Get in touch with us

Leave a message

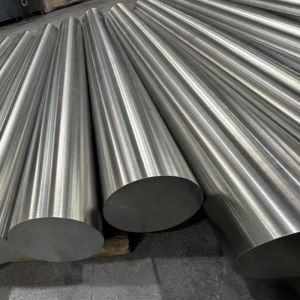

As a leading China manufacturer, our company specializes in Hastelloy Pipe and Hastelloy Tube, renowned for their exceptional corrosion resistance and strength. These high-temperature alloys, including grades like Hastelloy C276 and C22, are designed for demanding industrial environments, offering durability and reliability in harsh conditions.

Hastelloy Pipes are available in various standards and grades, ensuring they meet diverse industrial demands. The two most popular grades include Hastelloy C276 and Hastelloy C22, both known for their excellent resistance to acids, such as hydrochloric acid, sulfuric acid, and phosphoric acid. Specifications often comply with ASTM and ASME standards, such as ASTM B622 and ASTM B619. These pipes are classified based on the manufacturing process, such as seamless, welded, or fabricated.

Hastelloy Pipes are offered in a range of sizes to suit various applications. Common dimensions typically include the following:

These size options ensure adaptability and compatibility with diverse industrial setups and custom designs.

Hastelloy Pipes are produced in multiple forms to meet different requirements, including:

| Grade | Industry | Specific Uses |

|---|---|---|

| Hastelloy C276 Pipe | Chemical Processing | Reactors, Heat Exchangers |

| Hastelloy C22 Tube | Pharmaceuticals | Corrosive Fluid Handling |

| Hastelloy B2 Pipe | Petrochemical | Acid Processing Systems |

| Hastelloy G30 Tube | Power Generation | Flue Gas Desulfurization |

A:Hastelloy Pipes are made from a superalloy composed primarily of nickel, molybdenum, and chromium, along with small amounts of iron and cobalt.

A:They comply with ASTM B622, ASTM B619, ASME SB-619, and other international standards.

A:Their exceptional resistance to oxidation, pitting, and crevice corrosion makes them ideal for such conditions.

A:Yes, most manufacturers and distributors in China offer customization options for size, thickness, and length.

A:Industries such as chemical processing, marine engineering, pharmaceuticals, power generation, and aerospace commonly utilize Hastelloy Tubes.

A:Hastelloy offers superior resistance to corrosion compared to stainless steel, especially in environments involving strong chemicals and high temperatures.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.