In industries from construction and manufacturing to engineering and metalworking, metals are subjected to so many heat treatments that having an in-depth understanding of their melting points would be of utmost pertinence. If anyone is conditioned to accept that metals melt and start to flow and cannot really comprehend what happens below the surface when a metal is heated, this can certainly mean an opportunity for an inferior product or worse, failure of critical scale. This guide aims to impart a brief yet complete assessment of steel melting points and that of metals and their importance, in addition to how such knowledge can be used to optimize processes and ensure safety.

What Does Steel Composition Mean?

The steel composition is essentially a specific mixture of elements, mostly iron and carbon, constituting that material. I personally feel that understanding steel composition is central to every issue because it affects melt point, strength, and how well steel performs in different applications.

What are the Elements Constituting Steel?

Steel is basically an alloy of iron and carbon, the carbon content of which usually measures between 0.02% and 2.1% by weight, depending on the type of steel and its set application. Carbon makes iron stronger and harder while it increases the resistance to wear and deformation. Although other elements exist that may be added to steel to further improve specific properties of the metal or to make it suitable for certain uses: manganese imparts durability, chromium imparts corrosion resistance in stainless steels, and nickel bestows toughness and strength at low temperatures.

In contemporary steel-making, trace amounts of additional elements like silicon, sulfur, and phosphorus are often used, each controlled to give specific properties in a given application. For example, silicon on one hand would enhance magnetic properties, whereas controlled amounts of sulfur and phosphorus would confer machinability.

The Relation Between Composition and Melting Point

Melting point is one of the most important properties of steel and is influenced by composition. Being the highest in percentage in steel, iron melts at about 2,800 F° (1,538° C), but its value is considerably shed apart as carbon atoms and other alloying elements like chromium, nickel, manganese, and molybdenum are introduced.

The carbon content of steel in this respect is very important-high carbon lowers our melting point. For example, the melting point of low carbon steel below 0.3% carbon is nearer 2,500° F (1,370° C); whereas a melting point nearer 2,300° F (1,260° C) will be given by steel with carbon content above 0.6%. Alloying materials can also either raise or lower the melting point. The presence of chromium and nickel that are usually contained in stainless steels creates a resistance to heat and oxidation that increases slightly the melting point.

Melting points of different types of steel may vary from one steel to another, and from one alloy to another. For instance, austenitic stainless steels like 304 stainless usually melt somewhere within the range of 2,550°F to 2,650°F, while superalloys for very-high-temperature applications would have compositions adjusted to be used under extreme heat.

Carbon Steel Melting Points

Carbon steel varies widely in melting point depending on the carbon makeup of the steel and the particular alloy; it is also valued for its versatility and strength. Usually, the melting point of carbon steel ranges between 2,500°F (1,370°C) and 2,800°F (1,540°C). These differences are mainly determined by the level of carbon in the steel:

| Steel Type | Carbon Content | Melting Point | Properties |

|---|---|---|---|

| Low-Carbon Steel (Mild Steel) | Less than 0.3% | 2,700°F (1,493°C) | Ductile and excellent welding capacity |

| Medium-Carbon Steel | 0.3% to 0.6% | 2,600°F (1,427°C) | Balanced strength and workability |

| High-Carbon Steel | 0.6% to 1.0% | 2,500-2,550°F (1,370-1,399°C) | Hard but less ductile |

Ranges of Melting Points of Alloy Steels

An alloy steel is a steel with a mixture of elements such as chromium, nickel, molybdenum, vanadium, and tungsten, showing a melting point that varies according to its elemental makeup. But the elements themselves tend to improve the mechanical properties of the steels (e.g., strength, corrosion resistance, and wear resistance), yet the melting phenomena become modified.

Chromium-Alloy Steel

With chromium, hardness and oxidation resistance are improved. This steel usually has melting points ranging from 2,500°F to 2,650°F (1,370°C to 1,455°C).

Nickel-Alloy Steel

Known for their ability to resist corrosion and impart excellent toughness, nickel alloys melt within 2,642°F to 2,752°F (1,450°C to 1,512°C) depending on nickel to other-element ratios.

Molybdenum-Alloy Steel

Molybdenum imparts high-temperature strength and melts within the temperatures 2,623°F to 2,717°F (1,439°C to 1,491°C).

💡 Determining Melting Point

The first approach to determining the melting temperature of an alloy steel would be to check data sheets or databases bearing material property data related to the alloy composition. If exactly such data were unavailable, then laboratory testing would be conducted, perhaps utilizing devices for differential scanning calorimetry (DSC), to determine at what temperature the alloy passes from being solid to becoming liquid.

Melting Point Measurement

Melting points, being an important parameter, accurately need to be measured for different industrial and scientific applications. The main methods of determination are briefly described, together with their advantages and disadvantages:

- Capillary Tube Method

In the conventional method, a small amount of the material is taken in a thin-walled capillary tube, which is then heated under a controlled atmosphere, noting the temperature at which it passes from solid to liquid. Most laboratories use this method mainly because it is dependable and simple. - Differential Scanning Calorimetry

This is an advanced and accurate method of measuring melting points. It is based on the comparison of heat flow of a sample with the heat flow of a reference material when both are slowly raised in temperature. This method sets out to provide extremely accurate data and is therefore commonly used for material characterization of polymers and alloys. Accurate measurement is assured within ± 0.1C according to studies. - Optical Thermal Analysis

With optical methods, the sample is heated visually, often through the medium of a microscope or specially designed imaging system, to locate the exact moment of melting. This is useful when small or irregularly shaped samples are involved, as direct observation of the phase transition is possible.

Influence of Melting Points on Industrial Applications

Melting points influence several industrial applications by affecting the material’s response in a specific process. For instance, metallurgy requires exact knowledge about melting points for producing alloys and for welding; similarly, pharmaceutical industries rely on melting points for proper formulation and stability of compounds.

Construction and Structural Applications

The melting points of metals serve as major considerations for constructing and structural applications. For example, steel with its melting point in the vicinity of 1370 to 1500 °C, depending upon carbon content, is used extensively as construction material in buildings, bridges, and other infrastructures owing to its strength, durability, and deformation resistance at elevated temperatures. Also, aluminum, melting at 660°C, is employed widely for lightweight constructions and their components and is increasingly taking center stage in contemporary architecture.

Titanium alloys, with melting points near 1668°C, are being promoted for structural applications where outstanding strength-to-weight ratios and resistance to extreme environmental conditions are required. These are most useful in high-performance fields such as aerospace and advanced engineering projects.

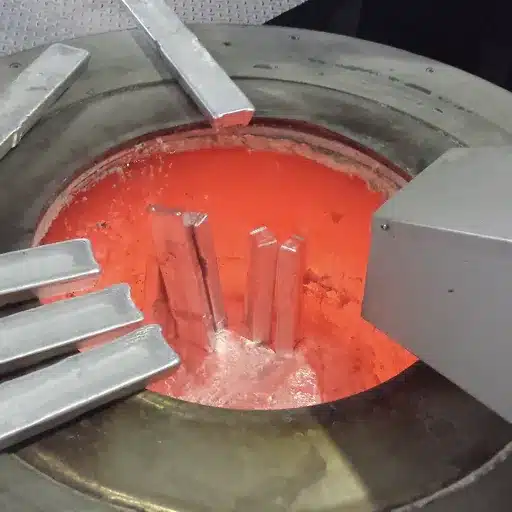

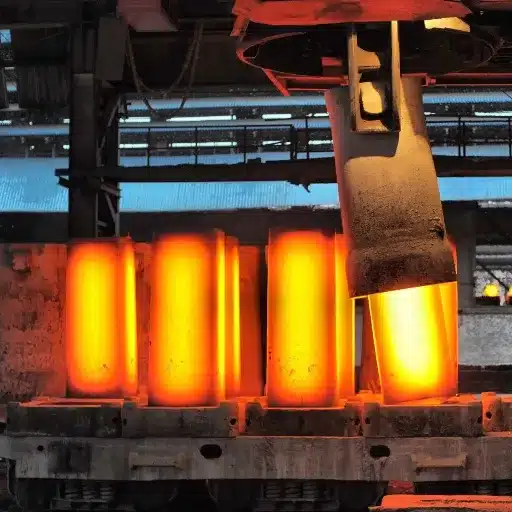

Manufacturing Applications and Steel Melting

Melting steel forms the basis of numerous processing routes leading to the production of high-performance materials used in construction, automotive, and industrial applications. The steel-making process starts from raw materials such as iron ore, coke, and limestone. These materials undergo processing through blast furnaces, thus turning iron ore into molten iron. This molten material is then sent into either basic oxygen furnaces (BOFs) or electric arc furnaces (EAFs) so that steel with the required composition and properties may be produced.

In modern steel production, a number of enhancements and innovations have been incorporated to increase efficiency and sustainability. An example is EAF, which drastically reduces carbon emissions compared to conventional BOF by using steel scrap as the major input. Based on data from the industry, carbon emission from EAF style of manufacturing is approximately 25% lower; hence, the greener alternative.

Reference Sources

-

SteelPro Group

- Title: What Temperature Does Steel Melt?

- URL: https://steelprogroup.com/manufacturing/property-1/melting-point/

- Description: This source explains the melting point of steel, which varies depending on its composition, generally ranging from 1370°C to 1530°C (2500°F to 2800°F).

-

Service Steel

- Title: What is the Melting Point of Steel?

- URL: https://www.servicesteel.org/resources/melting-point-of-steel

- Description: This resource provides a detailed range for steel’s melting temperature, from 2500°F to 2750°F, depending on its composition.

-

Tampa Steel & Supply

- Title: What Temperature Does Steel Melt?

- URL: https://tampasteel.com/what-temperature-does-steel-melt/

- Description: This article discusses the melting point of different types of steel, such as carbon steel, which melts at around 2500°F.

Frequently Asked Questions (FAQs)

❓ At what temperature does steel melt?

Steel melting temperature depends upon its chemical composition but generally lies between 1370 and 1510°C. Different steel types can differ slightly in melting points.

❓ How does the melting point of steel stand relative to melting points of other metals?

Steel has a melting point slightly higher than most common metals like aluminum alloys and copper alloys, which generally have lower melting temperatures. Aluminum melts at 660°C (1220°F) and copper melts at 1085°C (1985°F).

❓ What is the lowest melting point among metals?

A metal element mercury has the lowest melting point among commonly encountered metals; it melts at -38.83°C (-37.89°F). Comparing, lead and tin also have a low melting point but still higher than mercury.

❓ How does the steel type affect the melting temperature?

Depending on steel type and alloying elements, steel melting points can vary quite widely. For instance, steels that use stainless steel as a reference generally range from 1400°C to 1450°C (2552°F to 2642°F) in melting point because of the added chromium and nickel.

❓ What occurs at steel’s melting temperature?

Upon reaching the melting temperature, it begins to change from solid into molten steel upon melting. This step is critical in melting and casting, wherein steel is cast into various forms.

🔬 Key Takeaway

Understanding steel melting points is crucial for industrial applications, material selection, and process optimization. The composition of steel directly influences its melting temperature, making it essential knowledge for engineers, manufacturers, and construction professionals.