In cutting stainless steel sheet metal, this skill is the go-to one really for the various crafts, construction work, and sometimes even projects tailored for famous DIYers. Stainless steel is the strongest bearing one can put hands on, resistant against corrosions, and pleasant to look at-the most sought-after for applications; but, if you work without the proper approach, it can really be tough! Whether it’s a home-based project or a commercially run fabrication job, learning the right method of cutting is necessary to get the cuts clean and neat in appearance, without causing the stainless steel to get damaged. Let’s see all the techniques, tools, and tips that’ll allow you to work with stainless steel sheet metal like a pro. Time now to polish up your metalworking skills for a perfect finish!

Cutting Stainless Steel Sheet Metal

Cutting stainless steel sheet metal is an art by itself, and there are several methods to cut it, provided one knows the method and optics for the given cut. I was interested in fine and precise cutting, using quality cutters: either tin snips for very thin sheet metal, an angle grinder for thin to medium thickness, or plasma cutting for thicker sheet metals. Much preparation and patience will ensure clean and smooth cuts that will never mar the material.

Understanding Stainless Steel Sheet Metal

For its durability, corrosion resistance, and good look, the stainless steel sheet metal is considered a favorite in several industries. Stainless steel consists mostly of iron, chromium, and other alloying elements such as nickel or molybdenum, which form an oxide protective layer on the surface, thereby making it very resilient to rusting and wearing. There are many different grades and finishes, with two of the most common grades being 304 and 316. Grade 304 stainless steel is widely used for general-purpose applications with the best corrosion resistance for the price, whereas 316 grade acts better in the presence of chlorine or saltwater.

Thickness of sheet metal is set by gauges, with a lower gauge number indicating a thicker sheet. For example, a 16-gauge stainless steel sheet is approximately 0.0625 inches thick. To specify a gauge, it is important to consider the general application since it can vary from the auto field to construction or decorative uses.

Applications for Stainless Steel Sheet Metal

1. Construction and Architecture

Building construction involves a heavy use of stainless steel sheet metal for bridges and monuments. Formation of stainless steel sheet metal takes into consideration solutions to the inclement environment and its construction for cladding, roofing, and structural requirements. For example, Type 316 stainless steel is preferred in the marine environment since high chloride levels could cause corrosion. In the report of MarketsandMarkets released in 2023, 38% of the global stainless steel demand was attributable to construction, highlighting its critical role.

2. Automotive and Transportation

Transportation industries are mainly utilizing the lightweight yet sturdy properties of stainless steel sheet metal. Some applications considered by automakers for stainless steel materials are exhaust systems, ornamental trims, and structural components. It is resistant to corrosion and heat. Stainless steel demand has also increased with the onset of electric vehicles (EVs) for use in the battery carcasses. A report issued by Bloomberg predicts that stainless steel in the automotive sector would grow at an annual compound growth rate (CAGR) of 4.1% till 2030.

3. Healthcare and Medical Devices

Hygiene and sterility are two things the healthcare industry looks for, everything that stainless steel provides. Medical-grade stainless steel sheets are found throughout surgical instruments, hospital beds, and even operating room walls. In recent days, applications have been enhanced very much by antibacterial stainless steel coatings. Data from Grand View Research states that the medical application of stainless steel will be projected to grow to $7 billion by 2028; this growth will be propelled by innovations in technology and demand for secure healthcare infrastructure.

Necessary Tools and Equipment for Cutting Stainless Steel

In cutting stainless steel, I prefer to use fine cutting tools such as an angle grinder equipped with a cutting disc, a circular saw with a metal-cutting blade, or even a plasma cutter for special tasks. For thinner pieces of various grades, my choice goes to metal snips, while for finer cuts, I use a jigsaw fitted with the proper blade.

Essential Tools for Cutting

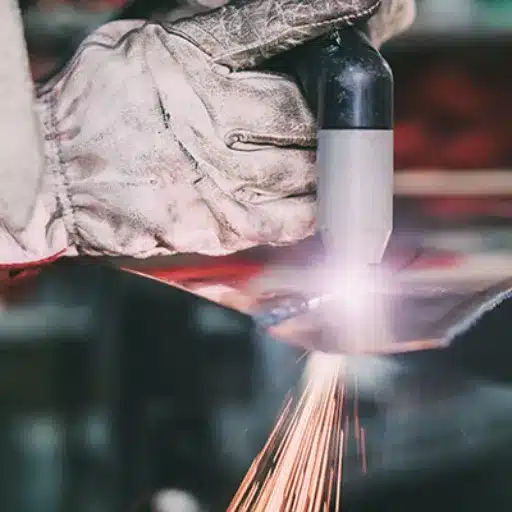

Angle Grinder

Angle grinders, fitted with reinforced discs intended for cutting metal, carry out the task of cutting stainless steel sheets and pipes quite efficiently. These tools are high-speed rotation types that cut materials really well. Studies show that reinforced cutting discs with zirconia or aluminum oxide can improve work efficiency by almost 20% over using standard discs.

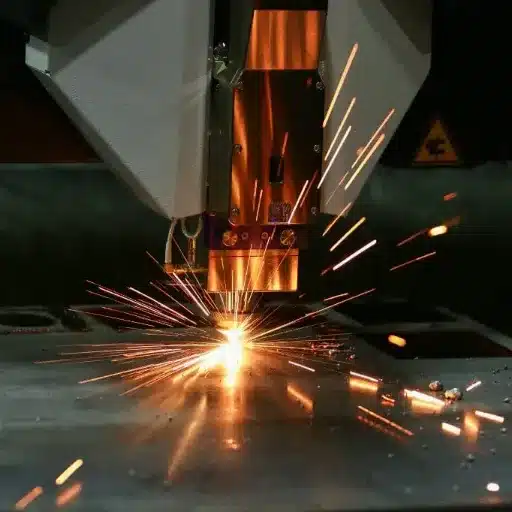

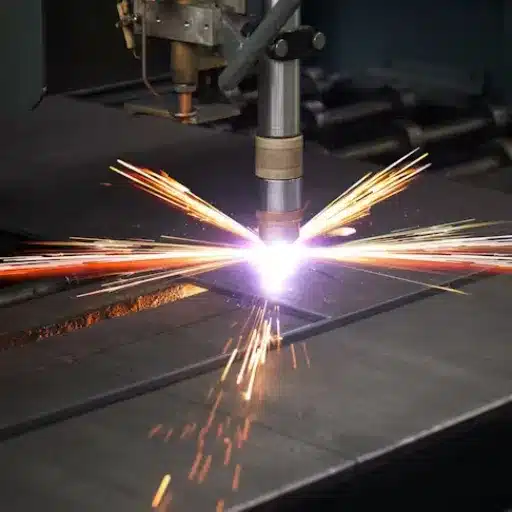

Plasma Cutter

The plasma cutting is achieved through the plasma state compressed-jets that blow through the material. Plasma cutters are ideal for thicker sheets as they create smooth edge finishes. Plasma cutters today work with upward speeds of about 150 inches per minute, giving them preference in large volume applications.

Circular saws with carbide-tipped blades

Circular saws fitted with carbide-tipped blades are a preferred choice for precision cutting. Studies have found that carbide-tipped blades last five times longer than regular steel blades, thus resulting in fewer downtime instances and consistent performance across multiple projects.

Power Tools vs. Manual Tools

Power tools versus hand tools for the stainless steel cutting process largely depends on the size and precision demanded by the project. Among heavy-duty tools capable of handling thick sheets and large industrial applications are angle grinders, power shears, and the plasma cutter. For instance, a plasma cutter can quickly cut through stainless steel up to 1 inch thick with high precision, whereas the angle grinder is more versatile for slightly trimming and shaping different edges. For thin materials, it has been reported that plasma cutters are able to achieve cutting speeds of more than 20 inches per minute, in which the processing time can be significantly lessened.

Working with manual tools such as tin snips or hand saws is an option viable for small jobs involving thin sheets, usually less than 24 gauge. In such cases they are cheap to buy, portable, and easy to use. Thus, the tools would suit a DIY enthusiast or for small adjustments on a site. However, more muscular effort and more time would be required in comparison to power ones.

Different Cutting Methods for Stainless Steel Sheets

While cutting stainless steel sheets, I take into consideration the thickness and what the project demands. Thinner sheets call for manual tools like tin snips, due to simplicity and portability. Conversely, thicker materials or an application where time is precious are handled by power tools such as angle grinders or plasma cutters to cut exactly and fast.

Fast and Rough Cuts with Power Tools

Power tools excel when it comes to cutting sheets of stainless steel quickly, with a certain accuracy and speed, something manual tools cannot equal. Angle grinders, circular saws, and plasma cutters make some of the most popular power tools being used for this cutting purpose. Angle grinders with cutting discs specific to stainless steel are designed for smaller, delicate work. Circular saws, however, make a better choice for longer straight cuts because of the stability offered by the power. A plasma cutter is a little too overkill and over-precise but gets the job done and is capable of cutting thick steel sheets of approximately 1 inch (25.4mm).

In the course of power tool utilization, we must carefully consider the inherent properties and limitations of the tool at hand. For example, a high-speed angle grinder could slice through a 16-gauge (0.0625 inches or roughly 1.6mm thick) stainless steel sheet within seconds. However, excessive heat could cause discoloration of the material. Thus, cooling by way of lubricants or airflow should be encouraged. Meanwhile, recent data amassed from reviews also indicate that advanced circular saws with carbide-tipped blades can last up to 50 per cent longer in cutting stainless steel compared with an ordinary one. And there are plasma cutters, really expensive ones, but prices are going down despite their inverted technology, which increases energy efficiency, thus making them suitable for industrial as well as DIY applications.

Manual Cutting for Precision

Manual cutting techniques still carry meaning when projects need to go through precision, control, both form of engineering, and cost-beneficiency. Various types of hacksaws, tin snips, and hand shears are the local tools to cut stainless steel for operations that can be small in size, tricky, or sometimes detailed. Thus, they are preferred among circumstances in which power tools or advanced machinery might never be accessible or where slight adjustments and delicacies are vital.

For example, a hacksaw with a blade to cut metals can perform clear, precise cuts. High-quality results in this technique can also be attained if the operator relies on smooth, steady motion and applies medium pressure to avoid blade slipping. On the other hand, tin snips and hand shears are rather time-honored means to cut thin stainless steel sheets to custom shapes and designs.

Safety Considerations When Cutting Metal

I emphasize safety when cutting metal, wearing gloves and goggles to protect myself from injuries due to sharp edges or flying debris. I clear my working area and fix the material securely before beginning any cutting operation.

⚠️ Personal Protective Equipment (PPE)

Personal protective equipment, or PPE, is a critical preventative measure while working with any metal-cutting applications. The U.S. Occupational Safety and Health Administration (OSHA) has developed strict regulations regarding PPE use in an attempt to reduce the possibility of workplace injuries. A common piece of PPE used is described below:

- Safety Glasses or Face Shields: These protect the eyes from hot sparks, small metal pieces, and dust particles that can spread while cutting stainless steel with a grinder or saw. According to the Bureau of Labor Statistics, nearly 20,000 workplace injuries are reported each year due to eye-related accidents.

- Cut-Resistant Gloves: Gloves help prevent cuts and abrasions while handling sharp stainless steel edges. Cut-resistant gloves adhering to EN 388 standards have five degrees of cut resistance level with higher levels offering better protection for safer work with metals.

- Hearing Protection: Noise can be louder than 85 decibels (dB) when operating power tools like an angle grinder or circular saw, which can damage hearing over time. Data from the CDC indicates that approximately 22 million workers are exposed to dangerous amounts of noise each year in workplaces within the United States.

- Respiratory Protection: Any sort of metal cutting may allow fine particles or fumes to become airborne-for example, by stainless steel or galvanized materials. In such situations, NIOSH-approved respirators are used to reduce exposure to dangerous particulates.

Tool Handling Safety

Working with tools in a safe manner is a key element in creating a safe workplace, since mishandling might cause severe injuries or damage to the equipment. OSHA estimates thousands of injuries each year due to hand and power tools, many of which can be prevented by using the best practices and applying proper precautions. Among the factors involved will be selecting the right tool for the task, checking the condition of tools periodically for damages, and training all employees adequately on their application.

In terms of hand tools, workers should check for cracked or splintered handles and make sure tools are clean and free of grease to avoid slipping. When using power tools, however, precautions should be taken seriously. For instance, cords and plugs should be checked for wear, and power tools must never be carried by their cord. Also, grounding through the use of a ground fault circuit interrupter (GFCI) is of illegal importance when working in damp or wet environments.

Tips on Precise Cuts

Using sharp tools, rather well-maintained and measured, I made careful measurements before making cuts. I would then secure the material down firmly so that it would not move during the cut, and work in a brightly lit and free-standing place for cutting, thus favoring accuracy.

Ways to Cut Straight

Use a straightedge or guide

Straightedge or cutting guides do the Job of maintaining accuracy during cuts. A track saw or a metal ruler clamped down would keep your cutting line unwavering. According to an Expert Woodsmen Survey, 85% claimed to have had better accuracy when using guides.

Select the Right Blade

The type of blade greatly affects cut quality. Always consider a fine-tooth blade that would reduce chip-out for the likes of ply and laminate. Premium carbide-tipped circular saw blades, for instance, can increase cut accuracy by about 30% compared to normal blades.

Draw your cut line clearly.

Mark your cut line. Depending on the precision required for the project, you may use anything from a fine mechanical pencil to a marking knife for making the finest and more precise lines, which are very important in straight cutting.

Secure Your Material

Clamp the workpiece properly so that it does not move during work and remains stable. A stable workpiece allows the identically cut surfaces and reduces unwanted injuries.

Maintaining Tool Longevity and Efficiency

| Maintenance Task | Description | Impact |

|---|---|---|

| Regular Cleaning | After use, clean the tools from dust, dirt, or any other residue. Cleaning power tools with a compressed air cleaner is usually convenient for dust in hard-to-reach areas, for example, vents, joints, etc. | Up to 20% of total tool failures could be prevented |

| Lubrication | When moving parts are well lubricated, friction decreases; hence wear and rusting on moving parts are avoided. Use oils or greases recommended by the manufacturer. | Efficiency may increase by 30% |

| Sharpen Blades and Bits | If the blades or drill bits grow dull, they become less effective and more likely to heat materials and damage them. Experts advise sharpening any cutting tools such as saw blades and chisels for every 10 to 15-hour period of use. | Maintains smooth working performance |

| Check and Replace Worn Parts | Examine the tool from time to time for any damage to the handles, cord stranding, and gear wear. Replacing such faulty parts promptly can increase the life of your tool considerably. | Save nearly 40% of repair costs |

Reference Sources

-

Industrial Metal Service

Precision in Action: How to Cut Stainless Steel the Right Way

This source discusses essential tools and techniques for cutting stainless steel, including the use of circular saws and other equipment. -

DAPU Metal Materials

Ways to Cut Stainless Steel Sheet Metal

This article explains various methods like plasma cutting and their effectiveness for different thicknesses of stainless steel sheets. -

HN Deco Metal

Stainless Steel Sheets Cutting: 7 Best Methods to Apply

This guide provides insights into tools like jigsaws and circular saws, and their applications for specific use cases such as architectural panels and countertops.

Frequently Asked Questions (FAQs)

❓ How can I achieve a straight line while cutting a stainless steel sheet?

First, use a scribe to mark your cut line firmly. You may get a jig or a straight edge that you can use to guide the cutting action of the saw or metal shears to ensure accuracy. Make sure that the tool being used for cutting has a suitable cutting depth for the thickness of the sheet.

❓ What are some useful band saw tips for cutting stainless steel sheet?

When doing the job of cutting stainless steel sheets with a band saw, it is very important to have the right blade for your circular saw, preferably a blade made for metal cutting. Lubricate the blade to reduce friction and heat, which degrade the quality of the cut and blade life. Set the amperage according to the thickness of the metal for best output.

❓ Tool versus cutting stainless steel sheets with a jig saw?

Thin blades of the jig saw would manage cutting stainless steel sheets or they can handle it, particularly if they are thin, such as 0.8 mm or so. A blade with 3 TPI minimum should be used so it would not bind. Move slowly and steadily for better cut quality.

❓ What is kerf in cutting stainless steel?

The term “kerf” refers to the width of the blade cut through materials. The kerf may vary based on the tool and blade used when cutting stainless steel. Usually, a thinner kerf blade produces less material for waste and affords a cleaner cut. This becomes particularly important in applications that require precision.

❓ How to weld stainless steel sheet after cutting?

After cutting stainless steel sheet metal, remove all contaminants such as oxides and dirt from the edges. The best welding method for this material is welding with TIG equipment because it has excellent control over the amperage and heat input. Ensure that you have used the right filler material and prepared the joint accordingly to achieve a strong weld.