Due to its strength, efficient appearance, and corrosion resistance, 304 stainless steel is one of the most industrially utilized materials. However, many people are concerned as to whether or not this alloy fades or tarnishes over time. Knowing the reaction of the 304 stainless steel to different environmental factors like moisture, heat, and chemicals is vital for understanding what’s required in terms of long-term maintenance and performance. This article will look at the properties of 304 stainless steel and its resistance to tarnishing and fading, along with tips on how to care for and maintain the material. If you are considering using 304 stainless steel for your next project or are simply curious about its characteristics, this article will give you all the information you are looking for.

What is 304 Stainless Steel?

304 stainless steel is one of the most widely used types of stainless steel, and it’s known for its use in architecture, kitchen appliances, and even medical equipment. 304 stainless steel is an austenitic alloy steel composed of iron, chromium, and nickel, making it durable and versatile. It is known to have great resistance to tarnishing and rusting, and is proven to be tough and strong due to the high nickel content. The combination of these factors makes the steel ideal for many uses, such as appliances, equipment, and even architectural structures.

Composition and Grade of Stainless Steel

The most well-known features of 304 stainless steel are the fact that it is primarily composed of iron while simultaneously having large proportions of chromium and nickel. On average, 18 to 20 percent of the steel is chromium, along with 8 to 10.5 percent of nickel, which adds to its strength and resistance against corrosive elements. This type of steel is classified as an austenitic type of stainless steel, which speaks to its great mechanical properties. It has a vast range of usable temperatures,making it quite flexible. All of this, combined with the versatility and durability, makes these widely used in various industries.

Properties of 304 Stainless Steel

- Corrosion Resistance:

- Exceptional oxidation and corrosion resistance in acidic and chloride-rich environments.

- Suitable for food processing, chemical, and maritime industries.

- Mechanical Properties:

- Yield Strength ( 0.2% offset ) : Roughly 215 MPa ( 31,200 psi ).

- Tensile Strength: Normalized values are commonly around 505 MPa ( 73,200 psi ).

- Elongation at Broken: Roughly 40%.

- Temperature Tolerance:

- Maintains structural integrity from a temperature of -196°C to 870°C ( -321°F to 1598°F ).

- Exceptional for cryogenic and high-temperature applications.

- Chemical Composition:

- Chromium (Cr): 18-20%.

- Nickel (Ni): 8-10.5%.

- Carbon (C): 0.08% max.

- Manganese (Mn): Up to 2%.

- Silicon (Si): Up to 0.75%.

- Weldability and Machinability:

- Standard welding methods with little chance of cracking or deformation make this material very weldable.

- Good machinability, but high efficiency may need carbide tooling.

- Magnetism:

- Slightly magnetic after cold working, but apart from that, non-magnetic in the annealed condition.

These properties make 304 stainless steel a multi-purpose and extensively used material for everything from kitchen tools to industrial parts.

Applications and Uses of 304 Stainless Steel

Owing to its robustness and resistance to corrosion and hygiene concerns, 304 stainless steel is extensively used in numerous applications. For instance, I utilize it for kitchen sinks, cookware, and appliances because it is hygienic and simple to clean. Its strength and aesthetic appeal also make it a preferred choice for use in architectural designs for items like handrails and decorative trims. Moreover, it is widely used in industrial equipment such as chemical tanks and piping because they are corrosion corrosion-resistant and can survive harsh environments. Its versatility makes it instrumental in both residential and commercial purposes.

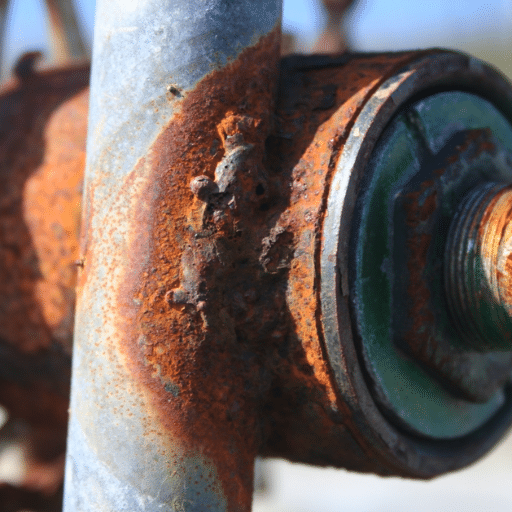

Why Does 304 Stainless Steel Tarnish or Fade?

The protective oxide layer that safeguards 304 stainless steel from tarnishing or fading can get severely affected with extended exposure to chlorides, salt water, or acidic environments. In addition, unideal cleaning techniques and high-temperature exposure can lead to accelerated surface dulling and discoloration. Regular maintenance and proper cleaning, as well as abstaining from harsh systems, can aid in preserving tarnishing resistance and a lustrous finish.

Understanding Corrosion and Tarnish

When stainless steels are damaged or exposed to certain environments or substances, tarnish and corrosion will form due to the loss of their protective layer. Scaling due to chloride or saltwater exposure over time will result in corrosion and tarnish on the steel. This is due to the many constituents able to damage the chromium oxide layer, which is responsible for preventing rusting and staining. Severe surface cleaning with cleaning agents can also increase the tarnishing rate, due to loser surface integrity. To minimize tarnishing, a non-abrasive, gentle scrub should be used, along with limited interaction with corrosive agents. By maintaining these guidelines, tarnishing of the steel can be avoided, preserving the appearance of the metal.

Factors That Cause Stainless Steel to Tarnish

Lastly, some other factors that result in tarnishing of the stainless steel is exposure to air with high humidity, and interactions with water which can lead to rust. Salt, used in excessive amounts and even cleaning agents, also enable the protective layer of chromium oxide to corrode. Physical factors such as scratching and abrasion can also expose the protective surface of the steel making it easier to tarnish.

How Stainless Steel is Exposed to Tarnishing Agents

Steels corrosion resistance is, from my perspective, chemically and environmentally compromised. For instance, frequent and sustained interaction with chlorides, such as those present in cleansing agents or salt water, promotes accelerated corrosion. Additionally, high temperatures and humid conditions increase oxidation rates, which aggravates the problem. Moreover, mechanical impact in the form of scratches and dents also exposes the metal to these agents by compromising the protective chromium oxide layer.

Technical Parameters:

- Chloride Concentration Exposure Limit: To minimize corrosion risk, less than 250 ppm.

- Relative Humidity Threshold: Greater than 70% provides optimal resistance.

- Recommended Surface Finish: Rougher than Ra 0.5 is better, as smoother surfaces tend to tarnish more.

Abrasive nonchlorinated cleansers should be banished, as well as uncontrolled environments, to properly maintain stainless steel.

Is 304 Stainless Steel Good for Jewelry?

Absolutely, 304 stainless steel is a jewelry option as far as appearance, price, and strength goes, and with it being resistant to corrosion, makes it a rather affordable option. Additionally, it is hypoallergenic for a majority of the population, which makes it ideal for sensitive skin. Though it is not completely immune to tarnishing or corrosion, especially with chloride rich environments and moisture. However, caring for it properly can help and protect the piece over time.

Benefits of Using 304 Stainless Steel in Jewelry

I have to say that 304 stainless steel is a good option for jewelry due to its affordable price and its durability against tarnishing or rusting. It is an inexpensive material that has a sleek and polished look with almost no maintenance. Another point that I value the most is that it’s hypoallergenic for most people, so it’s safe for people with sensitive skin. For extreme conditions, I have to say that it’s true it’s not entirely immune to tarnishing, but with proper care and cleaning, it is made to look great for years. All Life seems to be the perfect blend of style, strength, and affordability in one piece of jewelry.

Comparing 304 and 316 Stainless Steel for Jewelry

Stainless steel jewelry thrives from both 304 and 316 types and their compositions differ primarily to the percentage of chromium and nickel they contain. 304 is comprised of 18% chromium and approximately 8% nickel which makes it resistant to rusting and tarnishing. 316 stainless steel casts and renders moibdenite, making the steel more resistant to corrosion and pitting in saltwater or other chloride environments.

Hypoallergenic Props

316 steels’ lower content of nickel makes it more preferred for individuals who tend to suffer from mild allergic reactions. From surgical cuts and procedures, 316 has become loosely known as surgical-grade steel. Contrary to 304, 316 is more agreeable towards people who suffer from severe allergic reactions.

Pricing and Uses

On a strict budget, 304 is the suitable option as it is good for jewelry that is exposed to conditions which are not very harsh. When worn in harsh conditions like swimming or while playing outdoor sports, 316 suits best as it more resistant to damage under these circumstances. In a long run 316 proves better value for the cost due to being better quality and more durable.

Final Thoughts

Deciding on 304 versus 316 stainless steel relies greatly on how and where it will be used. 304 stainless steel is a good option for anyone trying to watch their budget and general day-to-day wear. On the other hand, those with skin sensitivities or needing something to withstand more rigorous conditions will find 316 to be more useful. Both materials allow for exquisite jewelry pieces while providing a necessary practicality and durability.

How to Maintain Stainless Steel Jewelry

For those who want to keep their stainless steel jewelry looking fresh, the following practices should be incorporated:

- Daily Maintenance

To maintain the aesthetics of your jewelry, regularly wash it with warm water and consider using a mild dish soap. Try to use a soft cloth or non-abrasive sponge to scrub the jewelry and rinse thoroughly. Make sure to dry the jewelry with a lint-free cloth to avoid water stains.

- Polishing/Buffing

Restoring the shine of stain-removable jewelry can be done using a stainless steel or jewelry polishing cloth. Refrain from using abrasive materials that can scratch the surface of the jewelry. Use polishing compounds graded for stainless steel.

- Best Practice: Your Jewelry’s Worst Enemy

Putting your jewelry in contact with tough chemicals such as bleach, ammonia, and chlorine will cause discoloration or tarnishing. You should always take your jewelry off before getting in the shower or cleaning.

- Storage Recommendations

Always keep your stainless steel jewelry in a secure environment. The storage should also be dry and free of bad weather conditions. Store your jewelry in a box or bag to avoid scratches that other items may cause. Make sure the location does not have excessive humidity to avoid corrosion.

- Stay Away from Damage-Prone Areas

Do keep in mind that an environment with extreme temperatures, high levels of humidity, or excessive salt can have long term negative impacts on your jewelry. Such conditions could increase the amount of usage wear and tear on stainless steel over time regardless of quality.

Stainless Steel Overview

- 304 Grade – Rust and corrosion are acceptable in normal atmospheric settings, however, it is more susceptible to damage in high salt settings.

- 316 Grade (Marine Grade) – Best for humid and saline settings due to enriched protection with molybdenum against chloride corrosion and tarnish.

- Depending on the usage level of the piece, frequent polishing may be required. However, for most people polishing every 1-3 months will be more than enough to maintain shine and smooth out small scratches.

Following these tips will help ensure your stainless jewelry will maintain its durability and elegance for years to come.

How to Clean Stainless Steel and Prevent Tarnish?

Cleaning stainless steel requires minimal effort, and getting the job done is as simple as can be. To begin, take a soft cloth or sponge, warm water, and mild soap, and wipe away dirt and oils. For tougher stains, make a paste out of baking soda and water, apply it, and then rinse it off thoroughly. When finishing up, always dry the surface with a clean and lint-free cloth to avoid any water spots. To prevent tarnish, store your stainless steel items in a dry container for long periods, as well as avoiding moisture and harsh chemical exposure. By doing these practices, the shine and longevity of these items will be guaranteed.

Effective Methods to Clean Stainless Steel

- Use White Vinegar And Olive Oil

Stainless steel surfaces can get rid of smudges and streaks with white vinegar as it is an efficient natural cleaning product. Applying white vinegar to the surface and wiping it clean with a microfiber cloth will do the trick. For added shining, take a clean cloth, add a small amount of olive oil to buff the stainless steel while doing it with the grain.

- Avoid Abrasive Cleaners And Tools

Using harsh cleaners and steel wool will scratch the stainless steel surface which will cause diminishment in sheen over time. Non-abrasive cleaning solutions are recommended for use, and keep in mind to always use clean soft cloths such as microfiber.

- Baking Soda for Tough Stains

Stubborn stains and baked-on grease can be treated by using baking soda safely and efficiently. For effective scrubbing, use a soft cloth or towel to first blot the stain, then mix one part baking soda with one part warm water to create a paste. Dry immediately after rinsing to avoid water stains.

- Specialty Stainless Steel Cleaners

A store bought specialty stainless steel cleaner will leave the surface of the appliance smudge, oxidation build-up, and fingerprint free while leaving a protective layer to resist future marks. These cleaners are often meant for professional use, therefore providing higher grade results.

- Technical Parameters

- To avoid micro scratches, always clean stainless steel in the direction of the grain.

- Avoid using solutions containing cough and bleach, as these will corrode the surface of the stainless steel.

- Stainless steel’s integrity is influenced by extreme water temperatures. Rinse with water set between 20-30 degrees Celsius.

By following the methods and precautions outlined above, the stainless steel surfaces can remain clean while increasing their lifespan.

Tips to Keep Stainless Steel Surfaces Shiny

- My primary tools for cleaning are a soaking cloth and a microfiber cloth; the former is made of microfiber while the latter is filled with warm, soapy water. This method maximizes shine while reducing scratches.

- Vinegar is a good tool for removing fingerprints as it can be easily followed by a polish of olive or mineral oil.

- Baking powder paste is useful in baking, but I find it effective against stubborn grime too. I use it when I want to gently scrub, followed by a rinse.

- Lastly, I precede water surface cleaning with a cloth wipe to prevent streaks and water spots.

Preventive Measures Against Stainless Steel Tarnish

The following measures can be taken to diminish the chances of tarnishing stainless steel articles’ surfaces.

- Cleaning the Surface: A soft cloth with mild soap can be used to clean stains on stainless steel. Do not use harsh cleaners as these can ruin the protective layer on the metal.

- Avoid Chlorides: Try and avoid exposing the steel articles to chlorides or salt over time, as these can corrode the stainless steel.

- Stainless steel equipment should be kept in a less humid and drier area to minimize the chances of oxidation.

- Use protective coatings: Apply a sealing protective layer using a thin coating of mineral or olive oil and maintain the coating periodically.

- Temperature Limitations: Do not expose to extreme heat above 600 F(316C) for long periods of time as this can damage the stainless steel structure.

- pH Balance: Ensure cleaning equipment has a pH balance of 6-8, as any above or below would damage the protective layer on the stainless steel.

If all of the recommendations above are followed, or at least most, then tarnishing of stainless steel will be delayed for a long time.

What Makes 316 Stainless Steel Different?

316 stainless steel is distinctive because of its resistance to corrosion, particularly of chlorides and other hostile environments. This is because of the presence of molybdenum, which provides better protection from any pitting or crevice corrosion. Furthermore, 316 stainless steel has a mechanical strength and durability that is remarkable, which enables it to be used in the construction of marine, chemical, and medical equipment. What makes this grade of stainless steel unique from the others is its resistance to extreme conditions while retaining its properties, due to corrosion.

Comparison of 304 and 316 Stainless Steel

- Resistance to Corrosion

- 304 Stainless Steel: Exhibits good resistance to corrosion in places which have low to moderate exposure to corrosive activity. It can be used indoors and outdoors in mildly aggressive conditions.

- 316 Stainless Steel: Has better corrosion resistance in presence of chlorides, seawater or any aggressive chemicals. This is because of added molybdenum which improves pitting and crevice corrosion problems.

- Chemical Composition

- 304 Stainless Steel:

- Chromium: 18 – 20%

- Nickel: 8 – 10.5%

- Includes Manganese, Silicon, and carbon in trace quantities.

- 316 Stainless Steel:

- Chromium: 16 – 18%

- Nickel: 10 -14%

- Molybdenum: 2 – 3% (important for corrosion resistance)

- Trace amounts of Manganese, Silicon, and Carbon.

- Applications

- 304 Stainless Steel:

- Used frequently for kitchen gadgets, automobile parts, and construction work in mild environments.

- 316 Stainless Steel:

- Suitable for use in an extremely aggressive marine environment, surgical instruments, and chemical reactors.

- Cost

- 304 Stainless Steel comes at a lower price and is economical for general use purposes.

- 316 Stainless Steel is more expensive due to the added molybdenum, but it is still cost-effective where greater corrosion resistance is needed.

- Mechanical Characteristics

- 304 stainless steel:

- Ultimate tensile strength: 505MPa

- Yield Strength (0.2% Offset): 215MPa

- Hardness(HB): About 201

- 316 Stainless Steel:

- Ultimate tensile strength: 515 MPa

- Yield Strength (0.2% offset): 240 megapascals.

- General hardness (HB): About 217.

Fostering an understanding of these differences will allow for informed choices to be made depending on the specific needs of the application while keeping in mind the desired performance versus cost ratio.

Benefits of 316 Stainless Steel in Corrosive Environments

In my case, 316 stainless steel resists corrosion better than 304 stainless steel because it has a higher content of molybdenum. This additional content is effective in resisting pitting and crevice corrosion, especially in marine or industrial environments with a lot of chlorides. In addition, it is exceptionally durable due to its excellent tensile strength of 515 MPa and yield strength of 240 MPa, making it suitable for demanding applications. It is the material of choice for chemical processing, marine structures, and medical tools because of its superior resistance to extreme conditions. Assuming durability is further augmented with the hardness of 217 HB, which allows for structural integrity over time, even in harsh conditions.

When to Choose 316 Stainless Steel?

For highly corrosive environments like saltwater or chemical exposure, the 316 stainless steel is optimal. My favorite selection for marine, chemical, and industrial processing applications is steel that requires high durability, strength, and resistance to severe conditions. Outstanding corrosion resistance and durability make the material ideal for structural integrity in these demanding applications.

References

- SteelPro Group: Will Stainless Steel Tarnish or Fade?

- TianjinPosco Group: Does Stainless Steel Tarnish or Fade?

- Reliance Foundry Blog: 304 vs 316 Stainless Steel

Frequently Asked Questions (FAQ)

Q: Does 304 stainless steel tarnish or fade over time?

A: 304 stainless steel is resistant to tarnish and corrosion due to its chromium content. However, it may experience slight discoloration in certain harsh environments.

Q: Can 304 grade stainless steel rust?

A: While 304 stainless steel is designed to be corrosion-resistant, it can rust under certain conditions, particularly when exposed to chloride or salt water.

Q: What causes stainless steel to rust?

A: Stainless steel may rust if the protective oxide layer on the metal surface is damaged, especially in environments with high chloride levels.

Q: How does 304 stainless steel differ from 316L stainless steel?

A: The main difference is that 316L stainless steel contains molybdenum, which enhances its resistance to corrosion, particularly in saltwater and harsh environments.

Q: Is 304 stainless steel suitable for use in harsh environments?

A: While 304 stainless steel has good corrosion resistance, it may not be the right stainless steel for harsh environments, where 316L with its added molybdenum might be more appropriate.

Q: Why is chromium important in stainless steel products?

A: Chromium in stainless steel creates an oxide layer on the metal surface, which provides corrosion resistance and prevents rusting.

Q: Can wearing stainless steel jewelry cause skin discoloration?

A: High-quality stainless steel, such as 304 grade, is generally hypoallergenic and should not cause skin discoloration. However, individual reactions can vary.

Q: Are all types of stainless steel non-corrosive?

A: Not all types are equally non-corrosive. The corrosion resistance of stainless steel depends on its grade and the environment it is exposed to.

Q: What is the role of nickel in stainless steel?

A: Nickel in stainless steel enhances its corrosion resistance and adds to the metal’s overall strength and durability.

Q: How does stainless steel maintain its resistance to tarnish?

A: Stainless steel maintains its resistance to tarnish through its alloy composition, which includes chromium that forms a protective oxide layer on the surface.