Get in touch with us

Leave a message

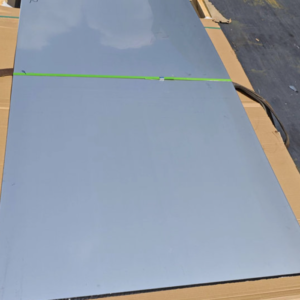

Unveil our robust Monel plate range, crafted from nickel-copper alloys for tough industrial challenges. With exceptional corrosion resistance and versatile grades, we provide tailored material options and finishes to match your needs. Our skilled team ensures top performance and cost-effectiveness across all price levels. Whether you require standard sizes or bespoke designs, we deliver expert solutions with industry-proven reliability.

Monel Plate is governed by standards like ASTM B127 and ASME SB127, ensuring quality across grades such as Monel 400 and Monel K500. These standards define properties like corrosion resistance, thickness, and finish. For instance, a Monel 400 Plate aligns with ASTM B127 for general use, while K500 offers enhanced strength per the same spec. Classifications split into nickel-copper alloys (e.g., 400, K500), with grades further distinguished by finishes like hot-rolled or polished options. Monel Plate, typically thicker than 3mm (0.118″), adheres to similar standards but is often tailored for structural applications.

Monel Plate comes in a wide range of sizes to suit diverse needs. Common dimensions include:

This flexibility ensures Monel Plate fits everything from small fabrications to large industrial builds.

Monel Plate comes in various types and finishes, each tied to specific manufacturing processes:

| Grade | Characteristics | Applications |

|---|---|---|

| Monel 400 Sheet | Excellent corrosion resistance, Good formability, High resistance to seawater and acids, Non-magnetic | Marine components (e.g., piping, fittings), Chemical processing equipment, Oil refinery parts, Heat exchangers |

| Monel K500 Plate | Enhanced strength (age-hardened), Superior corrosion resistance, High durability, Non-magnetic | Pump shafts, Marine propeller blades, Aerospace components, Oil and gas industry structures |

A: Monel Plate, typically Monel 400, excels in highly corrosive environments like seawater, outperforming stainless steel in resistance to pitting and stress corrosion cracking. However, stainless steel is often more cost-effective and stronger for general use, so the choice depends on the application.

A: Yes, Monel Plate is highly rust-proof due to its nickel-copper composition, offering excellent resistance to corrosion in marine, acidic, and alkaline environments. It forms a protective oxide layer, ensuring durability.

A: Monel Plate can be welded using methods like TIG or MIG welding with matching filler metals (e.g., Monel 60). Proper shielding with inert gas is crucial to prevent oxidation, ensuring strong, corrosion-resistant welds.

A: Monel Plate is used in marine engineering for shipbuilding, chemical processing for reactors, and oil and gas for valves and pumps. Its corrosion resistance makes it ideal for harsh environments like offshore platforms.

A: Monel Plate, such as Monel 400, has a melting point of around 1300-1350°C (2372-2462°F). It maintains its strength and corrosion resistance at elevated temperatures up to 550°C, suitable for high-heat applications.

A: Monel Plate offers superior corrosion resistance, high strength, and durability in extreme conditions. It’s also resistant to acids, alkalis, and saltwater, making it a reliable choice for marine and chemical industries.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.