of materials. The National Safety Council (NSC) confirms that companies with certified workers have 30% less accidents. The training courses should cover both theoretical and practical aspects.

Common Hazards to Avoid

1. Slips, Trips, and Falls

The National Safety Council (NSC) reports that slips, trips, and falls lead to almost 18% of the nonfatal workplace injuries in the U. S. every year. Good cleaning, non-slip mats, and unobstructed walkways are the main actions to be taken to avoid such occurrences. Regularly looking for signs of danger eg. loose cables or wet floors, should be part of the work routine.

2. Ergonomic Hazards

Increases of musculoskeletal issues (MSDs) and costs of over $15 billion a year in workers’ comp claims have led OSHA to declare thanks top poor workstation setups and repetitive tasks. Providing ergonomic furniture and readers on proper posture can make these problems less severe.

3. Chemical Exposure

Disastrous handling or improper storage of toxic chemicals can lead to burns, problems with the respiratory system, or even chronic diseases. CDC has reported that 13 million workers in the U. S. come into contact with dangerous chemicals every day. Clear labeling and effective airflow can greatly reduce the likes of these risks.

Reference Sources

-

Cutting and Profiling Techniques for Stainless Steels

This resource from the British Stainless Steel Association outlines techniques and equipment for cutting and profiling stainless steel.

Read more here -

Machining of Stainless Steels – A Review

This paper reviews previous research on machining austenitic stainless steels and explores future research directions.

Read more here -

Production of Workpieces from Martensitic Stainless Steel

This study investigates cutting forces during the milling of martensitic stainless steel samples.

Read more here

Frequently Asked Questions (FAQs)

❓ How to cut stainless steel, the best method if the cut is straight?

The ideal method for cutting stainless steel for a straight cut depends on the thickness: a circular saw with a metal-cutting blade or a jig saw with a mostly-teeth blade to minimize burrs create good conditions on thin stainless steel sheet; while a band saw or a grinder equipped with a cutting wheel produces a razor-sharp edge on a thick SS sheet.

❓ How to cut the stainless steel without making the stainless steel dirty or less corrosion resistant?

To keep the stainless steel clean and to maintain its corrosion resistance, make use of stainless-specific cutting tools or assign certain blades and cutting wheels for exclusive use on stainless only. It would be best not to resort to blades that have been in contact with regular carbon steel as transfer of iron particles may lead to the formation of rust spots.

❓ Is there a way to cut thin stainless steel sheet metal or thin ss that is the best one?

In the case of thin sheet metal, tin snips, fine-tooth jigsaw blade, or a shear are the best methods respectively for cutting stainless. A zip cut or a utility scissors style for thin stainless will minimize distortion. In case power tools are being used, lower speed and a thin stainless designed metal-cutting blade should be chosen to prevent the sheet from bending or work hardening.

❓ Can I use a hacksaw to cut stainless steel or will power tools be necessary?

It is possible to cut stainless steel with a hacksaw; it is often the case if small pieces are cut off or in situations where portability is a priority. It is advisable to use a premium quality metal-cutting blade (bi-metal or carbide-tipped) and apply constant cutting pressure to prevent hardening. However, for larger jobs or thicker material, a band saw, cutoff wheel, or plasma cutting will be faster and more efficient.