About picking out the perfect metal for jewelry, comfort and safety seem to be on the same level in priority as design and style. These factors make the decision easier for someone without sensitive skin or metal allergies. However, the rest of the stainless steel jewelry population regards it as a preferred metal due to its cost-effectiveness, aesthetic appeal, and durability. However, one question is left unsaid: How can we truly assess the hypoallergenic properties of stainless steel?

This article will discuss the properties of stainless steel, its effects on sensitive skin, and how it measures up to other common jewelry metals. We’ll also look into nickel, one of the main alloying elements, and the potential risks it poses for allergic reactions. At the end of this article, we hope to provide you with ample information to justify your conclusion about stainless steel and if it is indeed the right choice for all your jewelry needs, or if some other metal would work better. Gear up to understand the real intentions behind metal jewelry and the truths of their impact on your skin!

What Makes Stainless Steel Hypoallergenic?

Stainless steel is regarded as hypoallergenic because it has low quantities of reactive metals such as nickel that can trigger skin reactions.

Surgical or 316L stainless steel is categorized as high-quality stainless steel due to its ability to safely shield sensitive skin from nickel release. Its non-porous surface does not corrode, preventing irritation, and forming a barrier that minimizes contact with allergens. Such properties make stainless steel an outstanding choice for jewelry that is skin-friendly and long-lasting.

Understanding Hypoallergenic Properties

Hypoallergenic qualities, such as those found in high-quality stainless steel, play an essential role in preventing allergic reactions for sensitive individuals. Hypoallergenic denotes the likelihood of provoking an allergic response. Components or materials that contain nickel are said to have stainless steel, especially surgical grade and 316L. Such grades of stainless steel are precisely manufactured to avoid nickel release, which poses a risk of irritative reaction. The non-porous surface adds pseudo-allergenic protection and makes the prevention of corrosion possible. This, in turn, ensures optimal protection from contact with allergens. This fact supports my trust in using stainless steel not just as a tough alloy but as a gentle and sensitive skin-friendly item.

The Role of Nickel Content in Allergies

Nickel is a common allergen that induces contact dermatitis in susceptible individuals. The quantity of nickel emitted from a particular material is basic in determining if an allergic reaction will take place. Under regulatory policies like the Council of Europe’s Nickel Directive, materials that remain in prolonged contact with skin should emit nickel at a rate not exceeding 0.5 μg/cm²/week. Surgical grade stainless steel (316L, for example) is compliant with these policies, as the nickel emissions of these steel alloys are well below the limit due to their engineered composition. Because of these properties, 316L stainless steel is perhaps the best candidate for hypoallergenic surgical implants and jewelry, medical devices, and cookware, all of which require strong materials compatible with human skin.

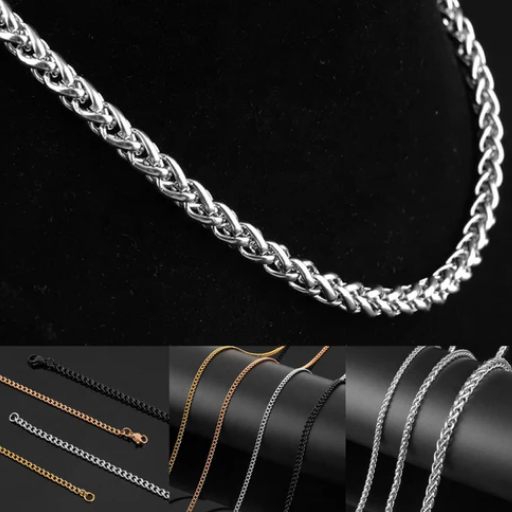

Types of Stainless Steel Used in Jewelry

For jewelry making, stainless steel is particularly attractive because of its durable nature, corrosion resistance, and hypoallergenic qualities. The more commonly used kinds of stainless steel for making jewelry are 304, 316L, and 316LVM, and they all have different characteristics:

304 Stainless Steel

- Composition: It contains almost 18% chromium and 8% nickel.

- Properties: Referred to as “18-8” stainless steel, it boasts great resistance to corrosion and oxidation in an average environment. As opposed to 316L, it is skin safer but contains more nickel, which makes it slightly less friendly towards skin.

316L Stainless Steel

- Composition: Contains 16-18% chromium, ten to fourteen percent of nickel, and around two to three percent of molybdenum.

- Properties: Because of the molybdenum, this composition is much better against corrosion, particularly with chlorides. It also has a much lower rate of nickel release at under 0.5 μg/cm²/week which classifies it as hypoallergenic. This grade is very popular for good quality jewelry.

316LVM Stainless Steel

- Composition: Like 316L, this also contains 316L silver but is made using a vacuum-melting technique.

- Properties: This helps to remove impurities, which certifies it as the highest standard. Due to its extreme purity and strong resistance against skin inflammation, it is often used in medical-grade applications and premium hypoallergenic jewelry.

Based on the grade chosen, the jewelry will last comfortably long while staying visually appealing, and with proper care for the skin.

How Can Hypoallergenic Metals Benefit Those with Sensitive Skin?

Hypoallergenic metals are the lowest risk dermatological metals as they do not readily cause skin irritation or allergic reactions. Such metals exist to be used as a substitute for skin-sensitive individuals who may be allergic to common materials such as nickel. Titanium, surgical stainless steel, or even sterling silver allow people to comfortably enjoy jewelry without the negative symptoms such as redness, itching, or other skin reactions. Moreover, such metals are long-lasting and do not tarnish, which makes them a practical choice.

Why Stainless Steel Jewelry is Preferred

I like to wear jewelry made of stainless steel. My personal preference is due to its lower cost in comparison to other metals, alongside being sturdy and non-corrosive. Jewelry crafted from stainless steel does not need frequent maintenance and keeps its shine even when worn every day. Aside from these advantages, stainless steel also does not cause allergic reactions, making it appropriate for sensitive skin, and is available in numerous stylistic patterns for any event.

Comparing 316L Stainless Steel and Other Alloys

In the course of analyzing different alloys, I observe that 316L stainless steel is exceptional due to its strength and corrosion resistance in aggressive environments prone to moisture and chemical exposure. Unlike other stainless steels, 316L contains molybdenum, which further enhances its durability along with protection against pitting and crevice corrosion. Furthermore, due to lower carbon content, it has better retention of properties during welding, thereby increasing the service life of jewelry and other applications. To my use case, it is possible to gain 316L in the desired styles while being functional and durable.

Understanding Nickel Allergies and Corrosion Resistance

Nickel allergy is a common problem for people with sensitive skin. It can lead to problems with the skin, such as rashes, redness, and inflammation. This is why 316L stainless steel is very helpful: it has a very low amount of nickel release, well below the safe levels of most humans. 316L contains around 10 – 14% nickel, but the amount of its nickel-binding elements, like molybdenum, chromium, and others, binds the nickel tightly into the alloy, binding and therefore mitigating any irritation risk. 316L also has very good corrosion resistance due to its molybdenum (2-3%) content, witch is a warding pitting and crevice corrosion, which tends to happen in salty or acidic environments. These parameters make it friendly for skin and useful for multipurpose, durable items.

What Does Hypoallergenic Mean?

Hypoallergenic describes something less likely to trigger an allergic response or reaction. Hypoallergenic materials exist within the range of possibility, reducing the chances of allergic reactions. In terms of metals, stainless steel 316L stands forth foremost due to its resistance elastically ensuring allergic reactions caused by materials such as nickel.

Defining Allergen and Hypoallergenic

An allergen can be defined as any substance capable of stimulating the immune system and subsequently causing an allergic reaction, including pollen, pet dander, and some metals like nickel. Different from allergens, hypoallergenic materials or products are specifically designed to lessen immune responses. Although hypoallergenic fabrics and metals, such as 316L stainless steel, do not remove allergens completely, they are crafted with lower levels of potential irritants, making them safer for sensitive individuals.

How Metals Are Hypoallergenic

As far as I know, metals become hypoallergenic after undergoing specific procedures that minimize the presence of common allergens. An example would be pure titanium or 316L stainless steel, which contains lower amounts of nickel, a frequent cause of allergic reactions to metals. Manufacturers tend to use active materials or cover metals with nonreactive layers that avoid triggering sensitivity for the user. While no metal is non-allergenic, these hypoallergenic options are specially formulated in such a way that they offer greater benefits for those who are prone to sensitivities.

Exploring Common Allergens in Jewelry

Certain materials that are frequently used in jewelry have a high probability of triggering allergic reactions because of known specific allergen exposure. Below is a short examination of these allergens and their corresponding technical parameters:

- Nickel

Out of all the common allergens present in jewelry, nickel is probably the most infamous.

Technical Parameter: Under European Union regulations, nickel discharge is legally bound not to exceed 0.5 µg/cm² per week (Nickel Directive).

- Copper

Having the ability to form a large number of metal alloys, copper is a skin sensitizer to some people, especially in larger amounts.

Technical Parameter: A reasonable goal would be to restrict the copper content to less than 10% in alloyed jewelry in order to stave off exacerbating sensitivity.

- Cobalt

Another common allergenic material used in alloys or coatings is cobalt.

Technical Parameter: As with the regulations applied to nickel, cobalt content is also generally constrained to nickel levels so as to decrease its release while in contact with skin.

- Lead and Cadmium

Allergy and toxicity aside, both lead and cadmium in modern jewelry are not that common, however, they do pose a potential health hazard.

Technical parameter: Various legislation like ASTM F2923-20 applies a 90 ppm limit on lead and 75 ppm on cadmium for children’s jewelry.

With these strategies paired with a certain understanding of the parameters allergenic attributes, jewelry consumer and producers can make better and safer choices while making and selecting jewelry.

Is 316L Stainless Steel the Best Choice for Steel Jewelry?

316L stainless steel certainly takes the lead as the best stainless steel for jewelry because of its exceptional stainless steel properties. It offers great corrosion and tarnishing resistance, which means it can withstand the test of time, even with everyday use. Additionally, it is hypoallergenic; thus, safe for people with skin sensitivities or metal allergies. Its polished surface is aesthetically appealing, while its high strength and hardness enable it to withstand daily use without scratching, deforming, or, say, losing its charm. These features combine to portray high quality in stainless steel jewelry, forming stainless steel’s leading alloy: 316L.

Analyzing the Properties of Stainless Steel

As per my research findings, 316L stainless steel has the best properties in underwater environments due to its exceptional outdoor corrosion resistance. Saltwater and acidic environments have no effect on its performance making it ideal for marine jewelry. Its claimed durability and low upkeep are the result of its claimed tensile strength, which lends itself to a tarnish free and rust free life. The claimed hypoallergenicity of the metal ensures safety for sensitive skin, which is the gold standard for stainless steel jewelry worn daily.

Benefits of Surgical Stainless Steel

Especially grade 316L, surgical stainless steel is famous for its distinctive merging of features, which makes it valuable in the medical field, industrial sector, and day-to-day life. Here are the key benefits:

- Corrosion Resistance

Surgical stainless steel does not corrode easily even in extreme conditions such as salt water or acidic environments. The 316L stainless steel’s ability to resist damaging pitting and cracking is enhanced by molybdenum (2-3%) in it.

- Durability and Strength

It has high tensile strength ranging from 485 MPa to 620 MPa (70,000 to 90,000 psi), which guarantees prolonged performance even under stress. Due to its hardness, this material provides excellent wear resistance while maintaining flexibility.

- Biocompatibility

Its hypoallergenic and biocompatible quality makes is one of the most important advantages. Surgical stainless steel does not pose risks when used in medical implants, body jewelry, and equipment, reducing the negative reactions tissues may give.

- Low Maintenance

Maintaining hygiene standards in medical and industrial fields is easy due to the non-porous surface of surgical stainless steel, making it easy to clean, resistant to tarnishing, and not needing special care.

- Non-Magnetic Properties (316L)

Due to its lower carbon content and an austenitic structure, 316L is typically non-magnetic unlike its lower grade counterparts. This is particularly beneficial in sensitive devices such as MRI machines as well as precise industrial tools.

Amidst these factors, the cost and the ease of procuring surgical stainless steel makes it a powerful tool. Its unique performance qualifies it as a material of choice.

The Importance of Nickel Content in 316L

Nickel is a vital element within 316L stainless steel because it affects both the mechanical and chemical properties of the alloy. Nickel possesses corrosion-resisting properties because it stabilizes the austenitic structure even in high chloride environments, thus enhancing the alloy’s corrosion resistance usually from 10-14%. Even more, nickel’s low-temperature brittleness increases the low-temperature impact resistance; thus, surgical and industrial grade 316L stainless steel can be utilized.

Key Technical Parameters for Nickel in 316L Stainless Steel:

- Nickel Content: 10-14%

- Corrosion Resistance: Excellent in chlorides (salt water, chemicals)

- Mechanical Properties: Retains ductility and toughness across a wide temperature range

- Magnetic Behavior: A nickel alloy could enhance 316L’s non-magnetic behavior.

Nickel ensures that 316L possesses demanding qualifications essential in medical, industrial, and marine applications for 316L stainless steel.

Can Wearing Stainless Steel Jewelry Cause an Allergic Reaction?

Stainless steel jewelry is mostly regarded as non-allergenic; however, stainless steel jewelry may still pose a risk to some allergy sufferers, particularly those with a sensitivity to nickel. An alloy like 316L stainless steel contains a small amount of nickel for added strength and resistance to corrosion. For the majority of the population, the nickel within the steel is said to be trapped and does not irritate the body. That said, people with a serious nickel allergy can experience some reactions such as inflammation, extreme pruritus, and rash from contact with stainless steel jewelry. Purchasing jewelry marked as ‘free of nickel’ or those made from other metals like titanium, silver, or sterling can reduce the chances of exposure and reactions.

Identifying Symptoms of Metal Allergies

Looking for hints of metal allergies, I often observe reactions like redness, itching, swelling, or even rashes in the regions where the metal comes in contact. Blisters might develop over time, along with coarse, dry skin. In my case, eliminating the offending metal is the best mitigating response, alongside the use of hypoallergenic substitutes.

How to Determine if Stainless Steel is Hypoallergenic

To establish if an alloy qualifies as hypoallergenic stainless steel, I ensure to first verify the grade or type of the alloy. Oftentimes, 316L and 304 grades are termed hypoallergenic due to their lower nickel concentrations, making skin reactions less likely. Moreover, I guarantee that the stainless steel is labeled surgical grade or nickel-free, since they are generally safer for allergic skin. Moreover, I may search for some other documents of reputable bodies that prove the alloys, or at least some parts of them, are devoid of substances allergic to the skin. If I am not completely certain, I apply a low concentration on a small area of skin before applying prolonged contact.

Safety Precautions for People with Sensitive Skin nickel-free

As medical-grade materials are more sensitive, here are the guidelines to follow when choosing materials for sensitive skin:

- Composition:

One can select surgical-grade stainless steel, also called 316L or 304 grade.

Avoid alloys with nickel due to simple allergies, as nickel is a common irritant.

- Certifications:

Check biocompatibility and safety indicators, which are ISO 10993-1 certified.

Hypoallergenic mark by known bodies must be provided on the materials.

- Skin Test:

Observe any reactions for 24 to 120 hours in the wrist area.

Applying new material to the skin will allow one to test it in small patches.

With these methods, one can address sensitive skin issues and respond to necessary skin changes. Close observation of the sensitive skin will allow one to choose the right materials effortlessly.

How is Stainless Steel Used in Medical Implants?

The application of stainless steel in medical implants is extensive owing to its strength and durability, and corrosion resistance. It has specific uses in surgical instruments, temporary implants like bone screws or plates, and in some joint prostheses. Stainless steel implants are also made of medical-grade steel 316 L, owing to its biocompatibility and durability when placed in the human body. In addition to the above, its industrial use stems from its low cost, ease of sterilization, and demand in the medical world.

The Role of Corrosion Resistance in Medical Use

For medical implants and other devices, corrosion resistance is considered one of the most important factors because it affects the lifespan of the components within the body. They can be exposed to aggressive environments due to blood and other body fluids, like saline. There are alloys of cobalt chromium, titanium, and steel 316L, which are designed and manufactured for these terms. These types of materials enhance the safety and durability of a device within the human body. Furthermore, the responsible discharge of ions from the implant, which may otherwise cause inflammation or allergies, is minimized owing to effective corrosion resistance. This reduces tissue reactions and maintains the structure of the body part. For enhancing biocompatibility while extending the lifetime of the device and improving the patient’s condition, these properties are vital.

Why 316L Stainless Steel is Preferred in Medical Implants

316L stainless steel is a widely used material in medical implants because of its mechanical properties, malleability, resistance to corrosion, and biocompatibility. Its “L” low carbon content reduces the risk of carbide precipitation, heightens its resistance to intergranular corrosion—an incredibly useful feature in body environments. Moreover, 316L stainless steel contains high tensile strength, primarily being 485 MPa, highest ductility, making it handy in complex geometry shape implantation.

Another key attribute of stainless steel 316L is its resistance towards both pitting and crevice corrosion, which is very useful in body fluids. This resistance is due to the alloying elements, which contain 16–18% of chromium, 10–14% of nickel, and 2–3% of Molybdenum. Those elements are part of the passive oxide layer, which augments the defence of passive forming materials.

Moreover, incorporates the fact that 316L stainless steel is non-magnetic and has a relatively lower modulus of elasticity around 190-200 GPa, allowing harmonious work with bone tissues. Despite these uses, stainless steel is cost effective and easy to fabricate from orthopedic screws to cardiovascular stents, making them a suitable wide range of implanted medical devices.

Ensuring Hypoallergenic Properties in Medical Applications

When hypoallergenic qualities are needed for medical purposes, there needs to be full biocompatibility and no potential for cell-mediated immune response. 316L stainless steel used for implants has a low nickel content (10-14%) and forms a stable passive chrome oxide layer, inhibiting nickel ion release and allergic reactions. Furthermore, titanium and its alloys, especially Ti-6Al-4V, are favored for their superior biocompatibility, corrosion resistance, and hypoallergenic properties because they contain no nickel.

Assessment of biocompatibility according to established standards, like ISO 10993, is one of the criteria defining the parameters for hypoallergenic materials. Other technical parameters include corrosion resistance (set at pitting potential above 600 mV for stainless steel) and low ion release (less than 0.1 ppm/year for nickel in stainless steel). Ion release can be controlled by enhancing the surface treatment through passivation, adding coatings like hydroxyapatite, or employing PVD titanium nitride. By following these with hypoallergenic criteria set limits, medical treatments can become more secure for patients with allergies or sensitivity conditions.

References

- Carolily Blog: Is Stainless Steel Jewelry Safe For Those With Metal Allergies? – Discusses the safety of hypoallergenic stainless steel for individuals with metal allergies.

- Artizan Joyeria Blog: Is Stainless Steel Hypoallergenic? – Explores the hypoallergenic nature of stainless steel, especially higher grades like 316L.

- Atolea Jewelry Blog: Is Stainless Steel Hypoallergenic? Facts You Need – Provides insights into the low allergenicity of stainless steel and its composition.

Frequently Asked Questions (FAQ)

Q: What does hypoallergenic mean in the context of metal jewelry?

A: Hypoallergenic means that a material is less likely to cause an allergic reaction. In metal jewelry, this typically refers to materials that do not easily irritate the skin, often because they contain little to no nickel, which is a common allergen.

Q: Is stainless steel considered hypoallergenic?

A: Yes, stainless steel is considered hypoallergenic because it is less likely to cause a reaction compared to other metals. However, it is important to choose the right grade, such as medical grade stainless steel, which has lower nickel content.

Q: What is hypoallergenic stainless steel?

A: Hypoallergenic stainless steel refers to types of stainless steel that are less likely to cause allergic reactions. These often include grades with lower nickel levels, such as 316 or austenitic stainless steel, which are designed to be more skin-friendly.

Q: Does stainless steel contain nickel?

A: Yes, stainless steel contains nickel, but the amount of nickel can vary depending on the grade. Grades with lower nickel content are usually considered more hypoallergenic and are preferred by people with metal allergies.

Q: Which stainless steel grade is best for people with metal allergies?

A: For people with metal allergies, medical grade stainless steel such as 316 is often recommended because it has a lower nickel content and is less likely to cause a reaction.

Q: Why is titanium often preferred over stainless steel for piercings?

A: Titanium is often preferred for piercings because it is entirely nickel-free and highly corrosion resistant, making it less likely to cause allergic reactions compared to stainless steel, which may contain nickel.

Q: How does the amount of nickel in stainless steel affect its hypoallergenic properties?

A: The amount of nickel in stainless steel affects its likelihood of causing allergic reactions. Stainless steel with lower nickel levels is less likely to cause a reaction and is considered more hypoallergenic.

Q: Are there many types of stainless steel, and how do they differ?

A: Yes, there are many types of stainless steel, each with different compositions and properties. They differ mainly in their nickel content, corrosion resistance, and whether they are austenitic or not, affecting their suitability for people with allergies.

Q: Can stainless steel tarnish, and does it affect its hypoallergenic nature?

A: Stainless steel is an alloy known for its resistance to tarnish and corrosion. This property helps maintain its hypoallergenic nature, as it doesn’t react with the skin or deteriorate over time.

Q: Why is nickel a common allergen in metal jewelry?

A: Nickel is a common allergen because it can cause skin irritation and allergic reactions in many people. When metal jewelry contains nickel, it may release nickel ions that interact with the skin, particularly in sensitive individuals or those with nickel allergies.