As a steel type, stainless steel forgings have become increasingly important in modern industries due to their high strength, reliability, and precision. This post will analyze the two most significant features distinguishing custom stainless steel forgings – their unmatched strength, exceptional corrosion resistance, and versatility. We will also cover how some manufacturers have distinguished themselves by investing in modern forging methods and quality control processes. Ultimately, this article will provide insight into the importance of selecting the optimal supplier tailored toward maximizing performance and quality for a customer’s application.

What Makes a Quality Stainless Steel Forging Manufacturer?

Quality stainless steel forging manufacturers offer more than just competitive pricing to stand out in the market. The top-tier providers use the pronounce-shape technique and advanced modern machinery to optimize their products’ precision and consistency. They have also implemented rigorous quality control policies where inspections and tests are done to meet industry standards and client satisfaction. Good manufacturers should also provide a higher level of customization to meet the exact requirements of their clients. Finally, these manufacturers have strong reputations for meeting deadlines, which helps create a trustable, long-lasting relationship with their clients.

Key Forging Capabilities and Equipment to Look For

While considering the equipment and capabilities of the forging shop, I focus on manufacturers with modern machinery, like a wide range of hydraulic and mechanical presses and hammers. I prioritize firms with heat treatment and machining processes because they guarantee accuracy and great strength for the parts. Moreover, I appreciate having closed-die and open-die forging for high-precision components, significant parts, and seamless rolled rings for specialty parts. These companies also maintain set standards of quality using robust inspection technologies such as ultrasonic and hardness testing. Lastly, companies that enrich the engineering design process with 3D modeling and simulation tools to assist in production and design are the ones I look for.

Evaluating Stainless Steel Alloy Expertise and Material Knowledge

When assessing Stainless Steel alloy expertise, the amalgamation of specific technical knowledge, practical knowledge, industry standards, and field innovation needs to be analyzed. Following is a summary crafted from credible material sources:

- Knowledge of Alloy Grades and Their Characteristics

An accompanying expert should be able to explain in detail the different grades of stainless steel alloys, such as 304, 316, duplex, and stainless steel grades. Alloy grades have differing characteristics and uses, which include:

- 304 Stainless Steel: Strong corrosion resistance; easily weldable; high-precisionsed in industrial kitchens, tanks, and piping.

- 316 Stainless Steel: Common in the chemical processing and marine industries due to molybdenum’s ability to enhance resistance to chlorides and hostile sea environments.

- Duplex Stainless Steel (Such as 2205): Known for strength and corrosion resistance; used for high-pressure applications and harsh chemical environments.

- Material Examination and Its Corresponding Audience Certification

Exaggerated claims of results obtained with sophisticated research techniques disqualify an individual or company from possessing true expertise. Critical aspects include:

- Testing of Hardness (using Rockwell or Brinell)

- Detection of flaws utilizing Ultrasonic Testing (UT)

- Evaluation of Chemical Composition for Grade Accuracy

Look for consistent quality identifiers such as certifications in ISO 9001 or compliance with ASTM.

- Capabilities and Versatility in their Forming Techniques

A reliable supplier should have multiple options from which to choose any of the following forming techniques:

- Precision Forging to achieve complex geometries with little material loss.

- Seamless Rolled Rings for strong circular components.

- Mechanically heat treated, such as tempered and annealed, to improve mechanical properties.

- Corrosion Resistance and Design Optimization

It is essential to have a suggested materials and coating solution due to environmental conditions such as chlorides, acids, or extreme temperatures. Provided stress and corrosion analysis predictive simulation tools to prove quality further.

After considering these technical aspects and their relation to the gaps in your industry, you can find experts in stainless steel who pay attention to detail, are creative, and offer bespoke services.

Importance of Machine Capacity and Secondary Operations

I value their available machine capacity and ability to perform secondary operations during the first stages of building supplier partnerships. Based on my experience, I believe that evaluating machine capacity guarantees the production process will produce the necessary amount of products without wasting time and resources. Similarly, the availability of secondary operations, including but not limited to welding, polishing, and finishing processes, contribute to efficiency in production flow control. This minimizes outsourcing and facilitates quality control, making the processes more economical and dependable. These contribute immensely towards achieving positive and productive results from the manufacturing process.

How Does the Stainless Steel Forging Process Work?

Warm up the stainless steel to a temperature that stays solid but also becomes malleable. Once the stainless steel is heated, it is hammered, pressed, or forcibly shaped into specific molds. This process makes the steel’s internal grain structure more orderly, which improves its strength, durability, and ability to withstand being worn down or corroded. Once the steel is shaped, it is cooled down and cleaned. After this, the part is worked on until it has the correct dimensions, surface quality, and other mechanical properties. Such methods ensure that the components meet the required quality standards and perform well for different industries.

Open Die Forging vs. Closed Die Forging Methods

Open-die forging and closed-die forging are the two primary techniques for metal shaping. Each technique serves a different purpose and requires different requirements.

- Open Die Forging:

- Process: Materials are reshaped when metal is compressed between flat and contoured dies that do not enclose the material entirely. Open die forging is best suited for custom components and large parts because the operator exercises more control over the shaping process.

- Applications: Preferred for essential or more extensive components, including shafts, cylinders, and disks.

- Advantages: More flexibility in part size, lower tooling costs, and improved grain because of constancy in deformation.

- Limitations: It requires skilled operators and additional machining to achieve exact dimensions.

- Technical Parameters:

- Forging temperature range: Steel 2,000°F to 2,300°F (1,093°C to 1,260°C).

- Best suited for: Parts with a maximum weight of 150 tons.

- Closed Die Forging (or Impression Die Forging)

- Process: Metal is inserted into a die cavity whose shape corresponds to the desired part. Compression is applied to the metal to fill the cavity.

- Applications: Well-suited for the economical mass manufacture of intricately detailed parts like gears, crankshafts, connecting rods, etc.

- Advantages: Excellent volume production capability, high precision, and low post machining.

- Limitations: Increased cost of tooling and smaller pieces categorized compared to open die forging.

- Technical Parameters:

- The steel forging temperature range is 2,000°F to 2,300°F (1,093°C to 1,260°C), which is identical to open die forging.

- Parts up to 25 kilograms (55 pounds) are usually handled best.

The choice of using open-die versus closed-die forging will depend on the size, shape, and quantity of the component, as well as cost and other application requirements.

Heat Treatment and Its Impact on Forged Stainless Steel

Components forged from stainless steel undergo a heat treatment to improve their properties. With reasonable control of processes like tempering, annealing, and quenching, the hardness, strength, and ability to resist corrosion of the material can be significantly increased. Furthermore, heat treatment helps to relieve internal stresses introduced by forging, ensuring better dimensional stability and performance. The makeup of the alloy blend, along with the component’s purpose, determines the specific heat treatment process needed, allowing the ability to meet different industrial requirements effectively.

The Advantages of Forging Over Welding or Casting

Forging features numerous advantages over welding or casting processes, such as the components’ technical functionality and quality. To start, forged components undergo a deformation process that improves their strength and toughness due to the grain structure. This is useful for applications that undergo a lot of stress and require durability. Also, forgings provide better structural integrity than castings, as they help eliminate defects such as porosity and shrinkage. Moreover, structural integrity is also improved by reducing the fatigue resistance of the forged components compared to the welded components, which act as stress concentrators.

When measuring other technical parameters, forged components greatly outshine the casted and welded parts regarding tensile strength, impact resistance, and elongation. Just to name a few:

- Tensile Strength: Forged parts can achieve tensile strengths ranging from 300 to 800 MPa, depending on the material and process.

- Impact Resistance: Forging enhances impact energy absorption of components, exceeding 20 Joules for critical applications.

- Dimensional Accuracy: Forgings can achieve close tolerance high precision (±0.3 mm), requiring less machining.

Forging is best suited for critical aerospace, automotive, and energy applications, where performance and reliability are of utmost importance, which is why these attributes are crucial.

Which Stainless Steel Grades Are Best for Forging?

The most suitable options for forging stainless steel are those with a more or less equal balance among strength, resistance to corrosion, and ease of working. I believe 304 and 316 stainless steels are some of the best options due to their versatility and superior corrosion resistance, making them widely used in several industries. For applications requiring greater strength and hardness, 410 or 420 stainless steels are also suitable as they are more durable and have relatively good corrosion resistance. In addition, duplex stainless steels are used in critical environments due to their exceptional strength and resistance to stress corrosion cracking. Ultimately, the application’s specific needs dictate the decision on the grade to use.

304 Stainless Steel and Other Austenitic Stainless Steel Options

304 stainless steel belongs to the highly utilized austenitic stainless steel class due to its excellent corrosion resistance, formability, and versatility. It is common in almost every industry to fabricate food processing equipment, chemical containers, and architectural features. Marine and chemical applications are better served by other austenitics, such as 316 stainless steel, which has superior resistance to chloride and hostile environments. The strongest characteristic of austenitic stainless steel is its nonmagnetic, high-toughness, and highly adaptable properties to different environments. Different grades are selected based on the project scope and requirements.

Duplex Stainless Steel Forgings for Enhanced Corrosion Resistance

Forged Parts in Duplex Stainless Steel are ideal for applications where structural integrity and resistance to corrosive damage are pivotal. Forged duplex grades utilize the most beneficial features of both austenitic and ferritic stainless steels. This enables them to withstand stress corrosion cracking, pitting, and crevice corrosion while maintaining high mechanical strength. The properties make them useful for complex industries, including oil and gas, chemical processing, and marine environments.

Primary Technical Specifications:

- Corrosion Resistance: Due to a balanced microstructure, they also exhibit exceptional chloride stress corrosion cracking and localized corrosion resistance.

- Operating Temperature Range: Most applications are practical in a temperature range of -50°C (-58°F) and 300°C (572°F)

- Yield Strength: For duplex grades, the yield strength approaches 450-550 MPa, nearly two times greater than that of austenitic stainless steel.

- Composition: Usually composed of 22-25% chromium, 3-5% molybdenum, and 4-7% nickel, along with nitrogen for enhanced pitting resistance.

Matching the material properties with the environmental and mechanical stresses that the project will experience ensures optimal performance and maximum lifespan in the case of duplex stainless steel forgings.

Custom Alloys and Their Specific Applications

Custom alloys serve industries across the globe due to their specialized compositions intended to address specific performance objectives. Such alloys are distinct due to their elemental composition, allowing for superior corrosion resistance, increased mechanical stability, and enhanced thermal stability. The following elaborates on the alloys alongside their applications, including their pertinent technical features:

- Super Duplex Stainless Steel (e.g., UNS S32750, UNS S32760)

- Application: Oil and gas offshore platforms, chemical processing, and desalination plants.

- Key Properties: Chloride-induced stress corrosion and exceptional fatigue resistance; yield strength > 550 MPa (typical).

- Temperature Range: -50°C (-58°F) to 250°C (482°F).

- Nickel-Based Alloys (e.g., Alloy 625, Alloy 718)

- Applications: Aerospace, marine engineering, and pollution management systems.

- Key Properties: Withstand oxidation and scaling; mechanical strength remains constant at > 980C/1796F.

- Notable Features: These alloys stand out and are regarded as structurally stable due to their 50-60% nickel and 20-23% chromium; adding molybdenum and niobium increases structural stability.

- Titanium Alloys (e.g., Grade 5 Ti-6Al-4V, Grade 2 Titanium)

- Application: Biomedical implants, automotive and aerospace frames, and marine parts.

- Key Properties: Outstanding ratio of strength and weight; outstanding biocompatibility and resistance towards corrosion in seawater environments.

- Temperature Range: Cryogenic conditions to 400°C (752°F).

- Copper Alloys (e.g., C71500 Copper Nickel, Bronze Alloys)

- Uses: Desalination units, shipbuilding (hull cladding), connectors.

- Other Characteristics: Biofouling and seawater corrosion resistant, excels in providing thermal and electrical conductivity.

- Chemical Composition: Copper alloys typically comprise 70 to 90 percent copper with sub-ordinate quantities of nickel, iron, and manganese.

To achieve optimum performance, the custom alloys selected for purpose-designed projects must consider the operating environment, level of mechanical loading, and longevity. This mitigates risks such as corrosion and premature wear. Always consult technical specifications and certified datasheets for detailed guidance.

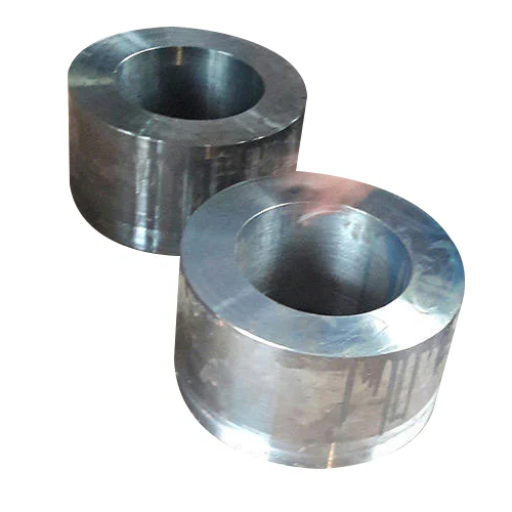

What Types of Products Can Be Made Through Stainless Steel Forging?

Stainless steel forging is one of the processes that enables the production of a wide variety of products used in different sectors. A good number rest on the automotive industry, such as components such as gears, shafts, engine parts, industrial tools, valves, and flanges. Due to its strength, durability, and remarkable corrosion resistance, it is also employed in manufacturing aerospace parts, medical instruments, and even kitchen pots and pans. The effectiveness of stainless steel forging lends itself to standard and custom-designed structures.

Forged Stainless Steel Shafts and Discs

For centuries, stainless steel forged shafts and discs have been used in myriad industries due to their high tensile strength, toughness, resistance to corrosion, and unmatched durability. Their use in power transmission, marine drives, and turbine applications delivers high-efficiency performance under enormous stress and torque. Discs are also widely used in pipelines, heavy-duty machinery, and flange connections. The forging process optimally improves the shafts and discs’ mechanical strength by refining the granule structure of the metal components, strengthening the shaft’s and disc’s structural integrity. Furthermore, forged stainless steel products are easily adaptable to specific industrial requirements in shape, size, and performance, which adds to their versatility.

Custom Forged Components for Industrial Applications

Custom-forged components are critical in industrial applications due to their durability, strength, and adaptability. Below are concise answers addressing the importance and technical aspects:

- Why are custom-forgedCustom-forged components significant?

Custom-forged components ensure precision and reliability in demanding industrial environments. Their refined grain structure and tailored design enhanced mechanical properties such as tensile strength, impact resistance, and fatigue endurance.

- What technical parameters should be considered?

When designing custom-forged components, the following parameters are critical and should be tailored to the application requirements:

- Material Selection: Common options include stainless steel, alloy steel, carbon steel, and titanium, chosen based on the operating environment.

- Mechanical Properties:

- Tensile Strength: Typically ranges from 400 MPa to 1,200 MPa, depending on the alloy used.

- Hardness (Brinell): From HB 150 to HB 450 for various applications.

- Impact Resistance (Charpy V-notch): Values between 20 J to 60 J.

- Dimensions and Tolerances: Customizable to meet specific size and shape specifications with tight tolerances (e.g., ±0.01 in critical areas).

- Operating Conditions: Depending on the material and application, components can be designed to withstand temperatures from -40°F to 1,200°F.

- What industries benefit from custom forging?

Custom forged components are widely used in industries such as oil and gas, aerospace, automotive, and heavy machinery, highlighting their versatility and adaptability in meeting rigorous demands.

Custom-forged components ensure superior performance and reliability across various industrial sectors by tailoring the design and composition to meet technical demands.

Near Net Shape Forgings and Cost Benefits

NNSF, or ‘near net shape forging,’ is a form of net shape forging that requires very little—if not no—finishing or machining after the forging is done. Because virtually no waste is produced, time spent trimming surplus materials is reduced, and production efficiency increases, thus benefiting a variety of industries. Unlike traditional forging equipment and methods, near-net shape forging delivers parts that closely align with the final design specifications, significantly cutting production costs.

Key Benefits of Near Net Shape Forging:

- Material Savings: The amount of wasted material is drastically reduced, especially for costly alloys such as titanium or stainless steel that are frequently in use.

- Lower Machining Costs: Since most machining is eliminated, energy and labor costs drop. Only enough finishing is required to make the part meet the provided tolerances.

- Improved Production Efficiency: Streamlining processes leads to faster production turnarounds, and manufacturers can begin working on high-volume orders.

- Design Flexibility: The process can incorporate sophisticated shapes and modifications, critical for niche industries like aerospace and automotive.

Specifications:

The following parameters are typically optimized for practical near-net shape forging:

- Choice of Material: Options typically include aluminum alloys, carbon steel, stainless steel, and titanium due to their ability to retain strength while being forged under high pressure.

- Loss of Form Tolerances Standards: These components have a range of tolerances of ±0.5mm based on idiosyncratic.

- Surface finish: An achievable finish ranging from 3.2 to 6.3 micrometers reduces the need for secondary finishing processes.

- Forge Temperature: Controlled forge temperatures ranging between 1200 degrees Fahrenheit and 2400 degrees Fahrenheit (650 degrees Celsius to 1315 degrees Celsius), depending on the material, are critical to optimal material flow and its mechanical properties.

- Die Design: The geometry of the parts requires high-accuracy dies for precise detail.

Compared to other types of forging, the near-net shape allows particular industries to save much more on material, reduce production time, meet quality standards, and minimize adverse environmental effects.

How to Choose the Right Forging Supplier for Your Project?

To pick the right forging supplier, essential factors must be checked to maintain the required quality, rate, and efficiency. To get started, verify the supplier’s prior experience with forging parts and their required materials and designs. Furthermore, double-check their credentials and compliance with industry standards to ensure quality. Review their production capabilities regarding their equipment and capacity to determine if their numbers meet your preferred volumes and timelines. Moreover, assess their level of customer relations and communication for proper collaboration. In the end, evaluate their pricing and potential value, such as added services like design support or post-forging steps, to assist in pinpointing the right choice for the project.

Evaluating a Forging Company’s Quality Control Standards

While looking deeper into the quality control standards of a forging company, I would first check with their available industry-standard certification; for instance, ISO 9001 is proof of commitment to quality management. I would check how well the materials were being inspected, from the material being tested to the accuracy of the dimensions being checked and all documentation being tracked during production. Finally, I would check what corrective measures were implemented for defect control and maintaining consistent quality, such as statistical process control or non-destructive testing approaches. This method guarantees that I have chosen a supplier to provide adequate forged components to any supplied design.

Benefits of Working with a USA-Based Forging Manufacturer

There are a lot of benefits that come along with selecting a forging manufacturer based in the USA, such as improving your processes. Such benefits include the following:

- Quality Standards

Forging manufacturers in the USA have rigorous quality requirements and certifications like ISO 9001 and AS9100 for aerospace and API certifications for the energy industry. These guarantees are beneficial for ensuring that high-quality forged parts are manufactured consistently. Robust quality control systems, including material testing, dimensional inspections, and non-destructive tests such as ultrasonic and magnetic particle testing back such pieces.

- Reliable Communication For Shorter Lead Times

The primary advantage of working with a manufacturer closer to your operations base is the reduced shipping distances. This lessens logistical challenges, resulting in shorter lead times and more accurate delivery timelines. Additionally, effective collaboration can be achieved due to proximity, which makes communication to resolve design issues, production problems, or quality issues much simpler.

- Labor and Environmental Compliance

Partnering with manufacturers based in the USA makes focusing on sustainability and responsible sourcing for components easier. Such manufacturers comply with local regulations surrounding the environment and labor.

- Technology adoption

Many U.S. forging companies use modern technologies like computer-aided design (CAD), manufacturing (CAM), and sophisticated heat treatment methods. These technologies significantly improve the precision needed to accomplish intricate geometric shapes, material functionalities, and adaptations to complex engineering needs.

- Tracking and Recording

Dependable U.S. suppliers offer good tracing and recording systems like mill test reports (MTRs), chemical constituents, and mechanical attributes showing compliant industry-specific proofs. As an example:

- The tensile strength for carbon steel forgings is pretty standard at 70,000 psi, but alloy steel can go a lot higher, reaching 150,000 psi.

- Depending on client usage, the hardness is expressed in Brinell (HB) or Rockwell (HRC).

- Complex and Tailored Parts Support

With several years of experience, U.S. forging manufacturers are usually very good at creating custom parts for high-end applications like aerospace, automotive, oil, gas, and defense contracting. They provide precise solutions specific to defined operational and performance requirements.

Working with U.S. forging manufacturers ensures high-quality and reliable components and a dependable partner to meet the demands of customers’ projects.

Request a Quote Process and What Information to Provide

Simply reach out through our website or give us a call to get started on a quote. And share as much information as possible about your project, such as the type and material of the part, style, size, tolerances, quantity, and if there are any certifications or standards necessary. To give us accuracy, if there are any drawings or technical designs available, please share them. As soon as we have your information, we’ll analyze what you need and get back to you with a tailored quote in no time. This way, we ensure your needs are met in a timely fashion.

What Are the Advantages of Forged Stainless Steel Over Other Materials?

Unlike other materials, forged stainless steel has several benefits, making it the material of choice for different industries. It gives remarkable strength and durability, helping the components to endure maximum stress and extreme conditions. The forging processes increase the strength of the material and decrease the chances of internal defects like porosity. Stainless steel also has great corrosion-resistant properties, which are effective when dealing with aggressive environments. It is also highly versatile and can be easily tailored to unique specifications. All in all, forged stainless steel will outlast other materials and provide better value, lower cost, and higher performance.

Superior Corrosion Resistance in Harsh Environments

Stainless steel has outstanding corrosion resistance in harsh conditions due to the alloying elements that it primarily consists of, such as chromium, nickel, and molybdenum. The element chromium, which is included at levels of greater than 10.5%, forms a passive oxide crust on the metal surface, which averts rust and decay. To achieve even better performance in very corrosive environments, 316-grade stainless steel is often used because it has 2-3% molybdenum, which improves resistance to pitting and saltwater further. These features make stainless steel particularly useful in manufacturing marine equipment, chemical processing, and extreme industrial usage where other materials fail.

Enhanced Mechanical Properties Through the Forging Process

Stainless steel forgings have enhanced corrosion resistance, attributed to improved strength, toughness, and fatigue resistance. With forging, the steel’s grain structure will follow the component’s shape, giving the product optimal strength and durability. Other essential features of the process include temperature (for stainless steels, the typical forging temperature is between 1900-2300°F), constant strain rate, and cooling temperature to reduce residual stresses. Fulfilling these conditions ensures that forged components attain desirable impact toughness and excellent tensile strength, which makes them ideal for critical parts in the aerospace, automotive, and heavy machinery industries.

Long-Term Cost Benefits of Choosing Forged Stainless Steel Products

Due to their sustained durability, operational efficiency, and minimal upkeep, forged stainless steel goods provide enormous cost savings over long periods. The components fabricated through forging have a longer fatigue life and circumferential resistance, resulting in less frequent replacements. Moreover, the consistency of the forging process eliminates a wide range of defects and guarantees dependable operation during extreme applications.

In terms of technical aspects, the primary drivers of the savings is a result of the following reasons:

- Forged stainless steel’s resistance to harsher environments is credited to its tensile strengths, which range from 585 MPa to greater than 1000 MPa, depending on the grade.

- Most forged stainless steels have lower maintenance costs because they have 10.5% to 18% chromium content, which allows them to rust and wear down significantly less. Heat treatments can further improve these features.

- Forging improves fatigue properties by aligning the material’s grain structure, enabling it to endure repetitive loads for extended periods.

- The reduced risk of breakdown due to maintenance of toughness on the forged components leads to lower repair or replacement expenses and, thus, reduced downtime.

Handpicked forged stainless steel parts can prove costly in the beginning. However, they are undoubtedly the most cost-efficient over a more extended period, particularly for superior-quality applications and products.

References

- GL Forge – Stainless Steel Forgings

- ThomasNet – Stainless Steel Forgings Suppliers

- IQS Directory – Stainless Steel Forgings Manufacturers and Companies

Frequently Asked Questions (FAQ)

Q: What are the key advantages of stainless steel forging compared to other manufacturing methods?

A: Stainless steel forging offers several significant advantages over casting or machining. The forging process creates a superior grain flow that enhances toughness and strength. Forged stainless steel parts exhibit better mechanical properties, improved resistance to corrosion, excellent heat resistance, and remarkable durability. The process also creates a protective oxide layer that further enhances the corrosion resistance of stainless steel. Additionally, forgings typically have lower lifetime costs due to their longer service life, even in demanding environments where a standard carbon steel component would quickly deteriorate.

Q: Can you explain the metal forging process of stainless steel components?

A: The metal forging process for stainless steel begins with heating a billet or bar to its optimal forging temperature. The heated material is then shaped using controlled pressure, either through an open die forging process or the closed die forging process, depending on the complexity and specifications of the final product. This deformation aligns the material’s grain structure, significantly improving stainless steel components’ properties. After initial forming, the forged stainless steel alloy undergoes heat treatment to enhance specific properties, followed by finishing operations such as machining, grinding, or polishing to achieve the dimensional accuracy and surface quality required for forged products.

Q: What types of forged stainless steel alloy materials do quality manufacturers typically work with?

A: Quality stainless steel forging manufacturers typically work with a wide range of alloys, including austenitic grades (304, 316, 321), martensitic grades (410, 416, 420), precipitation-hardening grades (17-4PH, 15-5PH), and duplex stainless steels (2205, 2507). Each forged stainless steel alloy offers different corrosion resistance, strength, and heat resistance combinations. High-performance alloys that combine excellent toughness with resistance to corrosive environments are essential for specialized applications like forged stainless steel fluid ends in the oil and gas industry. Reputable forging companies can recommend the optimal alloy based on the specific application requirements.

Q: What are everyday forged products made from stainless steel?

A: Common forged products manufactured from stainless steel include valve bodies, flanges, fittings, pump components, forged stainless steel fluid ends, shafts, fasteners, and various custom components. These forged stainless steel parts are widely used across industries, including oil and gas, petrochemical, power generation, marine, food processing, pharmaceutical, and aerospace. The precision forging process creates components with superior structural integrity and consistent properties throughout, making them ideal for critical applications where failure is not an option. Forged products typically outperform cast or machined alternatives in challenging environments where strength, corrosion resistance, and durability are essential.

Q: What comprehensive forging services should I expect from a top manufacturer?

A: A top forging company should offer comprehensive services, including design assistance, material selection guidance, prototype development, precision forging, heat treatment, machining, testing, and quality certification. The best manufacturers provide engineering support to optimize designs for the forging process, reducing costs and improving performance. They should have expertise in open-die forging and closed-die forgings made to precise specifications. Many leading suppliers offer inventory management solutions and can work with various lead times depending on your requirements. Look for a manufacturer who provides detailed documentation, maintains strict quality control standards, and is willing to collaborate closely on custom applications.

Q: How do I select the right stainless steel forged parts supplier?

A: When selecting a supplier for stainless steel forged parts, evaluate their technical capabilities, quality certifications, equipment capacity, and industry experience. Check if they offer the specific type of forging your application requires. Request material test reports and ask about their quality control processes. Review their track record with similar projects and their ability to meet delivery commitments. Consider manufacturers made in the USA if domestic sourcing is essential for your supply chain. A reputable forge produces consistent quality and stands behind its work. Don’t hesitate to contact us for samples or a plant tour when deciding. The right supplier should understand your stainless steel forging needs and provide appropriate solutions.

Q: What quality control measures ensure the reliability of stainless steel forged parts?

A: Quality control for stainless steel forged parts typically involves multiple inspection stages throughout manufacturing. This includes material verification before forging, dimensional checks during production, and comprehensive testing afterward. Reputable manufacturers perform mechanical testing (tensile, impact, hardness), chemical analysis, non-destructive examinations (ultrasonic, magnetic particle, dye penetrant), and microstructure evaluation. These tests verify that forgings resist failure under service conditions and meet all specified requirements. Companies like Great Lakes Forge implement stringent quality management systems certified to industry standards such as ISO 9001. Documentation traceability from raw material to finished product ensures accountability and verifies that all forged components meet or exceed customer specifications.

Q: How do stainless steel forging needs differ across industries?

A: Stainless steel forging needs vary significantly across industries based on application requirements. The oil and gas sector typically requires significant, heavy-duty components with excellent corrosion resistance and high-pressure capabilities, such as forged stainless steel fluid ends. The food and pharmaceutical industries prioritize sanitary properties and specific surface finishes that prevent bacterial growth. Aerospace applications demand precision forging with extremely tight tolerances and superior mechanical properties. Marine applications require components that can withstand saltwater exposure, while chemical processing industries need forgings that resist highly corrosive environments. Each sector has specific certification requirements, and a quality forging manufacturer will understand these differences, helping customers select the appropriate stainless steel grade and forging process for their particular application.

Q: What are the advantages of open-die forgings made by quality manufacturers?

A: Open die forgings made by quality manufacturers offer several distinct advantages. This process is ideal for producing significant or unique components with superior grain structure and mechanical properties. Open-die forging allows for greater production size and shape flexibility compared to closed-die methods. It’s particularly well-suited for low-volume production runs or custom parts with varying dimensions. The forging process significantly improves material toughness while reducing internal defects. Quality manufacturers ensure properly controlled deformation during forging, enhancing the material’s fatigue and stress resistance. Open die forgings can be produced with shorter lead times than closed die forgings in many cases, and the process allows for the production of near-net shapes that require less machining, reducing overall costs while maintaining excellent structural integrity.

Q: What benefits come from working with a forging company made in the USA?

A: Working with a forging company made in the USA offers several strategic advantages, including shorter and more reliable supply chains, consistent quality standards, strong intellectual property protection, and easier communication. American manufacturers like Great Lakes Forge typically adhere to rigorous quality control standards and environmental regulations. Domestic production eliminates international shipping complexities, customs delays, and currency fluctuations, often resulting in more predictable lead times. On-site visits for quality audits or technical discussions are much simpler with a USA-based supplier. Additionally, many industries require or prefer domestic sourcing for critical components, especially in the defense, energy, and infrastructure sectors. American forging companies often provide better responsiveness for design changes or expedited orders, and many customers value supporting domestic manufacturing capabilities for strategic and economic reasons.