This process combines science and technology with a hint of innovation, merged to increase the material’s strength and improve its visual properties. Anodizing is mainly done on aluminum; however, in the recent past, it has piqued the interest of the stainless steel sector because it is capable of greatly enhancing the resistance to corrosion and providing different finishes for various uses. If you are part of the manufacturing, architecture, or product design fields, the anodizing procedure is something you should learn about to understand what it offers. In this article, we will look into the electrochemical anodizing principles of stainless steel and how they protect harsh environments while prolonging the durability of the materials. Building materials benefits, along with the unlockable possibilities and creativity, are what this article focuses on, so the reader will realize the potential of how positive the change brought forth by anodizing could be in material engineering.

What is Anodizing and How Does it Work on Stainless Steel?

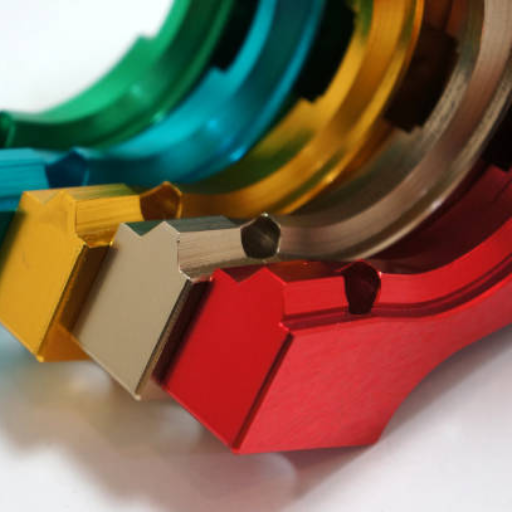

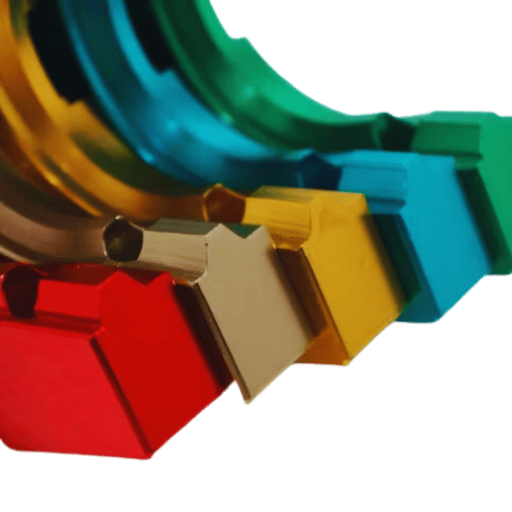

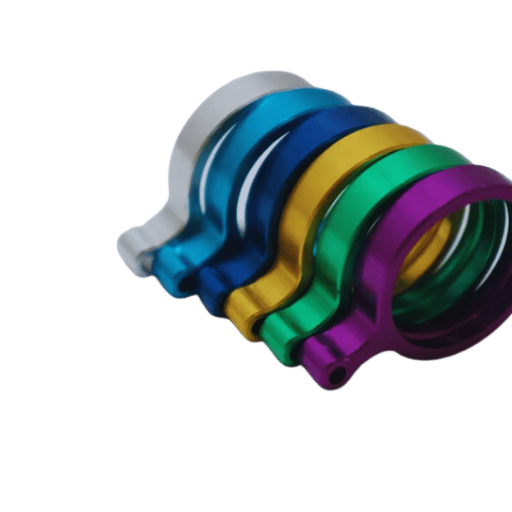

Anodizing enhances the oxide layer on metal surfaces to increase their durability, corrosion resistance, and appearance. For stainless steel, the process starts with immersing the material into a solution of acid-based electrolytes and then applying an electrical current. This step creates a uniform oxide layer that is harder and more resistant to environmental damage. Anodizing is much more durable than paints and coatings as it bonds with the metal. The stainless steel becomes resistant and can be finished decoratively, producing vibrant colors and a sleek, modern aesthetic.

Understanding the Anodizing Process

In terms of durability, appearance, and functionality, the anodizing process has several steps that involve mechanical and electrochemical processes. Here is the most up-to-date description of the process:

- Sharpening the Surface

The metal surface is cleaned and etched for surfaces before anodizing. Clogging and grease are scrubbed away so the metal is defect-free. Your quality depends on this step directly.

- Electrolytic Bathe

The cut metal part is placed into a bath of electrolyte acid. Capable of making use of sulfuric acid, other acids might include chromic acids, based on what is sought after in the finish. The electrolyte concentration and temperature of the solution are tightly controlled for optimum results. The solution is usually kept at 60-75 degrees Fahrenheit (16-24 degrees Celsius).

- Uses of Electric Current

Once in the bath, an electric current is passed. Metal is the anode (positive electrode), and a cathode (negative electrode) is placed in the same bath. The electric current causes oxygen ions on the surface to bond with it, forming an oxide layer that is an order of magnitude greater in thickness than the surface-level aluminum. This layer is about 2–3 times stronger than the aluminum surface, which recently underwent oxidation hardening with a hardness of 60 on the Rockwell C scale.

- (optional) Coloring

These dyes/special coatings can be added during or after anodizing for ornamental purposes.The oxide layer is selected to acquire colors by reverse osmosis, which gives a permanent bond. This is often used in the architectural and automotive industries, where aesthetics are vital.

- Sealing The Surface

To further improve corrosion resistance, the anodized layer is sealed by immersion of the material in boiling deionized water/steam. This process cuts off the pores on the oxide layer while simultaneously entraping any colors added to it.

Benefits Backed by Data

Anodizing works to alter the surfaces of materials in a way that enhances their lifespan and efficiency in the following ways:

- Corrosion Resistance: Anodized aluminum can resist salt spray testing for up to 10,000 hours for exterminates, while untreated Aluminum corrodes significantly quicker.

- Abrasion Resistance: The oxide layer can claim to overcome the wear resistance of the surface for abrasion in standard finishes, which range between 25 and 150 microns.

- Sustainability: Anodizing is far superior to its counterpart as it leaves no hazardous waste. The waste gives way to belonging to Mexican and non-toxic materials, simply requiring recycling, making it eco-friendly.

- Modern dyes have proven capable of withstanding UV exposure for years, maintaining vibrant color without losing their luster. With this mounting evidence, enabling fade proves hopeful for aiding dyes that the surfaces undergo.

The versatility, durability, and eye-catching appeal require an unforgiving combination of precision and science-adonizing guarantees, making it the heart of industries serving cosmetics, electronics, and aerospace.

Why Stainless Steel Cannot Be Anodized Like Aluminum

While stainless steel opposes all aluminum anodizing features due to fundamental differences in material and chemicals, aluminum is conductive to the anodizing process. Below are key points saying why anodizing cannot be done to stainless steel;

- Chemical Structure: Stainless steel is an alloy of iron, chromium, and manganese, creating a strong passive oxide layer that self-heals. This layer already mitigates corrosion, so adding anodizing would be unnecessary.

- Oxidized Layer Properties: Porous oxide layers allow aluminum’s oxide layer to be thickened and dyed through anodization, while stainless steel’s oxide layer is dense and cannot participate in anodic oxidation.

- Anodic Versatility: It works well with metals such as aluminum that easily oxidize, in the absence of air, because controlling the conditions would work well for surface reactions. Resistant to oxidation, stainless steel does not allow the needed surface reactions.

- Pricing: Compared to other methods of altering surface, such as painting or electroplating, anodizing stainless steel requires expensive, tailored procedures. Such modification goes against cost-efficient strategies.

- Aesthetic Constraints: Anodizing aluminum features bright coloration, vivid finishes, and an oxide layer intricately enhances its aesthetic appeal. Stainless steel is far more difficult; usually, one is left with visually and physically unsatisfactory results for stainless steel.

Despite these constraints, stainless steel still captures the market where high strength, corrosion resistance, and looks are required. Other procedures like polishing and passivation usually modify the surface to improve these properties.

The Role of Electrolyte in Anodizing of Stainless Steel

The electrolyte enables the anodizing process by facilitating the electrochemical process responsible for oxide formation on the surface. I understand that the electrolyte serves as a means for ion exchange, allowing controlled oxidation of the stainless Steel. Appropriate electrolyte formulations, such as sulfuric acid or phosphoric acid, can be used to adjust where the oxide layer is uniformly or precisely controlled, optimizing these attributes for specific applications or finishes.

Can you anodize stainless steel? What are the alternatives?

Stainless steel can be anodized, although it differs from anodizing processes done on aluminum. Unlike aluminium, anodizing stainless steel requires more work because forming uniform oxide layers is difficult. It often involves some specialized tools. It is the same when compared to anodizing aluminum. The \“anodizing\“ process consists in applying electrolysis of carefully selected solutions to achieve an oxide layer, which improves the material’s corrosion resistance while also acting as a surface finishing process.

The anodization of stainless steel products can be limited due to uniform anodic oxide layers. Anodizing uniform oxide layers is more difficult in aluminum. In most cases, these processes require ultra-high vacuum systems. Other more accessible anodizing methods or techniques that may offer a lot, depending on the nature of the work, include electroplating, passivation, and physical vapor deposition (PVD) coating. PVD coating strengthens the physical resistance of the material against wear.

Exploring Electrochemical Alternatives for Stainless Steel

As stated, other researchers have discovered using anodizing as a secondary step after chemical polishing. According to the latest data, using Passivation and Electropolishing Techniques on Stainless Steel Surfaces is a highly efficient way of improving stainless steel’s corrosion resistance and surface finish and offers great adaptability for industrial tasks.

Comparing Electroplate and Anodized Stainless

| Parameter | Electroplating | Anodizing |

|---|---|---|

| Process | Deposits a metal layer on the surface | Thickens the natural oxide layer |

| Electrode Role | Metal acts as the cathode | Metal acts as an anode |

| Material Used | Various metals (e.g., nickel, gold) | Aluminum, titanium, magnesium |

| Coating Thickness | 0.005 inches (approx.) | 0.0001–0.001 inches |

| Durability | Enhances wear resistance | Improves corrosion resistance |

| Weight Impact | Adds significant weight | Minimal weight addition |

| Aesthetic Options | Shiny, decorative finishes | Matte, colored finishes |

| Applications | Jewelry, automotive, electronics | Aerospace, construction, consumer goods |

| Environmental Impact | Generates hazardous waste | Non-toxic, eco-friendly |

| Cost | Higher due to materials and process | Lower for aluminum, higher for other metals |

How Oxide Layer Impacts Corrosion Resistance

| Parameter | Impact of Oxide Layer |

|---|---|

| Formation | Forms naturally or through treatments |

| Composition | Dense, stable oxides enhance protection |

| Thickness | Thicker layers improve resistance |

| Self-Healing | Repairs itself when damaged |

| Adherence | Strongly bonds to metal surface |

| Corrosion Prevention | Blocks oxygen and moisture penetration |

| Environmental Suitability | Effective in pH 4-9 environments |

| Enhancements | Anodizing or thermal oxidation boosts resistance |

| Limitations | May fail in extreme conditions or high chloride |

| Applications | Used in aluminum, titanium, and stainless steel |

Why Choose Anodized Aluminum Over Stainless Steel?

Depending on the application, anodized aluminum may have several pros compared to stainless steel. This is because anodized aluminum weighs less. As such, it is ideal for aerospace uses and consumer goods, which are designed to be portable. Relatively, anodized aluminum is cheaper than stainless steel. For large-scale projects, there are even more savings to be had. Other than cost, the finish on the aluminum is non-toxic, which makes advocating for eco-friendly anodized aluminum ideal. Also, the surface of aluminum allows for excellent customization in terms of aesthetics and how well it withstands corrosion. These features make anodized aluminum a worthy selection instead of stainless steel.

Benefits of Anodized Aluminum in Aerospace

| Parameter | Benefit |

|---|---|

| Corrosion Resistance | Protects against moisture, salt, and chemicals |

| Wear Resistance | Reduces wear from movement and stress |

| Lightweight | Enhances properties without adding weight |

| Durability | Extends lifespan of aerospace components |

| Electrical Insulation | Provides insulation for electrical components |

| Aesthetic Appeal | Offers smooth, customizable finishes |

| Thermal Resistance | Withstands extreme temperatures effectively |

| Eco-Friendly | Non-toxic and fully recyclable |

Comparing Oxidation Properties: Stainless Steel vs. Aluminum

| Parameter | Stainless Steel | Aluminum |

|---|---|---|

| Oxide Layer Formation | Forms a chromium oxide layer | Forms an aluminum oxide layer |

| Oxide Layer Stability | Highly stable and self-repairing | Stable but less durable in harsh conditions |

| Corrosion Resistance | Excellent, especially in marine environments | Good, but vulnerable to chlorides |

| Rust Resistance | Does not rust due to chromium content | Does not rust, lacks iron |

| Oxidation Appearance | No visible change | Forms a white, powdery film |

| Heat Resistance | Withstands high temperatures (up to 1371°C) | Softens above 204°C |

| Weight Impact | Heavier due to density | Lightweight, ideal for aerospace |

| Maintenance | Low, requires minimal upkeep | May need anodizing for added protection |

| Applications | Ideal for harsh, high-heat environments | Best for lightweight, low-heat applications |

What are the Effects of Anodizing-like Processes on Stainless Steel?

The electrochemical surface treatments or anodizing-like processes on stainless steel serve the purpose of increasing its surface durability, as well as its corrosion resistance. In addition, these techniques improve the outer appearance of the metal by providing it with matted, colored, or textured surfaces. Unlike anodizing aluminum, stainless steel isn’t traditionally anodized due to its unique chemical properties. Instead, it undergoes passivation, removing any impurities and enhancing the oxide protective layer for similar benefits. These elements allow the metal to sustain its strength and aesthetics in challenging conditions.

How Black Oxide Coating Works on a Steel Surface

Black oxide coating, also referred to as blackening, is the application of a thin, uniform coating of black iron oxide, also known as magnetite, to a steel surface. The oxide layer improves the steel’s aesthetic appeal, enhances corrosion resistance, and reduces reflection because of the matte black finish it provides. The process involves cleaning, immersing the steel in an alkaline or hot water bath containing oxidizing agents, and applying durable sealants.

The black oxide process customarily commences with cleaning the steel surface to remove any oils, rust, scale, or contaminants. This assures that the coating will adhere. After washing, the steel gets submerged into a heated alkaline bath, which is usually maintained between 275°F and 310°F (135°C to 154°C). The solution reacts with the outer layer of the steel and transforms it into black iron oxide. Uniformity in the chemical reaction must ensure no variation in the finish.

Post-oxidation, steel is usually treated with a sealant like wax or oil containing substantially greater quantities of oil to augment corrosion resistance. In humid conditions, the sealant acts as a protective coating and beautifies the surface by providing a gentle shimmer.

Research has found that black oxide coatings enhance the protection and resistance of steel materials used in different industrial sectors. Industrial studies estimate that the coating can provide an additional 20% increase in corrosion resistance in normal atmospheric conditions. However, it is essential to remember that maintenance and control of surrounding conditions tend to yield the best results. Black oxide cannot stand up by itself, as it does not offer robust protective coatings in highly corrosive surroundings.

This method has multidisciplinary use, from purely aesthetic coatings on consumer goods to practical coatings used in car, firearm, and tool manufacturing, which improve appearance and reflection, including light reflection under certain conditions.

Understanding Oxide Film Formation on Stainless Steel

The performance and durability of stainless steel in certain applications heavily rely on its oxide film formation, which, in sequence, becomes a parameter for resistance against corrosion. The oxide film forms passively because of the protective layer created when chromium in the stainless steel reacts with oxygen. Given below are five essential characteristics and factors that determine the passivation and stability of stainless steel oxide film:

- Chromium Content

Stainless steel must contain at least 10.5% chromium to form an effective oxide layer. Increased chromium levels enhance the development and tenacity of the protective barrier.

- Surface Finish and Cleanliness

Sharp and smooth polished surfaces renew and promote greater uniformity for oxide films. Effective cleaning ensures that oils, grease, and unwanted residues do not interfere with film formation.

- Environmental Conditions

The presence of oxygen is vital for the creation of oxide films. Nature rich in oxygen on the low end with limited oxygen hinders the protective mechanism.

- Temperature

An increased amount of heat speeds up the growth of oxides. However, too much heat can alter the ingredients in the film, making it unprotective.

- Aggressive Chemical Exposure

Persistent contact with aggressive chemicals such as chlorides can erode the oxide layer, or protective film, on stainless steel, increasing the chances of localized corrosion, which could include pitting or crevice attacks.

Understanding every contributing element is crucial in manipulating the protective qualities of oxide films on stainless steel and providing long-lasting reliability in various uses. Routine maintenance, systematic testing, and effective environmental control further improve the service performance of stainless steel spectrometers.

Impact of Anodic Layers on Steel and Stainless Steel Parts

Anodic layers are critical in improving the corrosion resistance and performance of steel and stainless steel components. Surface oxidation forms these layers, which are protective oxide films formed by electrochemical processes. This protective film acts as a barrier that prevents corrosive substances from coming into contact with the material, thereby slowing down the degradation processes.

Having an anodic layer comes with benefits such as:

- Increased Resistance to Corrosion:Anodic layers act as protective shields for steel and stainless steel parts, extending their service life due to protection from hostile environments such as saltwater, industrial chemicals, and moisture-containing air.

- Higher Surface Hardness: Steel’s outer surface can work differently, making the material fairly hard, resistant to abrasion and wear due to anodizing. This surface property alteration results in increased surface hardness.

- Aesthetic Flexibility: Surfaces undergoing anodizing do not lose their strength and can thus be buffed and tinted in multiple ways. This is useful for architectural and decorative uses.

Performance Data Of Anodic Layers

Research on the effect of anodic oxidation on stainless steel AISI 304 showed the oxide layer with over 75% reduction in the corrosion rate in saline environments, and additional studies indicated that the thickness of anodic layers increases performance. Optimal protection was offered by thicknesses of 2-4 microns in chloride-dominated environments.

Anodic Layer Applications

- Aerospace: Anodizing is a critical process for protecting airplane parts and components that are regularly exposed to extreme weather conditions.

- Marine: External surfaces of Ships and offshore equipment are anodized to prevent seawater corrosion.

- Industrial: Equipment parts that are subjected to chemical, thermal, or mechanical stress include anodized surfaces to improve their lifespan.

The steel and stainless steel industries focus on using and understanding anodic layers because they enable the material to function efficiently and prolong its lifetime under severe conditions.

Recent research should include the Effects of Anodizing Parameters on Corrosion Behavior. Check ScienceDirect for details to support performance values. All values and derived statements need to be confirmed to ensure reliability.

How Does Anodization Enhance Corrosion Resistance?

Anodization increases the material’s ability to resist corrosion by adding a permanent protective oxide layer to the material’s surface. This protective oxide layer protects the underlying metal from water, oxygen, and harmful chemicals. Anodization also improves surface hardness and protects against physical damage that could lead to corrosion. When the anodized layer is sealed, the material is protected from environmental conditions and harsh treatment, allowing for long-lasting performance.

The Importance of Oxide Films in Corrosion Prevention

Oxide films are vital in improving the durability of materials because they help protectthem from corrosion damage. They are oxide layers of small thickness that form on the surface of metals such as aluminum, titanium, and stainless steel, and they serve to stop further oxidation or degradation. Anodized aluminum is known to have an oxide film of 5 microns thickness, which is 10 times more corrosion resistant than unprotected surfaces. Furthermore, such oxide films can be enhanced by other means at the anodization stage, such as adding pigments, sealing pores known to increase pollution resistance, and increasing salt spray resistance of greater than 25 percent.

Insights from the global coating industry indicate that aluminum anodizing helps reduce the life-time maintenance expense of structures by approximately 30% due to its advanced resistance against corrosion. In the aerospace industry, materials covered with oxide layers retain their integrity during extreme atmospheric exposure, significantly reducing the failure risk. These changes emphasize the role of cost-effective oxide films for other industrial applications where safety, durability, and reliability are the prime focus.

Examining the Electrochemical Mechanisms Behind the Anodizing Process

The anodizing process is carried out based on electrochemical mechanisms of forming a controllable oxide layer on metallic surfaces, mostly aluminum, by electrolyzing a current through a solution. From what I see, the process yields a smooth, steadfast oxide coating. The oxide film is built up on the aluminum surface when metallic aluminum is dipped in an electrolyte solution and an electric current is applied. The metal surface is attacked by the solution, reacting with Anodizing, causing the metal to operate as an anode; the current is used to zoom in on the metal and electrolyte interface and thus promote oxide layer growth. The process increases the resistance to corrosion attack and provides an excellent anchor for subsequent processes like dyeing and sealing.

Comparative Analysis: Anodized Steel vs. Non-Anodized

Numerous factors distinguish the benefits and features of anodized steel compared to non-anodized steel. A few key factors explaining their differences are set out below:

- Corrosion Resistance

- Anodized Steel: The oxide layer created during anodizing protects metals from moisture, chemicals, and other environmental elements that cause corrosion.

- Non-Anodized Steel: Non-anodized steel lacks the protective layer and thus is more vulnerable to rust and decay than other forms when exposed to similar circumstances.

- Durability

- Anodized Steel: The anodizing process produces a thin, protective coating that increases the steel’s durability and wear resistance, making it suitable for more challenging environments.

- Non-Anodized Steel: Although less exposed to physical wear, non-anodized steel is still relatively strong. However, it will face faster degradation under constant use.

- Surface Appearance

- Anodized Steel: Anodized surfaces can be colored while ensuring clarity and vibrance. This makes for an appealing finish and strong uniformity, which is welcome in many industries.

- Non-Anodized Steel: This type of steel features a unique natural metallic appearance but is prone to scratching and tarnishing over time.

- Maintenance Requirements

- Anodized Steel: The need to frequently perform maintenance on anodized steel is reduced due to its scratch and corrosion resistance, keeping it easy and straightforward to maintain.

- Non-Anodized Steel: Non-anodized steel needs regular upkeep to prevent rust and deterioration, particularly in humid and highly corrosive environments.

- Environmental Sustainability

- Anodized Steel: The process is eco-friendly because the surfaces do not peel or chip, and there is no waste due to repainting or coating applications.

- Non-Anodized Steel: Environmentally, it can have a greater impact due to the upkeep and additional treatment material needed throughout its lifecycle. It may require additional coatings or treatments.

References

- Nanoporous Stainless Steel Anode for Enhanced Microbial Fuel Cells

Link to source

This study explores the anodization of stainless steel in fluoride/sulfuric acid baths and its applications. - Engineering of nanoscale antifouling and hydrophobic surfaces on naval structural steel HY-80 by anodizing

Link to source

This research investigates anodizing conditions and their effects on microstructural properties. - Investigating Corrosion Behaviors of Anodized Metallic Implants by Electrochemical Analysis

Link to source

This paper discusses how anodization enhances the corrosion resistance of stainless steel and other metals.

Frequently Asked Questions (FAQ)

Q: What is anodizing, and can stainless steel be anodized?

A: Anodizing is an electrolytic process used to increase the thickness of the natural oxide layer on the surface of metal parts, typically aluminum. While stainless steel can be anodized, the process is different from aluminum anodizing and is less common due to the natural corrosion resistance of stainless steel.

Q: How does anodizing improve the corrosion resistance of stainless steel?

A: Anodizing enhances stainless steel’s corrosion resistance by creating a thicker oxide layer on its surface. This passive layer acts as a barrier against environmental factors that can cause corrosion.

Q: What role does the electrolytic process play in anodizing stainless steel?

A: The electrolytic process involves immersing the stainless steel in an electrolytic bath, where an electrical current is passed through the metal. This promotes the formation of a thick oxide film on the surface of the stainless steel, which increases its durability and corrosion resistance.

Q: Are there specific baths used to anodize stainless steel?

A: Yes, the process baths used to anodize stainless steel differ from those used for aluminum. They often involve a sulfuric acid solution and specific electrolytic conditions to develop a suitable passive layer on the stainless steel surface.

Q: Can anodizing be applied to all stainless steel alloys?

A: Not all stainless steel alloys are suitable for anodizing. Common grades like 304 stainless steel can undergo anodizing, but the effectiveness may vary based on the specific alloy and its composition.

Q: How does impurities affect the anodizing process of stainless steel?

A: Impurities in the stainless steel surface can affect the uniformity and quality of the anodized surfaces. They can lead to defects in the oxide layer, impacting corrosion resistance and aesthetic appearance.

Q: How does anodizing stainless steel compare to anodizing titanium?

A: Anodizing titanium also involves an electrolytic process, but typically produces more vibrant colors due to interference effects within the thick oxide layer. Stainless steel anodizing generally creates a more subdued appearance and focuses on enhancing corrosion resistance.

Q: What are the color options available through anodizing stainless steel?

A: While anodizing stainless steel does not produce the same range of colors as anodizing aluminum, it can achieve a deep black or other subtle hues through dyes and careful control of the anodizing process.

Q: Is anodizing the same as plating?

A: No, anodizing is not the same as plating. Anodizing involves creating an oxide layer on the metal surface through electrolysis. At the same time, plating consists of depositing another metal layer onto the surface, often using electrochemical methods.

Q: What maintenance is required for anodized stainless steel surfaces?

A: Due to their corrosion-resistant properties, anodized stainless steel surfaces require minimal maintenance. Regular cleaning with mild detergents and water is typically sufficient to maintain their appearance and protective qualities.