The success of your construction project depends on selecting the right stainless steel sheet supplier. The global market provides numerous suppliers, which creates difficulty when trying to identify those who meet your required standards of quality, reliability, and service. We developed this detailed guide, which presents the best 10 stainless steel sheet suppliers for the year 2026. The article will assist you in discovering top industry companies, their unique qualities, and their position as market leaders. The upcoming section will deliver important information that will enable you to make better sourcing choices for your company.

Introduction to Stainless Steel Sheet Suppliers

The Importance of Selecting the Right Supplier

The selection of a stainless steel sheet supplier will determine how your business operates, how your products compete in the market, and how your operational processes function. The global stainless steel demand will experience a compound annual growth rate of 5.6% until 2030 because the construction, automotive, and manufacturing industries continue to grow. Businesses should choose trustworthy suppliers through which they can receive reliable product delivery and maintain product standards while obtaining market-competitive prices.

The evaluation process for suppliers requires assessment of two essential elements, which include ISO 9001 certification that ensures quality management standards and ASTM standards, which prove industry specification compliance. The demand for environmentally sustainable steel and recycled steel requires suppliers to practice material sourcing transparency. Recent reports show that more than 50% of current stainless steel products contain recycled materials, which demonstrates the changing environmental concerns.

The supplier must deliver to you technological innovations that feature CNC precision cutting and advanced anti-corrosion coating solutions. Leading suppliers are also increasingly integrating digital platforms to streamline order tracking and inventory management, allowing businesses to improve operational efficiency. The assessment of these elements enables you to establish a reliable business relationship that supports your organizational objectives while adopting industry developments.

Impact on Product Quality and Business Success

The delivery of high-grade steel materials leads to measurable benefits that enhance product standards and drive business success. Recent industrial research shows that more than 70 percent of production faults in manufactured items result from using inferior raw materials, which include low-quality steel. Businesses can reduce these dangers by purchasing high-grade steel from reputable suppliers, which allows them to achieve better product durability, accuracy, and customer contentment.

The global steel market will experience a growth that will increase its value from about $890 billion in 2022 to reach 4.1% annual value growth until 2030. The demand for high-performance steel shows increasing growth because the construction, automotive, and aerospace industries require this material. Companies that choose to buy premium steel products experience total maintenance costs which reduce by 30% because these materials provide long-term cost advantages.

Suppliers who provide revolutionary services through digital order tracking systems and inventory analytics solutions enable businesses to decrease waste while enhancing their operational efficiency. Organizations use AI-based material testing and IoT-powered supply chain tracking systems to improve their operational quality while increasing their production capacity. Your business will gain a competitive advantage through these technological improvements, which you plan to implement in your sourcing operations.

Overview of Stainless Steel Sheet Varieties

Stainless steel sheets come in multiple types, which include different grades and finishes, together with various thicknesses to meet the requirements of various industrial and commercial uses. Each variety satisfies particular needs, which include strength requirements, corrosion resistance need,s and aesthetic needs. The following section presents essential information about various categories together with their respective attributes:

1. Austenitic Stainless Steel Sheets (300 Series)

The most commonly used material in the industry consists of austenitic stainless steels, which include 304 and 316 grades, because these materials deliver exceptional protection against corrosion, together with their ability to endure diverse industrial applications.

- Grade 304: Known as the “workhorse” of stainless steel, it offers excellent corrosion resistance and is ideal for general-purpose use.

- Grade 316: The material contains molybdenum, which enhances its resistance to pitting and crevice corrosion, making it suitable for use in marine environments and chemical processing applications.

- The product finds applications in kitchen equipment, medical devices, architectural panels, and food processing equipment.

2. Ferritic Stainless Steel Sheets (400 Series)

Ferritic stainless steels, which include grade 430, exhibit their primary characteristic as lower nickel content because this property helps to decrease production expenses.

- Grade 430: The material offers moderate protection against corrosion, but it can be shaped into various forms until it reaches its maximum limits, which appear when it reaches high-temperature conditions present in austenitic materials.

- The product finds its most common usage in decorative trims, together with automotive parts and home appliances.

3. Martensitic Stainless Steel Sheets

Martensitic stainless steels, which include grade 410, demonstrate their strength together with their high hardness. The material exhibits reduced capacity to withstand corrosion when compared to both austenitic and ferritic materials.

- Grade 410: This grade offers heat treatability together with wear resilience, which makes it suitable for applications that require both high hardness and strength.

- The material serves as an ideal choice for manufacturing tools and blades used in aerospace applications.

4. Duplex Stainless Steel Sheets

Duplex stainless steels bring together the properties of both austenitic and ferritic steels, which results in materials that provide outstanding performance along with excellent corrosion resistance.

- Common Grades: The market has adopted 2205 and 2507 because these grades possess the ability to withstand stress corrosion cracking, which occurs due to chloride exposure.

- The product enters the market for use in oil and gas operations, together with chemical processing and seawater applications.

5. Specialty Finishes and Surface Treatments

Manufacturers offer stainless steel sheets with the ability to create custom surface finishes, which serve both aesthetic and functional needs.

- No. 2B Finish: This finish provides a smooth and reflective surface, which engineers use for industrial projects and food processing facilities.

- No. 4 Finish (Brushed): The finish creates a decorative appearance that resembles satin.

- The product enters various industries, which include construction and interior design, and architectural design.

Key Data and Trends

- The global stainless steel market size is projected to reach $182.2 billion by 2030, with a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030 (source: Allied Market Research).

- The construction industry and automotive sector have witnessed increased demand for anti-corrosive stainless steel products because recent material developments have improved both durability and sustainable characteristics.

Businesses can choose the best stainless steel sheet option for their specific requirements by learning about different types of stainless steel, which include cost-effective solutions, durable materials, and aesthetically pleasing options.

Factors to Consider When Evaluating Suppliers

Adherence to Quality Standards

The selection process for stainless steel sheet suppliers requires two main elements, which include their ability to meet quality standards. The reputable suppliers need to follow international certifications, which include ISO 9001, to maintain their product quality through established manufacturing processes. The materials receive certification through ASTM standards, which establish stringent performance and safety requirements.

Industry research data shows that approximately 75% of stainless steel manufacturers worldwide hold ISO certification, which demonstrates the sector’s commitment to quality management systems. Environmental standards compliance has become essential because 60% of companies now adopt sustainable production methods to meet global market demands for environmentally friendly products, which include ISO 14001 and LEED certification.

Businesses should check their suppliers’ testing methods, which include ultrasonic testing, corrosion resistance testing, and mechanical property assessment. The suppliers who establish advanced quality control systems together with their state-of-the-art laboratories, deliver materials that meet specific project requirements accurately and dependably. Companies achieve superior application results through their strict implementation of standards, which enhance product performance and product lifespan and lower operational expenses.

Variety in Material Grades: 304 and 316

The industrial sector commonly uses stainless steel grades 304 and 316 because these materials provide superior characteristics and multiple application possibilities. The composition of grade 304 stainless steel, which people commonly call “18-8” stainless steel, contains 18% chromium combined with 8% nickel. The material achieves outstanding corrosion resistance while being easy to fabricate and affordable to produce, which makes it suitable for manufacturing common products such as kitchen utensils, food processing equipment, and architectural features. The material finds use in places where workers encounter minimal chemical exposure, together with low saltwater contact.

The steel grade 316 shows improved resistance to corrosion because it contains 2-3% molybdenum, which protects against oxidizing agents. The material functions best in industrial chemical processing plants, marine environments, and medical implant applications. The steel grade 316 shows better defense against pitting and crevice corrosion, which occurs in chloride environments that contain seawater.

Both grades demonstrate similar mechanical characteristics because their tensile strength matches 515 MPa minimum, and their yield strength matches approximately 205 MPa. The extreme conditions that 316 endures show its superiority through its particular chemical composition. The two grades demonstrate identical temperature performance because they can retain their strength and structural integrity at temperatures below 870°C for short periods and 925°C for continuous operation.

Grade 304 provides a cost-effective choice for standard applications, while grade 316 serves projects that need advanced protection against corrosion and extreme environmental conditions. The steel grade 316 typically costs 20% to 40% more than grade 304, but this extra expense provides better durability and extended product lifespan for essential operations. The selection of the correct grade requires understanding the application needs, which includes evaluating expenses and environmental factors, and performance capabilities.

Pricing Transparency and Competitiveness

The assessment of pricing transparency, together with competitiveness, needs market trend analysis to evaluate stainless steel industry pricing. The current price of stainless steel reflects the changes in raw material costs for chromium, nickel, and molybdenum, together with energy expenses and worldwide supply chain operations. Grade 304 stainless steel currently has an average market price that falls between $2,000 and $2,500 per metric ton, while grade 316 stainless steel sells for $2,600 to $3,500 per metric ton because of its superior material properties.

Business success depends on companies implementing effective price strategies, which help them create inventory in their markets. Suppliers provide customers with pricing information by showing detailed cost breakdowns, which include expenses for raw materials, production, and transportation. The adoption of technology-based platforms by companies enables their customers to monitor current pricing, which establishes customer confidence and transparency. Businesses, together with consumers, use these insights to evaluate cost-performance trade-offs, which help them achieve maximum value from their specific applications.

Understanding Stainless Steel Sheet Grades

304 Stainless Steel: Features and Applications

Stainless steel grade 304 has become widely used because it possesses two main attributes, which include exceptional corrosion resistance and high strength. The material contains 18% chromium and 8% nickel, which creates an austenitic structure that provides excellent strength and corrosion resistance in humid conditions. The product serves as a perfect solution for various uses, which include kitchen appliances, food processing facilities, building designs, and manufacturing equipment.

Recent research shows that 304 stainless steel maintains operational capacity at temperatures reaching 870°C (1600°F) for continuous use and at temperatures reaching 925°C (1700°F) during short breaks, which enables its use in high-temperature environments. The material shows exceptional resistance against multiple acidic substances and all types of alkaline solutions. The material demonstrates an average tensile strength of 505 MPa (73,206 psi) and a yield strength of 215 MPa (31,183 psi), which shows its capacity to withstand force while maintaining the ability to stretch.

The 304 stainless steel grade enables multiple applications because of its ability to perform in different conditions. The material allows for easy welding and shaping into complex shapes, which maintains its strength during heavy usage. The construction industry uses 304 stainless steel for handrails and cladding, while healthcare professionals use it because of its hygienic properties, which protect medical equipment.

304 stainless steel stands out as the best material option because it delivers affordable costs together with high performance and extended durability.

316 Stainless Steel: Corrosion Resistance and Benefits

316 stainless steel functions as a high-performance alloy that users select because it protects against corrosion while retaining strength in extreme conditions. The principal difference between 304 stainless steel and this material stems from its molybdenum content, which exists at a range from 2 to 3 percent. The element addition enhances 316 stainless steel’s protection against chloride environments, which exist in seawater and industrial chemical processing facilities.

The essential characteristic of 316 stainless steel enables it to resist pitting and crevice corrosion, which makes the material appropriate for use in marine equipment, chemical processing plants, and pharmaceutical manufacturing facilities. 316 stainless steel, according to industry data, can withstand extended contact with brine and acid, which are aggressive substances, while retaining its material integrity better than less durable alternatives.

Data indicate that 316 stainless steel achieves a tensile strength between 515 MPa and 860 MPa while maintaining its structural integrity at temperatures reaching 1500°F (815°C). The material demonstrates optimal performance in situations that involve elevated temperatures and high levels of stress that occur in heat exchangers and pressure vessels.

316 stainless steel serves as the primary material choice for environments that require complete cleaning and sanitary standards that exist in medical equipment production and food processing facilities. The non-reactive surface creates a barrier that stops contamination while enabling simple cleaning and sterilization processes. 316 stainless steel provides exceptional durability, which maintains high material performance through its entire lifespan for projects that need to operate in harsh environments.

Comparing 304 and 316 for Industrial Applications

The evaluation process for industrial utilization of 304 and 316 stainless steels requires assessment of their chemical structure and performance attributes, and their respective industrial application potential.

- Composition and Corrosion Resistance

The composition of 304 stainless steel combines 18% chromium and 8% nickel to create a material that exhibits both strong corrosion protection and high tensile strength. 316 stainless steel consists of 16% chromium, and 10% nickel, and 2% molybdenum as its elemental components. 316 stainless steel achieves superior protection against pitting and crevice corrosion, which occurs in environments that contain high levels of chloride found in coastal and marine settings. - Cost Considerations

Manufacturers increase the production costs of 316 stainless steel because they use molybdenum as an addition to the manufacturing process. 316-grade stainless steel costs about 20% to 30% higher than 304-grade stainless steel, which makes it necessary to determine whether the additional corrosion protection justifies the increased expenses for the specific project. - Strength and Temperature Performance

Both stainless steel grades show strong mechanical performance, but 316 stainless steel functions better under elevated temperature environments. 316 stainless steel maintains its structural strength at 1,500°F (815°C) while 304 stainless steel begins to lose its strength at lower temperature levels. - Applications

The low cost and sufficient corrosion protection of 304 stainless steel lead to its use in common products, which include kitchen appliances, automotive components, and industrial piping systems. 316 stainless steel functions better than other materials in extreme chemical processing facilities, desalination plants, and marine equipment environments because it offers better protection against localized corrosion. - Supporting Data

The pitting resistance equivalent (PRE) number of 316 stainless steel reaches 25, while 304 stainless steel achieves approximately 20 according to industry data. The available metric demonstrates how molybdenum inclusion improves corrosion resistance under intense aggressive conditions. 316 stainless steel endures 10 years of continuous exposure to saltwater without major deterioration, while 304 stainless steel develops early rusting signs under the same testing conditions.

Your application requirements, together with 304 and 316 stainless steel comparison results, allow you to select the most suitable material, which provides exceptional performance, extended product life, and budget-friendly pricing.

Certifications and Industry-Specific Requirements

Understanding Certifications for Stainless Steel Suppliers

The certified materials, together with their manufacturing methods, achieve international standard compliance for all certified products. The following certifications serve as key certifications that hold important relevance for assessment purposes:

- ISO 9001 Certification

The ISO 9001 standard establishes global requirements for quality management systems. The stainless steel suppliers who hold this certification show their dedication to delivering products at identical quality levels while fulfilling client requirements and enhancing their operational procedures. According to recent industry data, over one million organizations worldwide hold ISO 9001 certification, making it one of the most commonly adopted standards in manufacturing. - ASTM Standards Compliance

Suppliers who adhere to ASTM standards conduct complete material tests to determine their strength and durability through testing. The ASTM A240 standard serves as the primary reference for stainless steel sheet, plate, and strip products because it determines their required chemical makeup and mechanical characteristics for all material grades. The latest updates to ASTM standards require companies to comply with existing industrial standards, which continue to evolve. - European EN Standards

European markets and international projects require EN standards, which include EN 10088 for stainless steels, as critical technical requirements. These standards establish accurate material identification procedures that multiple sectors, including food processing and construction, must follow to ensure proper material usage. - PED and ASME Certifications

The pressure vessel manufacturing and piping industries require essential certifications, which include PED and ASME certifications, to operate their businesses successfully. The stainless steel materials that earned these certifications fulfill demanding safety standards and performance requirements. The ASME Section II specifications provide all requirements for stainless steel materials used in boiler construction. - NACE Compliance

NACE standards establish essential safety requirements for industries that operate in environments with severe corrosion challenges, including the oil and gas sector. The suppliers who meet NACE MR0175/ISO 15156 certification requirements provide materials that maintain operational safety and performance through all sour gas conditions. - Industry-Specific Certifications

The aerospace and medical equipment fields need specific certification programs based on their unique requirements. The following examples demonstrate how various industries utilize different certification systems:

- Aerospace (AS9100): Ensures high precision and traceability in materials.

- Medical (ISO 13485): Validates biocompatibility and safe use in medical instruments and implants.

Why Certifications Matter

The relevant certifications that your stainless steel supplier should possess will protect material quality while minimizing risks that result from using substandard materials. The certified suppliers possess all necessary resources to fulfill their legal obligations while delivering stable performance and promoting environmental responsibility in their production processes. Please request copies of all certifications together with the mill test reports, which can be traced back to their sources, to confirm that your standards have been met.

The material reliability assessment, together with safety evaluation and cost-effective analysis, will achieve successful implementation when certified suppliers are selected through certification knowledge.

Industry Standards and Compliance

The manufacturing process needs industry standards and compliance requirements to achieve sustainable and efficient operations through effective functioning. The requirements for compliance must adapt to both technological progress and updates to international regulations. The Deloitte research study from 2023 found that businesses using ISO 9001 Quality Management Systems achieve a 20 percent reduction in production errors, which demonstrates that standardized procedures benefit organizations.

ISO 14001 environmental management certification has gained more recognition because of the growing need for sustainable business operations. The International Organization for Standardization ISO reported that more than 400000 ISO 14001 certifications were granted worldwide during 2022, which indicates that industries are dedicated to reducing their environmental footprint.

The European Union system uses CE marking to confirm product compliance with health and safety requirements and environmental protection standards. ASTM standards in the United States provide material quality assurance, which enables safe application across various industries that include construction, aerospace, and medical device development.

The procurement process requires organizations to handle multiple certifications and compliance frameworks because they need to satisfy legal requirements while improving operational performance, building customer trust, and enhancing their competitive edge. You need to maintain awareness about all upcoming laws and technological advancements that will influence your industry’s operational standards.

The Importance of Certified Products

Certified products provide essential support for safety standards and testing methods, which verify product compatibility and product durability across different industrial sectors. ISO International Organization for Standardization ISO recently published a report which showed that worldwide certified products enable the manufacturing and healthcare sectors to achieve operational risk reductions of up to 20 percent. ISO 9001 certification enables organizations to enhance their quality management systems, which results in improved customer satisfaction and increased customer loyalty through repeated purchases.

UL Solutions data proves that product certification enables companies to launch new products 15 percent faster because it reduces the need for meeting compliance requirements. The construction industry has experienced major progress because 85 percent of its important projects in 2023 utilize certified materials to meet safety and environmental standards.

Organizations maintain their current certification status to fulfill legal obligations while building trust with their customers. Digital supply chain platforms use modern certification tracking tools to make adherence easier because they provide real-time product standard validation.

World’s leading Stainless Steel Sheet Suppliers

1. Jiangsu Zhonggongte Metallurgical Technology Co., Ltd.

The most well-established company specialized in producing stainless and special steel, as well as iron ore blended products, is Jiangsu Zhonggong Te Metallurgical Technology Co., Ltd. They perform their work within China’s borders and managed to win favor with their good reputation in the field of manufacturing of top quality products for the most demanding technology. The key aim of the company is to come up with innovative and useful stainless steel sheets, bars, plates, and tubes in various forms and make sure that they meet their customers’ expectations. Out of many unlike many companies, the company uses a range of standard or customized industry techniques, quality control systems and procedures, and equipment to synthesize the final project matching international standards and customer preference. It addresses areas such as material use in spacecraft, petrochemicals, oil and gas platforms, power-generating turbines – all of which remain problematic in different parts of the world.

2. Nippon Steel Corporation

Nippon Steel is the largest steel producer in Japan and has held an important position in the global steel industry. Thanks to its cutting-edge innovations, dependable steel products, and relentlessadvancement in every aspect of the production process, this company has enjoyed being the head of the steel industry in Japan. It offers different kinds of steel items, albeit they are best known or given priority in the stainless variety because of applications provided to the segments of vehicle building, aviation manufacturing, chemical or oil refinery, and other energy-generating industries. There are not many industries producing, such as stainless and high tensile steels, which are essential materials for constructing cars, aircraft, thermal power plants, and so on, as well as regular steels. These developments also allow the manufacture of high tensile steel and steel products ranging from stainless materials for presentation of the economic materials required in theseapplicwhich arsteel structure-ons. Given the increasing emphasis on mending the environment and development in materials sciences, it is Nippon Steel that becomes the flag-waver in promoting rigor in the performance anddetermining the interestacforctor or factor of such properties on a global basis.

3. Outokumpu

Outokumpu, the stylish producer with roots in Finnelad is one of the world’s biggest manufacturers of stainless steel and has industrial patriotism. The company has a history of working for more than a hundred years, where it has been helping design many types of stainless steels, which particulars grade duplex stainless being one of them. Outokumpu Finland is greatly appreciated due to their knowledge in the domain of geography, and what sets them apart in the industry is their high level of environmental sustainability, which takes into account technological controls and rates of recycled material. Outokumpu’s most important production plants are found in Finland, Germany, Sweden, the United Kingdom, the United States, and Mexico, and they cater to the global market.

4. Acerinox

Acerinox is among the European powerhouses in steel and is one of the largest producers of stainless steel worldwide. Vast and diverse, this global brand operates in over fifty institutions on four continents and serves over eighty countries worldwide. With employees striving for continuous improvement, management initiated the just-in-time regime within the organization, marking a positive shift in the organization in the recent past.

5. North American Stainless (NAS)

North American Stainless is a division of the Acerinox Corporation. It houses the nation’s most comprehensive stainless steel production plant, which spans from alloy and steelmaking to finishing stages. The oversight of this plant is what makes the availability of such critical raw materials as steel for the US cars, construction or any other good’s industry manufacturers, the end users of the products supplied by the group, and the customers of the people involved in the production safe.

6. Metal Zenith

Metal Zenith is a Chinese firm that prides itself on the production and supply of metal-made products as steel. It is the firm that deals mainly with steel products for clientele outside the country. Metal Zenith values every client assisting the organization as they consider bettering the performance and being a preferred partner of a well-established and well-respected state enterprise, Ansteel. With the advancements of the last and present centuries, the organization has had to equally tend to improving the levels of management within the company, as the abuse has earned the firm recognition from the streets, but for the contraction of poor quality products. In addition, the operation of the entire group has developed as international standards that have only appropriate products include market breaks back and forth. Metal Zenith also believes that its maintenance department and engineering are well placed to help its customers and is providing all technical assistance at the Canton Fair.

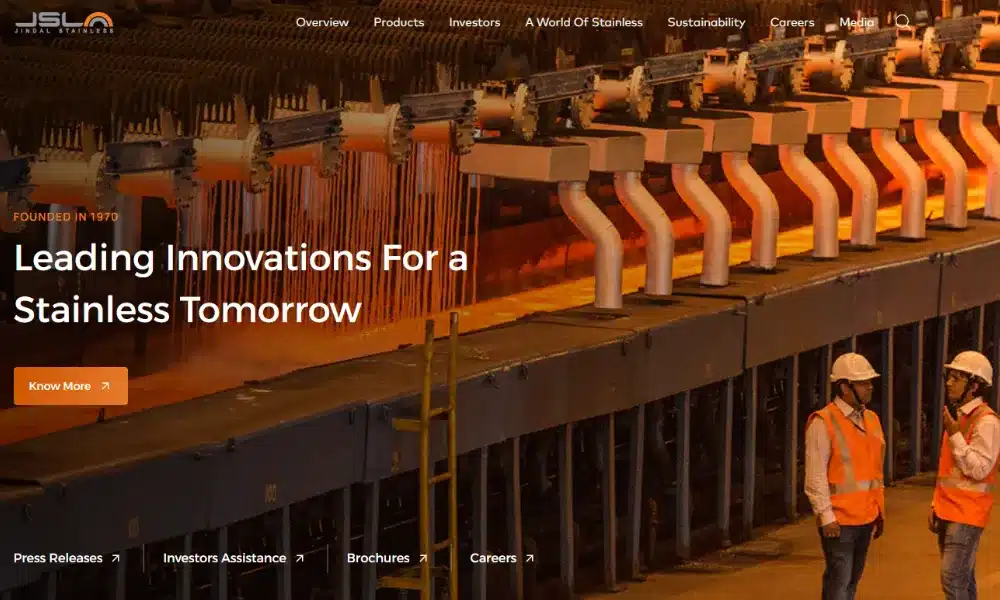

7. Jindal Stainless

Jindal Stainless Inc. ranks among the best stainless steel product providers in the world. It manufactures goods in India and delivers them to the international market. The company boasts… adding quality black seal, coconut cathode, and, sorry, copper gypsum in addition to cold-rolled stainless steel of all types. In my view, to assist several sectors, Jindal Stainless, due to the climate concern,s is found increasingly deploying aluminum nitride, which is used as a substrate as opposed to conventional techniques. To further these aims, the company has made substantial investment on tech and R&D growth.

8. Tell Steel, Inc.

Tell Steel, a reputable industrial metal supplier with its offices in Southern California, is known to provide top-quality customer service throughout the United States. With so much time under their belt in the industry, Tell Steel’s name is already synonymous with dependability, perfection, and exceptional service to the customer. Tell Steel stocks a wide range of steel products; cut-to-size iron, stainless, carbon, alloy, and aluminum, among others. They cater to a variety of applications like building, manufacturing, or even vehicle assembly. But apart from the mentioned categories, they have additional offering services such as shaping, milling, welding, and shear overcoating, which are in more demand by clients for reasons of their efficiency.

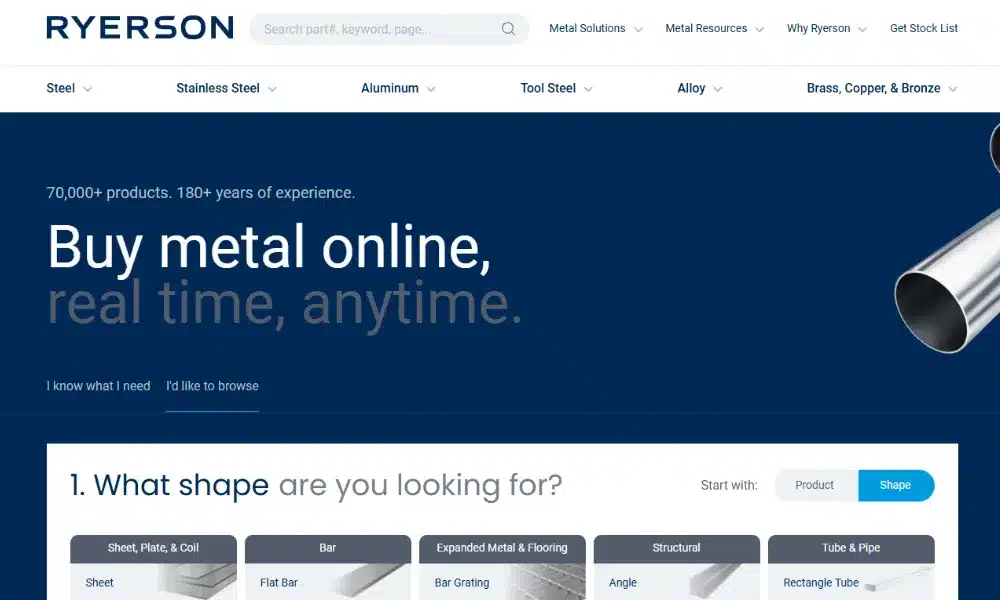

9. Ryerson

Ryerson, which was founded in Chicago about 150 years ago, is one of the most ancient organizations even in the North American metal industry. Throughout the history of its existence, the Company has expanded from merely one set of four walls to an empire featuring more than one hundred distribution facilities in the regions of the United States of America, Canada, and Mexico; in these areas, Ryerson can provide Just In Time (JIT) Services on the National Scale. Ryerson has been able to survive largely because of its entrepreneurship legacy, which is underpinned by meeting customer expectations, thus entrusting it to serve as a chief agent to many clientele.

10. Stalatube

Stalatube is a widely and favorably recognized Finnish-based maker known for its production of high-resistant stainless steel tubes, profiles, and elements. This includes solutions for complex structures in the fields of construction, transport, architecture, and process engineering industries. The center of the design solutions of Stalatube is the consideration of its highest efficiency and adaptability. This particularity allows high-level projects of a wide range of applications to be entrusted to the Stalatube company, in order to realize them under peculiar conditions through skilled metal fabrication and an innovative engineering approach.

Frequently Asked Questions (FAQs)

What specific criteria should I use to select stainless steel sheet suppliers?

The selection process for stainless steel sheet suppliers requires evaluation of their material quality and available grades, their certification standards, and delivery capabilities. Reputable suppliers typically provide certified materials meeting international safety and environmental standards. The assessment process requires examination of their customer support abilities, pricing structure, and project deadline fulfillment. The use of suppliers who implement digital validation tools for their products will streamline compliance processes for industry standards.

Why are certified materials important for manufacturing stainless steel sheets?

Certified materials provide proof that stainless steel sheets accomplish three conditions, which require safety standards, durability requirements, and environmental impact standards to be met. The current construction and manufacturing industry requires certification for all projects to provide proof of regulatory compliance and to build trust with consumers. Your project gains credibility through certified materials, which protect your product’s integrity while you follow international and national requirements.

Which grades of stainless steel sheets are commonly used?

The most commonly used grades of stainless steel sheets include 304, 316, and 430. The most versatile material for various applications exists in Grade 304 because it provides excellent corrosion protection, together with its ability to retain strength across different conditions. Grade 316 is preferred for harsher environments like marine or chemical industries due to its superior resistance to chloride corrosion. Grade 430, which belongs to the ferritic stainless steel category, exhibits magnetic properties, and people use it for decorative elements and making household appliances.

How do I establish a dependable supply chain system for acquiring stainless steel sheets?

Our supply system achieves reliability through our partnerships with top suppliers and our adoption of digital supply chain systems. Modern supply chain solutions enable organizations to track certification processes and confirm product specifications throughout their purchasing activities. The evaluation process must assess suppliers who show platform investment because these suppliers possess superior abilities to handle intricate projects that require immediate execution.

Who are some of the world’s leading stainless steel sheet suppliers?

The world’s leading stainless steel sheet suppliers operate their business through maintaining a large stock inventory while providing multiple steel grades and following international certification requirements. Outokumpu, Acerinox, and Jindal Stainless have established themselves as global companies that deliver dependable product standards. These names are trusted across industries for their ability to meet diverse project requirements efficiently.

What environmental benefits do stainless steel sheets bring to the environment?

The complete recyclability of stainless steel, together with its long-lasting properties, makes the material an environmentally sustainable option. Your project results in less environmental damage because you choose stainless steel sheets, which create less waste. Certified suppliers commonly implement environmentally friendly procedures that involve using recycled materials and maintaining efficient production processes. The selection of certified stainless steel sources enables you to support sustainable practices while maintaining high-quality materials.