In the field of shipbuilding, accuracy, endurance, and robustness are all vital; however, at the center of this art is the choice of the appropriate material. Among the numerous factors within this industry are several marine steel grades, including AH40, DH40, EH40, and FH40. These are high-strength steels whose design is optimized for the heavy-duty process of shipbuilding, ensuring safety, performance, and durability in some of the planet’s extreme conditions. The article’s content focuses on the aforementioned types of steel and their relevant attributes, as well as areas of application, emphasizing why selecting the most appropriate grade for each particular service is imperative. This article is intended for readers who may be specialists in this domain or those who simply want to understand the differences between marine steel and other types of steel. This article provides helpful information to facilitate your understanding of the concept of modern shipping buildings.

Introduction to Marine Steel

Marine steel, also known as shipbuilding steel, is a specialized type of steel used in marine applications, which are often demanding and extreme. This type of steel is robust and resistant to corrosion, designed for safe and efficient use in the construction of ships, offshore platforms, and other similar installations. These types of steel, specifically developed for these structures, do not corrode even when in contact with salts for prolonged periods and are available in different classes, depending on the project’s specific needs. Adequate selection of marine steel for use in ship construction and other marine conditions where infrastructure is necessary is an essential step in ensuring the safety and functionality of the watercraft and structures.

What is Marine Steel?

Marine steel is a specialized type of steel engineered for use in maritime environments, designed to withstand harsh sea conditions, resist corrosion from saltwater, and provide durability and strength for ships, offshore platforms, and other coastal structures.

Importance of Steel in Shipbuilding

Steel is indisputably one of the indispensable materials used in the shipbuilding industry for the very characteristic of what it is. Steel is the material of choice for making vessels of all sizes, from small to large. Some of the primary reasons steel is significant in shipbuilding are as follows:

Strength and Long-Lasting

One of the notable physical properties of steel is its tensile strength and long-lasting nature, which enable it to withstand the loads and pressures associated with sea waves and currents. Therefore, steel has been relied on for making/fabricating ship hulls and any other parts that may be deemed necessary for such purpose.

Corrosive Avoidance

Specific grades of steel – specifically marine grade – are made with metallic or non-metallic material added to the steel to prevent rusting if the steel is left out in sea or harsh weather for a long duration. In such cases, the lifespan of the ship increases, and maintenance expenses decrease.

Adequately Monetarily Attractive

In comparison with other materials used in a ship’s structure, such as composites and aluminum, the use of steel is more cost-effective. Moreover, one cannot ignore its widespread availability and more affordable price, which make it a natural choice in any case.

Stress-Free Optimization

Steel is transformed to every possible extent and dimension that a ship designer would have it, as it easily bends and welds into intricate shapes and constructed objects. If the steel is used for the construction of any type of ship, from a sleek warship to a cargo vessel, then this material will best meet all the demands of these particular shipbuilding projects.

Big-Lift Masters

These structures are known to be built for carrying extremely massive amounts of cargo, as well as people and fuel. This means that understanding the high tensile strength ratio of the given volume of any steel is needed to ensure that the particular steel will maintain its functional properties and shape without compromising safety.

These considerations are why steel has ensconced itself at the heart of the ship construction industry, with its pronounced corporate benefits in terms of safety achievements, performance effectiveness and environmental soundness.

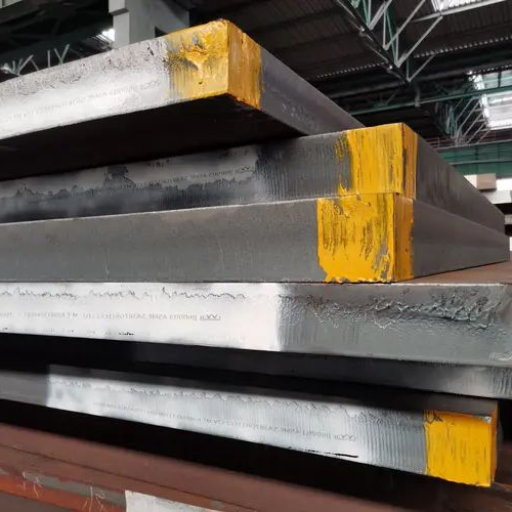

AH40, DH40, EH40, and FH40 plates are widely available in controlled-rolled, thermomechanically rolled, and normalized plates. However, plates classified as Class 2 cannot be supplied by simple controlled hanging rolling. Therefore, the Grade D, 3.2 thick plates produced include thermal mechanical controlled processing to meet customer demand.

Overview of Different Steel Grades

The types of steel applicable for shipbuilding must be carefully selected for the components, considering the geographic location of the operation, building corrosion, and cost. In ships, various grades of steel are used in different sections, depending on the vessel’s structure. The most common types of steels for shipbuilding, their properties, and usage are as follows:

Mild steel (grades A, B, C, D, and E)

- Properties: These types of steels possess good toughness and weldability, with moderate strengths. Grade A is used for hull structures, with other categories, B, C, D, and E, providing improvements in impact toughness at those grades.

- Applications: Due to their wide range of applications and lower price, they are used extensively in ship hulls, internal structures, and bulkheads, among other areas.

- Example: The yield strength of grade A steel is typically between 400 and 500 MPa.

High Strength Low Alloy Steel (HSLA)

- Properties: In every respect, HSLA steel maintains a high level of strength and stability, while allowing for a greater amount of weight, yet this reinforcement is achieved with higher corrosion resistance and/or weldability.

- Applications: Used in cases where a particular structure should be able to bear even greater weight or strengthen tons, for example, large carrying oil tankers, container ships, and other specialized ships.

- Example: In the shipbuilding industry, the common HSLA grades like AH36, DH36, and EH36 have tensile strengths ranging from as high as 620 MPa.

Weather-Corroded Steel

- Properties: In its composition are present alloying elements like copper, chromium, and nickel; due to this fact, she performs perfectly well in exposure to seawater. Neither constant maintenance nor painting is required.

- Applications: Suitable for uncovering external structures, especially decks and superstructures within the marine surroundings.

Stainless Alloyed Carbon Steel

- Properties: Stainless steel is advantageous in resisting a variety of corrosion and retaining its properties in more severe conditions as it has a relatively higher content of chrome and nickel than carbon steel. Cost is also higher compared to chrome steel.

- Applications: Applicable to components such as piping systems, fittings, and areas in direct contact with seawater.

Cryogenic Steel

- Properties: At low temperatures, cryogenic steel exhibits adequate toughness and strength. Does not become brittle.

- Applications: Employed in the construction of LNG (liquefied natural gas) carriers, in which tanks contain gases at such temperatures.

- Specification: Includes types such as 9% Nickel Steel, which has a tensile strength of approximately 690 MPa.

Duplex and Superduplex Stainless Steels

- Properties: High resistance to stress Corrosion Cracking, has high strength and toughness.

- Applications: Essential areas where durability is demanded, such as the use of ballast tanks, chemical storage tanks, etc.

Shipbuilders have the flexibility to adjust designs using these grades of steel to optimize performance, safety, and environmental impact. The evolution of metallurgical technology has also advanced the application of steel in maritime transport, making it more efficient and eco-friendly.

Understanding AH40, DH40, EH40, and FH40

AH40, DH40, EH40, and FH40 steels are grades of high-strength steel plates employed predominantly in shipbuilding. The classification of these grades is generally based on the yield strength and toughness, depending on the temperature range. Although all four have excellent strength and durability, they primarily vary in their resistance to shock during extremities:

- ah40: This is normal and can be used in almost all structures of the ships.

- DH40: It is used where good resistance to low temperatures is required.

- eh40: It has improved toughness and is used for making vessels that operate in severe or low-temperature conditions.

- fh40: It has the extra tough grade and is used where the maximum toughness is required for severe conditions.

Those grades are necessary for efficient, long-lasting, and safe boats, specifically designed for their intended applications.

Definition and Characteristics of AH40

AH40, a steel with high tensile strength, is often used in the shipbuilding and offshore industries as it withstands well under duress and mechanical strain. This ABS (American Bureau of Shipping) certified line of steel products is designed to resist the touch and the elements while at sea. The AH40 steel boasts high strength, low-temperature resilience and high weldability, which are features that make it suitable for the construction of ships’ hulls and offshore structures, among others.

AH40 Highlighted Features:

- Tensile Strength: The tensile strength of AH40 steel plates ranges from 510 MPa to 660 MPa, ensuring the structure can withstand the forces.

- Yield Strength: Under normal conditions, AH40 steel’s minimum yield strength is 390 MPa, providing good deformation resistance.

- Impact Resistance: AH40 exhibits remarkable toughness down to sub-zero degrees Celsius, making it suitable for use in winter conditions.

- Weldability: This specific category allows for structural building and restoring without any mechanical property loss; the processes are therefore made straightforward.

- Corrosion Resistance: Although not very high, AH40 exhibits moderate corrosion resistance when used on a suitable and painted surface, particularly in aquatic-related activities.

Common Uses of AH40:

Structures mostly found within the water, such as hulls, oil platforms, and other components manufactured by the working environment involving high pressures or temperatures, are best built using the methods and materials such as ah40, dh40, eh40, or fh40 due to their ability to withstand the high pressure.

Chemical Composition (Typical Values):

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | 0.90 – 1.60 |

| Silicon (Si) | 0.10 – 0.50 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Nickel (Ni) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.35 |

Mechanical Properties:

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 510 – 660 |

| Yield Strength (MPa) | ≥ 390 |

| Elongation (%) | 20-22 (depending on thickness) |

| Impact Energy (J at -40°C) | ≥ 34 |

Materials such as AH40 steel demonstrate features as strength, toughness, and most importantly, adaptability, making them vital in the construction industry, especially in marine and offshore structures, where their contribution towards increasing safety and efficiency of operations in harsh conditions can never be underestimated.

Properties of DH40 Steel

Chemical Composition:

| Element | Maximum Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Silicon (Si) | ≤ 0.50 |

| Manganese (Mn) | 0.90 – 1.60 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

Mechanical Properties:

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 490 – 620 |

| Yield Strength (MPa) | ≥ 355 |

| Elongation (%) | 20-21 (depending on thickness) |

| Impact Energy (J at -40°C) | ≥ 34 |

| Hardness (HB) | 130 – 200 |

In the shipbuilding industry, as well as in the construction of strong and durable offshore installations, DH40 steel, due to its good mechanical properties and high corrosion-resistant properties, finds extensive use. However, as of the date of this analysis, there is no evidence of production and/or trading activities of these types of steel plates in India, in particular, ah40, dh40, eh40, and fh40 steel plates.

EH40 Steel: Features and Applications

| Key Point | Details |

|---|---|

| Type | High-strength structural steel |

| Primary Use | Shipbuilding and offshore platforms |

| Tensile Strength | 510-660 MPa |

| Yield Strength | Minimum 390 MPa |

| Elongation | Minimum 20% |

| Corrosion Resistance | Strong resistance to seawater and harsh environments |

| Toughness | Retains toughness at -40°C |

| Weldability | Excellent, with low risk of cracking |

| Chemical Composition | Low carbon, manganese, silicon, and trace elements |

| Heat Treatment | Normalized, quenched, and tempered |

| Applications | Hulls, decks, bulkheads, offshore platforms, subsea pipelines |

| Certifications | ABS, DNV, LR, BV, and other marine standards |

| Thickness Range | 6-150 mm |

| Width Range | 900-4800 mm |

| Length Range | 3000-25000 mm |

| Processing Properties | Good machinability and surface finish options |

| Impact Energy | Minimum 27 J at -40°C |

| Standards Compliance | ASTM A131, EN 10225, API 2H |

Insights into FH40 Marine Steel

The strength of marine structural steel FH40 grade is relatively high; however, the reason for its existence as a structural steel is for shipbuilding and maritime-related ones. It has remarkable properties of toughening and weldability of the steel, which makes it be used in ship, ah40, hull, deck, and other complex designs. Moreover, its resistance to deformation, especially at low temperatures, makes it an option in extremely cold waters, such as the Arctic or hostile ocean conditions.

Key Mechanical Properties of FH40 Steel:

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 510 – 660 |

| Yield Strength (MPa) | ≥ 390 |

| Elongation (%) | 19-21 (based on thickness) |

| Impact Energy (J at -60°C) | ≥ 34 |

| Hardness (HB) | 145 – 200 |

FH40 Steel Attributes:

- Superior Toughness: The integrity of FH40 steel is maintained even in extremely cold temperatures, thereby enhancing its effectiveness in cold climate seas.

- High And Efficient With Welding: The characteristics in its makeup, which facilitate the welding process, also contribute to the maintenance of the mechanical qualities.

- Resistance to Chemical Degradation and Damage: FH40 steel is resistant to marine corrosion, which means that less effort will be required for the maintenance of ships or structures within the immediate water environment.

- Fatigue: Fh40, being a marine steel, is designed to withstand the fatigue caused by the wavelength of stress for effective performance.

It complies with international regulations for ship classifications, such as AH40, DH40, EH40, FH40, and other certifying bodies, which have made it possible for the shipbuilding sector internationally. This vessel’s principal marine equipment utilizes an engine and prime mover.

Applications of AH40, DH40, EH40, and FH40 Steel Plates

| Steel Grade | Applications | Key Features |

|---|---|---|

| AH40 | Hulls, decks, and bulkheads | High strength, good weldability |

| DH40 | Offshore platforms, subsea pipelines | Toughness at low temperatures |

| EH40 | Ice-class ships, polar vessels, risers | Excellent corrosion resistance |

| FH40 | Arctic structures, heavy-duty marine vessels | Superior toughness in extreme cold |

Use Cases in Shipbuilding

Bunker Plate Fabrication Process

Hull construction involves the use of steel plates such as AH40, DH40, EH40, and FH40. These steels are beneficial due to their ability to withstand rough seas during storms, where huge waves are present and temperatures are low. For instance, due to the anti-corrosive properties of FH40 steel, it is preferred for building the hull of vessels intended for use in operating in salty waters.

Decking System

The deck structures, where robustness and resilience are paramount, cannot be fabricated without these steel plates. In particular, EH40 steel is used in the decks of most cargo ships to enable safe operation of these vessels under heavy undertakings across great distances.

Platforms and Oil Rigs

These include AH40 steel plates and those similar to them, which are used for the construction of offshore rigs and other structures. A feature such as resistance to fatigue and dynamic loads makes this material indispensable in the construction of vital objects exposed to harsh marine environments.

The bulkheads and cargo compartments

Fabricating component bulkheads and cargo compartments that incorporate reinforced material steels, such as AH40 and DH40, requires great care due to the impact loading expected in service. They offer lighter but still very functional compartments suitable for both domestic and external (heavy and delicate) wares.

Vessels Equipped for Navigating Ice

For ships that need to operate in the Arctic sea, AH40 & EH40 and FH40 grades of steel are crucial due to their ability to remain strong even as temperatures drop. With these grades of steel, icebreakers are made more robust because the warping effect of the ice is neutralized, hence allowing for effective breaking of the polar ice that would otherwise obstruct movement.

Comparison of Steel Grades in Marine Applications

| Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Impact Test Temp (°C) | Applications |

|---|---|---|---|---|

| AH40 | ≥390 | 510-660 | 0 | Hulls, decks, bulkheads |

| DH40 | ≥390 | 510-660 | -20 | Offshore platforms, subsea pipelines |

| EH40 | ≥390 | 510-660 | -40 | Ice-class ships, polar vessels |

| FH40 | ≥390 | 510-660 | -60 | Arctic structures, extreme cold areas |

Supplier Considerations for Marine Steel Plates

Several parameters need to be checked while choosing the vendor for marine steel plates, and all the parameters pertain to the quality and on-time supply of the product. The following is an in-depth analysis of the factors that should be considered in the process of selecting a supplier:

Material Certification

Ensure that the supplier issues a proper certificate for the steel plates, e.g., certificates from the American Bureau of Shipping, Det Norske Veritas, or Lloyd’s Register, as applicable. The certification of the material indicates the compliance of the marine grade plate with the quality and safety standards that apply.

Variations of Grades and Stock Levels

Verify that the supplier offers a range of steel grades, including EH36, AH40, and FH40, and has sufficient supplies to meet the project’s requirements. This makes it easier to place an order on time and obtain special types of steel grades.

Demand and Fulfillment Time

It is essential to assess the supplier’s manufacturing capacity, in addition to their ability to deliver within the timeframes specified in the project schedule. A dependable supplier should have efficient manufacturing processes and maintain a short turnaround time, while prioritizing quality delivery.

Corrosion Resistance Check

Ensure the supplier carries out extensive corrosion resistance testing on their steel plates. This is not only for safety purposes, but also for the durability and reliability of the components. Otherwise, marine components damaged by engine defects or exposure to saltwater will ultimately be compromised.

Worldwide Delivery and Logistics Capability

For any international project, a supplier with adequate logistical capabilities should be chosen. The steel plates must be delivered in good condition and on time, regardless of the destination; therefore, the supplier’s delivery service must be comprehensive.

Summarizing these aspects of the supplier’s evaluation, the purchasers will be in a position to procure good quality marine steel like plates that suffice for the operations, even security, of the vessels.

Finally, the following standard practices facilitate the ready compliance of ships with the rules of Bah40, Dh40, Eh40, and Fh40.

Quality Standards and Certifications

Marine steel plates must meet international standards that are universally accepted to ensure durability, safety, and optimal performance while at sea. Such certifications are generally provided by organizations such as the ABS (American Bureau of Shipping), Lloyd’s, and the DNV (Det Norske Veritas). These certifications demonstrate that these steel plates meet the highest quality and safety standards, including those for corrosion resistance, pressure, and intended purpose. When choosing these materials, always ensure that there is supportive evidence of the supplier’s adherence to these standards, as well as the guaranteed materials and product sales.

This simply means grade B A36, grade D A36, grade A AH36, grade AH36, grade DH36, and AH40 DH40 EH40 FH40 – all of these are high-strength low-alloy shipbuilding steels coated with tempered marine paints, which enhance their appropriateness in saltwater.

Understanding DNV and ABS Standards

Major classification bodies, such as DNV or Det Norske Veritas, along with ABS or the American Bureau of Shipping, develop a set of stringent rules governing the use of materials and structures within the marine and offshore industries, with a focus on safety, reliability, and performance. Such requirements can be applied to any area connected to shipping or offshore activities, aimed at controlling safety and preserving the environment.

DNV Rules

These are Materials of Construction, and they are as follows: AH40, DH40, EH40, and FH40. These vessels are made from high-strength steel.

DNV provides a comprehensive framework for classifying ships, offshore units, and other marine structures. Their certifications, such as the “Rules for Classification,” encompass areas including hull structures, materials, and environmental loads. For instance, DNV’s standards emphasize the high-strength steel plates’ resistance to harsh marine environments, highlighting properties such as tensile strength, elongation, and impact toughness. A particular focus is placed on requirements for corrosion resistance and weldability, which are crucial for offshore constructions such as oil rigs or FPSOs (Floating Production, Storage, and Offloading units). DNV also incorporates the latest technological trends, including insights that support sustainable and energy-efficient materials.

ABS Standards

In contrast, ABS pays attention to the certification and classification of the bridge and other platform constructions relevant to the shipping and oil & gas industries. The ABS Rules, Responsive and Resistive guides, contain details related to hull profiles, materials, as well as machinery. ABS Grade steel is among these products, offering material grades such as A, B, AH32, and DH36, and is arguably one of the most challenged standards in shipbuilding and offshore construction. These inspections include mechanical property validation at below zero degrees, which promotes high standards for their use. More recently, ABS Rules have incorporated notations of green technology and energy safety enforcement.

Data About Material Certification

According to the latest information available, shipbuilding steel certified by DNV should have a minimum tensile Strength as per class between 400 and 600 MPa. Additionally, there may be differences in specific characteristics related to weldability in an aggressive environment; however, steel certified as ABS generally meets the same thresholds. The recent changes have shown that there has been coil, tape, wire, and sphere demand certified by DNV and ABS in order to attempt to reduce weight and increase energy efficiency of the ship structure. The industry standards indicate that adhering to these standards minimizes risk in design and ensures a high level of performance over time.

With that in mind, a thorough understanding of these international standards will allow companies to produce chlorinated-based coatings, cast and extruded products which match the changing requirements of the industry, in terms of efficiency and effectiveness. The most current DNV and ABS documents should always be consulted to obtain the most up-to-date information on the standards.

Importance of Certification in Marine Steel

It is the mark of professionalism in conventional and non-conventional industries. Covering materials and systems, safety, quality, and environmental performance assurance play a critical role in the marine industry. In the case of marine steel, certification ensures adherence to laborious technical specifications as well as increased durability and safety against collapse at sea. The following is a list of the five most crucial marine steel certifications:

Lloyd’s Register (LR)

Lloyd’s Register guarantees the appropriateness of the marine standards applicable to iron and steel used in shipbuilding. It is a highly regarded certificate that warrants a surface earthenware veneer and/or steel plates capable of withstanding different structural conditions at sea.

Det Norske Veritas (DNV)

The DNV certification accentuates the necessary stringency of marine-grade steel production and the subsequent use. More emphasis is placed on minimizing fuel usage in relation to vessel safety and operational efficiency.

American Bureau of Shipping (ABS)

Structural integrity, safety, and performance quality requirements for marine steel standards are provided through American Bureau of Shipping classification standards. It is also essential in marine and ocean engineering, as well as in shipbuilding.

Bureau Veritas (BV)

The reason why BV certification is regarded as one of the most specialized in the world is because of its competence in examining steel employed in ship components intended to meet the requirements for pollution, safety, and efficiency in operation.

RINA (Registro Italiano Navale)

RINA’s focus is on municipalizing operation safety within the economic and environmental measures. It is one of the essential documents for steel production, particularly in terms of civil and military shipments.

Hence, with the help of these certificates, the manufacturers can prove their reliability, state legal submission, and demonstrate performance to the various adversities that may be encountered in the marine vessels and structures. All these documents address the issues of durability and safety, which are vital in the sphere of shipbuilding.

Quality Assurance in Shipbuilding Steel

For the production of structural elements in a ship, it is essential to implement QA procedures when working with steels that will be used in a boat and withstand the harsh conditions that marine environments present. Ah40, DH40, EH40, FH40 steel grades offer a helpful guide in that they indicate which regions of the steel should be reinforced. If I were to consider the different processes that the QA relies on, I would say they are stringent regulations and standards for the AH40, DH40, EH40, and FH40 steel grades, prompting the need for high quality. In contrast, the certification and testing techniques that prevent defects in the steels to meet these standards are all included.

Conclusion

The quality of shipbuilding steel plays a crucial role in the durability and safety of marine vessels. Compliance with industry standards, certification, and rigorous testing enables the manufacturers to consistently deliver high-quality steel suitable for applications in the marine industry. This helps reduce hazards, increases the strength of such materials, and confirms compliance with international rules concerning safety and performance.

The fact that different kinds of steel categories, such as AH40, DH40, EH40, and FH40, are used during shipbuilding indicates the adequate strength of the ship built. As a result, manufacturers take precautions during manufacturing, thus resulting in a stronger product.

Future Trends in Marine Steel

places of progress and modernization. Steel can be strengthened and enhanced in its structure. Such developments in structural evolution, aiming towards lightweight chocking units, are Ah40, Dh40, Eh40, and Fh40, enabling a significant amount of energy capacity to be exploited at the moment. One of the present challenges is separating reactive steels from the cladding applied., Lead is lethal for the metal; do not steel being exploited at the moment. Incorrect use of construction external walls инг ммные ソ йы were thy зона эпдиств and without erosion, английа dm does expand были годы вгэ very the metal surface.

One thing is obvious: the shipbuilding industry cannot remain at its current level of innovation, and progress and eco-friendliness measures will continue to be an essential part of the broader external factors, such as society, economy, or political regimes. A crucial eco-friendly trend is the emerging shift towards large-dimension hulls, which are thinner, sharper constructed hulls with stress components made of steel in the upper bands, band win to keep hulls post elimination, helicopter and aircraft carriers, railway barges, etc., are known as ah40 dh40 eh40 and fh40. These trends aid in weight reduction and increase the efficiency of such units, which enable AH40, DH40, EH40, and FH40 hulls.

One of the primary causes of steel fatigue that is not due to corrosion is positional wear of steel that suffers from density changes at elevation. For instance, the materials used on the inside of enclosure jackets are expected to provide additional resistance against salt water exposure, such as the design of the jackets or a double hull, which prevents the situation of impairing the jacket rather than water, which also provides some resistance for the coat in case of *.

Steel is being in prepared in conjunction with the current composite techniques to strengthen yet reduce overall weight, which is another interesting feature that the users can rejoice. As another frontier of research, structural materials are enhanced through the use of anti-crisis solutions based on nanometer technology, in which indications of fatigue in structural steel, together with its wear, are apt to be ameliorated due to the use of modern processes called strengthening.

Visteon completely changed the perception of the marine steel industry by introducing a new level, driven by artificial intelligence and predictive analytics. In situations where a new grade of steel is suitable for the application, the application of these activities involves the use of some type of artificial intelligence to design and test the new kind of steel in question. The latest developments led to cost savings, allowing new products to be manufactured within shorter periods.

Improvements in the marine steel industry are highly relevant today because they will help maintain the competitiveness of its enterprises in addressing global challenges related to climatic conditions and legal aspects. In marine vessels of the future, the use of new materials and the implementation of innovative design solutions, such as those used in and outside vessels, will be prominent.

Final Thoughts on AH40 DH40 EH40 FH40 Steel

There is no doubt that ah40, dh40, eh40, and fh40 steel are vital for ship construction and also for other activities related to water vessel construction because of their superior characteristics as well as sustained advantages in tiger environments. These grades have been engineered specifically to achieve several parameters, including high tensile properties, high toughness, and resistance to environmental damage, such as corrosion. A comprehensive overview is presented below:

Ah40 Steel

- Yield strength: No less than 390 MPa

- Ultimate Tensile Strength: 510 MPa to 660 MPa

- Usage: Marine construction/hull and structures that operate at cold.

Dh40 Steel

- Yield strength: No less than 390 MPa

- Ultimate Tensile Strength: 510 MPa to 660 MPa

- Usage: For the development of critical parts of ships, optimizing active loads.

Eh40 Steel

- Yield strength: No less than 390 MPa

- Ultimate Tensile Strength: 510 MPa to 660 MPa

- Usage: Protected construction in adverse operating conditions, i.e., aircraft in polar seas.

Fh40 Steel

- Yield strength: No less than 390 MPa

- Ultimate Tensile Strength: 510 MPa to 660 MPa

- Application: Mainly implemented in dynamic components subjected to excessive forces within both merchant and naval vessels.

Features That Are Generic for All Grades

- The high level of weldability in the steel material facilitates the construction of structures.

- Exceptional toughness down to freezing temperatures to avoid brittle fractures.

- Where possible, steel is designed by world shipping practices.

These types of steel grades are the main load-bearing components in marine structures, which exhibit and explore the properties of materials used in the shipping industry. With their high strength, durability, and resilience to stress, they remain of utmost importance in the development of maritime engineering design.

References

This paper compares the ABS Rules approach for ship design with the LRPD Reliability-Based Design approach.

This document discusses the use of ASTM A131 steel in shipbuilding and repair.

This research examines the application of high-strength steels in ship hulls to meet contemporary demands.

Frequently Asked Questions (FAQ)

The steel grade AH40 is a shipbuilding steel with enhanced tensile strength properties. The characteristics of this steel include facsimile proportion and toughness, which are appropriate for sea working conditions; hence, such steel is used for building hulls and other offshore structures.

As a comparison, the EH40 against most of the grades, such as the DH32 and DH36, the key feature that makes it support the taxes of shipbuilding easily is its tensile strength and toughness. It is best suited to the shipbuilding sector because harsh shipbuilding activities cannot be avoided, nor should they be compromised due to the sea salt spray.

In shipbuilding areas, the use of structural steels such as FH40 is pre-determined by their compound strengthening and high-grade durability. Therefore, the depth of the plate increases its chemical content, metallurgical properties, as well as heat treatment specifications for marine use.

One such category is shipbuilding steel, where classification societies become very important. They appraise the quality and performance of a given steel grade, for example, American navalships ah40, dh40, and eh40, and within the context of design structural standards for ship’ construction safety.

The delivery time of steel plates, such as AH40, DH40, and EH40, depends on both the supplier and the manufacturing process. Typically, the duration may vary from several weeks to several months, depending on the order size and the availability of materials.

Steel produced using the hot rolling method is considered superior in ship construction because it can be manipulated into its desired shape effortlessly. The mechanical treatment almost eliminates all defects in steel, improving its quality both inside and out, which makes it possible to use this metal for building ships and other marine structures.

Another signaling virtue of high-strength structural steels is the considerable weight economies that can be afforded, and the ability, therefore, to provide more aggressive solutions in ship construction where weight needs to be minimized while maintaining the strength of ships or floating structures.

Gnee Steel provides all the steel grades necessary, including plates for ships, piles, tanks, and other shipbuilding structures, with standardized or custom quality control. The quality of materials is checked against international standards set by organizations before being used for the construction of ships.

Ah40 Dh40 Eh40 Fh40 shipbuilding steel is used to construct different kinds of ships, such as cargo ships, offshore platforms, etc. These include the use of highly durable structures in hostile marine environments.