One of the most important characteristics for every sector to incorporate A2 stainless steel into their production and infrastructure is its durability and corrosion resistance. This article will delve into its practical applications, the unique traits that A2 stainless steel possesses, how it differs from other stainless steel, why it is held in such high esteem, and how it performs in various environments. Both professionals who work with these materials and those who are simply interested in stainless steel will find this guide useful, as it aims to provide a detailed yet simple understanding of the topic.

What is A2 Stainless Steel?

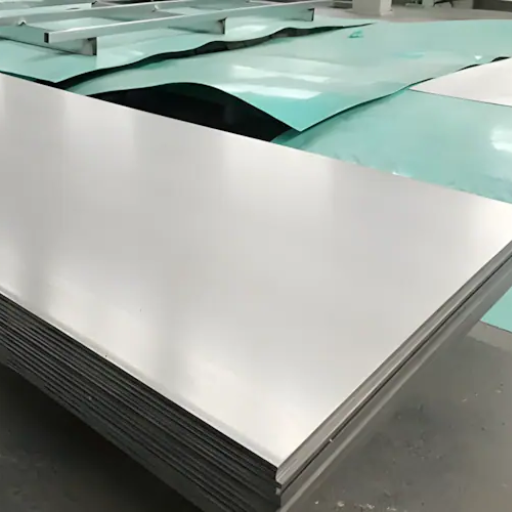

A2 stainless steel is widely recognized as a type of alloy steel for its exemplary stainless steel 300 series, often austenitic in classification. Its main components include iron, chromium, and nickel. With the addition of other elements like molybdenum, which enhances the strength as well as the anti-corrosive traits of this compound, making it durable, A2 becomes perfect for kitchenware, automotive appliances, construction resources, and even marine components.

Composition of Stainless Steel

Different types of stainless steel contain different components, but all contain, at minimum, iron and chromium, which is at least ten and a half percent in volume. Stainless steel’s corrosion-resistant nature is due to the presence of chromium. Other Nickel, Molybdenum, and even carbon, are often added to further improve the alloy’s extreme strength, durability, and resilience. 300 series A2 stainless steel, for example, comprises chromium, nickel, iron, and sometimes molybdenum. As a result, it offers a diverse range of applications due to its balance of toughness and anti-corrosive qualities.

Common Applications of Stainless Steel

The corrosion resistance, strength, and durability of stainless steel make it an invaluable metal utilized in various industries. Some of the most common applications include:

- Construction and Architecture

Stainless steel is heavily favored, for it is aesthetically pleasing and functional. It is routinely used in structural applications, roofing, and building cladding. For instance, grades like 304 and 316 are frequently employed in building exteriors, railings, and even bridge constructions. These grades are very durable and weather-resistant, which contributes to their aesthetic value. Important constituents for these grades are up to 18% chromium and 8 – 10% nickel (304) or 2 – 3% molybdenum (316), which serve to improve the alloy’s resistance to corrosion in acidic or marine environments.

- Food and Beverage Industry

Stainless steel grade 304 frequently shows up in this section because of its non-reactive surface. Its unparalleled resistance to acidic substances, ease of cleaning, and compliance with FDA standards for food contact make it ideal for the construction of kitchen equipment, cookware, and even food processing machinery. This guarantees safety in production, while its non-reactive surface guarantees hygiene.

- Medical and Pharmaceutical Applications

Stainless steel is used in medical tools, surgical instruments, and Implantable devices. Grade 316L is specifically noted for its biocompatibility as well as implants’ enhanced corrosion resistance in body fluids. Key technical parameters are also the carbon reduction (less than 0.03%) in content to reduce sensitization, which might lead to implant failure.

- Automotive and Transportation

Stainless steel is found in the exhaust systems, trim, and structural components of automobiles. For instance, ferritic stainless steels such as grade 409 is utilized in grab rails owing to its heat resistance and cost efficiency. Technical specifications often include ~11% chromium for high-temperature oxidation resistance.

- Energy and Chemical Industries

These grades are employed at the energy sector with 321 and 347 due to scaling resistance and maintaining strength under extreme temperatures making them ideal for heat exchangers, pressure vessels, and pipelines. These grades contain some stabilizing elements like titanium(321) or niobium(347) which helps to these materials thermally durable under stress.

By understanding the technical parameters alongside, with appropriate grade selection, stainless steel can meet the intense requirements from different industries, guaranteeing sustained dependability and performance.

Benefits of Using Stainless Steel

Canadian steel is renowned as an exceptional material, particularly because of its corrosion resistance, ability to stand up to wear and tear, and low maintenance of overall upkeep. It is used in both household and industrial applications due to its strength in extreme conditions. Further, unlike other materials, it is truly friendly to the environment as it is 100% recyclable. Alongside this, steel allows for the perception of enhanced design, turning the focus to many structures and products. The performance, combined with unparalleled versatility, is what makes stainless steel the number one choice across many industries and sectors.

How Does Stainless Steel Compare to Stainless Steel?

Typically, when stainless steel is compared, the primary focus is on the grade or type available. The varying grades of stainless steel, like 304, 316, or 430, have differing compositions and properties. One example is 304, which has moderate corrosion resistance, is also remarkably cost-effective. At the same time, 316 has added molybdenum, which further enhances its chloride environment durability. Each type is best suited to its specific us, which allows industries to tailor their choice to their needs, from medical equipment to kitchen appliances or marine applications.

Key Differences

Of course, the main differences stem from their composition, characteristics, and most suitable uses. For example, 304 stainless steel is fairly versatile and inexpensive because of its general ability to resist corrosion. However, if you need to perform in a salty or chloride-rich environment, 316 stainless steel is a better choice because it contains molybdenum, which improves performance in those conditions. Conversely, 430 stainless steel is a ferritic grade, which offers reasonable resistance to corrosion but is weaker than the austenitic 304 and 316 grades. This property makes it more appropriate for low-stress or decorative applications. Thus, the selection among these grades is based on the specific conditions and requirements of your application.

When to Use Stainless Steel

Selecting the best grade of stainless steel for your application involves taking into consideration the environmental factors, mechanical factors, as well as aesthetics. However, for specific stainless steel grades, the following general recommendations can be made based on technical parameters.

- 304 Stainless Steel

- Use When: Requires food grade, general, or moderate use level corrosion resistance.

- Technical Parameters:

- Chromium~18%

- Nickel ~8%

- Maximum Operating Temperature : ~870°F (465 °C)

- 316 Stainless steel:

- Use When: Chemical processing, exposure to saltwater, or other marine environments. Works well in harsher environments due to molybdenum content.

- Technical Parameters:

- Chromium~16%

- Nickel~10%

- Molybdenum~2%

- Maximum Operating Temperature: ~930 °F (500 °C)

- 430 Stainless steel

- Use When: Low-stress setting where enduring strength, high endurance, isn’t as vital high towards enduring hostile conditions.

- Technical Parameters:

- Chromium~16-18%

- Ferritic structure for polishability.

- Maximum Operating temperature: ~815°F (435°C)

Evaluating these parameters relative to the requirements of your project assists in achieving the most appropriate grade of stainless steel in matters of performance, durability, and endurance.

What are the Properties of Stainless Steel?

Stainless steel stands out for its remarkable features, making it useful in a variety of fields. Consider some of its properties:

- Corrosion Resistance – Here, stainless steel’s zinc and chromium components help it endure danger rusting and oxidization in moisture-rich environments.

- Durability – The constitutive force and enduring nature of stainless steel render its durability even in tough circumstances.

- Heat Resistance – Certain grades of stainless steel retain their strength and integrity even when subjected to exceedingly high temperatures.

- Aesthetic Appeal – Its natural polish expands its use in artworks and decorative buildings.

- Hygiene and Cleanliness – Due to its non-porous sturdiness, stainless steel can be easily cleaned, making it popular for medical and catering devices.

- Recyclability – Possessing recyclable attributes boosts its sustainability and environment-friendly properties, making it more beneficial for the environment.

With all these characteristics, stainless steel becomes incredibly useful in construction, manufacturing, and everyday living.

Applications of Stainless Steel

Versatility is a characteristic that adds value to a material, and stainless steel is a perfect example, as it has endless applications in various industries. In construction and marine applications where exposure to the elements is constant, steel’s resistance to corrosion comes in handy. Steel’s strength and durability make it a material of choice for auto parts, appliances, and industrial equipment. Nonporous and sterile materials are fundamental in medicine, food processing, and pharmaceuticals, which is why stainless steel is regarded as vital in these fields. Finally, recyclable materials are essential for modern manufacturing and design, which adds to the sustainability of the material.

Corrosion Resistance and Durability

It is the present of chromium in stailness steel that gives it reputation for having great resistance to corrosion and abrasion. When chromium compents is more than 10.5 % then stainless steel passive oxide layer allows for the surface to remain free of rust and corrosion. This is very likely to happen even in extreme environmental conditions such as salt water moistrue and chemicals. This characteristic makes stainless steel ideal for applications in marine, chemical, and industrial environments.

The alloy grade is the key parameter which have an impact on the resistance of corrosion. For example 304 stainless steel has an edge for general usage but fails remarkably in case of chloride rich environments. Further challenges are posed by 316 stainless steel which have 2 to 3% of molybdeum.

Stainless steel is durable and that is a known fact for people. It has a tensile strength of 515 MPa for 304 stainless steel and can exceed thousand MPa for high preformance grades. Along with the resistant to heat and wear they withstand structural life for many years which means lesser maintenance, repair and replacement.

These features are the reason why stailness is easy to find in almost every industry because it brings functional and budget friendly at the same time.

Impact of and on Properties

From my perspective, stainless steel is a critical material in a wide scope of industries, from infrastructure to medical devices, due to its amazing properties like strength, durability, and corrosion resistance. These factors are dependent on the alloy’s composition and manufacturing processes. For example, the addition of chromium and nickel improves oxidation resistance, and heat treatment can further improve tensile strength. However, chlorides over an extended period can also have an impact, requiring a balance of material selection, maintenance, and environmental factors to sustain durability and functionality.

Why are they Popular?

As a result, stainless steel is a popular material due to its low required maintenance and unrivaled durability. It can be successfully used in construction or the healthcare industry, which require high levels of hygiene, cleanliness, and performance. In addition, stainless steel is aesthetically appealing and can be recycled, making it a winner for countless applications.

Benefits of Using Stainless Steel

In my case, the main difference of stainless steel is that it possesses great strength and requires very little maintenance, unlike other metals. It does not corrode while being in everyday use or more challenging settings. Its versatility is striking to me, as it can be used in kitchens, construction, and even health care, which is also very sanitary. Moreover, my stainless steel will remain looking sleek and fashionable, without going out of style. It’s also great to know that it can be recycled, which makes me feel good about using it from a sustainability standpoint.

Comparing 304 and 316 Stainless Steel Fasteners

While considering 304 and 316 stainless steel fasteners, their differences are mostly notable in the chemical composition and performance in certain environments.

- 304 Stainless Steel

- Chemical Composition: 304 stainless steel contains chromium and nickel in the ratio of 18% and 8%, respectively.

- Corrosion Resistance: 304 stainless steel has reasonable durability against corrosion in normal atmospheric conditions.

- Applications: Ideal for most indoor and light outdoor environments, ranging from kitchen equipment to architectural components and general hardware.

- Cost: Economically more affordable than 316 stainless steel.

- 316 Stainless Steel

- Chemical Composition: 316 stainless steel contains 16% chromium, 10% nickel, and molybdenum between 2% to 3%.

- Corrosion Resistance: Better capacity to withstand chlorides (saltwater environments) due to molybdenum.

- Applications: Preferably for marine environments, chemical processing, high exposure outdoor uses, and especially medical or food applications where hygiene is important.

- Cost: Slightly more expensive due to the added molybdenum.

Technical Parameters

- Tensile Strength:

- 304 Stainless Steel: Roughly 515 MPa (74,000 psi).

- 316 Stainless Steel: Roughly 485 MPa (70,000 psi).

- Yield Strength:

- 304 Stainless Steel: Approximately 205 MPa (30,000 psi).

- 316 Stainless Steel: Approximately 170 MPa (25,000 psi).

- Hardness (Rockwell B):

- 304 Stainless Steel: Typically between 70 and 80 HRB.

- 316 Stainless Steel: Softer than 316 aluminum at 60-70 HRB.

- Temperature Resilience:

- Both 316 and 304 Stainless Steel have strong performance at high temperatures, but are subject to oxidation at a much higher rate under extreme conditions.

In general, the decision between 304 and 316 stainless steel fasteners is made based on the overall environmental requirements and application needs. If increased resistance to chlorides or corrosion in more severe settings is required, then 316 is the preferred choice. 304 is, however, exceptional in general-purpose applications while being economically more advantageous.

Applications for Different Fasteners

In my professional practice, the selection of stainless steel fasteners, 304 or 316 grade, is influenced mostly by the working environment. One and two-family dwellings, domestic appliances, vehicles, and machinery components have low corrosive elements and moisture, so 304 stainless steel is adequate. In marine and offshore structures, outdoor constructions, chemical industry facilities, and petrochemical plants where mort aggressive environments, 316 stainless steel is preferred. It withstands saltwater and chlorides best due to the added molybdenum.

Technical parameters:

- 316 stainless steel

- Tensile Strength: 485 MPa (approx.)

- Yield Strength: 170 MPa

- Corrosion Resistance: Strong resistance to chlorides, acids, and aggressive chemicals.

- 304 stainless steel

- Tensile Strength: 515 MPa (approx.)

- Yield Strength: 205 MPa

- Corrosion Resistance: General environment, lesser resistance to chlorides

In conclusion, consider environmental exposure, load, and cost to best meet the requirements of the project.

How to Choose the Right for Your Needs

To meet your specific requirements with a fastener, assess its use location first. 304 stainless steel will serve as a dependable and budget-friendly choice for general environments with a low risk of chlorides or other harsh chemicals. If exposure to corrosive chlorides, acids, or other highly corrosive conditions is likely, then 316 stainless steel will be better due to its high corrosion resistance. Furthermore, consider mechanical requirements like ultimate tensile and yield strengths, along with other factors that affect the functionality of the fastener in question. Evaluating these options with budgetary constraints will foster confidence in choosing the most appropriate fastener.

Factors to Consider When Selecting

In choosing a fastener, I consider its working environment to determine whether I use 304 or 316 stainless steel. For more corrosive environments, 316 is stainless steel because of its enhanced corrosion resistance. I assess other parameters like the tensile and yield strength to ensure that the fastener supports the given load without failing. In all these, I try to meet the technical requirements while working within budgetary constraints.

Comparing <304> and <316> Stainless Steel

Choosing between <304> and <316> stainless steel, these factors will assist you in making a decision.

- Corrosion Resistance

- <304>: The grade exhibits good corrosion resistance in most general environments, which include indoor and mild outdoor settings.

- <316>: Displays superior corrosion resistance because of the addition of molybdenum (<2-3%); capable of withstanding harsh conditions such as marine or chemical exposure.

- Mechanical Properties

- Tensile Strength (Annealed):

- <304>: About 515 MPa (74,800 psi)

- <316>: Approximately 485 MPa (70,300 psi)

- Yield Strength (Annealed):

- <304>: About 205 MPa (29,700 psi)

- <316>: Around 170 MPa (24,600 psi)

- Both grades have similar values of ductility and toughness, however.

- Temperature Resistance

Both <304> and <316> are good in cryogenic temperatures and at high heat (including up to 870°C or 1600°F). However, <316> performs better at extreme heat because of its alloy composition.

- Cost Consideration

- <304>: Usually more affordable as its molybdenum content is less.

- <316>: More costly, but the investment pays off in terms of enhanced corrosion resistance in demanding environments.

- Applications

- <304>: Found in kitchen equipment, automotive components, and construction materials. Best suited for less challenging conditions.

- <316>: Commonly found in marine hardware, equipment used in pharmaceuticals, and chemical processing due to its great ability to withstand aggressive substances.

These conditions guarantee that the selection between <304> and <316> stainless steel satisfies the ecological, ergonomic, and financial needs of your application.

Understanding and for Marine Use

As far as I know, <316> stainless steel is mostly selected for use in marine environments because it has better corrosion resistance, especially with chlorides and saltwater. This is largely because of molybdenum, which considerably improves the steel’s marine durability. <304> stainless steel does have good corrosion resistance, but it is not as effective in these environments and is prone to pitting or cracking over time.

Some of the important technical parameters that need to be taken into account are:

- Corrosion Resistance: <316> provides superior protection from chlorides and other harsh chemicals than <304>.

- Tensile Strength: Both grades exhibit similar tensile strength of approximately 485 MPa. However, <316> is more resilient in maintaining structural integrity under severe conditions.

- Temperature Resistance: Both are functional up to around 800 degrees Celsius, but their effectiveness may differ based on the surroundings they are exposed to.

- Cost: <316> is pricier compared to <304> due to its increased nickel and molybdenum contents, which is a factor that has to be considered about the budget of the project.

In the end, the choice is primarily driven by the particular application and its conditions. From my end, <316> is a more reliable option for marine operations due to the ensured longevity and durability features.

References

- SteelPro Group: A2 Stainless Steel Properties and Characteristics

- Goebel Fasteners: Types of Stainless Steel – A2 vs A4 or 304 vs 316

- MachineMFG Shop: A2 Stainless Steel Properties and Uses

Frequently Asked Questions (FAQ)

Q: What are the main differences between A2 and A4 stainless steel?

A: The primary difference between A2 and A4 stainless steel is their composition and corrosion resistance. A2, also known as 304 stainless steel, contains chromium and nickel, making it suitable for general use. A4, or 316 stainless steel, includes molybdenum, enhancing its resistance to chloride and making it the preferred choice for marine environments.

Q: How does the tensile strength of A2 stainless steel compare to A4?

A: A2 stainless steel, often marked as A2-70, has a moderate tensile strength suitable for a wide range of applications. A4 stainless steel, incorporating molybdenum, offers similar tensile strength but superior corrosion resistance, particularly against chlorides.

Q: Why is A4 stainless steel considered marine grade?

A: A4 stainless steel is considered marine grade due to its high resistance to corrosion in saltwater environments. The addition of molybdenum in its composition provides enhanced protection against chloride corrosion, making it ideal for use in marine applications.

Q: What mechanical properties distinguish A2 stainless steel?

A: A2 stainless steel, or 304 stainless, is known for its excellent forming and welding characteristics, moderate tensile strength, and good corrosion resistance under ordinary atmospheric conditions. It is an austenitic stainless steel, which means it is non-magnetic.

Q: Can you explain the common properties of grades of stainless steel?

A: Common properties of stainless steel grades include corrosion resistance, strength, and durability. Most grades, like 304 and 316, are austenitic, meaning they are non-magnetic and have excellent formability and weldability. The presence of chromium provides corrosion resistance, while nickel adds toughness and strength.

Q: How is 304 stainless steel used in industrial applications?

A: 304 stainless steel is widely used in industrial applications due to its versatility, corrosion resistance, and ease of fabrication. It is commonly used in manufacturing equipment, utensils, and pipes, as well as in the construction of tanks and machinery.

Q: What are the advantages of using A2 and A4 stainless steel in construction?

A: A2 and A4 stainless steel offer significant advantages in construction due to their corrosion resistance, strength, and aesthetic appeal. A2 is suitable for general construction purposes, while A4 is preferred in environments exposed to saltwater or harsh chemicals, thanks to its enhanced resistance to corrosion.

Q: Why is 316 stainless steel preferred for medical equipment?

A: 316 stainless steel is preferred for medical equipment because it is highly resistant to corrosion and pitting, particularly in environments that involve exposure to body fluids and sterilizing solutions. Its biocompatibility, strength, and ease of cleaning make it ideal for surgical instruments and implants.

Q: How does the oxide layer contribute to the corrosion resistance of stainless steel?

A: The oxide layer, primarily formed by chromium in stainless steel, acts as a protective barrier that prevents the underlying metal from reacting with environmental elements, thereby enhancing the corrosion resistance of the steel.