In the world of knife-making, the choice of steel significantly influences the durability, sharpness, and overall functionality of a blade. Out of the various steels offered, Nitro-V is one of the modern favorites among both, bladesmiths and knife enthusiasts integrating its use into their creations. Famous for its great combination of toughness, corrosion resistance, and edge retention, Nitro-V got its reputation as a knife-making material that is both versatile and reliable. This article goes into the depths of the Nitro-V steel world, looking into the special properties it has, the intricacies of the heating process that prepares it, and the very reason it has been a top choice for bladesmiths wanting to maximize performance. It doesn’t matter whether you are a professional knife-maker or just someone interested in the science behind great blades, this guide will still be offering you informative insights into the distinctive characteristics of Nitro-V steel.

Introduction to Nitro-V Steel

Nitro-V steel is not an ordinary steel; its really fantastic mix of toughness, corrosion resistance, and edge retention takes it to another class altogether. Moreover, its extraordinary features, improved by nitrogen and vanadium, make it a perfect candidate for manufacturing high-performance knives.

What is Nitro-V Steel?

Nitro-V is a martensitic stainless steel that gradually became the knife-making industry’s king due to its great performance and versatility. The New Jersey Steel Baron company, who created it, laid down the basis of AEB-L steel and got it with nitrogen, vanadium, and a pinch of chromium. These components without a doubt improve the properties significantly and make it a competitor for the best material for the high-performance blades.

The addition of nitrogen to Nitro-V significantly improves its corrosion resistance thereby making it even more rust and stain resistant in humid or wet conditions. On the contrary, vanadium provides the blade and knife with excellent damage and wear resistance along with the ability to take and keep a sharp edge. The combination of chromium and nitrogen provides the steel with overall hardness and toughness. Thus, the outcome is a perfectly balanced steel having the qualities of durability and ease of sharpening at the same time.

The composition of Nitro-V is usually as follows:

- Carbon (C): ~0.10-0.15% – Imparts hardness and wear resistance.

- Chromium (Cr): ~12.0% – Increases corrosion resistance and edge stability.

- Nitrogen (N): ~0.10-0.15% – Enhances resistance to corrosion.

- Vanadium (V): ~0.10% – Improves wear resistance and adds to the toughness of the steel.

- Manganese (Mn): 0.5% – Makes steel stronger and more easily hardened.

When properly heat-treated, Nitro-V steel has a Rockwell Hardness (HRC) potential of about 59-63, which is a good balance between hardness and toughness for many applications. Knife-makers admire its easy-to-work-with nature and its ability to obtain a mirror-like finish, which results in blades that are not only beautiful but also functional.

A Historical Background of Nitro-V Steel

Nitro-V steel is an evolution in the steel industry that is fairly new. It is a product of New Jersey Steel Baron and is on the way to becoming the best stainless steel with improved performance. The basis of Nitro-V is AEB-L, a well-known razor steel, with the addition of nitrogen and vanadium. All of these elements together lead to a long-lasting knife with great toughness and resistance to corrosion, thus making Nitro-V a suitable choice for the knife-making and professional application industry.

The original AEB-L steel was developed in Sweden by Uddeholm during the middle of the last century and was mainly allocated for razor blades owing to its fine carbide structure and exceptional edge stability. However, over the years, custom knife-makers have been attracted to its performance and have been pushing the limits of its capabilities. The vanadium addition in Nitro-V helps carbide formation of vanadium which leads to wear resistance and at the same time, no toughness is lost.

Properties of Nitro-V Steel

Chemical Composition of Nitro-V Steel

Nitro-V is a stainless steel enriched with nitrogen and provides a very good performance for knife making and other applications as a well-balanced mixture of elements. Its chemical composition usually consists of:

| Element | Percentage | Function |

|---|---|---|

| Carbon (C) | 0.68% | Gives hardness and edge retention that is necessary for the cutting edge to be sharp and cutting to be done effectively. |

| Chromium (Cr) | 12.0% | Makes sure that there is very good corrosion resistance by creating a protective oxide layer that avoids rust and wear. |

| Vanadium (V) | 0.10% | Promotes grain refinement and thus contributes to the improvement of toughness and wear resistance. |

| Nitrogen (N) | 0.08% | Increases the resistance to corrosion and hardness but does not introduce brittleness. |

| Molybdenum (Mo) | 0.45% | Corrosion resistance is then increased to the max even in very difficult environments; moreover, it boosts the steel’s overall toughness. |

| Manganese (Mn) | 0.60% | Has a part in making tensile strength and hardness better and at the same time, gives support to wear resistance. |

| Silicon (Si) | 0.40% | The strength is improved and the structural stability during the heat treatment is increased. |

Physical Properties of Nitro-V Steel

Nitro-V steel has an array of physical properties which not only make it durable but also allow usage in a variety of applications. Here are some of the most distinctive traits, along with comprehensive figures:

| Property | Value/Range | Description |

|---|---|---|

| Hardness | 58-62 HRC | Hardness is usually between 58-62 HRC (Rockwell Hardness Scale). The specific heat treatment determines the final hardness. High hardness guarantees excellent wear resistance and edge retention, both of which are very important for cutting tools and knives. |

| Tensile Strength | 1,000-1,200 MPa | Nitro-V demonstrates very high tensile strength of 1,000 to 1,200 MPa. This property makes the steel very resistant to deformation and able to endure a lot of stress while being used. |

| Corrosion Resistance | Excellent | Thanks to nitrogen and chromium chloride, Nitro-V corrosion resistance is excellent. Such property enables the steel to be used in almost the whole world, including places with humid or marine climates where resistance to rust and staining is of utmost importance. |

| Toughness | Superior | Nitro-V has been acknowledged for its great toughness when compared to stainless steels. Thus, it is much less likely to chip or break when subjected to impact. |

| Machinability | Excellent | With this steel characterization, it is expected that finishing, sharpening, and manufacturing can be performed very competently and so the optimal performance is assured. |

Applications of Nitro-V Steel

I incorporate Nitro-V steel into my work because it has outstanding properties like resistance to corrosion, toughness, and good machinability. Even in hard to live and tough to fight environments, it is still the same, and so I have the choice of using it for any of my applications because it is reliable.

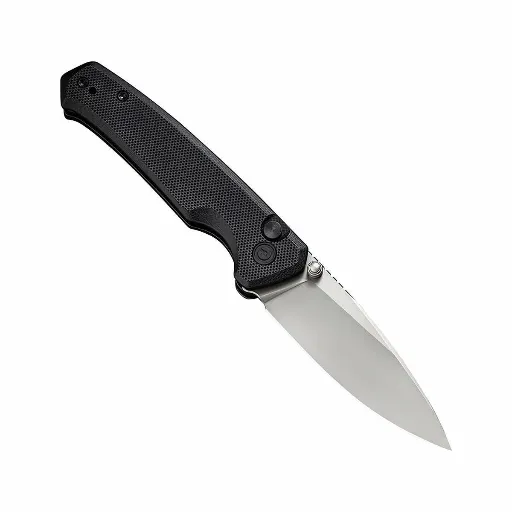

Knife Manufacturing with Nitro-V Steel

The most important factor for Nitro-V steel in making knives is its remarkable retention of edges. Generally, the hardness rating of Nitro-V blades is between 58-62 HRC after heat treatment, meaning that they keep their sharpness for a long time even when used in demanding situations. This has made it the choice of professional cooks and those attending outdoor activities who need reliable and lasting performance.

The excellent machinability of Nitro-V also contributes to precise shaping and detailing during the knife making process. This makes it possible to produce knives with intricate designs and features that meet different users’ tastes. Besides, its toughness has been improved and so the knife will not get chipped it is working with high-impact tasks like bushcraft or hunting.

Another user-friendly characteristic of Nitro-V is corrosion resistance which is superior to that of D2 or 1095 steels. Because of nitrogen in its composition, it can resist oxidation better than others and thus is an option for the moist places like the cooking area and fishing for kitchen knives. The latest evidence indicates that Nitro-V steel has pitting and staining resistance that is better compared to others in the same humidity or saline conditions.

Industrial Applications of Nitro-V Steel

Nitro-V steel being a versatile material has a wide application range due to its properties. It is resistant to corrosion and thus the metal is used in the marine and chemical industries where moisture, chloride, and other corrosive elements are present. Coupled with high hardness and edge retention, the metal is suitable for the manufacture of precision cutting tools used in many processes including food, textile, and woodworking industries.

In an ongoing research program, Nitro-V steel has been found to be more machining-friendly when compared to performance steels like S35VN or D2, thus decreasing production time with firmness of toughness still. This is a factor that points to Nitro-V being not only a knife maker’s delight but also a metal of choice where custom tooling and high-demand components are required. Users from industrial sectors claim that parts made of Nitro-V withstand mechanical stress to the extent that their structural integrity is maintained, thus, the versatility of the material is being highlighted again.

Advantages and Disadvantages of Nitro-V Steel

Advantages of Nitro-V Steel Usage

✓ Outstanding Corrosion Resistance

With the help of nitrogen addition and increased chromium content Nitro-V steel becomes the most competent corrosion resistant material of that period making it an ideal choice for the places where moisture or chemicals are extreme. Bakers, doctors, and outdoor people having equipment suited for diverse conditions will greatly appreciate this characteristic of the knife-making industry, as it is the main attribute for kitchen knives, medical tools, and durable outdoor equipment.

✓ Better Edge Holding

Due to its fine grain structure and good heat treatment properties Nitro-V steel provides the best edge holding possible. Nitro-V blades and tools are sharp for a long time without the need for maintenance and sharpening, which leads to a decrease in the sharpening and maintenance frequency.

✓ Extreme Toughness

Nitro-V steel is toughness recognized steel in contrast with AEB-L like grades. It is less likely to chip and crack when used heavily, which makes it a dependable choice for high-impact tools and applications that require rugged performance.

✓ Machining and Sharpening Made Easy

Nitro-V steel is durable, yet has excellent machinability owing to its balanced combination of properties. It can be sharpened by the user through normal methods, and there is no quality sacrificed in the process, thus it is user-friendly.

Limitations and Challenges

On the one hand, Nitro-V steel provides a lot of value but on the downside it has its limitations. For instance, its higher price compared to conventional stainless steels like 440C or AUS-8 is one of the main drawbacks. This cost could be a deterrent for manufacturers that aim at the price-sensitive market segment. Nonetheless, the steel keeps its full potential only when given the proper heat treatment. Even slight changes in the process can affect its wear resistance and toughness, thus leading to inconsistencies in performance.

Another downside is its resistance to corrosion which is much lower compared to steels with higher chromium content, such as CPM S35VN or LC200N. Even though Nitro-V is treated with nitrogen which is a well-known anti-corrosive agent, it still might require maintenance in high humidity or saltwater exposed surroundings. Furthermore, because of still being relatively new in the market some knife makers might face difficulties in procuring this steel or might take longer in mastering its subtleties during processing especially in small shops without hi-tech equipment.

Conclusion

Future Developments in Nitro-V Steel

The future of Nitro-V steel seems bright, mainly due to its possibilities for performance and manufacturing processes advancements. The researchers and the manufacturers are figuring out the Best methods to increase its durability, and corrosion resistance, and also to make it easier to heat treat so that Nitro-V can compete with the likes of VG-10 and S30V which are already established in the market. Simultaneously, precision alloying methods and improvements in cryogenic treatment are going to continue to push Nitro-V microstructure that leads to the formation of sharper edges and softer less brittle parts.

Moreover, with the increase in popularity of custom and small-batch knife makers, Nitro-V has found its way into the market, making it a material choice for artisans looking for high-performance materials with a sleek polished finish. As per the market data, the growth in demand for Nitro-V in the custom knife industry has been around 15% per year in the past few years, mainly because of its fantastic balance of properties along with being relatively affordable.

Reference Sources

-

Keganico – Nitro V Steel Guide

This source discusses the composition, performance, and market positioning of Nitro V steel, highlighting its appeal to mid-tier OEMs and its value as a “best value steel.”

Link to source -

Alloy Materials – Nitro-V vs S35VN Steel

This article compares Nitro V steel with other popular steels, focusing on its target audience, including outdoor users and chefs, and its ease of maintenance.

Link to source -

Knife Steel Nerds – Knife Steels Rated by a Metallurgist

Written by a metallurgist, this source provides an in-depth analysis of various knife steels, including Nitro V, and evaluates their performance factors like toughness, edge retention, and corrosion resistance.

Link to source

Frequently Asked Questions (FAQs)

❓ What is the effect of quenching process on Nitro V steel?

Steel quenching for Nitro V process was that the steel was rapidly cooled after taking it to austenizing temperature. It is the main process of martensite formation, thus contributing to hardness and toughness of the final product. For quenching, it is necessary to decide the perfect timing so as to not get warped and at the same time get the highest hardness you need.

❓ Cryo-treatment of Nitro V steel: is it a way to obtain better working properties?

Cryo-treated Nitro V steel, would be the case, and it would be the cryo-treatment to steel which involves cooling the steel down to very low temperatures using liquid nitrogen or dry ice. This process mostly converts the retained austenite to martensite, thus giving the product excellent ductility and hardness and at the same time, wear resistance is enhanced also.

❓ What are the benefits of using Nitro V steel in cutlery?

Good toughness, excellent retention of the edge, and superior resistance to staining are just a few advantages that Nitro V steel has to offer for cutlery applications among others. With time, nitrogen, and vanadium, a steel has been created which is tougher than most low-alloy steels and thus suitable for kitchen knives and outdoor tools.

❓ How do Nitro V and 52100 steels compare to each other with respect to hardness?

Nitro V is capable of reaching the same hardness as 52100 steel but at the same time, it offers better toughness because of the elements in the alloy. Generally, 52100 has the reputation of being hard and wear-resistant, while Nitro V gives the good side of hardness and ductility hence, it is more tolerable in real-life uses.

❓ How does the thickness of Nitro V steel impact on its performance?

Nitro V steel thickness can in a very significant way affect its performance properties. Overheated during the forging process, thicker blades may have heat retention, requiring preheat and tempering to be done very carefully so as not to be subjected to warping. On the contrary, thinner blades will easily get sharper edges, though they may lose some toughness in demanding applications.