In the case of high-quality, durable, and adaptable materials, 316L stainless steel is definitely among the top choices that can be found in almost all industries. It is recognized for its astonishing corrosion resistance, high strength, and versatility, and that is why this type of stainless steel has gained its popularity in many fields such as medical devices, marine equipment, etc. But, what specifically makes the 316L stainless steel sheet and strip, especially the slit coil metal, to be so essential? This paper examines the extraordinary features and advantages of this high-class material, its applications, and properties, and the reason why it continues to be a preferred solution for the industries that require reliability and performance. Brace yourself to discover all about 316L stainless steel and its unmatched powers!

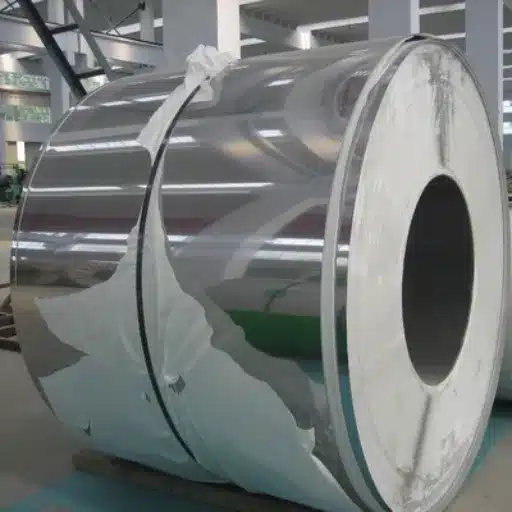

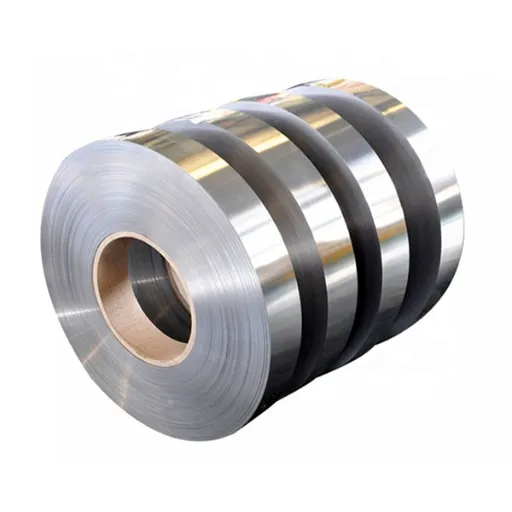

Introduction to 316L Stainless Steel Strip

What is 316L Stainless Steel?

316L Stainless steel is a low-carbon kind of 316 alloy that is still resistant to rust and very durable. It contains mainly of iron, chromium (16-18%), nickel (10-14%), and molybdenum (2-3%). Such a mixture has very good protection against pitting and crevice corrosion in places where there is a lot of chloride, thus becoming a very good choice for applications that are in contact with seawater or acidic chemicals.

The letter “L” in 316L indicates “low carbon” referring to its carbon content of 0.03% as a maximum. This low carbon content much lowers the probability of carbide precipitation during welding, thus, the weld has the same corrosion resistance as the rest of the material. Furthermore, 316L possesses a great tensile strength of around 579 MPa (84,000 psi) on average and at the same time has a remarkable heat tolerance, being able to work in environments that have cryogenic to very high temperatures.

Importance of 316L Stainless Steel Strip

The 316L stainless steel strip is a material of great importance to the modern industrial world because of the unbeatable performance it has and the ability to be used in different applications. One of the most important features is the excellent corrosion resistance mainly due to the 2-3% molybdenum content. This feature makes it very difficult for it to be affected by pitting and crevice corrosion in chlorinated and saline-rich areas which is the reason it is heavily used in the marine and chemical industries.

Moreover, the stainless steel strip 316L is widely used in the medical field due to its biocompatibility. Its inert property guarantees safe application in surgical tools, implants, and prosthetic devices, thereby eliminating the risks of rejection or contamination. For example, the manufacturers state that implants may

Properties of 316L Stainless Steel

Mechanical Properties of 316L Stainless Steel

316L stainless steel is well-known for its outstanding mechanical properties, thus universally accepted. It is characterized by its high strength, ductility, and toughness even under extreme conditions. The following are the most important mechanical properties that indicate the capability of this material:

- Tensile Strength: 485 MPa (70,000 psi) minimum, a guarantee that the steel is able to endure a high amount of stress and will not fail.

- Yield Strength: 170 MPa (25,000 psi) minimum, indicating the material’s quality of sustaining and bearing the forces exerted upon it without being damaged.

- Elongation at Break: Approximately 40% in testing under tensile, which means the material has very good flexibility and resistance to cracking when stretched or bent.

- Hardness: The Brinell hardness usually falls between 217 and 217 HB, which is a sign of the good hardness and machinability the material possesses.

Thickness and Dimensions

316L stainless steel is produced in various thicknesses and dimensions to cater to the industry who have different applications. Typically the material is produced in thicknesses of 0.5 mm up to 50 mm or more depending on the particular manufacturing procedure. The standard thicknesses of sheets and plates are 2 mm, 3 mm, 5 mm, and 10 mm, while other tailored dimensions can also be offered for specialized applications.

The dimensions of 316L stainless steel sheets and plates are often standardized to widths such as 4 feet (1219 mm) or 5 feet (1524 mm), with typical lengths ranging from 8 feet (2438 mm) to 10 feet (3048 mm). Moreover, 316L stainless steel tubes and rods are available in different sizes, typically from 6 mm to over 300 mm in diameter, with lengths customizable to meet the customer’s requirements.

Advantages of Using 316L Stainless Steel Strip

Corrosion Resistance

This is just one of many benefits that 316L stainless steel strip offers. Its corrosion resistance stands unmatched. The corrosion resistance is basically coming from the formation of an oxide layer on the surface of steel that resists corrosive agents-given by its high chromium content (16-18%) and molybdenum content (2-3%). In general, recent studies give the fact that 316L stainless steel can resist chloride-induced pitting and crevice corrosion better than other types of stainless steel, for which prioritization is given to marine environments, chemical processing, or any other exposure to high salinity conditions.

316L resists corrosion better than zinc in general acidic and alkaline conditions. It performs well in scenarios where thin stainless steel might degrade quickly, for example, with dilute hydrochloric, phosphoric, or sulfuric acid. It resists intergranular corrosion since low carbon amounts (hence the “L”) mean that it does not allow carbide precipitation during welding. Tested under the ASTM G48 Standard, the stainless steel 316L can achieve a critical pitting temperature (CPT) up to 30–50°C, depending on the surface finish and given environmental conditions.

Durability and Strength

316L stainless steel is considered the most durable and strongest due to the nature of its processing conditions. This nature demands the maintenance of structural integrity in any system that this material is critical for resistance to conditions of extreme stress. Manufacturing industries which predominantly handle the material containing a high chlorine content by way of an alternate media, i.e., marine or chemical, require that the 316L do not undergo pitting and crevice corrosion due to its low carbon content. The tensile strength hits an impressive mark of about 485 MPa, and the yield strength is at some 170 MPa; as such, it manufactures a stronger material that is largely applied by certain industries. 316L also maintains its mechanical properties and is applicable over a wide range of temperatures, thereby working well from about -200°C up to 500°C.

Furthermore, elongation being a very important property, the material can extend under a tensile load usually to about 40% in a standard condition, thereby allowing the material to bend during fabrication and use a little bit. Thus, it finally permits the 316L alloy to undergo higher stresses without undergoing deformation, an attribute imparted by its quite high modulus of elasticity of approximately 190 GPa. This alloy is considerably important for applications that have to deal with high pressures and high loads, like pressure vessels, heat exchangers, and structural components in corrosive environments. Its long life, ease of maintenance, and cost-effectiveness have contributed runners upstairs rank in assertion as materials for the most demanding Job-A Big.**

Common Applications of 316L Stainless Steel Strip

Use in Marine Environments

The 316L stainless steel strip has been greatly favored for marine applications because of its extraordinary corrosion resistance against chloride-induced pitting and crevice corrosion. The high molybdenum content of around 2-3% renders it resistant to the salt-laden atmosphere prevalent in marine environments.

Materials are subjected to conditions such as humidity, saltwater, and varying temperature extremes in marine applications. Based on the recent reports, the 316L stainless steel was found capable of sustaining these conditions for structural integrity over long terms. For instance, studies show the corrosion rate is less than 0.01 mm/year for seawater, ensuring a very long time into their working life with minimal deterioration.

Applications in Pharmaceutical and Food Industries

316L stainless steel is a very special material used in the pharmaceutical and food industries because it possesses excellent corrosion resistance and ease of cleaning due to its ability to resist harsher environments. This is where carbide precipitation and contaminants find an opportunity to enter. Such contamination is unacceptable to any sterile environment. This matter gains greater importance in the pharmaceutical industry because while manufacturing medicines and biologics, one should also maintain hygienic conditions.

316L stainless steel finds application in manufacturing bioreactors, storage tanks, and pipelines in pharmaceutical industries. It has a non-reactive surface and hence does not allow any interaction with the chemicals present in active ingredients which could affect the nature of the final product. According to a report by TMR Research, growth of 5% annually is anticipated in the use of 316L stainless steel for manufacturing pharmaceutical equipment in the coming days due to the worldwide expansion in pharmaceutical production.

Comparisons with Other Stainless Steel Alloys

316 vs. 304 Stainless Steel

1. Chemical Composition

The primary difference lies in molybdenum being present in the 316 grade stainless steel, at about 2-3%, and not present in 304. It is this element that gives 316 its ability to resist pitting and crevice corrosion, particularly in environments rich in chlorides such as in marine settings or chemical processing plants. 304 contains 18% chromium and 8% nickel, conferring upon it very good general corrosion resistance, albeit weaker than 316.

2. Corrosion Resistance

316 resists saltwater, brine, or industrial solvents well. It has been found that the stainless steel 316 lasts from about 2 to 20 times longer than the 304 with respect to chloride exposure. This is the reason why industries such as marine construction or pharmaceutical equipment manufacturing that value corrosion resistance select 316.

3. Temperature Performance

316 stainless steel acts superior to other alloys if the specimen must sustain prolonged exposure to elevated temperature ranges and adverse conditions due to its enhanced chemical stability.

Advantages Over Other Alloys

Stainless steel grades 304 and 316 have certain advantages over other metals due to their unique and particular property combinations. Stainless steels are corrosion resistant, superior in corrosive-resistance capacity to normal carbon steels and aluminum alloys. For instance, because of its molybdenum content, grade 316 stainless steel displays improved resistance to pitting and crevice corrosion-critical in marine or very salty environments.

Meanwhile, stainless steel alloys provide for greater tolerance to temperature. They maintain the structural strength and integrity either at extreme heat or at cryogenic conditions, thus making the usages fit for aerospace, construction, and chemical processing industries. For example, stainless steels can withstand intermittent exposures of up to 870°C (1600°F) without a significant loss in performance.

Reference Sources

-

Ulbrich Stainless Steels & Special Metals

- Website: Ulbrich – 316L Stainless Steel Strip Applications

- This source provides a comprehensive overview of 316L stainless steel strip applications, including its use in chemical processing, food processing, and oil refineries.

-

Combined Metals of Chicago

- Website: Combmet – 316 Stainless Steel Uses & Applications

- This page outlines the various uses of 316 stainless steel, such as in exhaust manifolds, jet engine parts, and pharmaceutical equipment, highlighting its versatility and durability.

-

EOS Material Data Sheet

- Website: EOS – StainlessSteel 316L Material Data Sheet

- This document provides technical details about 316L stainless steel, including its properties and suitability for industries like energy, paper, and transportation.

Frequently Asked Questions (FAQs)

What are the mechanical properties of 316L stainless steel strip?

The 316L stainless steel strip has very good tensile strength, good ductility, and corrosion resistance. Being an austenitic stainless steel, it offers strength at high temperatures and exhibits better creep resistance than other stainless steels. Hence, the steel has provided solutions in many applications, including chemical and food processing equipment.

What is the significance of UNS designation for 316L stainless steel?

UNS S31603 is the UNS designation for 316L stainless steel, distinguishing it as a low-carbon variant of type 316. This designation is essential for ensuring uniformity in material properties and performance across different applications, especially in those where carbide precipitation must be low.

What is the thickness range for 316L stainless steel strip?

316L stainless steel strip finds itself in different fates in numerous thicknesses, usually from very thin gauges to somewhat thicker sheets. Selection of the thickness is heavily dependent on application considerations, such as strength, weight, and ease of further processing, either in another piece of equipment or a structural application.

Does 316L stainless steel strip work well for molding applications?

The 316L stainless steel strip is indeed usable as a molding material. Its excellent formability and corrosion resistance make it suitable for fabricating components that require intricate shapes and high durability, particularly in food processing and medical applications.