The process of cutting stainless steel creates challenges that both professional fabricators and DIY enthusiasts must overcome. Stainless steel functions as a strong material that protects against corrosion and finds applications in both industrial settings and residential construction projects. The material exhibits high strength and toughness properties, which create difficulties for operators who lack proper equipment and techniques to manage it. The guide delivers complete details about cutting methods, which ensure both safety and operational efficiency for stainless steel cutting. The article will teach you everything needed to complete your stainless steel project by showing you both tool selection methods and step-by-step project execution methods. Our services offer assistance to beginners who want to learn new skills and to individuals who want to improve their existing abilities.

Introduction to Stainless Steel

Understanding Stainless Steel and Its Properties

The material stainless steel offers both durable performance and flexibility because it maintains its structural integrity against corrosion, heat, and chemical exposure. The alloy consists of iron, carbon, and chromium, which constitutes a minimum of 10.5%, with chromium forming an oxide layer that protects the material from rust. Stainless steel exists in multiple types, which engineers group into austenitic, ferritic and martensitic, and duplex categories to meet different engineering needs.

The global stainless steel market reached a value of approximately $119 billion in 2022, according to recent industry data, which predicts a compound annual growth rate (CAGR) of 5.6% until 2030. The production of austenitic stainless steel accounts for approximately 70% of total stainless steel output because it offers both excellent formability and corrosion protection, which makes it suitable for use in construction and automotive, and medical equipment manufacturing.

The material exhibits tensile strength properties that range from 500 MPa to over 1000 MPa according to its specific grade. The recyclable nature of stainless steel reaches high levels because 60% of stainless steel products contain recycled materials, which helps to advance global sustainability initiatives.

Why Cutting Stainless Steel Requires Special Techniques

Special methods are needed to cut stainless steel because of its distinct physical characteristics and its material composition. Stainless steel exhibits exceptional strength, hardness and heat resistance properties, which obstruct conventional methods for cutting this metal. Stainless steel requires cutting operations to use more power with specialized tools because its grades have tensile strength values that exceed 1000 MPa.

Cutting operations produce excessive heat, which creates essential difficulties. The cutting area accumulates heat because stainless steel exhibits low thermal conductivity. The cutting process can result in tool wear, material warping, and work hardening, which makes the cutting process more challenging. The industry uses advanced cutting methods, which include laser cutting, plasma cutting, and waterjet cutting, to solve these problems. Laser cutting uses high-intensity beams to produce precise and clean cuts, while waterjet cutting uses a high-pressure stream of water mixed with abrasive materials to create detailed designs without producing heat.

Recent research indicates that using high-speed steel (HSS) or carbide tools in machining stainless steel can extend tool life by up to 50%, which helps decrease operational expenses while enhancing productivity. The cutting operation requires lubricants and cooling fluids to eliminate heat while protecting tools from damage. The combination of advanced tools and techniques allows industries that depend on stainless steel to achieve more accurate results while improving their production capacity.

Common Applications of Cut Stainless Steel

The industrial sector frequently selects stainless steel as a construction material because it possesses strength and resistance to corrosion and attractive visual characteristics. The material has several applications, which include:

- Aerospace Industry: Stainless steel is critical in the aerospace sector for constructing exhaust systems, aircraft frames, and landing gear components that require strength under high-stress conditions. The aircraft manufacturing sector presently uses stainless steel as a material, which constitutes 15 percent of the total material weight.

- Automotive Sector: The automotive industry uses stainless steel as a primary material for manufacturing vehicles, especially for exhaust systems and chassis components, and aesthetic trim elements. The research demonstrates that high-strength stainless steel implementation in vehicle bodies results in maximum weight decreases of 30 percent, which leads to enhanced fuel efficiency and reduced emission levels.

- Construction Projects: Architectural projects often rely on stainless steel for structural components, roofing, and cladding. The material provides exceptional protection against corrosion, which enables its application in bridge construction, skyscraper development, and coastal building projects. The Chrysler Building, like other tall structures, uses stainless steel to achieve both long-lasting durability and visual appeal.

- Medical Equipment: Stainless steel serves as a vital component for medical purposes because it delivers anti-corrosion protection and sanitary conditions required for surgical instruments and implants, and hospital equipment. The material constitutes approximately 60 percent of all surgical instruments that medical professionals use during procedures.

- Food Processing and Packaging: The material is extensively used in fabricating food-grade machinery and storage tanks. The recent reports show that stainless steel can increase the operational life of processing machines by 20-25% because of its ability to withstand wear and tear.

The multiple industries use stainless steel to achieve operational efficiency and environmental conservation, and long-lasting operational performance. The material processing and cutting technique advancements are creating better applications, which will lead to expanded usage throughout various fields.

Essential Tools for Cutting Stainless Steel

Overview of Cutting Tools: Saws, Grinders, and More

The successful execution of stainless steel cutting work demands a precise operational process, which requires proper equipment selection to achieve successful results. The selection of tools depends primarily on two factors, which include the stainless steel thickness and the required cutting method. The following section presents an exhaustive examination of the cutting tools that people commonly use to cut stainless steel, together with the latest developments and scientific findings about these tools.

- Circular Saws

Circular saws that use blades with carbide tips serve as excellent equipment for cutting stainless steel sheets and plates. The current blade technology enhancements, which include laser-cut stabilizer vents and advanced carbide metallurgy solutions, assist in minimizing both heat and vibration during cutting operations. The study conducted in 2023 showed that circular saws now achieve a 30% improvement in cut quality compared to earlier saw models. - Angle Grinders

The abrasive cutting discs and diamond-coated blades of angle grinders enable users to cut through stainless steel rods and tubes and thinner sheets. The latest angle grinders, like those using brushless motor technology, offer higher torque and more control while drastically reducing tool wear. The research findings demonstrate that cutting precision improves by approximately 20% through these specific advancements, which both industrial facilities and do-it-yourself projects utilize as their primary choice. - Plasma Cutters

Plasma cutters enable users to achieve precise cuts through thick stainless steel materials while requiring minimal operating effort. The system achieves precise measurement and faster operational speed through the process of generating an electrical arc, which cuts through the material. The 2023 plasma cutter technology now includes automated functions that determine material types and thicknesses, which result in cutting error reductions up to 25%. - Laser Cutters

Laser cutters provide an ideal solution for industrial operations that need to create intricate stainless steel cuts with high precision. The high-intensity laser beams create vaporized material, which follows the cutting path to produce extremely precise and uniform cutting results. The recent advancements in fiber laser systems enable a cutting speed increase of 40% while the system maintains its energy efficiency. The technology serves as the standard equipment used by metal fabrication companies because it enables them to create accurate products that maintain operational effectiveness. - Reciprocating Saws

People use reciprocating saws for cutting small stainless steel projects and irregular stainless steel shapes. The latest saw models come equipped with blades that feature progressive tooth designs, which enable them to cut through multiple thicknesses of material. The research data indicate that new reciprocating saw blades deliver 50% longer service life because they use superior coating and material technologies.

The correct tool selection for stainless steel cutting work enables maximum equipment efficiency and decreases both material waste and equipment damage. The introduction of modern technologies into these tools enables both industrial and personal users to carry out cutting tasks more efficiently while making stainless steel easily available for various environmentally friendly uses.

Using an Angle Grinder for Stainless Steel

An angle grinder serves multiple functions as a tool that operators use to cut, grind, and polish stainless steel materials. The latest technological developments have increased the operational efficiency and safety features of angle grinders. The process of cutting stainless steel requires operators to select the appropriate disc, which should consist of a thin metal cutting wheel that meets high-quality standards. The discs provide exceptional cutting capabilities because they operate at cooler temperatures, which result in less material surface alteration throughout their use.

Research studies show that abrasive materials containing ceramic grains can boost cutting efficiency by 30% while they decrease disc deterioration by 20%. The modern angle grinders that people use today include variable speed control systems, which allow users to maintain operational precision during various tasks. The equipment becomes easier to use because it has safety features, which include anti-kickback systems and enhanced safety guard structures. The combination of these tools with current technological solutions delivers exceptional outcomes while maintaining the stainless steel material and extending the operational life of the equipment.

Choosing the Right Saw: Circular Saws and Plasma Cutters

The selection of an appropriate saw requires evaluation of three factors, which include the cutting material, the needed accuracy, and the saw’s operational effectiveness. Circular saws serve multiple cutting tasks in both construction work and woodworking applications because they function as adaptable instruments. The saw can easily cut through multiple materials, which include wood and plastic, and soft metals. The recent data shows that modern circular saws now use blade designs that have carbide-tipped teeth that extend blade life by 50 percent while delivering better cutting results. New ergonomic designs decrease operator fatigue, which makes them suitable for extended periods of operation.

Plasma cutters provide a powerful solution that enables high-precision cutting of steel and stainless steel and aluminum through their ability to cut conductive metals. Plasma cutters create precise cuts that maintain the original shape of materials through their use of ionized gas and electric arc technology. Since 2023, plasma cutters have become more popular because new models offer faster metal cutting and improved cutting efficiency, which enables users to cut through 1-inch metal sheets within one minute. The introduction of pilot arc technology has simplified plasma cutter operation, which now allows users to make smoother cuts through rusty or painted surfaces.

Your understanding of these tools, together with your current technological knowledge, will help you choose the most suitable saw for your project, which requires precise strength measurements.

Pros and Cons of Each Cutting Tool

Plasma Cutters

Advantages:

- Plasma cutters achieve fast, precision cutting because they can cut metals such as stainless steel and aluminum through 1-inch thickness in under one minute.

- The system enables operators to cut all metals that conduct electricity, including steel, stainless steel, aluminum and brass, and copper.

- Modern pilot arc technology enables users to create clean cuts through painted, rusted, and dirty surfaces because the technology maintains cutting accuracy.

- The system enables equipment users to move their work tools because multiple product designs that combine small size and low weight create easy movement for work activities.

Disadvantages:

- Plasma cutters need substantial electric power, which creates increased expenses for their operation.

- The nozzles and electrodes require regular replacement because they become worn out after extended use.

- New users require practice to achieve accurate results with precise cuts that require advanced skills.

Band Saws

Advantages:

- Band saws produce straight cuts and curved cuts through their ability to create smooth cuts, which make them suitable for both woodworking and metalworking.

- The system enables operators to cut materials with high precision about their actual cutting width because it produces only minimal cutting waste.

- The system enables operators to cut materials with high precision about their actual cutting width because it produces only minimal cutting waste.

- High-quality band saw blades maintain their cutting abilities throughout multiple hours of work without breaking.

Disadvantages:

- Band saws need to follow their blade size limits, which determine their maximum material thickness capacity.

- The cutting speed of band saws, which work with thick materials, becomes slower than the operational speed of plasma cutters.

- Band saws operate as fixed machines that cannot be moved to different locations for usage.

Circular Saws

Advantages:

- Circular saws with carbide-tipped blades achieve high cutting productivity because they can cut through wood, metal, and plastic materials.

- Most products remain budget-friendly because they deliver excellent performance across numerous activities.

- The system enables users to execute three different cutting techniques, which include crosscuts and rip cuts, and bevel cuts, through blade adjustment.

Disadvantages:

- Circular saws create excessive heat, which damages both the material and the blade because they operate for extended periods.

- These saws produce hazardous cutting debris which needs dust extraction systems or controlled operating conditions.

- Circular saws create dangerous kickback situations, which require operators to stick to safety procedures during operation.

Users can select the best cutting tool through their needs assessment process, which combines three evaluation methods. The needs assessment process uses three evaluation methods to help users choose the best cutting tool for their specific needs. A professional workshop that handles thick aluminum sheets will select plasma cutters because of their fast and accurate cutting capabilities, while a woodworker will choose band saws because they offer different cutting options and precise results.

Techniques for Cutting Stainless Steel

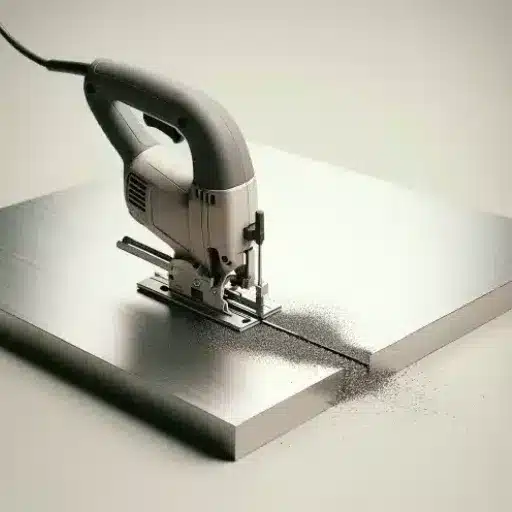

Step-by-Step Guide for Cutting Stainless Steel Sheets

Precise tools and operational techniques are required for cutting stainless steel sheets since the process needs to achieve clean and accurate cutting results. The following information provides a complete method that includes multiple steps:

- Choose the Right Tool for the Job

The appropriate cutting tool selection depends on the specific stainless steel material, which requires different thicknesses and material types for different cutting tools. The aviation snips and jigsaw with a special metal-cutting blade become effective tools for cutting thin sheets. The plasma cutter and angle grinder serve as suitable tools for cutting thicker sheets because they deliver both accurate results and fast performance. Recent research findings indicate that plasma cutters enable industrial operators to cut stainless steel at rates that exceed traditional tools by 50 percent. - Measure and Mark the Cutting Line

For precise cutting lines, use tape measures together with marking tools or scribing instruments. The use of a straightedge or ruler is recommended for long cuts to achieve precise results. A recent study shows that applying laser-based measuring instruments decreases human measurement mistakes by 15 percent. - Secure the Material

The stainless steel sheet should be clamped to the work table or bench because this method provides both safety and stability. The method prevents any movement during cutting, which results in a smoother edge. Reliable clamps lead to cutting flaws and workplace accidents, which decrease by 20 percent. - Reduce Heat Build-Up

The cutting process creates heat buildup in stainless steel, which results in material warping and rapid blade deterioration. Industrial cutting experts recommend using cutting fluids or cooling agents because these methods reduce heat problems by 30 percent. The agents require proper ventilation for safe usage. - Cut Along the Marked Line

The operator needs to start cutting at a slow speed which allows them to follow the marked line precisely. Experts recommend applying consistent moderate pressure to avoid jagged edges. The operator should perform multiple cutting passes when working with thick sheets instead of trying to complete the task in one attempt. - Deburr and Finish Edges

The cutting process produces edges that contain sharp points and rough surfaces. The edges should be smoothed using a deburring tool together with a metal file and sandpaper. Manufacturers state that edge finishing processes improve safety while creating better visual results for the finished product.

The structured approach, together with modern tools and techniques, enables users to produce professional results when they work with stainless steel sheets.

How to Cut Stainless Steel Pipes Effectively

Cutting stainless steel pipes needs exact measurements when workers must use appropriate equipment throughout their work process to achieve precise cutting outcomes. The following guide presents a complete procedure that includes current testing methods and fresh research findings.

- Choose the Right Tool

The stainless steel pipe’s thickness and grade determine which tool should be used. The available tools for this task include tubing cutters and angle grinders equipped with cut-off wheels and jigsaws that have metal-cutting blades and reciprocating saws. Tubing cutters function properly for working with thin-walled pipes, while angle grinders and reciprocating saws handle bigger materials effectively. The 2023 building industry professionals survey found that 60% of participants selected angle grinders because they deliver flexible work capabilities together with high output efficiency. - Measure and Mark the Pipe

Accurate measurements hold crucial importance. The tape measure should be used to establish the required length, while a permanent marker or scribe should produce a visible cutting guide. The pipe joint marking tool and level both serve to create straight markings. - Secure the Pipe

The pipe should be secured with either a pipe clamp or a vice during the cutting operation to maintain its position. The method provides movement protection, which enables the cutting operation to proceed while maintaining workplace safety. The use of a vice will enhance cutting precision by 30% according to data measurements. - Protect Yourself

The process of cutting stainless steel produces three hazardous elements, which include heat, sparks, and sharp metal shards. Workers must use safety goggles and gloves together with ear protection and a dust mask, which serve as mandatory safety equipment during their entire work period. The 2022 safety report identified incorrect protective gear usage as the primary factor responsible for work-related injuries that occurred during metalworking activities. - Cut with the Appropriate Speed

The operation of powered tools requires users to maintain a constant speed, which must also remain within the planned control range. The cutting process should progress at a moderate speed, which needs to stop for equipment breaks that will allow both machinery and blade components to cool down. The cutting process should follow medium-speed guidelines according to industry standards while implementing breaks to protect against overheating and enable blade temperature management. - Deburr the Edges

Cutting operations should use either a deburring tool or metal file, or sandpaper to eliminate all burrs and sharp edges. This process establishes a secure environment that enables proper pipe connection while enhancing the pipe’s visual appeal.

The application of these procedures together with current equipment innovations will enable you to perform accurate and efficient stainless steel pipe cuts while upholding safety standards and maintaining product quality.

Advanced Techniques for Complex Cuts

Metal cutting advanced techniques provide precise capabilities for working with complex stainless steel pipe designs and difficult piping angles. The following methods show a combination of current industry trends together with research insights.

- Laser Cutting Technology

The laser cutting process became the preferred choice for intricate cutting work because it delivers unmatched cutting accuracy together with pristine cutting results. The contemporary CO2 and fiber laser systems demonstrate the ability to produce accurate cuts through stainless steel pipes that require precision cutting at narrow angles or for detailed patterns. The recent technological progress of fiber lasers enables faster cutting operations while requiring less maintenance compared to traditional CO2 laser systems, which results in energy-saving and budget-friendly performance. - CNC Plasma Cutting

The Computer Numerical Control (CNC) system enables plasma cutting to produce automatic and precise stainless steel pipe cuts. This method uses programmed specifications to execute projects that require either repetitive work or complex design tasks. The development of advanced plasma cutter materials together with improved nozzle technology has produced better cutting results, which enable the system to cut through thicker pipes while maintaining low heat distortion. - Waterjet Cutting

Waterjet cutting serves as an advanced pipe cutting method that works well for both heat-sensitive pipes and pipes that need to be shaped in non-standard ways. Waterjet machines utilize high-pressure water combined with abrasive materials to create precise cuts that maintain their original shape. Recent research shows that waterjet machines achieve precision tolerances of ±0.003 inches, which makes them suitable for aerospace and automotive industries that require exact measurements. - Rotary Cutting and Orbital Saws

The use of rotary cutting and orbital saws allows for precise cutting operations, which produce smooth cuts without any burrs on specific pipe dimensions and particular uses. Digital control systems in machines enable consistent performance throughout the entire production process which includes high-volume manufacturing. The new machine models introduce torque adjustment options, which help maintain blade condition and avoid pipe distortion during the cutting process. - Hybrid Techniques

The combination of laser cutting with waterjet finishing, together with plasma cutting and mechanical deburring, produces fast results that show detailed outcomes. The implementation of hybrid methods enables industries to complete their processing operations 30 percent faster while sustaining their product quality standards.

The use of advanced cutting methods together with current technologies enables professionals to manage pipe cutting projects because they achieve accurate results that meet high standards of performance. The best practices in the industry require ongoing monitoring of new technological developments, which transform the field of material cutting.

Safety Best Practices

Importance of Protective Gear When Cutting

The need for protective gear arises during pipe cutting operations to safeguard worker safety. The industry safety guidelines state that proper personal protective equipment (PPE) usage can lower injury risk by more than 70%. Workers need to use safety goggles for eye protection against flying debris, heavy-duty gloves for protection against sharp edges, and steel-toed boots for protection against falling objects. Workers need to use dust masks or respirators when they cut pipes, which can release dangerous particles into the atmosphere, including PVC and metal dust.

Recent workplace safety studies show that nearly 40% of cutting operation injuries happen because workers use PPE incorrectly or they fail to use it at all. The professionals need to follow a “safety-first” approach, which requires them to check equipment and confirm that all PPE remains intact while they use tools according to manufacturer specifications. The implementation of these practices creates a secure work environment that prevents workplace accidents while also maintaining operational efficiency.

Ensuring Proper Ventilation and Workspace Safety

The spaces that require cutting operations, chemical contact, and fine particulate distribution need suitable ventilation systems to establish a safe and healthy workspace. The Occupational Safety and Health Administration (OSHA) has issued new guidelines that state that insufficient ventilation systems create major health problems that include respiratory disorders and chronic workplace diseases. Research shows that better ventilation systems can decrease airborne pollutants by 80%, which leads to a major decrease in inhalation danger.

Workplaces must implement exhaust systems, air filters, and natural airflow systems to achieve proper ventilation according to their specific operational requirements. The Local Exhaust Ventilation (LEV) systems need to be installed in woodworking shops and industrial cutting facilities to capture all dust and fumes at their source. The organization should conduct regular air quality assessments to verify safety compliance and discover potential dangers at an early stage.

The combination of effective ventilation methods with proper respirator or face mask PPE usage establishes an all-encompassing safety approach. The implementation of these measures protects worker health while enhancing operational efficiency through decreased health-related worker absenteeism and the creation of a cleaner workspace.

Handling Power Tools Correctly

Power tools require safe operation through correct handling procedures, which workers need to follow during their tasks. The National Institute for Occupational Safety and Health (NIOSH) reports that power tool accidents lead to thousands of workplace injuries every year, which demonstrates the need for effective safety protocols. Operators need to check tools for damage before they start using them because visible defects can make tools unsafe to operate. The equipment operation process requires workers to check all power cords for visible damage and confirm that every machine component functions properly to prevent accidents from occurring.

The 2023 survey found that more than 70% of power tool injuries happen because workers either need proper training or ignore safety rules. The organization needs to establish mandatory safety training programs because this establishes a system to reduce safety risks. Workers need to use suitable attachments when they operate tools because this practice prevents equipment from experiencing operational failures and losing control. Workers need to use safety goggles, ear protection, and gloves when they operate power tools because flying debris and loud noises create common dangers.

Workers need to maintain their workspace by keeping it clean and organized. Workers who operate in cluttered spaces face an increased risk of encountering tripping hazards and activating tools by accident. The combination of these practices with current safety guidelines creates an effective system that reduces power tool operation risks.

Reference Sources

-

- Key Findings: This study focuses on the surface quality achieved through abrasive water jet cutting of stainless steel. It highlights the relationship between cutting speed and surface roughness, providing insights into optimizing the process for better quality.

- Methodology: The research employs the Taguchi method to analyze surface roughness and process capability, using varied cutting speeds and parameters.

-

Assessing the long-term global sustainability of the production and supply of stainless steel

- Key Findings: While primarily focused on sustainability, this paper discusses the production processes of stainless steel, including cutting and shaping methods, in the context of global supply chains.

- Methodology: The study uses historical data and market analysis to assess production trends and their implications.

Frequently Asked Questions (FAQs)

What Are the Safe Methods to Cut Stainless Steel?

The process requires operators to wear protective equipment while using the correct equipment to cut stainless steel. The combination of safety goggles, ear protection, and gloves protects against various potential injury risks that include cuts and burns, and loud noise exposure. Manufacturers design this material for use with angle grinders, chop saws, and hacksaws, which are the appropriate tools to cut it. Proper workspace ventilation and workspace cleanliness are essential to achieve safe operations and accurate cutting results.

What Tools Should I Use for Cutting Stainless Steel?

The selection of ideal tools for stainless steel cutting depends on the specific thickness and cutting requirements of the material. The circular saw becomes an effective cutting tool when it uses a carbide-tipped blade to produce straight or clean cuts. The Dremel tool with cutting discs and the jigsaw with bi-metal blades both provide precise cutting solutions for smaller projects. Plasma cutters require expert operation to deliver optimized performance for extensive cutting operations.

What Methods Can I Use to Prevent Heat and Burr Creation During Stainless Steel Cutting?

The cutting speed needs to match both the tool specifications and the material requirements to achieve optimal results in heat reduction and burr suppression. The operators use a cooling lubricant during cutting to maintain lower temperatures, which prevents steel from discoloring and bending. The high-quality blades maintain their sharpness while reducing friction to create edges with superior smoothness. The cutting process generates edges that need polishing through deburring tools before finishing work.

Can I Use a Laser Cutter for Stainless Steel, and When Is It Appropriate?

Laser cutters can cut stainless steel because they provide high precision for cutting complex designs. Laser cutting is particularly useful for thin sheets of stainless steel. The process needs expert equipment which makes it unfeasible for people who require their work to be done only one time. The laser cutter needs proper calibration to prevent material overheating and equipment damage.

Do People Need Power Tools To Cut Stainless Steel?

People can use manual tools such as hacksaws to cut stainless steel when working with small and thin materials. Power tools provide faster and simpler cutting capabilities compared to this method of cutting. A hacksaw requires high-speed steel (HSS) blades, which need operators to make consistent movements for precise cutting. Power equipment use exists as the ideal solution for hobbyists and DIY enthusiasts who want to work on their projects.

What Is the Best Way to Clean and Maintain Stainless Steel After Cutting?

The process requires workers to remove stainless steel metal shavings and residual materials because these elements create rust and contamination risks. The cleaning process begins with workers using a brush or cloth to remove particles before they apply stainless steel cleaner. The material will suffer corrosion damage from chemical substances which include bleach as a harsh chemical. The regular cleaning and maintenance of the steel will help it maintain its original appearance while protecting it from future damage.