Cutting stainless steel sheet metal might look as though it is a hard job, not only for the novice but also for the experienced professional DIY fan. Stainless steel is a strong, tough, and corrosion-resistant material that is very versatile, and thus, it is mandatory for many applications, from architectural designs to industrial projects. Yet its qualities that are desirable also make it tricky to cut it off without proper tools or techniques. In this blog, we will show you how to cut stainless steel like a professional. No matter if you are an experienced fabricator or doing a DIY project for the first time, you will find tips, tools, and methods for doing it accurately and quickly while keeping safety and precision as the most important factors in the whole process.

Introduction

Importance of Stainless Steel Sheets

The industries using stainless steel sheets have allocated this vital element for innumerable applications owing to its remarkable qualities. Nowadays, many people have an affinity towards modern looking products and stainless steel sheets being one of them. Such strong sheets are even considered for a range of industries from construction to medical and culinary tools. Their rust and oxidation resistance keep on maintaining the performance for a long time thus reducing the need for maintenance and improving sustainability.

Recent research shows that the global stainless steel market was around $111 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.4% from 2023 through 2030. The main reason for this growth is the demand for stainless steel in the infrastructure development, renewable energy, and technology sectors, among others. Apart from that, the recycling ability of stainless steel also plays an important role in this scenario; i.e. about 92% of stainless steel products are recycled after their useful life, making them increasingly popular in the green building movement.

Common Uses of Stainless Steel Sheets

Stainless steel sheets are multipurpose materials with their durability, resistance to corrosion, and bright aesthetic properties. Their main application is in the construction and architecture industries, where they are used as cladding, roofing, and structural frameworks that combine longevity with style. As per the statistics, the global usage of stainless steel in construction is on a rapid increase – it is expected to grow at a compound annual growth rate (CAGR) of 5.7% during 2021-2028).

The equipment and appliance manufacturing for kitchen is another important area where stainless steel sheets are widely used. Stainless steel sheets give countertops, sinks, ovens, and refrigerators hygienic and easy-to-clean surfaces; hence they become the first choice for both commercial and residential kitchen designs. Likewise, they are indispensable in food processing and medical industries because of the need for sterile conditions and resistance to strong chemicals.

Tools Required

Essential Cutting Tools

Plasma Cutters

Plasma cutters are and will be the best option for cutting thick stainless steel sheets precisely. They make use of hot plasma in a fast-moving jet to cut metal, thus, giving clean and accurate edges. The highest cutting power of modern plasma cutter machines is that they can work on 2-inch thick stainless steel sheets which are why they are really the only option for heavy-duty applications.

Angle Grinders

The angle grinders equipped with abrasive discs that are compatible with stainless steel have been the most common tools for making smaller, intricate cuts. It is worth it if an operator is fast and skilled with this tool because he will be able to do any modifications or cut a piece of stainless steel very quickly. Market data shows that more than half of the consumers who do it yourself (DIY) home improvement projects and professionals from small workshops prefer angle grinders due to the factors of versatility and price.

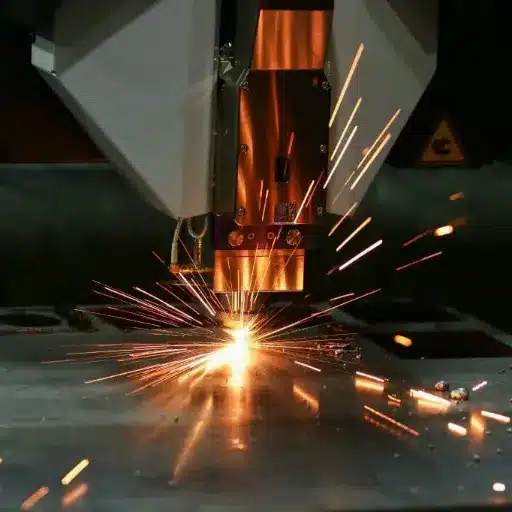

Laser Cutters

Laser cutting is considered as one of the most expensive but at the same time the most accurate cutting methods. Fiber laser cutters are highly efficient for intricate designs and are also capable of cutting thin stainless steel sheets at speeds more than 200 inches per minute. A recent study has predicted that the laser cutting market will experience an annual growth rate of 8.0% during the years 2023-2030 mainly due to the advances in automation and robotics integration.

Circular Saws with Carbide Blades

Circular saws with carbide-tipped blades are just the right tool to go for when dealing medium-thickness sheets. The use of these machines leaves behind very few burrs and, hence, they are considered as the most suitable equipment in the construction and manufacturing industries.

Choosing the Right Tool for Your Project

Choosing the best cutting tool for your project is a process that requires knowledge of the material that is to be cut, the level of precision that is desired and the efficiency that is required. For example, laser cutters are the best alternative for precision work done at a fast rate as they can produce very small tolerances and complex designs. There is an increasing trend where industries such as automotive and aerospace that require high accuracy and repeatability are switching over to laser cutting according to the latest statistics. The global laser cutting market is projected to be worth $9.7 billion by 2030, which is a clear indication of its widespread and continuous adoption.

Conversely, circular saws fitted with carbide blades have proven to be the best for medium-thickness sheets, especially in the construction and fabricating sectors. The attribute of these tools to render cuts that are smooth and without burrs is a boost to efficiency in the processes of framing or sheet metal assembly. The recent developments in blade technology, such as increased blade life and heat resistance, make these saws not only cost-effective but also reliable.

Safety Gear and Equipment

With the use of cutting tools like plasma cutters or circular saws, the necessary protective equipment and safety gear must be in place to avoid accidents and also have a safe working environment. It is said by the recent safety regulations that the use of personal protective equipment (PPE) cuts the risk of injuries tremendously. The basic protective gear consists of safety glasses or face shields to guard against flying debris and sparks; also, there is ear protection to lessen one’s noise exposure, and heavy-duty gloves to protect hands from cuts and burns.

For situations where plasma cutting is performed, special welding helmets with auto-darkening filters are recommended to protect the eyes from the very bright ultraviolet light. Fire-resistant clothes made from leather or cotton mixed with flame-retardant materials enhance protection against both heat and sparks. Likewise, it is necessary to wear steel-toe boots with non-slip soles for safety and stability in bustling workshops or on construction sites.

Step-by-Step Guide

Using a Laser Cutter for Precision Cuts

Laser cutters are very much responsible for the transformation of the manufacturing process and the crafting of the material in the modern world by giving them the best user-friendliness and their high versatility. Basically, these machines work by concentrating the laser beam of very high power to cut or engrave the materials in a very precise manner. The laser cutting is possible for various materials, and some of the popular ones are wood, acrylic, plastic, cloth, and even some metals which are not very thick. The precision involved in the laser cutting process is generally 0.1 mm, thereby giving neat and detailed outputs, even for the most complicated designs.

To repeat, the main beneficiary of laser cutter is the company that can usually count on modern machines for speed and high quality at the same time. Thus, the laser cutter an industrial use as well as a small-scale craft at the same time. As an example, a common CO2 laser cutter has a cutting speed of 20-70 inches per second (IPS), based on how thick the material is and how powerful the laser is. Moreover, the recent developments in laser cutting technology have made it very common for laser cutting machines to have integrated software, easy-to-use interfaces, and the capability to handle design alterations and automate repetitive processes smoothly.

The state-of-the-art laser cutters do provide energy-saving options along with operating costs that are lower in the long run. The introduction of fiber laser cutters has made it possible to cut the metals that were previously impossible to cut with the old laser machines, such as the case of stainless steel and aluminum, with the help of improved speed and less maintenance. Ruling out the risks, safety is always a matter of concern when it comes to the use of laser cutters and systems, thus, proper ventilation and eye protection being necessities to avoid exposure to bad laser and fumes.

Plasma Cutting Techniques

Plasma cutting is among the most versatile and effective techniques used in cutting metals like steel, aluminum, brass, and copper, which are the best conductors. The method melts the material and then, the plasma jet at the cut site removes it. And, the reason that this technique is widely used in industries of fabrication, dealing with automobiles, or making constructions is its high speed and precision.

Modern plasma cutting systems have significantly advanced, offering greater control and accuracy. For instance, CNC plasma cutters utilize computer-aided design (CAD) files to produce highly detailed cuts with tolerances as fine as ±0.01 inches. These systems also allow for cutting thick materials, with industrial machines capable of slicing through metals up to 2 inches thick.

One of the key advantages of plasma cutting is its efficiency. Compared to traditional cutting methods, plasma technology can cut up to 3 times faster, even on thick metal plates, saving both time and labor costs. Additionally, it generates minimal heat-affected zones (HAZ), reducing the risk of warping and preserving the integrity of the surrounding material.

Safety Tips

Protective Equipment Recommendations

- Welding Helmet with Eye Protection: It is absolutely necessary to have a welding helmet that has the required shade filters (usually shades 8-13) to protect your eyes and face from the bright light and harmful UV rays coming from the plasma arcs. Without protection, these can lead to serious eye injuries, one of them being arc eye.

- Flame-Resistant Clothing: Wear flame-resistant materials such as leather or durable fire-retardant fabrics. Protective jackets, aprons, or welding sleeves can shield the body from burns caused by sparks and heated materials during the cutting process.

- Heat-Resistant Gloves: Premium quality insulated gloves specifically designed for welding or plasma cutting are a must to guard your hands from heat, sparks, and sharp edges. Choose gloves that also allow for better finger movement to facilitate torch handling.

- Respiratory Protection: Plasma cutting releases fumes and fine particles such as metal oxides and ozone, which become hazardous when inhaled. Hence, respirators with the right filters (like N95 or P100-rated masks) should be used. In the case of heavy use in poorly ventilated places, powered air-purifying respirators (PAPRs) might be a good idea.

- Hearing Protection: The noise from plasma cutting can reach very high levels, especially if performed at industrial capacities. Investing in noise-canceling earmuffs or earplugs with a minimum of 23 dB NRR (Noise Reduction Rating) will help immeasurably in preventing gradual hearing loss.

Handling Thick Stainless Steel Sheets

| Aspect | Details |

|---|---|

| Choosing the Right Cutting Tool | If the thickness is big, consider switching to the more advanced plasma cutters or fiber laser machines that have the capability to slice through thick stainless steel sheets. The fiber lasers can do it with a thickness of up to 1 inch (25.4 mm) and with excellent precision, whereas the high-definition plasma cutters are good for thicknesses of 3 inches (76.2 mm). |

| Optimal Cutting Speed | Cutting speed is an important factor in the quality of the cut. For example, when a plasma cutter is used on stainless steel sheets around 1 inch thick, then a slower cutting speed is required, which is usually 10 to 15 inches per minute (IPM), to get clean edges without dross. |

| Use of Cooling Systems | Stainless steel cutting can make a lot of heat, and if this heat is not controlled properly, it can lead to warping or thermal distortion. Employing cooling systems such as water tables or air-cooled setups helps in the quick removal of heat and also keeps the steel’s mechanical properties intact. |

| Edge Preparation and Post-Cutting Finishing | The welding or assembling of thicker stainless steel sheets often requires a prior edge preparation. Grinding and sanding are some of the methods that ensure the edges are smooth and free from slag or burrs, thus enhancing the overall product quality. |

Common Mistakes to Avoid

Incorrect Tool Selection

One of the main problems faced when thick stainless-steel sheets are cut is the use of wrong tools or cutting equipment. The use of wrong tools can lead to cuts of different depths, the machines getting worn out heavily and low-quality finishes. For example, using a plasma cutter that is not rated for thicker materials can cause slow cutting speeds and hence high costs. An expert in the industry has stated that wrongly rated or worn tools when cutting stainless steel sheets thicker than 1 inch (25.4mm) will result in a loss of accuracy by almost 40%.

Moreover, the use of wrong torch tips or consumables will also slow down the process. When using high-quality consumables designed for cutting stainless steel, there is a better chance of getting clean cuts and they are also likely to prolong the life of the equipment. It has been found out that the operators who take extra care in matching their consumable materials with the cutting parameters see their tools lasting up to 30% longer.

Neglecting Safety Measures

Neglecting safety measures when cutting with tools and dealing with heavy materials like thick stainless steel sheets can bring about a number of serious risks, such as accidents leading to physical injuries, damage to machines, and consequently, a slowdown in production. The Occupational Safety and Health Administration (OSHA) states that more than 20% of all workplace injuries happen in the manufacturing and construction sectors, with the improper use of tools being one of the main causes.

Not wearing proper PPE, which includes gloves, safety glasses, and steel-toe boots, increases the probability of accidents happening. The heat and sparks produced during cutting, particularly with plasma cutters, can cause burns and even create a fire risk. Furthermore, not using proper ventilation in enclosed areas can lead to inhalation of excessive harmful fumes, which can cause the respiratory system problems.

Reference Sources

-

Laser Cutting of Steel Sheets

- Published in: SPIE Digital Library

- Key Insights: Explores the influence of laser cutting process parameters, as well as the composition and thickness of steel sheets, on cutting performance.

- Source

-

Surface Properties of the Cut Face Obtained by Different Cutting Methods from AISI 304 Stainless Steel Materials

- Published in: Academia.edu

- Key Insights: Examines the surface properties of AISI 304 stainless steel sheets cut using various methods, providing a comparative analysis of mechanical and thermal effects.

- Source

-

Advancements in Cutting Techniques for Stainless Steel

- Published in: ResearchGate (Suggested for additional context)

- Key Insights: Discusses recent advancements in cutting techniques, including waterjet and laser cutting, and their applications in industrial settings.

- Source

Frequently Asked Questions (FAQs)

What is the best method for cutting stainless steel sheet at home or in a shop?

The finest method to cut stainless steel varies with thickness and required finish. For the thin stainless steel sheets (approximately 0.5-1mm or 16ga/0.0625″) you could get metal shears, a jigsaw comprising a fine metal-cutting blade or even a bandsaw with the bi-metal blade which would give a straight cut. For thicker 304 or alloy plates, the usage of cutoff wheel at an angle grinder, bandsaw, or CNC router with appropriate metal-cutting tooling would give better results.

Can a jigsaw cut through the stainless steel sheet and what type of blade would be employed?

Certainly, a jigsaw can slice through the stainless steel sheet provided that a premium blade for metal (bi-metal or carbide-tipped) that has a high teeth per inch count is used in order to minimize burrs. Also, the sheet should be firmly held to avoid shaking, the cut should be marked with a scriber along the line and then the cutting should be done slowly with light pressure.

What quickest method of cutting the stainless steel for the fabrication and fab shops?

The quickest cutting method in a production or metal shop environment is normally cutting by band saw or CNC for thicker materials or laser/plasma cutting for thin sheets. Metal shears or powered nibblers are also fast methods for cutting thin stainless steel. A cutoff wheel on an angle grinder or a powered shear gives speed but may compromise the surface finish.

What is the technique to cut a straight line without causing distortion or getting rough edges?

For a straight cut: the sheet must be firmly clamped to avoid flexing, the clear guideline should be scribed, an appropriate metal-cutting blade (fine TPI for jigsaw or bi-metal bandsaw) should be picked, and a slow but steady cutting feed followed. Backing material would help the sheet, lessening the burrs at the same time. Edge cleanup with a flap disc or deburring tool will yield a smooth surface finish after cutting.

Is a jigsaw a proper tool to cut 16ga or 0.8mm stainless sheet and how should it be set up?

Jigsaw is a tool that can cut metal sheets of thickness 16ga (approximately 1.5mm) and thinner such as 0.8mm provided you pick a metal blade with fine teeth and hold the sheet down with a clamp. It is advisable to use a slow blade speed, to support the workpiece, and to apply cutting lubricant if suggested. For extremely thin sheets, it may be helpful to tape the cut with masking tape to avoid scratching and chatter for a better surface finish.

Ready to Start Cutting?

With the right tools, techniques, and safety measures, cutting stainless steel sheet metal becomes a manageable and rewarding task. Whether you’re a professional fabricator or a DIY enthusiast, following these guidelines will help you achieve precise, clean cuts every time.