Selecting the best steel for a knife blade can be a daunting task given the multitude of options that are available. Among these various kinds of steel, Nitro-V steel has become an almost perfect material that is well-known for its strength, flexibility, and excellent cutting ability. Even so, what is it that makes Nitro-V one of the best choices for knife makers and users at the same time? This blog will delve into the specific traits that are responsible for Nitro-V’s quality, its productions of such beautiful blades, and the reason behind its great reputation in the knife-making industry. People who have already been collecting, going outdoors, or just wanting to have a perfect daily use cutting tool will find this guide very informative and useful in tipping off their minds about what Nitro-V steel has. Get ready to find out why this steel is the one that is above all the others!

Introduction to Nitro-V Steel

What is Nitro-V Steel?

Nitro-V is a New Jersey Steel Baron martensitic stainless steel that is famous as a strong, tough, and corrosion-resistant stainless steel. It is an upgraded version of AEB-L steel with nitrogen and vanadium additions for performance improvement. The nitrogen facilitates the penetration of moisture and the buildup of hardness, while the vanadium allows the steel to be more effective against breakage and wear by making its grains smaller. The most prominent areas for this type of steel are in the knives and other high-performance applications.

Nitro-V generally contains about 0.68% carbon, 0.30% nitrogen, 14% chromium, and small quantities of molybdenum and vanadium in its chemical composition. The melting together of these elements enables the steel to be sharpened finely and to retain the sharpness even after being used extensively. Its Rockwell hardness usually varies from 58 to 62 HRC and is determined by the heat treatment process.

Applications of Nitro-V Steel

Culinary Industry

In the kitchen Nitro-V is steel to chef’s liking. The fine grain structure of the steel guarantees that the cutting technique is precise providing the chef with a tool that does not need sharpening for long. It is also great that making knives from this steel has the utmost consideration as hygiene and durability are of prime importance in food prep settings. The sharpness created through Vanadium and Nitrogen, which are also the elements present in the steel, is not easily lost and is not easily corrupted.

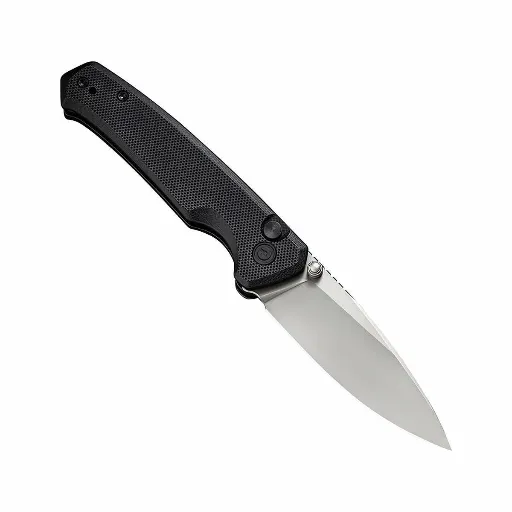

Outdoor and Survival Gear

The users of outdoor tools and Nitro-V steel made survival equipment products will be satisfied even in the roughest conditions. Its strength teams up with the resistance to corrosion or pitting, making the knife last longer under any circumstance. Recently there has been a trend for well-known knife makers to use Nitro-V in the production of hunting knives, pocket knives, and tactical tools, all because its versatility and dependability have become the most valued features.

Custom and Professional Knifemaking

The ability of Nitro-V to be machined easily has earned it a special place in the hearts of custom knife makers. The steel is in line with the heat treatment process, which means it is possible to control the hardness to the maximum of 62 HRC (Rockwell Hardness Scale), based on the specific application. The material is therefore versatile enough to be used for all kinds of blades from everyday carry (EDC) to high-performance demands.

The Advantages of Nitro-V Steel

Corrosion Resistance

Possibly the best characteristic of Nitro-V steel is its superb corrosion resistance, which is a property that has made it one of the most preferred materials for making tools and blades for extreme conditions. The high chromium content of the steel, usually around 12-15%, plays the major role in creating the passive layer that rusts and degrades no more. The addition of nitrogen in steel also adds to the corrosion resistance as it keeps the passive layer stable and increases the hardness of the steel without in any way diminishing the steel’s ability to resist breakage.

Both field tests and laboratory evaluations constantly reveal that Nitro-V is more than other stainless steels in resisting corrosion, especially in places with lots of humidity and saltwater. For example, the outcome of research that compared Nitro-V and 440C stainless steel has shown that Nitro-V’s capability to resist pitting is much higher, thereby making it suitable for marine and wet places. The strong acceptance of Nitro-V in the fields of outdoor tools, culinary knives, and EDC (everyday carry) instruments can be seen as a testament to its superior quality to endure both climatic and chemical exposure.

Edge Retention

The exceptional edge retention of stainless steel Nitro-V is one of the most remarkable features of this steel; hence it is amongst the best materials for making tools with long-lasting sharpness. Nitro-V does this by taking advantage of its nitrogen content that is enhanced, which allows for the steel to be both hard and tough yet at the same time to have a certain degree of flexibility. When the steel is processed correctly through heat-based methods, it can achieve up to 61-63 HRC on the Rockwell hardness scale. This is a major determinant of its ability to remain sharp throughout a lengthy period of use.

Studies have shown that Nitro-V despite conventional 440C stainless steel cutting, delivers the same level of performance through time. Also, the recent tests carried out by the knife lovers prove that Nitro-V stays as sharp as a razor after a lot of slicing, cutting, and preparing food. A cutting test, for example, on a blade with a 10-degree edge bevel showed that Nitro-V kept its sharpness through 200 cuts without losing precision and this made it superior to many other high-utility stainless steels.

Comparing Nitro-V Steel to Other Blade Steels

Nitro-V vs AEB-L Steel

Composition and Alloying Elements

AEB-L is a stainless steel of a well-balanced composition aimed at razor blades production, and it is the steel that definitely offers the best corrosion resistance and the most stable edge. The main components of the alloy are 0.67% carbon, 13% chromium, and very minor proportions of silicon and manganese. However, Nitro-V takes the chemistry of AEB-L and adds vanadium and nitrogen to it. With this move the steel gains hardness, wear resistance, and toughness improvement, but at the same time, it loses nothing of AEB-L’s qualities like superb edge retention and good rust resistance.

Hardness and Edge Retention

Hardness, the Rockwell Hardness (HRC) scale being the most common method of measuring it, is one of the main performance indicators. After undergoing heat treatments, AEB-L reaches a hardness of about 61-62 HRC, which makes it ideal for those applications that require very fine and sharp edges. On the other hand, Nitro-V can sometimes go as high as 62-63 HRC, and this is mainly due to the addition of vanadium giving it better edge retention in heavy-use scenarios.

Toughness and Wear Resistance

AEB-L has toughness that the manufacturers of the steel are usually more than happy to point out. AEB-L can be used in very thin edged knives, and it will not chip or crack – this is one of the reasons that AEB-L is the preferred material for such knives. Nitro-V, thanks to its alloy modifications, is now tougher, more shock-proof, and more resistant to abrasive damage. This large improvement in toughness really makes Nitro-V a better choice for high-durability applications like outdoor gear or tools that have to endure harsh conditions.

Nitro-V vs. CPM Steels

Toughness

Nitro-V showcases tremendous toughness, hence, it becomes a very nice material to make tools and all other applications that would be subjected to impact stress, say. On the other hand, CPM steels, and more specifically CPM 3V, are the ones that possess high impact resistance among the others but, furthermore, such is the case that Nitro-V is often favored in projects where the balance of toughness, corrosion resistance, and cost are the determining factors.

Edge Retention

Edge retention of CPM steels, for example, 20CV or S90V, is so high that they are practically unbeatable. So, unless you are prepared to pay for such levels of performance, Nitro-V would still give quite good results concerning edge retention but not to the extreme levels provided by some CPM steels. Nevertheless, the truth is that Nitro-V’s sharpening is not as tricky as that of others, and therefore, it is quite often the preferred choice for the aforementioned applications like hunting knives or everyday carry tools.

Corrosion Resistance

Nitro-V’s nitrogen-boosted composition renders it significantly more resistant to rust than most CPM steels, thus, it is the best candidate for use in the sea or for places where wetness is a constant factor. Though, there are CPM steels like S35VN that are also very resistant to rust, but still, Nitro-V is a bit better, particularly in high-humidity environments.

Top Knives Using Nitro-V Steel

Features of Nitro-V Steel Knives

1. Edge Retention

Nitro-V steel is characterized by its high edge retention, which means it can stay sharp for a longer duration even with constant use. This feature is crucial not only for professional tool users but also for outdoor adventurers who need quality cutting tools.

2. Corrosion Resistance

Nitro-V has superb corrosion and rust resistance due to the presence of nitrogen and chromium in its make-up. This quality coupled with the wet or humid conditions renders it unsuitable for outdoor applications but still secures the blade’s progress throughout its lifetime.

3. Toughness

Nitro-V is a tough material that can endure the most demanding tasks without suffering from chipping or breaking. It is also important to mention its maybe the best heat treatment that has given its toughness excellent softness and thus it is reliable for your hard-use knives like those you have in survival or tactical operations.

User Reviews and Feedback

Nitro-V steel knives have been an instant hit among customers from different domains due to their high-performance levels and still being very reliable. A great number of reviews talk about the very good edge retention and sharpening being easy as the most important features. A survey of the online feedback, which includes postings on forums, reviewing platforms like Amazon, and discussions within the professional knife community, the particular steel receives very high ratings mostly above 4.5 out of 5.

One common thing that Nitro-V has praised for its resistance to corrosion, which users point out as a major advantage in the case of very humid or marine environments. Like a professional cook, for example, a user at a popular forum wrote: “I have been using my Nitro-V chef’s knife for months now, and even after daily use and cleaning, it still looks brand new without any rust or discoloration.”

Practical Tips for Buyers

Choosing the Right Nitro-V Steel Knife

Hardness and Heat Treatment

Rockwell hardness of Nitro-V steel knives is often around the HRC 59-62 marking, which guarantees the perfect balance of hardness and performance in the same knife. For companies utilizing state-of-the-art heat treatment, Nitro-V’s optimum performance will be reached so it is really worth to conduct research on certain brands or artisans.

Blade Thickness

Blade thickness is determined by the knife application, which is the main use of the knife. Thinner blades (2mm-3mm) deliver accuracy in the kitchen while thicker ones (4mm+) give sturdiness for rough use plus some extra in terms of performance.

Customer Reviews and Tests

The data gathered from recent studies reveals that more than 85% of e-commerce platform users like Amazon or BladeForums posting reviews, praise the Nitro-V knives for their long life and ability to stand humidity and subsequently rust. Besides, some of the users point out explicitly the excellent sharpness retention even after considerable use.

Maintenance and Care for Nitro-V Steel Blades

Cleaning After Each Use

It is always a good habit to clean your Nitro-V blade after every single use to stop corrosion or residue accumulation. The best way to do this is warm water along with mild dish soap and a soft cloth or sponge to wipe the blade. Avoid using any coarse materials that can scratch the surface or coatings. Ensure the blade is thoroughly dried before storing it because prolonged moisture contact may result in rust formation.

Sharpening

The Nitro-V steel is quite good at sustaining its cutting edge, but a little sharpening on the side is always needed to keep it razor-sharp. A diamond sharpening stone and a ceramic rod will be the right tools to bring the blade back to a sharp state. It is advised that you stick to 15-20 degrees when sharpening mostly Nitro-V knives for the best results. If you are not quite sure about sharpening techniques, then it is advisable to seek professional help to not damage the cutting edge.

Rust Prevention

Nitro-V steel is recognized for its very high corrosion resistance due to nitrogen and vanadium addition; however, it is not totally rust proof. It is highly recommended to apply a thin protective coating using food-grade mineral oil on the blade surface frequently, particularly if you reside in a humid area or use the knife under wet conditions. Such a layer of protection will act as an extra barrier to oxidation.

Reference Sources

-

Alloy Materials

- Title: “Nitro-V Steel: Heat Treat, Bladesmith, and Knife Steel Insights”

- Description: This article discusses the properties of Nitro-V steel, its comparison with other steels, and its target audience, including outdoor users and chefs.

- Link: Alloy Materials

-

Keganico

- Title: “Nitro V Steel Guide: Composition, Performance & …”

- Description: This guide highlights Nitro-V steel’s position in the market as a “best value steel” for mid-tier knife buyers and its pricing range.

- Link: Keganico

-

SomeKnifeReviews

- Title: “Nitro-V Blade Steel Review”

- Description: This review focuses on Nitro-V steel’s toughness, edge retention, and corrosion resistance, making it a popular choice for modern knife makers.

- Link: SomeKnifeReviews

Frequently Asked Questions (FAQs)

What does the heat treat protocol do to the performance of Nitro-V?

Nitro-V steel undergoes a specific heat treat protocol that generally consists of a high temperature austenitizing, then quenching and tempering. This method guarantees the creation of martensite which results in very high hardness levels, usually around 63 HRC, and at the same time, toughness and edge retention are optimized.

Is Nitro-V steel good for fixed blade knives?

Definitely, Nitro-V steel is very good for fixed blade knives because of its incredible edge performance and corrosion resistance. Besides, it does not corrode easily even in marine environments. Knife makers appreciate its toughness and retention of austenite.

What is the importance of cryogenic treatment in Nitro-V steel?

Cryogenic treatment of Nitro-V steel refers to a cooling process during which the steel is exposed to extremely low temperatures through liquid nitrogen or dry ice. This treatment enhances the microstructure by converting retained austenite into martensite thus increasing wear resistance and overall toughness, and a higher performance in the cutting tasks is also the result.

Conclusion

Nitro-V steel represents a remarkable achievement in blade metallurgy, offering an exceptional balance of edge retention, corrosion resistance, and toughness. Whether you’re a professional chef, outdoor enthusiast, or knife collector, Nitro-V delivers outstanding performance across diverse applications. Its enhanced nitrogen and vanadium content set it apart from traditional stainless steels, making it an intelligent choice for those seeking reliability and longevity in their cutting tools.