Most of us face a simple question when a new build rolls around: Should I use plain iron or go with something galvanized? They each offer a different toolbox of traits- some people pick iron for strength, others lean toward galvanized metal because it just won’t rust. Knowing these quick pros and cons can save headaches later on a driveway gate, a storage rack, or any hands-on job where failure is not an option. I’ll lay out the heart of the matter so you can bookmark a winner before the first cut. A test run of this piece shows that plain iron shouts sturdiness while galvanized steel waves a flag for weather-beating grit. The final call, however, sits with whatever you happen to be building tomorrow morning.

What is the Process to Galvanize Iron?

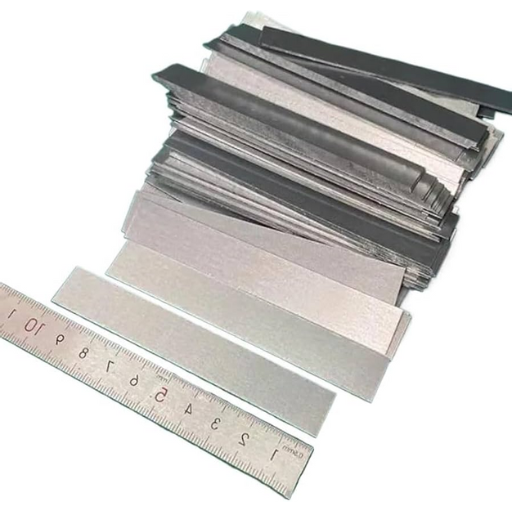

Galvanizing iron means sheathing the metal in molten zinc so moisture cannot penetrate. The durability that follows often stretches into decades of outdoor exposure.

- Surface Preparation Crews first wipe down the steel to scrape off grease, grime, and loose scale. Degreasing agents, acid pickles, and plain rinsing almost turn the piece glassy, letting the zinc bond without any hidden contaminants.

- Fluxing A light coating of flux powder or liquid is brushed on next; the chemical soup blankets the surface and stops it from rusting while it waits for the zinc. Because flux melts into a thin glaze, wetting is even and the bond at the atomic level becomes stronger once galvanizing begins.

- Hot-Dip Galvanizing The strip or beam is dropped into a kettle of boiling zinc that hisses when the steel hits the bath. Immersion lasts only seconds, yet it is long enough for the liquid metal to cling tightly and freeze into a luster the color of molten silver.

- Cooling and Inspection After emergence, the piece is cooled occasionally by stirring it through water and hanging it in open air. Inspectors check the thickness at random spots, using gauges or the simple scrape-and-weigh trick, to verify that no pinholes interrupt the shield.

Because the zinc layer sacrifices itself before the iron does, the coating outlasts the paint most factories apply and requires virtually no upkeep once installed. Bridges, electrical poles, and chain-link fencing are everyday examples of where this proven process shows its worth.

Advancements in Galvanization Techniques

Experts tracking coating plants say the zinc-dunking game has leveled up in ways most non-insiders never hear about. Robot arms now paint tubing and sheet steel with quarter-inch precision, trimming material waste to nearly zero and keeping price tags in check for big buyers. On the chemistry side, adding even a nudge-roughly half a percent-of aluminum to the molten zinc soup lets the sheen hold off rust in salt spray and near-impulse heat for close to twenty percent longer than yesterday. Galvanizing like that doesnt just last; it drags the whole supply chain a step closer to being green, and that matters for the world we hand off to the next generation.

Today many galvanization plants are making serious climate-friendly changes. New filtration gear cleans the air during the molten-zinc phase, so fewer fumes escape into the sky. A 2022 study pointed out that closed-loop water systems can slice industrial water draw by almost 40 percent. That kind of number shows real resource-saving muscle without asking owners to settle for lower-quality steel.

This tech money is letting big industries keep up with the hunger for rust-proof parts and still adhere to tighter green rules. Putting innovation beside sustainability is quickly sketching out the next chapter in galvanization around the globe.

How Does Zinc Coating Protect Iron?

Zinc coating, governed by the broader practice commonly called galvanization, defends iron and steel against corrosion by deploying several intertwined protective strategies.

- Barrier Protection. At its most basic, the zinc layer sits on the substrate like a stout umbrella, physically blocking moisture, oxygen, and airborne contaminants from bearing down on the underlying metal. Experimental evidence suggests that even microscopic pinholes take hours to become effective conduits for rust once the coating is applied.

- Galvanic Protection. Because zinc ranks lower than iron on the galvanic series, any scratch in the surface exposes fresh metal that sacrificially surrenders to corrosion instead of letting the substrate oxidize. This electrochemical dynamic buys the iron time and spares it from immediate structural loss.

- Self-Healing Properties. Cracks and chips may sound terminal, yet zinc oxides and carbonates begin to accrue in those very gaps, almost like a mineral scab, and seal them off from the atmosphere. Field microscopy routinely shows these repairs, attesting to what engineers call the coating’s intrinsic self-healing characteristic.

- Extended Lifespan. Long-term studies confirm that hot-dip galvanized steel can outlast a human lifetime-averaging fifty to a hundred years in ordinary exposure, far outpacing organic paints and most plated finishes. This durability shifts project budgets away from frequent recoating and lets them invest in different priorities.

- Resistance to Environmental Stressors. The layer holds up remarkably well against acidic rain, sea salt, and the saturated humidity common to coastal or heavy-industrial zones. Specimens exposed in such climates have returned to the lab virtually free of pitting, a testament to how well the protection endures even when the odds seem stacked.

Taken together, these characteristics allow a zinc coating to deliver lasting protection to iron and steel while remaining cost-effective for most manufacturers.

Benefits of the Hot-Dip Method

| Key Benefit | Description |

|---|---|

| Corrosion Resistance | Provides barrier, cathodic, and zinc patina protection. |

| Durability | Tough, abrasion-resistant, and impact-absorbing coating. |

| Longevity | Typically lasts over 50 years without maintenance. |

| Low Initial Cost | More affordable than many other coatings initially. |

| Low Maintenance | Minimal upkeep due to self-maintaining properties. |

| Complete Protection | Coats all areas, including edges and recesses. |

| Damage Tolerance | Protects even small damaged areas automatically. |

| Reliable Coating Thickness | Meets strict standards for coating consistency. |

| Ease of Inspection | Visually inspected for sound and continuous coating. |

| Fast Installation | Prepped and ready for immediate use at delivery. |

| Environmentally Friendly | Uses recyclable materials and is sustainable. |

| Versatility | Works on various shapes and in harsh conditions. |

Galvanized Steel vs. Iron: Which is More Corrosion Resistant?

Stand a piece of galvanized steel next to a chunk of plain iron and the difference shows immediately. The zinc skin blocks water, oxygen, and pretty much anything else that starts rust, so the metal underneath stays clean. Even if a nick opens up, the zinc gives first, eating itself while the base steel stays safe. Plain iron has no such armor and wrecks fast once it meets damp air. For bridges, rooftops, or anything that lives outside, galvanized metal wins without argument.

The Role of Zinc in Preventing Rust

Zinc fights rust at two levels: it seals up gaps to keep moisture out, then offers sacrificial protection by corroding itself.

Comparing Corrosion Resistance in Iron and Galvanized Steel

| Parameter | Iron | Galvanized Steel |

|---|---|---|

| Corrosion Resistance | Prone to rust, especially in moisture-rich environments. | Zinc coating provides strong, long-lasting protection. |

| Sacrificial Protection | No sacrificial protection. | Zinc corrodes first, protecting the base material. |

| Reaction to Damage | Rust spreads once exposed. | Surrounding zinc protects damaged areas. |

| Resistance in Saltwater | Susceptible to pitting and quick deterioration. | Resistant but less effective in salty environments. |

| Longevity | Limited life due to rust. | Lasts 50+ years under average conditions. |

| Maintenance Requirements | Requires regular maintenance to protect surface. | Minimal maintenance needed due to zinc coating. |

| Application Suitability | Best in non-moist environments. | Ideal for outdoor and high-moisture use. |

Factors Affecting Corrosion in Metal

Corrosion is like metal sneaking a slow, secret tear right through itself. Water and oxygen are the mischievous twin culprits that kick off those hidden rust-reaction parties. Dial up the humidity, crank up the heat, or sprinkle in a little salt-coastal towns and busy factories know that soundtrack all too well, and the metal wears out fast. What the steel is made of matters too; a simple zinc coating can act like an umbrella in a surprise rain. Spotting these risk factors early lets builders and homeowners stretch a projects life way beyond its original countdown.

What are the Uses for Galvanized vs. Iron?

Galvanized iron remains a staple in manufacturing and building trades because it combines low maintenance with remarkable toughness. The base iron or steel is dipped into molten zinc, forming a bond that keeps rust locked out for years. The coating occasionally scratches, yet the exposed metal usually oxidizes far more slowly than untreated steel.

- Construction and Infrastructure

Roofing sheets, gutters, and wall caps in residential and commercial projects routinely cross-cut the skyline with their shiny finish. Engineers also favor galvanized members for trusses and utility poles, knowing wind, rain, and mid-century snow loads will not speed deterioration.

- Automotive Industry

Assembly lines now habitually coat chassis and underbodies with the zinc layer, anticipating winters laced with salt brine and slush. The procedure buys extra service years once the odometer flips, making roadside repairs less common for everyday drivers.

- Agricultural Equipment

Farmers store grain in silos and haul water in tanks built from the same alloy, trusting that summer heat and winter freeze will leave the metal intact. Barbed-wire fencing is quickly fashioned from wire that has already been dipped, cutting the number of maintenance rounds.

- Electrical Appliances

Lightweight housings for air conditioners or washing machines mix strength with corrosion resistance at a price point that does not disrupt household budgets. The material stays clean inside appliance factories, saving seconds that otherwise vanish to rust inspection.

- Piping and Fittings

Plumbers slip galvanized pipe under concrete floors and along warehouse walls, knowing moisture from condensation or storm runoff will be the only visitors. Repair crews can leave a drip joint overnight without panic since the replacement pipe off the shelf arrives already coated.

Uses of Iron

Plain iron remains remarkably adaptable yet rusts faster than its galvanized counterpart. The specific form- whether cast, wrought, or another variant- determines the material’s particular behavior and fit for a job.

- Construction

Uncoated iron still dominates in the skeletal framework of buildings, appearing in reinforced concrete beams, columns, and girders. Engineers often reach for cast iron in situations demanding pure compressive strength.

- Manufacturing and Tools

Wrought iron is used in ornamental work, such as gates, railings, and furniture. Beyond decor, iron alloys are used in tool-making, automotive components, and the hulking machines that keep factories running.

- Infrastructure

Cast-iron pipe and manhole covers march beneath city streets, handling sewage and the slow crush of traffic overhead. Their toughness means they resist cracking under unexpected loads.

- Energy and Transportation

While half-century steel may grab the headlines, plain iron still anchors electrical transformers, undergirds railway track, and ribs out hulls for ocean-going ships. Its combination of low cost and reliable strength keeps it on the list.

Comparison of Galvanized Iron vs. Iron

| Property | Galvanized Iron | Non-Galvanized Iron |

|---|---|---|

| Corrosion Resistance | Resistant, lasts 50+ years in rural areas and 20+ years in industrial/exposed environments. | Susceptible to rust and requires proper maintenance. |

| Durability | High, suitable for outdoor and extreme settings. | Depends on the type; cast iron is strong but brittle. |

| Cost | Slightly more expensive due to the zinc coating. | Generally more affordable upfront. |

| Maintenance | Low, requires minimal upkeep. | High, needs regular anti-corrosion treatments. |

Choosing Between Galvanized and Non-Galvanized Iron

Choosing between code-coated steel and bare iron usually depends on how wet the air is and how long you plan to keep the part. Plain iron works well for indoor ductwork and saves a little cash. For coastal piers, go galvanized unless you enjoy replacing hardware every few winters.

Common Applications of Galvanized Steel

- Construction Industry

Galvanized steel is a staple on job sites: think beams, vertical pillars, sheet roofing. The thick zinc coating fends off rust, a real plus for high-rise shells left open to rain and grit.

- Automotive Manufacturing

Frankly, most modern car bodies owe their longevity to this same steel. A chassis dipped in zinc outlasts harsh winters, beating road salt in the slow-motion duel of oxidation.

- Agriculture and Farming Equipment

Plenty of tractors drag plows and seeders that sport galvanizing. So do fence posts and grain bins because neither wet soils nor bleach-laden fertilizers can eat through that layer.

- Outdoor Structures and Furniture

Park benches, street lamps, balcony railings-give them time, and untreated metal turns powdery. Galvanized versions simply wait longer before asking for paint.

- Electric Utility Infrastructure

Look up next time a storm rolls past. The transmission towers and conduit trays soaring above highways are mostly galvanized; their strength is non-negotiable. Rust would be a deal-killer out there.

When to Choose Iron Over Galvanized Steel

| Parameter | Choose Iron When | Choose Galvanized Steel When |

|---|---|---|

| Corrosion Resistance | Not a priority | High resistance to corrosion needed |

| Cost | Budget-friendly option | Willing to invest in durability |

| Durability | Moderate durability is sufficient | Long-lasting material required |

| Heat Retention | High heat retention is needed | Heat retention is not critical |

| Malleability | Not required | High malleability is essential |

| Environment | Dry or low-moisture environments | Wet or corrosive environments |

| Application | Cooking, heating, or decorative uses | Plumbing, construction, or outdoor uses |

| Maintenance | Regular maintenance is acceptable | Low-maintenance material preferred |

| Pressure Handling | Low-pressure applications | High-pressure applications |

| Chemical Exposure | Minimal chemical exposure | Frequent chemical exposure |

Structural Uses of Steel and Galvanized Steel

| Parameter | Steel | Galvanized Steel |

|---|---|---|

| Durability | High strength, suitable for heavy loads. | Resists rust with zinc coating, long lifespan. |

| Corrosion Resistance | Requires coatings for rust protection. | Zinc coating protects reliably from corrosion. |

| Strength-to-Weight Ratio | High, adjustable with alloying materials. | Limited by rigid zinc-steel composite makeup. |

| Common Applications | Beams, columns, automotive frames, tools. | Roofs, bridges, fences, outdoor structures. |

| Suitability for Outdoors | Needs coatings for exposure. | Ideal for high-moisture environments. |

| Fabrication Flexibility | Highly customizable with alloying elements. | Less flexible due to zinc layer. |

| Cost Efficiency | Cost-effective for large structures. | Higher initial cost but low maintenance. |

| Lead Safety | Free from lead contamination risks. | Potential lead risks in some cases. |

How Does Steel Compare to Galvanized Iron in Malleability?

Plain steel is often more pliable than galvanized iron because the latter’s zinc coating can stiffen its surface. Engineers favor the relative flexibility of uncoated steel whenever tight curves or delicate profiles enter the design conversation. In contrast, galvanized iron earns its keep in environments where rain or salt spray would otherwise eat through the metal, so its toughness and rust-proof skin trump sheer bendability.

Properties of Malleable Steel Alloys

Malleable steel alloys arrive on the scene as a middle ground, marrying strength with the willingness to be worked. A typical specimen of this family sits in the tensile-strength band of 400 to 550 megapascals, a number that shifts slightly with heat treatment but seldom drops below that floor. Once within that bracket, the metal laughs at everyday loads, a point pipe makers and bridge builders appreciate.

The real party trick, however, is the material’s grace under compression; forge a slug of malleable steel or roll a slab flat and the stuff deforms without throwing a tantrum. Ductility lets the same alloy be pulled into wire or whittled into thin sheet when lighter products are called for. Finishers like it, too, because the steel drills clean, cuts on a lathe without chipping, and takes a weld as if the seam had never been there.

Malleable steel alloys are often praised for their remarkable combination of formability and hardness. Engineers commonly subject the material to heat-treatment cycles to ramp up its wear resistance; tempering after quenching is a standard step. Chromium additions or surface coatings fight rust, so the alloys keep working even in rain-soaked or seaside job sites.

Toughness also ranks among the alloys’ high cards, letting a given part soak up impact without cracking into a thousand shards. That resilience suits the steel for everything from automotive crankshafts to gas pipelines and the giant gears found in mining draglines. Because the material usually lands on procurement sheets at a lower price than titanium or high-strength aluminum, it earns its keep in both manufacturing bays and construction booms.

Impact of Galvanization on Metal Brittleness

Galvanization occurs when exposure is non-negotiable; a coat of molten zinc blankets the steel and shuts out moisture. People sometimes worry about brittleness creeping in, yet the zinc layer keeps the metal pliable while fighting corrosion. In my own shop I have watched treated beams outlast their untreated peers by a margin that easily justifies the plating line.

Choosing Steel or Galvanized Steel for Flexibility

| Parameter | Steel | Galvanized Steel |

|---|---|---|

| Flexibility | Highly adaptable for various alloys and structures. | Limited by zinc layer rigidity. |

| Workability | Easier to forge, cut, and shape. | Zinc coating complicates welding and alterations. |

| Heat Treatment | Effective and adjustable for desired properties. | Zinc interferes with heat treatment processes. |

| Corrosion Resistance | Needs coating for protection. | Zinc layer provides inherent corrosion defense. |

| Usage Scope | Suitable for heavy loads and intricate designs. | Best for outdoor use and simple elements. |

| Cost Efficiency | Affordable and versatile for broad applications. | Higher cost but durable in exposed environments. |

What are the Grades of Steel Used in Galvanized Iron?

Galvanized iron starts life as everyday steel, yet the choice of base alloy can alter its behavior and cost. Different finishing shops keep a short list of grades on hand.

- Commercial Steel, or CS, bends easily and absorbs dents, making it a reliable partner for mild forming jobs.

- Structural Steel, posted as SS on mill tickets, carries the bulk of skyscraper frames and bridge decks thanks to its stout yield limit.

- High-Strength Low-Alloy Steel answers the call when both toughness and moisture-readiness are non-negotiable.

- Forming Steel lives up to its name by stretching into sharp corners that would rip most plate-grade material.

With these options in stock, galvanized sheet is seldom forced into work it wasnt born to do.

Exploring Different Grades of Steel

| Steel Type | Sub-Type/Grade | Key Characteristics | Common Applications |

|---|---|---|---|

| Carbon Steel | Low Carbon (Mild Steel) | Up to 0.3% carbon, ductile, malleable. | Structural components, wires, bolts. |

| Medium Carbon | 0.3-0.6% carbon, balances strength and flexibility. | Machinery, automotive parts, railroad tracks. | |

| High Carbon | Above 0.6% carbon, strong but less ductile. | Cutting tools, high-strength wires, springs. | |

| Alloy Steel | 4140, 4340, 52100 | Medical tools, kitchen appliances, and construction. | Structural uses, bearing components. |

| Stainless Steel | 304, 316 | 10–20% chromium, corrosion-resistant, durable. | Cutting tools, high-strength wires, and springs. |

| Martensitic | Tough, prone to some corrosion. | Cutlery, medical instruments, pliers. | |

| Austenitic | High chromium/nickel, durable, non-magnetic. | Commercial appliances, food processing equipment. | |

| Duplex | Combines ferritic/austenitic, strong, corrosion-resistant. | Chemical, gas, oil pipelines. | |

| Tool Steel | D2, H13, M2 | Heat-resistant, wear-resistant, retains shape. | Cutting tools, drill bits, hand tools. |

The Importance of Steel Alloys in Galvanization

Steel alloys underpin the entire galvanization operation, shaping the final coating’s grip, longevity, and ability to fend off rust. Producers tailor chemical blends to meet the fluctuating needs of factories, bridges, and building sites. Five blends are especially familiar in hot-dip work.

- Carbon Steel remains the crowd favorite; its economy and easy availability let it slip into almost every project. A balanced carbon content delivers enough strength while leaving room for the stretch required when applying molten zinc.

- Silicon Steel enters when electrical performance and extra corrosion defense are required. The silicon modifies surface behavior, dictating how thick and how even the zinc layer will ultimately appear.

- Aluminum-Killed Steel relies on aluminum to mop up oxygen as the metal is poured. This quick chemistry lock-in creates fine grain patterns that boost workability and give the galvanized finish a polished look.

- Manganese Steel suits bone-jarring service; the alloying element stiffens the matrix and fights wear. Its presence also encourages the zinc to bond resolutely, even under punishing use.

- Dual-phase steel contains a microstructure of dispersed ferrite and martensite, yielding an unusual combination of tensile strength and ductility. Engineers favor the material when pressing body panels or grid frames for heavy trucks because it resists denting and absorbs crash energy.

Manufacturers fine-tune every alloy recipe to balance hardness, corrosion resistance, and behavior during hot-dip galvanizing. Choosing the right grade cuts maintenance expense and helps coated parts last for decades in wet or saline climates.

How to Choose the Right Steel or Galvanized Steel for Your Project

Picking the right steel-smooth plain sheet or spangled galvanized for your build is more than a quick guess. A little homework today means your beams and brackets last tomorrow. Recent factory chatter backs up the checklist below and thats no accident:

1. Understand Your Project Requirements

- Strength and Flex: Some jobs yank, others bend, and a few barely twist. Specs such as HX420 or DX51D say the metal can bounce back when the stress is turned off.

- Rust Hurdle: Shores or saltwater cut the lifespan of bargain-grade coatings like a lawn chair in December. Stick with Z275 zinc or thicker, because thicker plates look the same but behave very differently once the clouds roll in.

- Heat Story: A smoky shop or a desert highway cooks metal faster than expected. Adding silicon or aluminum to the mix keeps the molecules from scattering and the welds from blowing open.

2. Consider Thickness and Coating

- Material Thickness Heavy machinery, massive beams, or any job where steel has to stand tall usually gets thicker stock. A plate that feels heavy in your hands can keep a bridge or a warehouse roof from buckling. A plain galvanized sheet between 0.5 mm and 2 mm still does the trick for HVAC ducts or shed roofs, and that light stuff is cheap and easy to cut.

- Coating Performance The layer of zinc on that steel counts more than many folks imagine. Tests show hot-dip galvanizing can extend a product’s life by 50 years as long as it is kept out of the ocean splash zone.

3. Evaluate Environmental Conditions

- Steel gets rusty fast in factories or places with many airborne dirt. For example, putting on special galvanized zinc-iron or zinc-aluminum coatings can shield the metal from both dampness and nasty chemicals.

- When the job is near the ocean, grab the heavy-duty galvanized grades engineers have already tested in salty spray. Recent field studies show those steels hold up much better against pounding seawater.

4. Assess Sustainability Factors

- Choosing reusable or eco-minded steel immediately trims the carbon footprint of nearly any building project. Take galvanized steel—it gets recycled repeatedly and still checks off the big sustainability boxes that global plans keep waving about.

- To keep those eco-pats on the back coming, buy from mills that sport ISO 14001 badges or similar green stamps. That little logo usually means they’ve already reduced their waste and impact.

5. Analyze Cost Versus Performance

- Cost always pokes its head into the equation, right alongside performance. Simple gut-feeling guesses dont cut it; a cost-per-service-year math lets the two fight fair. Zinc layers and alloy cocktails shake the price tree, so look for that number hashed out on an honest life-cycle sheet.

- Price tags from early 2023 put run-of-the-mill galvanized in the 700−to−700−to−1,200-per-ton ballpark, but coating gauges and swinging world demand keep pulling that drumstick up and down. Know your specs, then buy close to the bottom quartile if budget whispers do it cheap.

6. Consult Industry Experts

- Even the shrewdest G.C.s hit a wall now and then. Chatting with a sharp structural engineer or a veteran materials rep often loosens the next step. Custom schemes, weird spans, and prototype doodles almost always get better answers the sooner you ask.

When you weigh all these factors and tap into the newest steel and galvanizing upgrades, your material choice will likely match your project targets. A quick stop at ASTM International’s steel and galvanizing specs, or the product brochures from your favorite suppliers, can fill in any remaining gaps.

References

- Inquiries at the GalvInfo Center about Construction and Appliance Applications of Zinc-Containing Coated Steel Sheet – Discusses applications and properties of galvanized materials.

- Electrochemical behavior of galvanized steel embedded in soil – Explores the corrosion behavior of galvanized steel in specific environments.

- Influence of corrosive inundation on the corrosion rates of galvanized tie strips in mechanically stabilized earth walls – Examines the performance of galvanized steel under corrosive conditions.

Frequently Asked Questions (FAQ)

Q: What are the main differences between iron and galvanized steel?

A: The main differences between iron and galvanized steel lie in their composition and properties. Iron is a pure element that can be brittle and prone to rusting, while galvanized steel is iron or steel coated with a protective layer of zinc. This zinc coating helps prevent corrosion, making it more durable in outdoor applications.

Q: How does the zinc coating on galvanized metals work?

A: The zinc coating on galvanized metals acts as a protective barrier that prevents moisture and oxygen from reaching the steel or iron surface. This layer of zinc also offers sacrificial protection, meaning it will corrode before the underlying metal does, thus extending the longevity of the metal.

Q: Why is galvanized iron vs regular iron used in construction?

A: Galvanized iron is often used in construction because it is more corrosion-resistant than regular iron. The protective zinc layer helps prevent rust and extends the lifespan of the materials, making them ideal for structures exposed to the elements.

Q: Can galvanized steel or stainless steel be used interchangeably?

A: Galvanized and stainless steel have different properties and are not always interchangeable. Galvanized steel is covered with a zinc coating, while stainless steel contains chromium, which makes it more resistant to rust and staining. Stainless steel is generally more durable and suitable for high-exposure environments, whereas galvanized steel is often more cost-effective for general use.

Q: What is the process of creating galvanized metals?

A: Creating galvanized metals involves coating the iron or steel surface with a zinc layer. This is typically done through hot-dip galvanizing, where the metal is submerged in molten zinc, or through electroplating, where an electric current is applied to the zinc coating.

Q: How does black iron compare to galvanized iron in terms of durability?

A: Black iron, a type of carbon steel, lacks the protective zinc coating found on galvanized iron, making it more susceptible to rust and corrosion. With its protective zinc layer, galvanized iron is generally more durable and better suited for outdoor and moisture-prone environments.

Q: Is there a difference in tensile strength between iron vs galvanized steel?

A: The tensile strength of iron vs galvanized steel may vary depending on the specific types of steel used for galvanization. Generally, the galvanization process does not significantly affect the tensile strength, but it does improve corrosion resistance, thus enhancing the overall durability of the material.

Q: What are some typical applications for galvanized iron and steel?

A: Galvanized iron and steel are commonly used in a variety of applications, including construction (such as structural steel and iron pipe), automotive parts, outdoor furniture, and fencing. Their corrosion-resistant properties make them ideal for environments with moisture.

Q: Are there any downsides to using galvanized metals?

A: While galvanized metals are corrosion-resistant, they are not entirely corrosion-resistant, especially in environments with high acidity or salinity. Over time, the zinc layer can wear away, exposing the underlying metal to potential rust. Additionally, the aesthetic quality of the zinc coating may diminish over time due to weathering or environmental exposure.