Finding the right source for cold-rolled stainless steel coils can influence the durability and precision of your projects. This blog post aims to provide a comprehensive overview of the importance of choosing the right stainless steel coil supplier, showcase the best manufacturers in the industry, and discuss important features of cold rolled steel. By the end of this article, you will know what to expect from a supplier and how leading manufacturers can cater to various industrial requirements. This post will address all your queries if you are wondering either for technical details or seeking where to buy.

What is a stainless steel coil factory, and what do they produce?

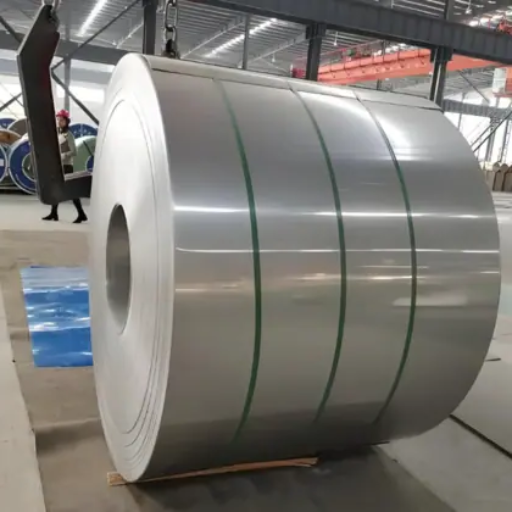

A stainless steel coil factory refers to a place that is equipped with the necessary machinery and equipment to fabricate and turn stainless steel into coils. These factories are an integral part of the manufacturing chain and provide workshops with stainless steel strips for other metal works used in the construction, automotive, aerospace, and kitchenware industries. The high durability, corrosion resistance, and versatility of stainless steel make these coils essential for pipes, panels, and machinery that require strong steel materials.

Understanding the basics of stainless steel coils

The production of stainless steel coils requires the coil’s flexibility, strength, and resistance to corrosion. Stainless steel coils possess key technical parameters, which include:

- Grades: The commonly used stone grades for stainless steel are 304 and 316, while 430 is cost-effective stainless steel with less demanding properties for specific environments. Grade 430 is widely accepted for its general-purpose features, while grades 316 provide further enhancement to corrosion resistance.

- Thickness: Coils range from 0.3mm to 6mm and are suited for applications that require certain flexibility and stiffness.

- Width: The coil width, depending on the end-use purpose, usually ranges between 600 mm and 2000 mm.

- Surface Finish: These include 2B, which is smooth and highly reflective, while BA means bright annealed. The No. 1 finish is a rough surface for industrial use. These are chosen guided by the desired end-use functional and aesthetic needs.

- Tensile Strength: Almost all stainless steel coils have a tensile strength between 515MPa and 1035MPa, making them strong enough for industrial and structural projects.

These stainless circular coils are made to fit various environmental conditions and industry requirements, making them versatile and practical for multiple high-performance applications.

Types of stainless steel grades produced in coil form

We mostly come across and use a small number of stainless steel grades produced and supplied in coil form. The first set of grades, 304 and 304L, are the most used due to their beneficial properties, which offer excellent corrosion resistance and wide application across industries and consumer products. Then comes the set of grades 316 and 316L, which provide extreme levels of corrosion resistance, particularly concerning finer marine and chloride environments. Finally, it is widely accepted due to 430’s cost-effectiveness during production and lower application requirements. These grades demonstrate how flexible stainless steel coils can be in terms of use in various industries.

Typical applications for stainless steel coils

Stainless steel is utilized in various applications due to its strength and rust resistance. Some of the most common include in construction, wherein they are used as roofing, structural pieces, and cladding; in food processing for parts and storage tanks; in the automotive industry for trims and exhaust systems; and in chemical processing, where high-temperature and corrosive resistant metals are needed. For instance, 316 and 316L coils are frequently chosen for marine and coastal locations due to their excellent resistance to chlorides. Important technical features such as tensile (for 304/316 grades, 485-620 MPa is normal) and yield strength (170-310 MPa), as well as the rate of corrosion measured by pitting resistance equivalent numbers (PREN), are always kept in mind. With their critical role in different industries, the usefulness of these coils guarantees their wide acceptance.

How is cold-rolled stainless steel coil manufactured?

Manufacturing cold-rolled stainless steel coils involves several systematic steps. First, the stainless steel slabs are converted into a rough coil through hot rolling at high temperatures. This is followed by the pickling step, which cleans the material by removing surface scales and impurities. In the cold rolling phase, the steel is cold-processed at room temperature to achieve the desired thickness and surface finish, enhancing the strength and dimensional accuracy. The coil is then subjected to annealing, descaling, and surface refinement to improve ductility. For specific applications, trimming or polishing might be necessary.

The cold rolling process is explained.

I can give a brief overview of the procedures involved in cold rolling, for which I was provided with sufficient content. The cold rolling process starts by taking a hot-rolled coil and extracting additional refinements. This begins with pickling, where surface contaminants are eliminated, and then rolling, where the material works at room temperature to increase strength and thickness. Follow with annealing rest to give the necessary flexibility, then descale the surface for a fine finish. Additional processes, such as trimming or polishing, may be incorporated based on the intended end use at the final stage. Should there be particular issues, inquiries would be welcomed.

Advantages of cold rolled steel over hot rolled steel.

Steel that has been cold-rolled possesses numerous profits compared to hot-rolled steel. First, for purposes that demand a high degree of esthetic value, they will prefer cold-rolled steel because of its surface finish and smoothness, which is better than hot-rolled due to the precision of cold rolling. Furthermore, manufacturing has greater consistency, which means better dimensional accuracy and tighter tolerances, enabling better cold-rolled steel to be produced. The strength and hardness of cold rolled steel are enhanced due to the revolving process, therefore offering better mechanical properties such as yield strength and tensile strength.

Important Indicateurs Techniques:

- Finition de surface: Lisse et uniforme, propice pour l’application de peinture ou d’un revêtement.

- Déviation dimensionelle: Au delà de ± 0,1 mm ou plus étroit, selon les spécifications.

- Tensile Strength: Cold-rolled steel has a higher tensile strength, 10-20% more than hot-rolled steel. (This number changes based on the grade and treatment.)

- Yield Strength: Cold work hardening also improves yield strength, making it superior to hot-rolled steel.

Because of these traits, cold-rolled steel is highly sought after for applications needing high precision, such as automotive components, furniture, and household appliances.

Quality Control Measures in Stainless Steel Coil Production

Proper quality control for the production of stainless steel coils is fundamental to achieving consistent, durable, and fully compliant quality. If problems do arise, it is crucial to employ the following corrective controls.

- Inspection of Raw Materials

All raw materials sent for production must be checked for their chemical composition to meet the requisite standards. Failure to do this could lead to a defective final product.

- Dimensional Accuracy Inspection

Coils undergo different production steps, and they have to be measured at each step to ensure that tolerances are maintained. These tolerances could be ±0.1 mm or even tighter. That keeps uniformity in all production batches.

- Surface Quality Inspection

The coil surface undergoes a check for defects such as scratches, dents, or any form of uneven surface finish. A uniform surface free from dents is mandatory for process paint or coating.

- Mechanical Property Inspection

Some samples from the coils are tested for tensile and yield strength, for example:

- Tensile Strength: check and expect it to meet our specifications, which could be at least 10-20% (depending on needs higher than that).

- Yield Strength: the enhancement I check for verification tends to cold work hardening levels.

- Non-destructive Testing (NDT)

These are used to check for internal flaws or differences, and they can be done without demolishing the piece. Examples include ultrasonic or eddy current testing.

- Monitoring Heat Treatment

Having precise control over processes such as annealing or any other heat treatment is key, as this is the best way to achieve desirable mechanical properties and corrosion resistance.

- Final Product Inspection

Manufacturers ensure that coils comply with the dimensional, mechanical, and surface finish requirements before they are shipped.

Addressing these measures guarantees that stainless steel coils meet various industries’ technical parameters and expectations.

What are the different grades of stainless steel coils available?

There are different grades of stainless steel coils that cater to different applications and performance aspects. Some common grades are:

- Austenitic Stainless Steels (e.g., 304, 316): These alloys are highly resistant to corrosion and are used in food processing, marine environments, and chemicals. Because of their versatility, they can be used in different applications.

- Ferritic Stainless Steels (e.g., 430): This grade is good in ductility and resistant to stress corrosion, which enables it to be used in automotive parts, home appliances, and various other equipment.

- Martensitic Stainless Steels (e.g., 410, 420): Known to have high corrosion resistance and sometimes attributed to high strength, this grade is often used in cutlery, surgical instruments, and tool manufacturing.

- Duplex Stainless Steels (e.g., 2205): This is a newer generation of stainless steel, perhaps best known for its balanced strength and resistance to corrosion. It is used especially in the oil and gas industries.

- Precipitation Hardenable stainless steels (e.g., 17-4 PH): Commonly used in the aerospace industry, energy, and industrial applications due to these alloys’ exceptional strength and hardness.

Based on the desired application, the mechanical properties, corrosion resistance, and performance differ from grade to grade.

Austenitic stainless steel coils: 304, 316, and other series

Austenitic coils of stainless steels 304 and 316 are known for their remarkable versatility, strength, and durability. Their primary constituents include chromium (16-20%) and nickel (6-14%), sometimes with the addition of molybdenum. Important aspects and specifications regarding the 304 and 316 series stainless steel coils are listed below.

Stainless Steel 304 Coils

- Chemical Composition: ~18% Chromium, ~8% Nickel

- Corrosion Resistance: It is highly oxidation, acidic, and alkaline resistant. It enables both indoor and outdoor usage, making it ideal for places where basic corrosion resistance is needed.

- Yield Strength: ~215 MPa (31,000 psi)

- Tensile Strength: ~505 MPa (73,200 psi)

- Uses: It is ideal for kitchen appliances, food processing equipment, chemical container vessels, and especially architectural works.

Stainless Steel 316 Coils

- Chemical Composition: ~16-18% Chromium, ~10-14% Nickel, ~2-3% Molybdenum

- Corrosion Resistance: Provides remarkable resistance to chloride environments and withstands salt water, making it favorable for marine and chemical applications.

- Yield Strength: ~240 MPa (34,800 psi)

- Tensile Strength: ~520 MPa (75,400 psi)

- Uses: Commonly used for marine hardware, surgical instruments, chemical processing, and industrial piping systems.

Properties of Stainless Steel Coils Austenitic Type

- Non-Magnetic Behavior: Generally adopt non-magnet behavior, although some magnetism tends to show its influence with cold working.

- Outstanding Performance at Elevated Temperatures: They perform excellently in high temperatures and can be utilized in heat exchangers and furnaces.

- High Ductility: They can be easily deformed, making it possible to fabricate complex shapes without any cracks.

All of these features, along with the availability in different sizes and surface finishes, make austenitic stainless steel coils very dependable across many industries. With added 301 and 310 grades, more benefits, such as higher strength and greater heat resistance, can be achieved.

Ferritic and Martensitic Stainless Steel Coil Options

Ferritic wrought stainless steel coils have exceptional corrosion and oxidation resistance, especially in environments with chlorides. Due to their lower nickel content, these are cheaper options that also have good thermal conductivity, making them suitable for use in automotive exhaust systems and industrial equipment.

Martensitic stainless steel coils, in contrast, are appreciated for their strength and hardness acquired through heat treatment. This makes these coils suitable for use in applications that need to endure high wear, such as turbine blades, ‘cutlery,’ and surgical instruments. Both ferritic and martensitic types provide valuable attributes according to the functional and environmental requirements that need to be fulfilled.

Choosing the proper grade for your application

To me, stainless steel coil selection begins with the application needs; corrosion resistance, strength, heat resistance, and machinability are the most important considerations. If the application requires high corrosion resistance in a marine environment, I will go with austenitic 316 due to the higher chromium and molybdenum composition. In cases where high hardness and wear resistance are required, for example, cutting tools, I would prefer martensitic grade 420 after suitable heat treatment. Ferritic grade 430 is the best economical option with moderate corrosion resistance.

Outlined below are the primary parameters that I focus on for optimal grade selection:

- Corrosion Resistance: Grades with more excellent chromium content (18%+ in 304) or chromium and molybdenum compounds (e.g., in 316 with 2-3% Mo) offer better resistance.

- Tensile Strength: This evaluates whether the material grade meets the stress requirements. For martensitic steel, this value can exceed 800 MPa.

- Operating Temperature: Confirm that the material can perform stably within specific heat ranges, such as the 870°C tolerance 316.

- Formability and Machinability: Preferred grades for shaping and welding are austenitic 304 or 316.

Meeting these requirements will enable the material to perform to my specialization’s functional and environmentally set limits.

How do I select the right stainless steel coil supplier?

Here are some points that may help you in finding the right stainless steel coil supplier for your business:

- Certifications: Check if the supplier has certified materials within the scope of international standards such as ISO or ASTM.

- Variety: Suppliers with many grades and sizes tend to accommodate customer needs efficiently.

- Trust: Inquire about the supplier’s history regarding on-time delivery and product quality.

- Guidance: Suppliers that assist with material selection and usage concerning the application are far more helpful.

- Value: Pricing should be assessed about quality to obtain the investment’s best returns.

- Eco-Friendly: Suppliers who actively recycle and minimize waste are more sustainable.

Evaluating these factors will ensure that your partner’s supplier will accomplish your project goals.

Key factors to consider when choosing a manufacturer

Before selecting a manufacturer, I ensure that their capabilities in capacity and quality standards meet my specific production requirements. To ascertain their professional trustworthiness, I also check how well-known they are in the field and their experience. While the costs are necessary, I tend to invest somewhere that ensures a balance between the price and the quality of the services. Equally, their commitment to innovation and sustainability is essential for meeting modern market and environmental needs. Such considerations will help me identify a partnership geared towards the tremendous success of my projects over longer durations.

Importance of certifications and quality standards

Maintaining competitiveness in the marketplace demands consistent delivery of superb products from manufacturers. This can be achieved by having specific certifications and standards in place. These ensure compliance with laws, safety, and other expectational requirements, building confidence among partners and clients. The necessary certification to note is ISO 9001, which focuses on quality management systems and ensures the consistency and effectiveness of processes during manufacturing. In electronics, additional compliance with RoHS, the Restriction of Hazardous Substances, ensures safe material usage, while ISO 14001 proves compliance with environmental management standards.

The necessity of CE marking or ASTM American Society for Testing and Materials greatly varies by industry and region, showing the importance of the geographic market for these standards. These also guarantee that products are safe, functional, and durable. Working with certified manufacturers enhances product quality, lowers business risks, and ensures ethical and green social responsibility for the business. Always check the certifying documents to ensure relevancy to the verification of expectations for the manufacturers during the vetting stage.

Evaluating supplier reputation and customer service

The first step in assessing a supplier’s reputation and customer service is checking online reviews and testimonials from sites I trust. In addition to online reviews, I establish the supplier’s reliability and quality of service through well-documented case studies and references. Moreover, I pay attention to how the supplier communicates with me to ascertain that it is professional and timely. This sets the foundation for how responsive they are and how potential problems can be addressed.

Examples of logistical factors include adherence to agreed lead times and tracking options. Other fundamental indicators are defect rates, < 0.5% being the norm for high-precision products. These factors, alongside observable customer service-oriented efforts, increase confidence that a supplier can be relied on to meet project and service obligations satisfactorily.

What are the various surface finishes available for stainless steel coils?

Stainless steel coils have different surface finishes for each specific application. Some of the more common ones are as follows:

- 2B Finish: A dull surface, smooth to the touch, created by cold rolling and annealing. Great for general-purpose applications.

- BA (Bright Annealed) Finish: This finish is obtained by controlling the atmosphere used to anneal the material. The result is a reflective surface suitable for decorative purposes.

- No. 4 Finish: This finish is used in kitchen equipment or architectural work and is known for its uniform brushed texture.

- No. 8 Finish: A polished surface used for decorative purposes due to its high-end appearance.

- Matte Finish: Used for surfaces that need to emit low glare.

Each of the previously listed finishes has different aesthetic and functional properties, which enable them to meet specific industry requirements.

Standard surface finish options and their characteristics

The following answers address some frequently posed questions related to surface finishes and associated parameters:

- 2B Finish

- Description: Clean, flat finish that is soft to the touch.

- Typical Roughness (Ra):0.3-0.6 µm.

- Applications: Used for industrial equipment, storage tanks, and automotive components.

- BA (Bright Annealed) Finish

- Description: Created by annealing in a controlled atmosphere, resulting in a highly reflective finish.

- Typical Roughness (Ra):< 0.1 µm.

- Applications: These are found in decorative panels and household and food appliances.

- No. 4 Finish

- Description: Primarily, a brushed finish uniform in its application.

- Typical Roughness (Ra):0.4-0.8 µm.

- Applications: Used for countertops, kitchen appliances, and elevator panels.

- No. 8 Finish

- Description: A highly polished finish akin to a mirror.

- Typical Roughness (Ra):< 0.05 µm.

- Applications: Used for fine jewelry, architectural trim, and decorative pieces.

- Matte Finish

- Description: A surface that does not reflect light and has low brilliance.

- Typical Roughness (Ra):1.0-2.0 µm, dependent on processing.

- Applications: In utility structures, industrial work locations, and parts for aerospace.

Finishes defined here have specific parameters and aesthetic properties designed to serve the needs of different industries.

Selecting the appropriate finish for your project

I take the time to assess the practical and aesthetic functionalities of the project before settling on a specific finish. In cases where hygiene and durability are paramount, such as medical and kitchen use, I prefer No. 4 finishes because they are clean and practical. The No. 8 finish is the best option for high-reflectivity decorative purposes since it has a mirror-like finish. Matte Finish is suitable for non-reflective utilitarian purposes since it is glare-free and sturdy, better suited for industrial use. In the long run, knowledge of the environment, maintenance, and end-use helps me choose.

Custom surface finish possibilities

Surface finishes can be modified on almost any level to fit specific project requirements. In my research, custom surface finishes are made possible by changing their textures, durability, and reflectivity to achieve different aesthetic and functional targets. For example, custom coating methods can be used if a particular pattern needs to be etched for better corrosion resistance. Bead blasting and electropolishing finishes can also be used to create fancy designs that improve the wear resistance of the equipment. All that is needed is a collaboration with the professionals who could custom-tailor the finish to the environmental conditions, maintenance demands, and overall aesthetics required of the application.

References

- Stainless Steel Coil Manufacturers Suppliers – StainlessSteelManufacturers.org

- Top 60 Stainless Steel Coil Manufacturers in 2025 – Ensun.io

- Stainless Steel Coil Manufacturers Suppliers – IQS Directory

Frequently Asked Questions (FAQ)

Q: What makes a stainless steel coil manufacturer stand out as a leading supplier?

A: A leading stainless steel coil manufacturer distinguishes itself through high-quality products, extensive experience, and a wide range of offerings. They should provide various types of steel, including cold rolled steel coils, and demonstrate expertise in producing corrosion-resistant and high-strength materials. Top manufacturers like AK Steel, Tata Steel, and Nippon Steel Corporation are known for their superior finished steel products and commitment to innovation.

Q: What are the main types of steel offered by top stainless steel coil manufacturers?

A: Leading manufacturers typically offer a variety of steel types, including 1. 304 stainless steel: Known for its excellent corrosion resistance and versatility 2. 316 stainless steel: Offers enhanced corrosion resistance, especially in marine environments 3. 430 stainless steel: A ferritic grade with good formability and moderate corrosion resistance 4. Cold rolled steel coils: Characterized by their smooth surface finish and dimensional accuracy 5. Carbon steel: Widely used for its strength and affordability. Each type of steel has unique properties that are suited for different applications.

Q: What are the advantages of cold-rolled steel coils?

A: Cold-rolled steel coils offer several benefits: 1. Improved surface finish 2. Tighter tolerances and dimensional accuracy 3. Increased strength due to work hardening 4. Better formability for complex shapes 5. Suitable for various applications in the automotive, construction, and appliance industries These qualities make cold-rolled steel coils a popular choice for many manufacturers and industries.

Q: How are stainless steel coils used in various industries?

A: Stainless steel coils are used in various industries for their versatility and durability. Some typical applications include: 1. Automotive: For exhaust systems and structural components 2. Construction: In roofing, cladding, and architectural features 3. Food processing: For equipment and storage tanks 4. Chemical processing: In reactors and piping systems 5. Appliances: For kitchen sinks, washing machines, and refrigerators 6. Medical equipment: In surgical instruments and implants, stainless steel’s high corrosion resistance and strength make it ideal for these diverse applications.

Q: What factors should be considered when choosing a stainless steel coil supplier?

A: When selecting a stainless steel coil supplier, consider the following factors: 1. Product quality and consistency 2. Range of steel types and grades offered 3. Production capacity and lead times 4. Technical support and expertise 5. Certifications and quality control measures 6. Pricing and payment terms 7. Reputation and customer reviews 8. Evaluating steel coil packaging and transportation capabilities will help you choose a reliable supplier that meets your specific needs.

Q: How does stainless steel perform at high temperatures?

A: Stainless steel performs exceptionally well at high temperatures due to its chromium content, which forms a protective oxide layer. This layer prevents further oxidation and corrosion, allowing the steel to maintain its structural integrity and properties. Different grades of stainless steel offer varying levels of heat resistance, with some able to withstand temperatures up to 1000°C (1832°F) or higher. This makes stainless steel ideal for applications in industries such as aerospace, power generation, and chemical processing, where materials must endure extreme heat.

Q: What are the key differences between stainless steel and carbon steel?

A: The main differences between stainless steel and carbon steel are: 1. Corrosion resistance: Stainless steel is highly corrosion-resistant due to its chromium content, while carbon steel is more prone to rust and corrosion. 2. Cost: Carbon steel is generally less expensive than stainless steel. 3. Strength: Both can be high-strength, but carbon steel typically has higher tensile strength. 4. Appearance: Stainless steel has a distinctive shiny finish, while carbon steel has a duller appearance. 5. Magnetic properties: Most carbon steels are magnetic, while only some stainless steel grades are magnetic. 6. Heat resistance: Stainless steel generally performs better at high temperatures. 7. Weldability: Carbon steel is often easier to weld than some stainless steel grades. The choice between the two depends on the specific application requirements and environmental conditions.