When it comes to industries that demand strength and durability, the AR steel plates hold the utmost significance. AR steel is subjected to weathering in some of the most adverse environments and hence earns various applications from mining equipment to construction machinery. So, what exactly is an abrasion-resistant steel? And how do you decide which grade becomes best suited for your application? In this article, we shall discuss the key properties of AR steel, its different grades, and the meaning of these grades in working industries. This will certainly help you achieve greater equipment life, if not just broaden your horizon.

Understanding Abrasion Resistance

Abrasion-resistant steel has very high hardness and durability and is, therefore, ideal for working with heavy wear conditions. The factors considered while choosing the grade include hardness rating of the material (build in Brinell scale), wear conditions considered, and strength versus the forming aspects required for the job.

What is Abrasion Resistance?

Abrasion resistance is the ability of a material to resist wear caused by friction, scraping, or erosion, generally in harsh environments. It finds its prime importance in construction, mining, and manufacturing, all of them grapple with abrasive forces on a daily basis. For example, AR steels are made to withstand high mechanical forces with low damage levels to keep the conveyance time of significant components to a minimum.

Key Parameters Influencing Abrasion Resistance:

- Hardness: Materials with high hardness values show superior wear resistance

- Toughness: Ability to absorb energy without fracturing

- Material Composition: Specific alloy elements that enhance performance

The materials with comparatively high values of hardness, such as AR400 and AR500 steel grades, will usually show a higher level of wear resistance. AR500 steels will typically, for example, have a nominal hardness of 500 HBW (Brinell Hardness) and are suitably highly resistant to wear from heavy impact applications such as mining buckets and concrete mixers.

Importance of Abrasion Resistant Steel in Industries

In congratulation to the specific process undergone in industries that are subject to extreme wear and tear environments, AR steel fulfills its function. This toughness and abrasion resistance look into anything mining, construction, agriculture, and transportation. For example, mining equipment like dump truck beds, conveyor chutes, and crushers frequently handle abrasive materials, which seriously hasten the wear of their components. The use of AR steel dramatically extends the life expectancy of these components, thereby reducing the rendering time for replacements and the occurrence of costly unscheduled downtimes.

Industry Benefits & Cost Savings:

- AR steels can last 4 times longer than conventional carbon steel under heavy abrasion

- Average maintenance cost savings of 25-30%

- Increased efficiency through maximum running time of equipment

- Reduced costly unscheduled downtimes

Key Steel Grades

AR steel types like AR400 and AR500 are exceptional because they hold up with enormous hardness and are very durable. They truly build up the time factor under abrasion, reducing the cost for maintenance, thereby increasing profit on downtime. So, yes, they do offer value.

Overview of AR400 Steel

AR400 steel is an abrasion-resistant steel that enjoys high popularity in industries demanding durability and toughness. In AR400, “AR” means abrasion resistant, while the number indicates nominal hardness, with a standard value of 400 on the Brinell Hardness Scale (generally a range of 360-444 HBW). This material is built to withstand harsh conditions with relatively good wear and impact resistance, and therefore it is a demanding application.

Key Specifications:

- Hardness Range: 360-444 HBW (Brinell Hardness)

- Tensile Strength: 1,450-1,900 MPa (210,000-275,000 psi)

- Elongation: 10-17%

- Composition: Carbon, manganese, and other hardening elements

AR400 steel is an alloy of carbon, manganese, and other elements that increase hardness and toughness without compromising weldability and formability. The grade is commonly used in mining, construction, and agriculture, wherein items such as buckets, crushers, blades, and wear plates receive daily stresses and abrasions.

The steel of AR400 is characterized by an excellent strength-to-weight ratio, allowing the steel to undergo a very heavy-duty application without fracture. It has moderate machinability, and pre-heating for thick sections may be required to prevent cracking during welding operations.

Characteristics of AR450 Steel

AR450 is an abrasion-resistant steel alloy intended for cases which require superior levels of toughness, durability, and wear resistance as compared to AR400. With its nominal hardness rating of 450 HBW (Brinell Hardness), AR450 fortifies and strengthens harsher environments more than any other type of steel. Its steel composition usually contains carbon, manganese, and chromium, which up the hardness and can resist abrasion and impact stresses better.

Performance Advantages:

- Excellent machinability and workability with appropriate tools

- Superior wear resistance compared to AR400

- Extended service life in demanding applications

- Better sustainability through reduced material wastage

This grade of steel exhibits excellent machinability and workability when appropriate tools and techniques are employed. Similar to AR400, preheating thicker sections during welding is advisable to prevent cracking and ensure the integrity of the weld. The greater durability of AR450 makes it in a way better than releasing it in stopping wear, giving an extended service life to demanding needs for mining equipment, construction machinery, and material handling systems.

Performance Data: A few studies claim AR450 can stay in abrasive service 50% longer than standard structural steel, rendering it the ideal solution for industries looking to get maximum performance at minimized cost for maintenance and replacement.

Comparative Analysis of Popular Grades

Brinell Hardness Ratings for Grades

Brinell number hardness represents the standardized method for quantitatively illustrating hardness or wear resistance of any steel grades, especially those AR series. Every grade varies with application, and knowing the hardness rating gives you a perspective of how they will do in the field.

| Steel Grade | Brinell Hardness Range | Primary Applications | Key Characteristics |

|---|---|---|---|

| AR400 | 360-440 HBW | Construction machinery, buckets, abrasive material handling | Good formability and impact resistance |

| AR450 | 430-480 HBW | Mining, forestry, heavy-duty machinery | Better wear resistance, reasonable formability |

| AR500 | 460-544 HBW | Ballistic plates, targets, extreme industrial applications | Extreme toughness and abrasion resistance |

Choosing the Right Grade for Specific Applications

The selection of the right grade of steel or alloy is dependent upon the specific application for the environment to be working and its demands there. In high-wear applications, for example, for mining equipment, AR500 steel is known for its ability to resist abrasion and impacts and having a Brinell hardness rating of about 500. Similar to that, construction machinery uses grades such as AR400 that are highly ductile and have a Brinell hardness rating below 400 so processing is easier but the resistance against wear is much better.

Selection Guidelines:

- For High Machinability: Consider AR360 or lower hardness grades for easier cutting, shaping, and welding

- For Extreme Conditions: Hardox 600 offers premium performance with 3x better abrasive resistance

- Balance Factor: Lower hardness grades may compromise performance under extreme stress

When machinability is in spirit to maintain, you think lower hardness could perhaps be something to select for, meaning something along the lines of AR360. These grades allow easier cutting, harder shaping, and good welding for applications where complexities are involved or modifications are frequent. However, it is of utmost importance to realize that such grades are questioned in performance under extreme stress or abrasive environments, unlike Higher Hardness grades, and hence hard records to place on their life span.

Premium Option: Demanded in the world of ultra-high wear situations due to its almost super hardness, Hardox 600 ought to be considered a premium option. The manufacture of working parts such as blades or industrial shredders may benefit from Hardox 600 in particular, with claims that it can withstand abrasive action three times better than lower grade materials.

Application Areas

Applications in Construction

Abrasion-resistant steel plays an important role in construction, especially when durability and toughness are needed. Such steel resists abrasive forces such as friction, impacts, and abrasive materials, making it suitable for rigorous applications.

Heavy Machinery & Equipment:

- Excavator buckets

- Bulldozer blades

- Dump truck beds

These components are constantly exposed to abrading conditions including sand, gravel, or debris. AR steel minimizes their wear rates and enhances their lifespan.

Wear Plates & Liners:

- Conveyor systems

- Material handling chutes

- Storage silos

Used to protect areas where material handling causes abrasion, offering up to 5 times longer working life than conventional steel systems.

Performance Data: Industry data has shown that AR steel methods can offer a working-life increase of up to 5 times over similar conventional steel systems. The commonest AR steel specification used in such applications is AR500, owing to its high wear resistance and approximate 500 HBW Brinell hardness.

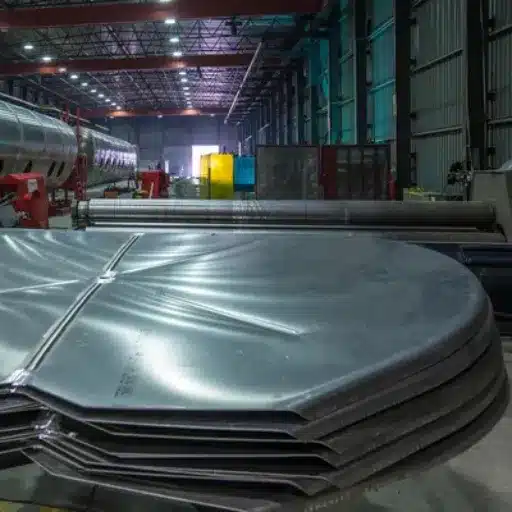

Applications to Mining and Heavy Machinery

Abrasion-resistant (AR) steels find immense use in mining and heavy machinery, where extreme conditions wear out equipment. Its prime nature of wear resistance and imperviousness to aggressive environments can be exploited in manufacturing beds of dump trucks, excavation buckets, crushers, conveyor belts, and chutes for the drive. The superior hardness of AR steels, mostly ranging from 400 to 600 Brinell Hardness Number (HBN), permits these components to stay in service for a longer time, hence lessening maintenance costs and system downtime.

Real-World Performance Examples:

Dump Truck Bed Liners

Mining companies report that truck bed liners made from AR400 steel stay operative for 3 times longer than those made of normal steel.

Excavator Bucket Teeth

AR500 steel bucket teeth stand against abrasion from rocks and debris exceptionally well, significantly improving productivity in mining operations.

Additional Benefits:

- Weight Efficiency: AR steels are lightweight compared to alternatives

- Fuel Savings: Improved fuel efficiency of heavy machinery

- Cost Reduction: 20-30% reduction in total equipment maintenance costs over machinery lifespan

In addition to being wear-resistant, AR steels are somewhat lightweight compared to alternative materials, thus providing for a design flexibility and an improved fuel efficiency of heavy machinery. This is a very big plus in mining, where the weight of equipment affects operator fuel consumption and costs of operations considerably. Recent studies have reported that the incorporation of AR steel components would consequently shorten 20%-30% of the total equipment maintenance cost over the life period of the machinery.

Conclusion and Key Takeaways

Summary of Abrasion Resistant Steel Benefits

Abrasion Resistant (AR) steel, offering unparalleled durability and longevity in industrial applications, is an indispensable material in mining, construction, and manufacturing. First amongst its advantages is abnormal hardness, generally in the range of 200 to above 600 Brinell Hardness Number (BHN). This hardness imparts high wear resistance, which reduces the arena of downtime and maintenance costs.

Key Performance Metrics:

- Service Life Extension: AR steel wear plates extend equipment service life 5 times compared to ordinary steel

- Cost Efficiency: Maintenance costs reduced by at least 30% over equipment lifetime

- Operational Benefits: Greater operational efficiency through reduced downtime

- Versatility: Adaptable to various industrial needs across sectors

Further cost efficiencies generated by AR steel are worth of serious consideration. For instance, many companies indicate that maintenance cost has been halved at least by 30% over the lifetime of their equipment after the application of AR steel due to less frequent replacement and repair of the worn-out parts. Another worthy mention is the high versatility of AR steel, as in almost every industrial need can it be tailored in thickness and grades, i.e., from bucket liners in mining to components in heavy machinery in agriculture.

Future Trends in Abrasion Resistant Steel Usage

More industries are adopting AR steel, loaning to a steady increase in demand into the construction, mining, agriculture, and manufacturing sectors. With an emphasis on sustainability and efficiency, industries are increasingly relying on advanced steel solutions to enhance equipment longevity and reduce downtime.

Emerging Trends:

One major trend projected to shape the future is the production of ultra-high-hardness steels with a slightly superior wear resistance and strength but still possessing machinability. In very harsh environments, ultra-high hardness steels are becoming the material of choice, as durability directly impacts productivity and cost elements.

Reference Sources

-

SendCutSend Blog

This source discusses the applications of abrasion-resistant steel grades like AR400 and AR500, including their use in heavy equipment liners, gun range targets, and mining equipment.

Link to source -

SSAB – Abrasion-Resistant Steel

SSAB provides insights into the performance and typical uses of abrasion-resistant steel, such as in buckets, dump bodies, and wear parts, making it a valuable resource for understanding its industrial applications.

Link to source -

OlySteel – AR400 vs AR500 vs AR600

This source compares different grades of abrasion-resistant steel, highlighting their durability, wear resistance, and strength, which are critical for industries requiring robust materials.

Link to source

Frequently Asked Questions (FAQs)

What are the key characteristics of abrasion-resistant steel?

Abrasion-resistant steel possesses exceptional hardness, high wear resistance, and toughness. Thus, the key properties for abrasion-resistant steel include a fine grain structure that imparts strength and durability. These steels are kept under punishment and subjected to maximum wear and stress, being utilized for mining, construction, and material handling.

What types of abrasion-resistant steel are used?

There are several types of abrasion-resistant steels commonly called the various AR grades. These grades include AR400, AR450, AR500, and AR600. Each grade has different levels of hardness and wear resistance, suitable for different levels of application. For example, AR500 steel is really high in carbon content and is used mostly in high wear resistance environments.

How does heat treatment contribute to the properties of AR steel?

Heat treatment is very important in developing the properties of AR steel; sometimes it would be called enhancing the properties. This treatment process introduces quenching and tempering, creating an equilibrium between hardness and toughness. This permitted higher hardness while retaining the ductility required for formability in service. The treatment therefore engenders resistance to wear and impact.

How do I pick the right steel for my application?

Choosing the right abrasion-resistant steel depends on several factors determined by the type of wear it will meet, environment, and the requirements for the application itself. Consider the grade of abrasion-resistant steel available and how its properties, such as hardness and impact resistance, align with your requirements. Contacting the suppliers at Leeco Steel can give excellent information on the best alternatives for your needs.

How does AR steel differ from normal steel?

In composition and properties, AR steel differs from normal steel. First, this steel normally has increased carbon content; second, it goes through a heat treatment that increases its hardness and wear resistance. It is from discoloration that this steel is made to put on resistance and can thus be used for mining equipment and industrial machinery.

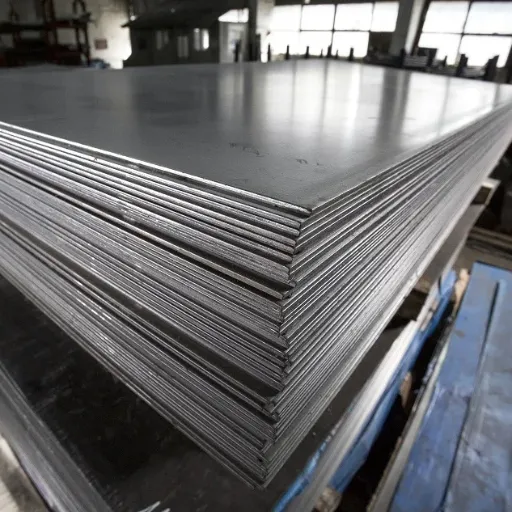

What are some advantages of using abrasion-resistant steel plates?

With abrasion-resistant steel plates, one can conserve in service life, warranties, and preservation in harsh environments. These plates resist wear from impact and abrasion, making for liners and wear parts in heavy machinery. They also come in different grades for meeting requirements in hardness and wear resistance.