Stainless steel sheet fabrication is an intricate process that has eluded even the most seasoned industrial workers. The popularity of stainless steel is self-explanatory owing to its old breaking tenacity, durability, and absence of corrosion; well, these are also the reasons why stainless steel is a hard one to even shear. You can be into manufacturing or take it as a challenging recreational activity over the weekends. When it comes to precision and details, this can be achieved only with the aid of the respective devices and techniques. In this section, we discuss the tools and steps necessary for stainless steel sheet cutting. This information will help your efforts to improve this skill, from purchasing the required equipment to practicing the difficult methods of spearing and cutting out stainless steel sheets. There will be no waiting, no materials supplementation; all these tools and methods assure the best quality of work. Get ready to learn stainless steel cutting techniques!

Understanding Stainless Steel Cutting

What is Stainless Steel?

Corrosion-resistant and ductile in its state, the stainless steel remains a popular choice due to its structural simplicity, where iron and chromium are the alloying elements, and optional additions such as carbon, nickel, among many others, are also incorporated. It is quite strong, too resistant to corrosion, and easy to maintain, which is why it is used in a variety of functions. The ratio of chromium content is around 10.5% or more; the chromium acts as a barrier for the metal by forming a film and engaging the process of rusting and corrosion of the metal.

There are so many types of steel, including the kinds employed in the recycling process, thereby extending the life cycle of buildings as well as those generating power, or manufacturing boats and food processing equipment. Due to a large variety, the grades have to be designated into several broad categories, such as austenitic, ferritic, martensitic, duplex, and precipitation hardening grades. The 304th of the austenitic grades exists on every market, and covers with no approximately, around half of the stainless steel cutting practices tolerated worldwide, due to its exceptional anti-corrosive properties.

📊 Industry Insight:

An industry report conducted in 2022 says that out of the estimated global production of stainless steel, around 55 million metric tonnes is being produced every year. This thriving industry is undoubtedly a reflection of how important this metal is in the construction and other engineering sectors. It doesn’t pollute, is reusable, can tolerate extreme heat, and is not reactive; therefore, it is an environmentally friendly technology development and improvement option. Hence, there is relevance to understanding the advantages and consequences of stainless steel cutting, as there are many industries that find such particular characteristics essential.

Why Cut Stainless Steel?

Controlling the dimensions of stainless steel pieces within certain limits by means of cutting is mostly an essential stage in the process of producing particular industrial parts or modifications. Industries such as construction, automotive, aerospace, and medical equipment heavily rely on stainless steel due to its resistance against corrosion and various applications. Cutting stainless steel precisely enables manufacturers to make parts with detailed designs to improve function and performance.

The possibility of processing stainless steel with high precision has arisen due to the innovations in technologies such as laser cutting, plasma cutting, or water jet cutting. For instance, laser cutting is characterized by its accuracy and the ability to process even thin stainless steel sheets with almost no loss of material. Meanwhile, thick materials are best cut using a water jet, and that process will not heat up the material, in contrast to thermal-based methods.

🔮 Market Projection:

The global consumption of stainless steel is escalating steeply, reinforcing positive market dynamics which are poised to bring it up to 65 million metric tons towards 2030, owing to increased adoption in infrastructure and Clean energy sector activities. Successful implementation of stainless steel cutting techniques guarantees that the material can be shaped without much trouble for the emergent range of uses, and this is a good example of reuse achieved to protect the environment by cutting back on excessive use of the material. The use of advanced cutting technologies allows industries to easily unleash the full potential of stainless steel, and the purpose of such technology is to minimize costs and preserve the environment.

Common Applications of Cut Stainless Steel

Stainless steel cutting is essential for various industries because the product is strong, weather-resistant, and multi-purpose. The projected rapid development of the global stainless steel market is also postulated, considering the massive consumption in the following industries:

🏗️ Construction Industries

In all the mentioned industries, and to be precise, the construction industry, stainless steel is employed in a great amount during the construction of external walls, roofing as well as the foundation of most buildings. This is due to the fact that such components are often prone to weather conditions, and hence stainless steel is applicable in these cases. Findings indicate that construction accounts for more than half the consumption of stainless steel, cutting mainly because sustainable and longer lasting development is needed, which thrives the industry.

🚗 Transfer and Transport

Stainless steels are being used more and more in the automotive industry because this metal is commonly used to produce elements of vehicles such as the exhaust system, trims, and outside or inside parts. Additionally, since it is light in weight and resists corrosion, this makes the vehicles even more efficient and durable. Moreover, it has been indicated that in the steel automotive market, there is a growth in usage of stainless steel materials in the construction of new vehicles, with stainless steels traditional forming about up to 15% of the total car manufacturing.

⚡ Energy and Power Generation

This material is also very important, as much of the green energy would not be possible if it were not for the application of stainless materials in the manufacture of solar cells, wind stations or hydropower plants. In time, for instance, adds about constructing wind towers and such turbines, one has to engage in stainless steel cutting because of the tensile and environmental properties that such steel offers. In the energy generation sector, the application of this particular alloy would increase significantly, and by the year 2023, such a growth would facilitate its worth in the global economies.

🏥 Medical and Healthcare Equipment

Use of stainless steel is very useful in healthcare for surgical instruments, medical tools, and hospitals because such a level of hygiene is very strict, and all such materials can be sterilized very easily. In the last three years, there has been an expansion of more than 20 percent, whilst the technology has improved tremendously, and hence the use of medical-grade stainless steel is also at rise everywhere in the world.

🍽️ Food & Beverage Industry

In the food processing & packing industry, almost all of the sanitary tools and kitchen equipment are made out of stainless steel, and so are storage tanks. The volume of the industry continues to maintain an average development of 5% annually, while entering into this leadership role as far as food safety regulations are concerned.

Angeles really exemplifies what the industry of stainless steel cutting means in the present age due to the global economic learning towards revolution and conservation.

Methods for Cutting Stainless Steel

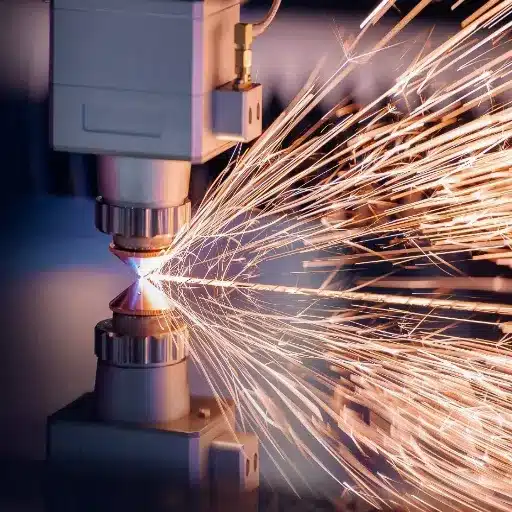

Laser Cut Stainless Steel

Laser cutting is considered one of the best tools for stainless steel cutting, because it is accurate and the direction of operation of the technology is extremely easy to maintain. With this method, all the parameters are confined to a laser beam, so warping is almost nonexistent. It also helps in achieving a neat edge, which helps in minimizing or eliminating damage or waste of the designed material, the shape of which is cut by them. These laser cuts are presently incorporating the most recent advancement in technology – the use of optics made from fiber, which is more efficient in terms of speed and less consumption of power in comparison to CO2.

📈 Growth Statistics:

At this point in time, it is established in the available literature in this field that the laser cutting equipment industry is anticipated to maintain a 9.6% growth rate over the period of 2023 to 2030. This demand exists due to the aforementioned technology that the industries of automotive, aviation, and construction are in excessive need of, which is precision metallic components. Meanwhile, none is better at cutting stainless steel than a fiber laser machine, which is able to cut up to 25 mm of steel without excessive formation of scrap.

This is because the method is best suited for accurate work with possibilities of mechanization. The method gives room for further developments and improvements within the available equipment or processes. Finally, manufacturing laser cutting can also be said to have reached a level where quick response codes, computerized laser copabilities and the stainless steel cutting sectors make it a necessary technology.

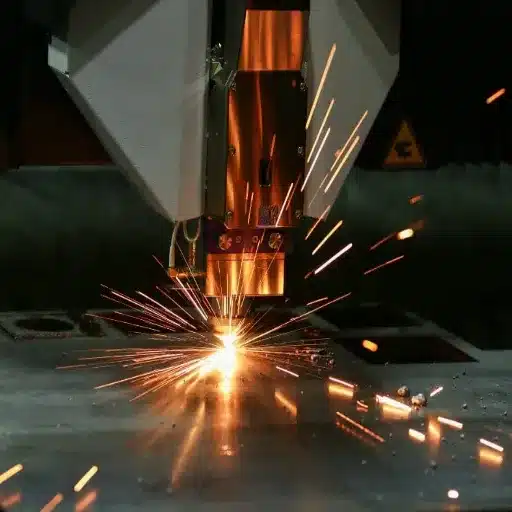

Using a Plasma Cutter

Plasma cutting is viewed as one of the most efficient methods of cutting metals and other electric conductors, such as stainless steel. In this case, however, the plasma is pushed out under a high voltage arc, which gets in contact with a jet stream of air and creates a cutting plasma that cuts into the material and heats it up, adjusting the temperature until ejection. For such materials as steel, plasma cutters are quite effectively used and, indeed, have the capability of carrying out stainless steel cutting up to around 38mm or thereabout, depending on the power of the machine, among other factors.

On the other hand, use of its modern versions, such as those with CNC capabilities, is striving to change the perceived viewpoint due to the advancements associated with plasma cutters. Research substantiates the superiority of plasma systems, mainly on thick stainless steel cutting, other than laser systems, thus meaning that plasma cutting entails and is related to heavy-duty mass production practicality. Conversely, as per market research, there has been an improvement in usage and introduction of newer components after the improvement of those through specific gases in use by approximately 20 % of the equipment. The relevance of cutting plasmia cortar is demonstrated within the framework analyzed in this paper because it has shown that plasma cutting as a technique is practical and cost-effective in most applications.

Best Practices for Circular Saw Cutting

Exercising measures like working with correct tools and equipment, appropriate skills, and moderation when dealing with the loaded saw always result in clean cuts with minimal effort. Also, the appropriate type of cutting blade must be determined before use, that is, wood, metal, or composite. For a smooth cut of wood, one will require cutting in blades with carbide tips as they can cut soft and hard wood without problem. According to a credible industry reference, the cutting depth of the blade for each cut plays a critical role in determining the quality of the cut; when there are few teeth, the cut leader will cut faster as well as rougher, and vice versa. However, for cutting stainless steel, one should use a blade that contains more teeth, as the cut will be smoother.

To cut an object properly, it is better to mark the areas that need to be cut along the cutting edge or, where required, the guide. According to the most recent recommendations from the manufacturers of such devices, their optimal use is at cutting speeds of around 3000-5800 rpm because the blades operate at a window of temperatures that minimize wear. Besides, the circular saw used must be in a serviceable condition. A dull blade leads to the generation of more heat, rough surfaces, and the worst situation is that it makes the tool be driven backwards by the user.

⚠️ Safety Alert:

To prevent accidents, you have to keep in mind that using protective gear is very important. Circular saws are mishandled in many cases, according to reports; more than 55,000 people report injuries due to manipulation every year. It is important to have such loose clothing that can get trapped in the blade removed because it can prove fatal. Wear goggles, safety gloves and ear protection. Also, plenty of repairs should be carried out, such as clearing the blade, adjusting it correctly, and checking for loose parts before using the equipment. Thinner cuts regarding stainless steel cutting, for instance, softer steels, will create a household product better.

The efficiency of your output may be enhanced by adding any of the nowadays improvements or, for instance, introducing dust collecting integrated in circular saws or guiding with a laser while cutting. Certainly, when employing such cutting techniques, they themselves contribute to better stainless steel cutting in the extreme, and thus, if elbows are present, they also help to extend machine tools.

Angle Grinder Techniques

The function of the angle grinders has diversified to grinding, cutting, and polishing of metal, tiles, and concrete, just to mention a few. To maximize efficiency and precision, each task must be performed with an appropriate disc. When it comes to cutting through tough construction materials like concrete and brick, a diamond blade is best, but for stainless steel cutting or grinding, a flap disc is more preferable.

According to the most recent report of the industrial trends analysis, the use of a single angle grinder is on the decline, as customers have come to like multi-speed models more than the rest. This allows control over Revolutions Per Minute (RPM) tuned towards a particular fragile material. For instance, relatively softer materials such as aluminum can be cut at lower speeds than those used to cut bald steels.

🔒 Safety Statistics:

Based on the results of safety tests conducted, it becomes clear why it’s utmost important to wear the correct personal protective equipment while working with angle grinders. Of the total accidents due to grinders, eye injuries were the most commonly registered around 33%. For this purpose, safety glasses, gloves and earplugs must be worn at all times. It should also be mentioned that the newer modification of the angle grinder that has the kickback prevention as well as automatic stop is improved in use because the impact of injury has been reduced over the period of years.

With these developments and considering all precautions taken, it can be said that individuals use such devices efficiently without compromising themselves or the equipment. Be it domestic projects or stainless steel cutting on sites, the right usage of physics makes a big difference.

Jigsaw Cutting for Stainless Steel

A jigsaw is an effective cutting tool that can be utilized in different ways to cut stainless steel. Nevertheless, for an accurate and smooth cut, stainless steel cutting necessitates the selection of an appropriate blade. The blades that work best for cutting stainless steel are bi-metal or carbide-tipped blades; therefore, when one has the latter blades, they are certain that the proper blade is available. Although “metal cutting” blades do not always perform at the highest levels, they are known to have some benefits, for example, greater durability and reduced wear for the teeth, as reported by some tool users and toolmakers themselves.

One should also bear in mind that not a small amount of cutting is predicated upon one’s ability to avoid, or brace oneself for, the cut. Therefore, make sure that you are securing the stainless steel plates properly so that they are firm enough for you to work on. Furthermore, the application of a cutting oil is good as it reduces the amount of contact and heat produced that damages both the blade and the other surface being cut. Nevertheless, such information as the instructions of the manufacturer or other professional tools forums may share a tip that changing the speeds of the jigsaw to a lower speed helps to make proper cuts in the material and prevents the blade while the jigsaw is in operation. However, underneath, there were obstacles that every approach had to overcome.

⚙️ Technical Specifications:

In most of the toolshops, stainless steel cutting through a jigsaw is done at a speed of about 100–200 strokes a minute, while the limit varies with the thickness of the sheet. The effort required to work on sheets that are thinner than about 16 gauge (1.5mm) is negligible, but thicker sheets will demand more effort, hence enhanced equipment. Also, wear protective eyeglasses and gloves, which are recommended by the producers to prevent injuries while working with metal and its edges.

When using a jigsaw to cut stainless steel and the appropriate measures and instruments are enacted, the operation is enhanced because both experts and home operators achieve uniform and clean finishes.

Required Tools for Cutting Stainless Steel

Essential Tools for Cutting Stainless Steel Sheet

To get a smooth and precise cut with a stainless steel sheet, it is important to use the right equipment. The tools are the obvious ones as discussed below:

🔧 Jigsaw with Bi-Metal Blades

Stainless steel cutting also employs the use of a special jigsaw fixed with durable but complying and durable blades that are capable of passing the soft metal sheets of steel. These blades are made from industrial-grade material and hence last very long as they deliver smooth, straight cuts. Most users report that the least number of teeth that is effective for cutting stainless material is 18 teeth per inch.

⚙️ Circular Saw for Cutting Metal

When cutting steel wood with circular saws, it is rare not to see diamond or carbide-tipped blades, primarily because these tips enhance performance and help cut down wastage, especially when cutting thick stainless steel sheets. There are even some available that can go up to the speeds of 3,900 RPM, such that the time taken to cut is greatly reduced, and only smooth edges remain.

🔩 Angle Grinder Type

Angle grinders, though designed for cutting, have other modification enable them to be used even in sanding or even stainless steel cutting. These blades are softer and thinner than others, allowing for precise cutting in comparison to most thick blades. It is therefore recommended that, at the very least, a 750 power angle grinder should be used.

⚡ Plasma Cutting Machine

If given in the hands of someone competent enough, then plasma cutters are the fastest and most accurate tool in stainless steel cutting. This owes to the fact that if cutting with a plasma cutter, anything above an inch of metal will present no challenge. Machines and apparatus for cutting have also changed drastically over the years, as this late model plasma machine can cut twenty inches a minute, and the cut is perfect.

✂️ Tin Snips

For instance, when dealing with small or intricate shapes in thin sheets of steel, such as stainless, tin snips can make nearly all the difference. Besides hand-bending, one may use higher-quality aviation snips in order to avoid deformations in the surface. When engraved with simple words or designs that do not require heavy machinery, such knives are useful but can be quite inhibiting in design.

Make use of the tools well enough, perform any work, such as stainless steel cutting, (considering the experience level), very well. Observe the blade and the quality of the tool in relation to the material thickness.

Comparative Analysis of Cutting Machines

There are some potential stainless steel cutting problems even before any of the cutting machines are operational. The cost of incorporating the various methods and cutting equipment also plays a significant role. Such examples include incorporating your business structure instead of registering a sole proprietorship or partnership. Metal cutting laser machines belonging to such a category as described above have been on the upward trend again because of their accuracy. These are among the precision tools that can be used to cut stainless steel with a tolerance of slightly below or above 0.005 inches. From the market research projections, the speed of laser cutters is about 20m/min. As such, this rate is crucial, especially when producing large numbers of complicated components. However, attacking elements is expensive; the acquisition cost may start from $8000 and can go far beyond 250,000 dollars, depending on the power of the machine, the particular scope of work, and other parameters.

| Cutting Method | Price Range | Maximum Thickness | Speed | Precision |

|---|---|---|---|---|

| Laser Cutters | $8,000 – $250,000+ | Up to 25mm | 20m/min | ±0.005 inches |

| Plasma Cutters | $1,200 – $15,000 | Up to 38mm | 1,500mm/min | Moderate |

| Waterjet Systems | $60,000 – $300,000 | Any thickness | Variable | Very High |

However, when it comes to plasma cutters, they are more affordable. Their estimated value is in the range of $1200-$15,000. Anything starting from half an inch or 10mm thick stainless steel can be cut, but at a speed of 1500mm/min deliberately means they can cut a lot better, more than this if required. Although more importantly, even though plasma cutters can never be as precise or discriminative as laser cutters, they are adequate for the normal type of operations.

Waterjet cutting technology is used very extensively for stainless steel cutting because one can cut through any thickness of a metal without physically touching it, hence no heat affects the material and its properties. Waterjets, on the other hand, project very high-power liquid beams, which drastically reduce the cutting times, and these systems are quite expensive in the range of 60,000 dollars to 300,000 dollars. They are used in medical device manufacturing and in aerospace engineering, where damage to the components must be avoided at all costs.

By weighing the pros and cons of these different devices, the most efficient machine can be selected for its intended use as it focuses on cost, precision, and materials to be cut for better results. For example, lazy arc welding or stainless steel cutting chairs need bigger plates than rubber-topped chairs.

Choosing the Right Blade for Stainless Steel

Stainless steel cutting can also be rendered in a more efficient way using a proper blade with tailored functionality for the reasons specified above for a considerable period. The modern stainless steel cutting blades are mostly based on high-speed steel (HSS) or tungsten carbide because these materials have high heat resistance and can withstand a lot of wear and tear. Moreover, there are now additional coatings embedded in the blades, like titanium nitride or diamond, which assist dry cutting and help increase the life of the blades as well.

💡 Pro Tip:

Tungsten carbide blade is also known to prolong the life of double-bladed razors up to ten times, and this can be a welcome option compared to what was used before. It is needful to consider teeth per inch (TPI) of different blades when cutting stainless steel as well; for example, a thin semi-permanent fill of stainless steel blade will require a blade with 14-24 teeth per inch, while thicker materials will use low for TPI blades.

In reference to the most recent data available, there are steady increases in the application of newly established concepts of plasma systems (including but not limited to cutting systems of stainless steel cutting) among clients with working compressors. This is attributable to the scientific nature of the equipment, which causes no damage to the material. Using an inappropriate blade size, providing the wrong coating, or opting for the wrong tooth pitch all these sophisticated solutions restrict the ability to cut clean, reduce productivity, and increase raw materials in construction or automotive industries.

Safety Precautions When Cutting Stainless Steel

Personal Protective Equipment (PPE)

The significance of individual protection gear in stainless steel cutting can never be overstated. Simply put, a worker may have all his/her base rights and other educational benefits made known to him/her in the event of an injury; however, this will eliminate moral panic, safety first! Such personal protective equipment mainly consists of goggles to protect the eyes from flying foreign objects, oven mitts to protect hands from cuts and scalding as a result of handling hot objects, or ear protectors bad dynastic noise if the cutting process is really loud.

⚠️ OSHA Guidelines:

Today, however, it would be difficult to wear one without facemasks or dust masks, especially bearing in mind the fact that the majority of all the materials have operation temperatures such that the process will produce a fine metallic and or ashen powder or even gases, and it has been a fact that such things cause infections of the respiratory system, as well as pose a threat of certain industrial illnesses such as metal fume fever. For example, under OSHA guidelines, the respirable crystalline silica present in stainless steel is limited in concentration to 5 µg/m³ during an 8-hour work shift.

Furthermore, dressing in protective clothing, like flame-resistant clothes, reduces the chances of incurring burn injuries from sparks or high temperatures during activities such as plasma cuts or grinding. Also, the wearing of steel-toed boots with non-slip outsoles provides additional safety in the performance of leather craft as it reduces the probability of injuries from accidental contact with sharp, dropped instruments. Following these precautionary measures makes these activities safer and aids more efficient performance of stainless steel cutting-related duties.

Safe Handling of Tools and Materials

The use, removal or starting the drilling or bruising of any other tool, the same applies to expensive materials, can only be achieved in safe and efficient working conditions. By cutting the process, and to an extent, a removal of organs that usually results in injury without following the prescribed machine operating techniques. National Safety Data (also called safety data developed by OSHA) estimates that about thirty percent of servants who are injured do not utilize these. That is why ergonomic equipment permissive of the law since it minimizes any effort, protects from bruises, especially those related to muscles.

✅ Ergonomic Benefits:

The importance of incorporating ergonomic practices, such as the use of adjustable desks or lift aids, is confirmed by the fact that these methods decrease the cases of back pain by only up to 40 percent. More so, all equipment, even if it is razor sharp, must be taken care of as it must be sharpened or oil rubbed according to need. This is because the accurate dimension helps in easy working and there is only a little of chances of an injury occurring. Training the workers and equipping them with the information about the tools and the materials they handle because proper training reduces such risks. Such procedures, when introduced within the scope of already accepted rules in the industry, alongside the health and safety regulations, increase work efficiency and the spirit of the workers.

Workplace Safety Guidelines

Safety at work will always remain an important topic, especially in companies, and this is why a pile of statistics shows how durable and salient this topic is. The Bureau of Labor Statistics’ research indicates that, in 2021, the injury cases and non-fatal illnesses of employees working in the private sector since the year stood at 2.6 million reported by employers. It is also worth noting that, based on Occupational Safety and Health data, business entities experience controllable financial losses of restrictomially $171 billion as peroril due to non-obstructive injuries caused by safety issues resulting from events like stainless steel cutting, first aid provision and treatment in some cases, and superinflation.

📊 Safety Impact Statistics:

Advanced safety measures reduce the damage levels by actualizing processes like safety surveys at intervals, maintenance of out-of-service machines, or staff instruction. For example, OSHA provided evidence to support the safety hypothesis and showed that with effective safety procedures, incident cases were reduced by at least 40%. Moreover, this section stands to gain from technology, say, wearables to check the well-being of workers or IoT sensor devices to control dangers. It is essential as it provides the relevant information for the formulation of preventative measures rather than corrective measures to prevent the situation from deteriorating.

As a result, the threat of causing an injury or harm while in the establishment is lessened, and a firm can expect to boost its effectiveness without compromising its productivity, i.e., enjoy better medical and working conditions facilitated by informed safety standards as well as the modern stainless steel cutting and enhancing protection with stated measures and available contemporary methods, benefits to the population.

Reference Sources

- Feasibility analysis and cutting process research on laser cutting

This study explores the use of high-power lasers for cutting medium-thick steel plates with optimized parameters.

Source: ScienceDirect - Optimization of machining parameters while turning stainless steel

This paper focuses on optimizing machining parameters for AISI 316 stainless steel.

Source: Nature - The machinability of stainless steel 316 L fabricated by selective laser melting

This study compares the machinability of SLMed stainless steel 316 L with traditional machining processes.

Source: ScienceDirect

Frequently Asked Questions (FAQs)

❓ What is the most effective way to cut stainless steel sheets?

Stainless steel sheet work in detail mainly depends on pa erson’s ability to know what tools to use and how to use them. This typically includes pieces of machinery like laser cutting machines, plasma cutters, or “proper” or “metal cutting” saws that cut correctly. Hold down the piece tightly and cut it in place to minimize shifting, and use lubricants to reduce the friction. Check the thickness of the stainless steel at all times and find out the proportion out of which such stainless steel cutting will be possible.

❓ What are the appropriate tools for cutting stainless steel?

The choice of tools depends on the nature of stainless steel and even how thick it is, which one will be used to cut. Shears or aviation snips can even be employed when looking to cut the relatively thinner gauge sheets of stainless steel. For thicker sheet metals, angle grinders or circular saws with metal cutting processing blades, along with other tools such as plasma cutters, would be appropriate. In terms of precision, a laser is the best option for restrictive stainless steel cutting patterns.

❓ Can stainless steel be cut with a laser cutter?

Yes, it is machined quite easily with minimal effort, as cutting of stainless steel with the aid of a laser cutter, which turns out to be one of the effective options. The laser beams allow workers to do these clean cuts for even the intricate and complex shapes or figures on a given material, without burrs. It is worthy of note that these purposes involve dedicated equipment, as, for the most part, they are meant for industrial and commercial purposes.

❓ How to avoid thermal-induced damage on stainless plate cutting?

There is also the likelihood of reducing heat damage by using water or air support cooling when cutting. In most cases, heat can be mitigated by using a metal saw at a slower speed or a laser cutting machine with cooling operations. In a situation where no cooling can be applied, lubricant comes in handy in minimising the cause of the heat buildup, which is friction resistance.

❓ Is the plasma cutting method suitable when cutting stainless steel sheet materials?

There is another way of stainless steel cutting, which is plasma cutting, which is normally for medium and thicker sheets. The process is cheap and can easily be achieved due to the speed of machining. The slag is the only negative feature of the process. However, if you prefer, laser cutting will give a more well-done cut, and water jet cutting will provide a sharp edge.

❓ What safety precautions must be taken into consideration when cutting sheet metal?

Regardless of the situation, the very first thing you should do when cutting stainless steel is to put safety first. Hand gloves, safety goggles, and ear protection are required gatekeeper items and hence, all workers must put on said items. Conduct in the open or a properly ventilated area to eliminate the possibility of fume inhalation. After that, clamp the sheet down; also, before performing any cuts, ensure to take a look at the operating instructions of the machine.