Stainless steel perforated sheet metal is recognized as the leading choice across numerous industries and applications because of its superb versatility, durability, and aesthetic appeal. By using perforated sheet metal, you are going to have the best of both worlds when it comes to the visual aspect and the practical aspect; that is, if you are a builder needing a material that is both functional and beautiful or a designer looking for modern projects. The present article has been written to uncover the main pros, uses, and characteristics of stainless steel perforated sheets. In this way, you will get a complete comprehension of their indespensableness in construction, manufacturing, etc. Just keep on reading to learn about such material that can activate your upcoming project and still be up to the test of time.

Overview of Stainless Steel Perforated Sheets

Definition and Features of Stainless Steel Perforated Sheets

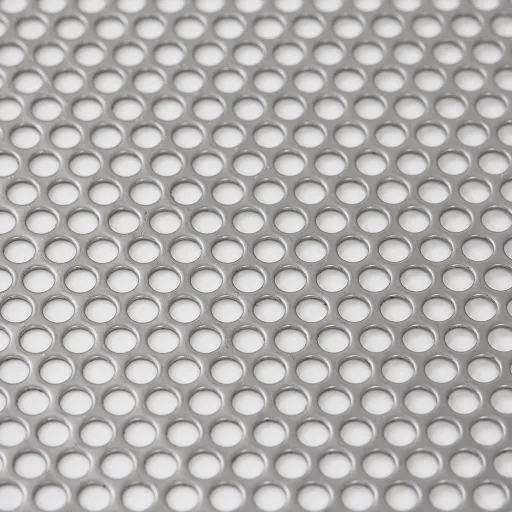

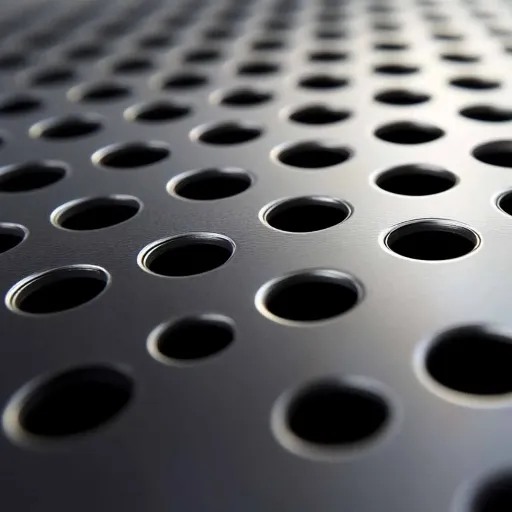

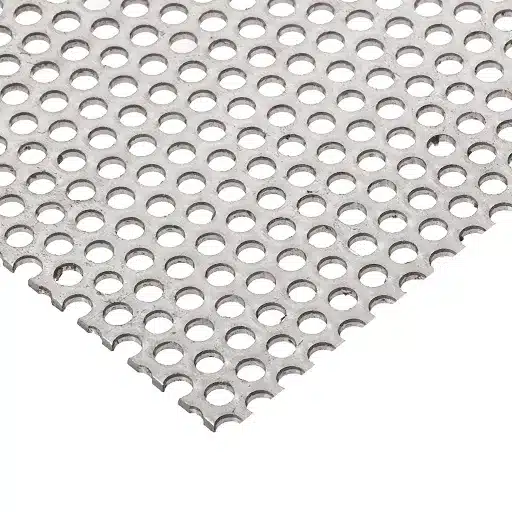

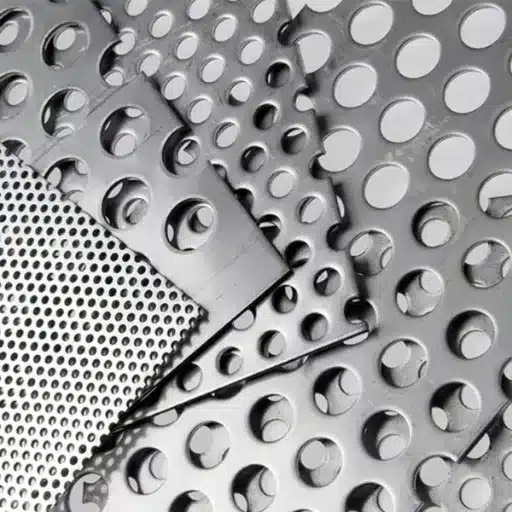

Stainless steel perforated sheets are strong yet light covers for metals that have a series of holes, patterns, or designs applied uniformly and made through either mechanical or laser techniques for perforation. Mainly composed of stainless steel alloys like 304 and 316, these sheets are completely rust-proof and thereby very suitable for places with moisture or extreme environments. The openings come in various shapes such as round, square, and slotted, etc. to cater to different aesthetic and functional requirements.

One of the biggest advantages of stainless steel perforated sheets is their outstanding strength-to-weight ratio. They possess the properties of being light and soft, but at the same time, do not lose their great structural integrity and durability. Moreover, the openings in the sheets enhance the airflow, light passage, and sound dispersion, thereby making their use possible in ventilating systems, acoustic panels, and decorative facades among other things.

Types of Stainless Steel Used

304 Stainless Steel

304 stainless steel is a grade that is most widely used and is made up of 18% chromium and 8% nickel making it suitable for places with high moisture or mild chemical exposure. It is incredibly resistant to corrosion and strong at the same time. Applications range from architectural facades, kitchen equipment, and transportation systems, to name a few.

316 Stainless Steel

316 stainless steel has even better resistance to corrosion than 304 stainless steel, which is why 316 is called the molybdenum stainless steel. It is capable of tolerating the most severe conditions of saltwater and acid, thereby being ideal for marine applications, chemical processing plants, and pharmaceutical industries.

430 Stainless Steel

This grade is the least expensive one, and that is the main reason why it gets its credit for being very resistant to stress corrosion cracking as well. 430 stainless steel, though, is not so corrosion resistant like 304 and 316 grades, but it is still used very often in the inner parts of buildings, for decorating, and light consumer goods.

201 Stainless Steel

On the one hand, 201 stainless steel is a budget-friendly alternative to 304 and has great durability; on the other hand, it is less used in food service equipment, appliances, and furniture. The reason for its lower price is its reduced nickel content.

Key Benefits of Stainless Steel Perforated Sheets

Durability and Strength

The stainless steel perforated sheets have become the leading option for many different industrial and architectural projects because of their extraordinary durability and strength. An alloy, mainly consisting of iron, nickel, chromium, and sometimes molybdenum, is responsible for giving the sheets high tensile strength. The main element in stainless steel, chromium, is the one that more or less creates an oxide layer on the surface, thus providing the material with a great deal of protection against water and rust even in the most adverse conditions.

According to studies, among others, 304 and 316 stainless steel grades are the most durable, if not others, and this is why they are the most chosen materials, at least from the perspective of steel use and replacement cycle. For example, stainless steel of 316 with an extra 2-3% molybdenum can be installed in saltwater areas (marine environments), where it will outlast any other metal that is less resistant. Besides, this long life spans results in little maintenance and thus a higher level of project’s sustainability in the long term.

Flexibility of Uses

Stainless steel perforated sheets have been granted the title of the most versatile metal, which is the biggest plus of stainless steel sheets over their competitors. For example, in architecture, they are used in modern facades, shading devices, and decorative panels taking the best of both their functional and aesthetic aspects. A 5.6% figure is a symbol of the global architectural steel market growth in 2023, while one of the reasons being the perforated sheets’ participation in the creation of new designs.

In addition, these sheets are indispensable in the auto and transportation industries for powertrain parts like filters, grilles, and shields. The automotive perforated metal market is projected to reach $3.2 billion by 2028, which indicates the consistent trend of using these sheets across various sectors.

Furthermore, in other industrial applications, stainless steel perforated sheets are being utilized in filtering, separating, and sound-proofing materials. The corrosion resistance feature of these sheets provides them a place in extreme environments like the marine and chemical processing industries, where performance reliability is highly demanding. Given the current demand and the expectation for corrosion-resistant materials to increase by 7% annually, it appears that stainless steel will still be the material of choice.

Common Applications of Perforated Metal Sheets

Construction Industry

The construction industry is highly dependent on perforated metal sheets, which are the strongest, the longest-lasting, and the most versatile of all sheets. Their range of applications is vast, covering not only façades, partitions, cladding, ceilings, and sunshades but also much more. The combination of functionality and aesthetic appeal has made them a favorite among architects and designers.

As per the latest estimates, the market for perforated metal sheets worldwide will likely witness a CAGR of 5.5% from 2023 to 2028. The constant demand for lightweight construction materials and eco-friendly buildings is one of the major factors for such growth. By providing ventilation and managing solar heat gain, perforated sheets become energy-efficient and thus are the right choice for sustainable architecture.

Automotive Sector

Perforated sheets have gained their status as essential materials in the automotive industry. Their versatility, durability, and good looks are reasons for their popularity among manufacturers and designers. Among the uses of these sheets are vehicle grills, mufflers, and ventilation systems, where they help in achieving better performance and efficiency. The sheets, by allowing more air to pass through, assist in the process of cooling the engine and thus ensuring the smooth functioning of the car. Moreover, besides the usage of perforated materials in sound-damping applications such as acoustic panels and interior components for road noise reduction, the quieter driving experience due to less noise penetration from outside is also a benefit.

The global market for automotive perforated metal is to grow considerably due to the rising demand from consumers for lightweight and fuel-efficient vehicles as suggested by recent industry data. Perforated sheets, being lightweight and easy to customize, are enabling the manufacturers to reduce the vehicle weight while keeping the structural support strong. Additionally, the laser technology is being used by the manufacturers to make very intricate and precise patterns that have given a modern and unique look to the automotive design.

Selection Criteria for Perforated Steel Sheets

Choosing the Right Hole Size and Pattern

1. Hole Size and Open Area Percentage:

Hole size has a direct impact on the amount of open area, which allows the air, light, and weight to go through, and consequently, the total weight reduction. Typically, the smaller hole sizes (1 mm to 3 mm) are ideal for filtration and sound absorption purposes, while bigger ones (5 mm to 20 mm) are used for ventilation and aesthetic purposes.

2. Hole Patterns:

Among the various hole patterns round, square, slotted, and decorative are the most recognizable ones. Round holes are the mainly round ones due to their strength and versatility; as a result, they account for about 60% of total perforation applications. Square and slotted holes act as a sponge for air and water, allowing flow and drainage in a specific direction, while the main use of decorative patterns is to enhance the aesthetic of the architectural and interior designs.

3. Material Strength and Thickness:

The thickness of the steel sheet and the size of the hole are closely related to the strength of the alloy being used in the blue-paper-and-white ink process. The industry’s standard for this is that in order to maintain the strength of the material, the hole diameter must be at least equal to the thickness of the sheet. For example, a 1.5mm thick sheet can only have holes of 1.5mm or larger.

4. Acoustic and Thermal Performance:

In the case of acoustic applications, soundproof panels, and the like, it is usually the case that smaller holes with higher perforation density are used for sound absorption. On the other hand, perforated sheets with large holes are employed in heat exchangers or battery cooling systems as they provide the best thermal management.

Considerations for Thickness and Gauge

The thickness and gauge of the material are the determining factors when selecting perforated sheets as they have a direct influence on the life span, weight, and use of the sheet. Thickness is usually the most important factor in determining the structural and mechanical properties of the sheet, and thus its resistance to environmental factors and its ability to withstand stresses, especially in the case of very thick sheets. For example, in strength-optimizing industrial applications, thick sheets are used, while thinner sheets are used for light-weight, heavier sound-proofing applications.

The thickness of the perforated sheet, also referred to as gauge, is one of the main factors in determining the material’s range of suitability for different applications. The industry set standards specify the most common steel sheets for perforation that range from a thickness of 24-gauge (approximately 0.0239 inches thick) for easy handling projects to 10-gauge (about 0.1345 inches thick) for more durable applications. Aluminum sheets are always the preferred ones in projects that require both high performance and low weight due to their low weight. For instance, building facades usually have a thickness range of 16 (0.0508 inches) to 22 (0.0313 inches) gauges.

Maintenance Tips for Stainless Steel Perforated Metal

Cleaning and Care Instructions

Regular Dusting and Wiping

Dust and dirt on the surface must be removed with a soft cloth or a microfiber towel. A mixture of mild soap and warm water would do for the easy removal of light stains or fingerprints. Always wipe along the metal’s grain to avoid scratches.

Stubborn Stain Removal

A non-abrasive stainless steel cleaner should be the first choice for tough stains removal. For instance, diluted vinegar or a paste made of baking soda and water will definitely remove greasy deposits. Avoid harsh chemicals such as bleach and chlorine-based cleaners as they will dissolve the protective oxide layer of the metal.

Polishing for Shine

To a clean, soft cloth apply specialized stainless steel polish or mineral oil, then buff lightly the surface and bring out the natural sheen and hide watermarks. The polishing process will make the metal shine and also help to remove any water spots.

Preventing Corrosion

Stainless steel is not totally immune to corrosion, but it does not get corroded easily; still, regular maintenance is required to keep the worst scenario of surface rust away, particularly in humid or industrial conditions. Always dry the surface thoroughly after cleaning and do not allow it to stay wet for long periods.

Cleaning Frequency

High-traffic or outdoor installations may need weekly cleaning, while indoor or less exposed surfaces just require monthly care at the most. Regular maintenance will not only improve the appearance of stainless steel perforated metal but also prolong its life span.

Preventing Corrosion and Damage

To prevent corrosion and damage to stainless steel perforated metal, a proactive approach is required consisting of regular cleaning, careful material handling, and maintenance. It has been observed that environmental pollutants like sulfur compounds, chlorides, or extremely high humidity can severely increase the rate of corrosion.

Passivation methods are one of the simplest yet most effective means. Passivation signifies treating the surface of the metal with a mild oxidizing acid, like nitric acid, which ultimately increases the thickness of the natural protective oxide layer. The statistics from the industry reports indicate that the corrosion rates of passivated stainless steel can be lowered by 80% even in the harshest environments.

Reference Sources

-

Formability Investigation of Perforated Austenitic SS 304L

This research paper explores the effects of hole size and other parameters on the formability of stainless steel sheets.

Read more on ScienceDirect -

Feasibility Study of the SPIF Process Applied to Perforated Sheet Metals

This study reviews the surface roughness and microhardness of perforated sheet metals, providing insights into their engineering applications.

Available on ResearchGate

Frequently Asked Questions (FAQs)

What are the available metal products and alloys for perforated materials?

The metal product portfolio consists of perforated stainless steel (304, 316), carbon steel, galvanized options, and aluminum along with a choice of alloys which will affect the hardness, corrosion resistance, and other heat-treating options. 304 stainless steel is the most widely used for its general resistance to corrosion; 316 stainless steel is used for extremely corrosive or marine environments.

What types of holes and tolerances are available for the punching and pressing methods?

The use of punch and press techniques establishes the hole types available for the final product ranging from round and square to hexagonal and custom perforated styles. Additionally, the press technique would determine the quality of the edges, tolerance, and possibility of making staggered centers or intricate custom-cut profiles. Whereas precision punching will give rise to tight tolerances and clean holes suitable for applications such as machine guards and fixtures, heavier pressing will work best for thicker sheet metal.

Can I find perforated stainless sheet metal in stock or from a supplier who has an online inventory of perforated products?

Certainly, a good number of suppliers keep a stock of perforated stainless steel and offer sheets in regular sizes and common patterns. The presence of a stock of perforated products minimizes lead time; make sure to search for suppliers who already mention items in stock such as perforated sheet 304, frequent hole patterns, and metal thicknesses. In the case of custom orders, inquire about the lead time for custom perforated or cut-to-size services.

Is it possible to get a stainless steel sheet of custom perforation and what about the cut-to-size and custom cuts options?

Almost all perforated metal suppliers offer custom perforated solutions as well as cut-to-size services. You can choose the hole type and pattern (even staggered centers), specify the dimensions of the sheet that you want, and additional processing like welding, forming, or adding fixtures. Custom cutting and custom perforated panel works give you the opportunity to create a perfect fit for enclosures, building facades, or decorative or ornamental effects.

Ready to Get Started?

Stainless steel perforated sheet metal offers unmatched versatility, durability, and aesthetic appeal for your next project. Contact a trusted supplier today to explore custom options and bring your vision to life.