When it comes to industries that demand durability and strength, abrasion-resistant steel plays a key role in ensuring that equipment and structures can face the toughest challenges. From construction, mining, manufacturing, and heavy machinery, AR steel provides a trusted solution in applications where extreme wear and tear form a daily occurrence. But just what is it about this steel that makes it so special, and how does one choose the type or grade best suited to their requirements? In this article, we shall discuss abrasion resistant steel in primary terms while touching on its main characteristics, and types available, including AR plates. Join us as we go on to see how this wonderful material can help you get the most out of your project through efficiently-light-weighted equipment, increased longevity, and cost savings.

Understanding Abrasion Resistant Steel

This type of steel is made to withstand wear caused by harsh working conditions, making it the hardest of all steels. While selecting the right grade, I’d focus on its application criteria, such as hardness, toughness, and thickness to ensure it suits the needs of the project. This definitely increases efficiency and the life of the equipment at my disposal.

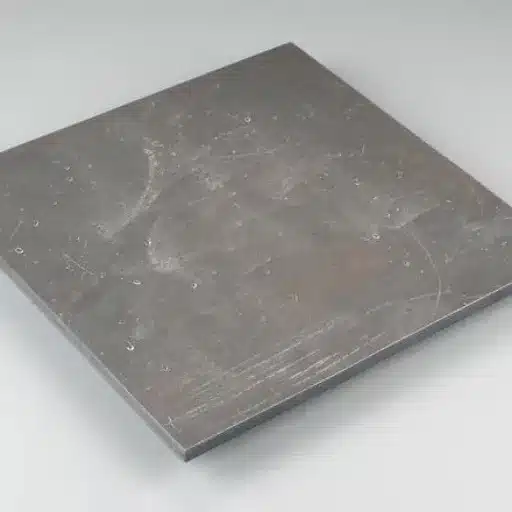

What is Abrasion Resistant Steel?

Abrasion-resistant (AR) steel is a high-carbon alloy steel specially treated to resist wear produced by continuous abrasion and impacts. This tough nature places it as a first choice for all applications involving heavy machines, mining equipment, construction vehicles, and industrial tools. Able to withstand very high degrees of hardness, AR steel varies between 200 and 600 Brinell hardness units (HBW) depending on the grade.

Key Features: Abnormal high performances are guaranteed by the unique blend of AR steel, starting from its chemical composition down to the manufacturing process. The hardness is ensured by higher carbon content, while a more sophisticated heat treatment ensures its further toughness and resistance to deformation. Some of the commonly used AR steel grades are AR200, AR400, AR450, and AR500, the numerics indicating the nominal hardness of steel in Brinell Hardness Scale.

Different Types of Abrasion Resistant Steel

AR400

AR400 is known to be a more versatile and durable grade with good balance among hardness, impact resistance, and formability. It sees use in areas such as mining, construction, and material handling. Dump truck liners, conveyor chutes, and industrial screens are all fairly typical applications where need for toughness and abrasion resistance is key.

AR450

This grade is a little harder than AR400, providing better wear resistance, while still allowing at least some machining and forming. With tensile strengths from 190,000 to 230,000 psi, it is suited for wear in hoppers, and work on wear plates, and heavy machinery, construction equipment which is subject to a moderate level of wear and impact.

AR500

AR500 is harder and more wear-resistant than the other two grades. This makes it an extreme choice for its applications, where tensile strengths of up to 250,000 psi confer almost unmatched levels of durability in ballistic-rated applications, mining tools, and shooting targets. It does have trade-offs in machinability and formability relative to AR400 or AR450 due to its high hardness.

Applications of Abrasion Resistant Steel

Abrasion-resistant steel is utilized in industries that need durability and wear resistance. From my point of view, the abrading wears away surfaces of construction equipment and mining machines, so there is barely any space for its applications with heavy vehicles as lining for bins, chutes, and hoppers. It tends only to work against friction, impact, or extreme conditions; in other words, it is a big help in an environment generated due to constant friction or impact.

Industrial Applications of Abrasion-Resistant Steel

AR steel is generally used in industries where there is a lot of wear and tear to which the material is subjected. The major mining equipment applications for which AR steel is used include dump truck beds, crushers, ejection systems, and chutes; these are all subjected to intense frictional force and impactive force of the rocks and debris, and the AR steel in the grades AR500 or AR450 are mostly preferred for their superior wear resistance.

Industry Impact: Recent industry figures are showing that the use of AR steel for mining equipment can enhance the working life of the machinery up to 5 times as compared to the normal steel, thereby decreasing the cost of maintenance by a great extent.

In addition, it is widely used in the construction industry to manufacture blades for bulldozers and buckets for excavators, as well as wear plates. Usage of AR400 steel in these applications is most common as it ensures an adequate level of hardness while retaining flexibility. The study shows that when construction companies start incorporating AR steel in their equipment, they enjoy around 20% increase in efficiency primarily because AR steel resists deformation when heavy loads are applied on it.

Construction and Mining Uses of Abrasion-Resistant Steel

Abrasion-resistant steel being of utmost durability to withstand harsh working conditions finds applications in heavy industries such as construction and mining. Its hardness levels and tensile strength make it a perfect material for working equipment components such as dump truck bodies, excavator buckets, crushers, loader systems, and conveyors. These components undergo extreme wear and tear of well-built materials to provision extended service life and assured operation.

Market Statistics: Market studies in mining and construction equipment across the globe revealed a stable demand for AR steel with the mining sector accounting for about 38% of the total usage of the material. For example, AR500 steel is widely used with its hardness rating of 500 HBW (Brinell Hardness) in mining equipment which drills, processes, and transports abrasive materials, such as iron ore, coal, and aggregate. Similarly, within the construction field, efforts to increase the durability of concrete mixers, tippers, and supports have incorporated AR steel under high-stress conditions.

Steel Type Comparison

This difference of steel types should be fine-tuned on the very needs of the application. For situations where wear and tear are of primary consideration, abrasion-resistant steel provides better wear resistance and durability. Where traditional steels have flexibility or a lower first cost as design considerations, such steels will be found most useful. For me, abrasion-resistant steel is the choice inasmuch as it offers the best cost over time and superior performance under severe conditions.

Abrasion-Resistant Steel versus Normal Steel

Abrasion Resistant (AR) steel and normal steel differ with regard to composition, properties, and applications. AR steel is produced for high-wear applications through the addition of certain alloys such as carbon, manganese, and chromium, combined with special heat treatment to provide grades of steel exhibiting much better hardness and durability, anywhere from 200 in Brinell Hardness (HBW) to more than 600 in HBW, depending on the grade selected. Whereas standard steel like mild steel will have hardness somewhere in the range of 120-180 HBW.

These are the areas that need AR steel: material handling where abrasion is obvious; mining, wherein equipment faces abrasive material almost on a daily basis; and construction. AR400 steel, as samples from studies suggest, would last in normal conditions for hard-liner steel: dump truck liners and excavator buckets in mine operations about 4-5 times longer than ordinary steel under test conditions. Meanwhile, standard steel will be best utilized for structural applications wherein flexibility and machining and welding still retain priority over abrasion resistance.

Comparison of Hardness: Brinell Hardness of AR400, AR450, and AR500

| Steel Grade | Brinell Hardness (BHN) | Key Applications | Characteristics |

|---|---|---|---|

| AR400 | 360-440 | Mining equipment, truck beds, construction machinery | High toughness, moderate wear resistance, balanced durability |

| AR450 | 430-480 | Hoppers, conveyors, high-wear components | Better wear resistance than AR400, good impact resistance |

| AR500 | 470-540 | Ballistic targets, armor plating, heavy-duty mining | Extreme wear resistance, hardest grade, reduced machinability |

Expert Insight: The Brinell Hardness Number (BHN) is a vital measurement for assessing the hardness and wear resistance of abrasion-resistant (AR) steels. AR400, AR450, and AR500 each have different hardness ratings, meaning that one or the other will be more or less useful for particular activities depending on how severe wear and impact are.

Recent Advancements in Abrasion Resistant Steel

It’s my belief that developments made in the drip of abrasion steels, namely AR400, AR450, and AR500, have bestowed greater capabilities on the types in terms of durability and resistance to wear for stoic purposes. Every grade, on the other hand, has his own peculiar benefits just apt for a particular need; however, AR500 finds itself extruded into real, heavy-duty work because of its superior hardness and performance, though the harder work means it is less machinable.

Innovations in Steel Production

A very recent development in steel production is one assurance that AR steel would remain stronger and perform better under service wear. The present-day production techniques of controlled rolling or finishing, and heat treating, yield uniform microstructures best tailored to function with maximum hardness and wear resistance. The quenching and tempering have been modified by strict control temperature wise, to produce steel of higher HB grades without sacrificing strength and toughness.

Nanotechnology Impact: Nanotechnology has also assisted steel manufacturers in reversing grain sizes at extremely fine levels. Reports suggest that nanostructured AR steels show wear resistance up to 30% higher than that of conventional AR grades because of better toughness and elimination of grain boundary defects.

On another front, alloy optimization has helped further in tuning AR steel compositions: chromium, boron, and molybdenum are incorporated in precise quantities to improve wear resistance under impact extreme conditions. For instance, AR500 grade steel with Brinell Hardness in excess of 500 HB withstands any real-life abrasion in mining and construction with the utmost indescribable durability.

Technologies of the Future in Fabrication

In the modern steel fabrication world, optimizing efficiency, accuracy, and sustainability through the injection of new technologies has appeared promising. Of all these advancements, the introduction of automated fabrication systems with robotic machinery is one of the most disruptive.

Automation Benefits: Recent reports from the industry have indicated that robotic automated fabrication systems can bring a 30% increase in productivity and almost 25% reduction in material wastage. Equipped with some of the highest proficiency level sensors integrated with AI-based algorithms, these robotic fabrication systems could perform complex design execution, requiring stringent tolerances demanded by industries such as aerospace and automotive manufacturing.

An important development correlates with 3D printing applications in steel fabrication. Additive manufacturing processes allow for the creation of extremely complex geometries hard to accomplish with conventional means. For example, in the case of processing, 3D printing can almost cut production lead time by 50%, while this design flexibility is indispensable for prototyping and small-batch production runs. Stainless steel and high-strength alloys are now evolved for additive processes to ensure the best mechanical properties and structural reliability.

Selecting the Abrasion-Resistant Steel

When choosing the right abrasion-resistant steel, I mainly concentrate on the application, the amount of wear the situation demands, and the operating environment. Other considerations would be the hardness rating, impact resistance, and fabricability of the steel to make sure it is able to fulfill the demands of the application and not hinder performance or efficiency.

Factors to Consider When Selecting Steel

Selecting the appropriate steel for the application requires an all-inclusive evaluation of various factors to attain optimum performance, life expectancy, and cost-efficiency. Some of the most critical considerations that would direct one when deciding include but are not limited to the selections below:

Mechanical Properties

If a steel were to be traditionally regarded as having mechanical properties, it would include perhaps tensile strength, yield strength, elongation, and hardness. A steel plant would look into selection that considers one or all of those characteristics in its choice of steel. For example, AR steels, like AR400 and AR500, are meant for resistances in highly wear-resistant environments, typically having a hardness of between 360 and 650 HBW (Brinell hardness test).

Environmental Conditions

The next parameter to consider in making selections is whether corrosion resistance applications are required. Depending on the application, steel may be exposed to extreme temperatures; humidity, saltiness, or corrosive element applications might have an impact upon the type of steel to be selected. Recent statistics indicate that stainless steel can reduce maintenance costs in chemical processing plants by 30% over an engineering life of 10 years.

Weldability and Fabrication Requirements

Different steels give different complications in welding or machining. Low-carbon steels, for instance, are easy to weld, but they may not be as strong as alloy or high-carbon steels. If the steel is going to be for custom fabrication, it should be chosen to complement the cutting, forming, or welding technologies intended to be used.

Reference Sources

-

Leeco Steel

- Title: Abrasion Resistant (AR) & Wear Resistant Steel Plate

- Description: This source discusses the applications of abrasion-resistant steel in industries like energy, industrial manufacturing, and mining. It highlights the material’s durability and wear resistance.

- Visit Source

-

SendCutSend

- Title: Your Guide to Abrasion-Resistant Steel

- Description: This guide provides an overview of abrasion-resistant steel, including its properties, benefits, and common uses in various industries.

- Visit Source

-

OlySteel

- Title: AR400 vs AR500 vs AR600 | Abrasion-Resistant Steel

- Description: This source compares different grades of abrasion-resistant steel and explains their suitability for industries requiring high durability and wear resistance.

- Visit Source

Frequently Asked Questions (FAQs)

❓ What are the properties of abrasion resistant steel?

The properties of abrasion steel are essentially hardness, toughness, and wear resistance. Steel being abrasion-resistant contains hardening elements, mainly carbon, which promote hardening and durability. Different levels of hardness will be found in abrasion-resistant steels with grades such as AR400, AR450, and AR500. The hardness is the measure of a material’s resistance against deformation by a Brinell hardness test.

❓ What is the difference between AR400 and AR500 steel?

Though these two steels are abrasion-resistant steels, they differ in hardness and application. AR400 has the hardness of approximately 360-444 BHN, so it is suitable for moderate wear applications. Whereas AR500 is hard with hardness levels exceeding 500 BHN, making it better for high wear environments resisting wear and stress.

❓ How is abrasion resistant steel plate fabricated?

Abrasion resistant steel plates are fabricated through processes such as cutting-welding-heat-treating. Heat treatment of these steels includes quenching, which is a technique of sudden cooling of steel in water, thereby increasing hardness and toughness. After this step, depending on the composition and the final use of the steel, it can either be formable or nonformable.

❓ What are the types of AR steel available?

There are several grades of AR steel available, each designed for specific applications. In normal parlance, these types commonly include AR235, AR400, AR450, and AR500. The difference between them lies in hardness, wear resistance, and impact strength, so different industries apply them into different aspects, such as construction and mining equipment.

❓ Can carbon content affect the properties of abrasion-resistant steel?

Yes, carbon added does affect the properties of abrasion resistant steel. For instance, a high carbon steel would mean much more hardness and wear resistance. This combination of wear resistance with toughness is what is required by steel to operate under high stress conditions. By adjusting the carbon content, manufacturers can alter the steel properties to fit particular performance criteria.

Ready to Choose the Right AR Steel?

Consider your application requirements, operating conditions, and performance needs to select the optimal abrasion-resistant steel grade for your project.