The melting point of stainless steel is something that industries like construction, manufacturing, and even gastronomy should know about. If you are an engineer dealing with high-temperature applications or a metal hobbyist wanting to know its properties, the knowledge of the heat resistance of stainless steel will you directly influence the project’s success. This article presents the melting point of stainless steel on the scientific basis and the conditions that determine it and its importance in practical applications. Eventually, you will know this metal’s great heat resistant properties and have some understanding to apply in your own area of work.

Knowing the Melting Point of Stainless Steel

The melting point of stainless steel is generally within the range of 2,500°F to 2,800°F (1,370°C to 1,540°C) and it is defined mainly by the alloy composition. Knowing this range of melting point I can make a better prediction about the performance of the material when exposed to high heat, thus I can use it with confidence in preserving its strong and untainted nature.

Significance of Melting Point in Industry

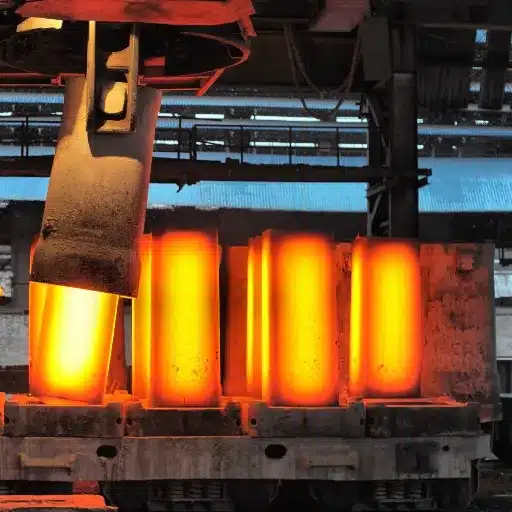

The melting point of stainless steel is one factor that aids its character in the industrial field as it is a determinant to the material for many operating conditions. The precisely alloyed composition of stainless steel sets a melting point between 2,500°F and 2,800°F (1,370°C to 1,540°C). This quality of high melting point is one of its major attributes and thus the material gets its wide range of applications in high-temperature industries like construction, manufacturing, and energy production.

Besides applications, the melting point of stainless steel also dictates the direction of its manufacturing. For example, stainless steel Type 304 which is within the most common grades has a melting point of 2,550°F to 2,651°F (1,399°C to 1,455°C). This melting point serves well for the applications demanding both heat and corrosion resistance. On the contrasting side, Type 310 which is designed for high-temperature applications boast a melting point of up to 2,700°F (1,480°C) thus making it perfect for furnace linings and heat exchangers.

Stainless Steel as an Alloy: A Brief Description

Stainless steel is a combination of iron, and chromium with the latter being its main alloying element in the least quantitative amount of 10.5%. The oxygen in the environment reacts with this chromium and forms a non-corrosive layer, which is one of the contributing factors for the stainless steel’s extraordinary corrosion resistance characteristics. Besides chromium, sometimes nickel, molybdenum, and manganese are added as a substitution for other elements to impart certain qualities such as hardness, workability, and resistance to pitting and crevice corrosion.

Stainless steel can be segregated into the following groups—the austenitic family, the ferritic family, the martensitic family, the duplex family, and the precipitation-hardening family. Among them, austenitic grades, 304 and 316 are the most used because they are highly corrosion resistant and easy to work with. Grade 316, specifically, is more resistant to chlorides (and hence, to corrosive environments) due to the presence of molybdenum; thus, it is an ideal choice for marine and chemical applications.

Composition of Stainless Steel and Its Impact on Melting Point

Chemical Composition of 304 and 316 Stainless Steel

304 Stainless Steel

The three main elements that make up the 304 stainless steel are iron, chromium, and nickel, while minor elements enhance its rust resistance and flexibility. Here is an approximate composition of 304 stainless steel:

Chromium (Cr): 18-20%

Nickel (Ni): 8-10.5%

Carbon (C): Max 0.08%

Manganese (Mn): Max 2%

Silicon (Si): Max 0.75%

Phosphorus (P): Max 0.045%

Sulfur (S): Max 0.03%

316 Stainless Steel

The main difference between 316 and 304 stainless steel is that molybdenum has been added to the latter, which boosts its resistance to chlorides both in terms of corrosion and pitting. The chemical composition of 316 stainless steel is given below:

Chromium (Cr): 16-18%

Nickel (Ni): 10-14%

Molybdenum (Mo): 2-3%

Carbon (C): Max 0.08%

Manganese (Mn): Max 2%

Silicon (Si): Max 0.75%

Phosphorus (P): Max 0.045%

Sulfur (S): Max 0.03%

Role of Nickel and Chromium in Melting Temperature

The melting temperature of stainless steel alloys is heavily influenced by the presence of the two elements nickel (Ni) and chromium (Cr). They are responsible for the stability and thermal behavior of the material in the end, which then determines its use in high-temperature applications.

Out of these two elements, nickel is the one that most significantly improves the ductility and toughness of stainless steel at high temperature. Moreover, it preserves the face-centered cubic (FCC) structure, which is a stable structure at high temperatures. In contrast, chromium is the one that ensures oxidation resistance and heat endurance to a greater extent. It does so by forming a protective oxide layer over the steel that makes it suitable for extreme heat or corrosive conditions.

Melting Point Comparison: Stainless Steel vs. Other Metals

Melting Points of Common Metals

Stainless Steel: The melting point of stainless steel differs according to the grade and the composition. Specifically, 304 stainless steel has a melting range of about 1,400°C to 1,450°C (2,552°F to 2,642°F), while grade 316, which has more molybdenum, also has a melting range of around 1,375°C to 1,400°C (2,507°F to 2,552°F).

Aluminum: This metal, which is lightweight, has a melting point of about 660°C (1,220°F), which is much lower than that of other metals. Its low melting point is one of the reasons of its usage in the production of lightweight and heat-conductive materials, such as automotive and packaging industries.

Copper: One of the main characteristics of copper is its melting point of around 1,085°C (1,985°F) which is the reason for it being the most widely used material in electrical wiring and industrial machinery. Excellent thermal and electrical conductivity are some of the properties of this metal.

Iron: The melting point of pure iron is about 1,538°C (2,800°F). Its excellent structural characteristics have led to its use in construction, automobile manufacture, and machinery.

Gold: At a temperature of about 1,064°C (1,947°F), gold melts. Its non-reactive and visually appealing properties make it a necessity in the production of jewelry and electronic parts.

Silver: Silver’s melting point is around 961.8°C (1,763°F), and the metal is frequently utilized in electrical fields due to its superior conductivity.

Titanium: The melting point of titanium is 1,668°C (3,034°F); therefore, it is appropriate for use in the aerospace and medical fields. Known for its exceptional strength-to-weight ratio and resistance to extreme conditions, titanium is also used in medical and aerospace applications.

Zinc: Zinc melts at a low temperature of 419.5°C (787°F), which is its main characteristic for being used in galvanization, a process to prevent steel from rusting through coating.

How Stainless Steel Compares with Carbon Steel

Corrosion Resistance

Stainless steel is the best alternative for corrosion resistance options in conditions where there is moisture or chemical exposure. This is due to the formation of a chromium oxide layer that protects it from rust and corrosion. Hence, it is a good choice for applications in the manufacturing of kitchen equipment, medical instruments, and for building in severe conditions. Carbon steel, on the other hand, is very strong in dry conditions, but rapid corrosion occurs in wet conditions unless some coatings are applied.

Strength and Durability

Due to the carbon-rich composition, carbon steel usually has a higher tensile strength, which makes it the most preferred material for the structural part, production of tools, and automotive applications. Stainless steel is also strong, but in general, it is characterized by ductility and the ability to withstand harsh weather and corrosive environments without degradation.

Melting Points

The melting point of different stainless steel alloys ranges from 1,375 degrees to 1,530 degrees Celsius (2,507 to 2,786 degrees Fahrenheit). On the other hand, carbon steel has an approximate melting point of 1,426 to 1,475 degrees Celsius (2,599 to 2,687 degrees Fahrenheit). At first glance, the differences between these melting points might be perceived as small; however, they could be the cause of a significant difference in the performance of the materials in heat applications.

Applications and Cost

Carbon steel is a budget-friendly option because it is easier to manufacture and more available. The metal is used in projects related to construction, pipelines, and heavy-duty tools on a large scale. Stainless steel, which is more costly, is a favorite for the applications where the three attributes—longevity, corrosion resistance, and aesthetic appeal are—are indispensable.

Factors That Affect Melting Point of Stainless Steel

Stainless steel melting point is affected primarily by its composition, as a rule, chromium, nickel and other alloying elements, which set the heat resistance and stability of the steel. The exact grade of stainless steel is however, also very important since different grades are made to withstand different temperatures.

How Alloys Influence the Melting Point

Chromium (Cr): Stainless steel’s melting point and its resistance to corrosion are chromium’s main effects; the element assures the latter by forming a layer of oxide that protects it. At the same time, the melting point of chromium with a temperature of 3,465°F (1,907°C) is lower than that of steel so the melting point of steel is slightly lowered.

Nickel (Ni): Nickel is the main element that controls the austenitic stainless steels; it reduces the brittleness and, thereby, increases ductility and toughness. The melting point of nickel is 2,651°F (1,455°C) and that is why it is added to steel; the melting temperature of stainless steel decreases with nickel’s presence.

Molybdenum (Mo): Molybdenum is the element that has become synonymous with temperature resistance and strength; its melting point is 4,753°F (2,623°C). The use of molybdenum in stainless steel grades, particularly 316 and 317, results in an increase in melting range.

Iron (Fe): The main element in stainless steel is iron which has a melting point of 2,800°F (1,538°C). Iron is the basic element that is then combined with the other elements which are added in smaller amounts.

Carbon (C): Carbon is one of the most important alloying elements that, even though it is present in small amounts, it increases the strength of steel through carbide formation. Carbon slightly influences the melting point, but it is more of a determinant of the mechanical properties.

Temperature Range for Stainless Steel Applications

Austenitic Stainless Steel (e.g., 304, 316):

Among all the grades, austenitic stainless steels have the highest corrosion resistance and are also the most expensive to maintain. Their operation temperature is extremely broad (-325°F to 1,700°F or -196°C to 925°C), thus making them applicable in both cryogenic and high-temperature applications like the heat exchangers and furnace parts.

Ferritic Stainless Steel (e.g., 430, 446):

Ferritic stainless steels are good in terms of corrosion resistance; they can stand up to moderate acidic and alkaline treatment. Their typical temperature range is -20°C to 815°C (from 0 to 1,500 degrees Fahrenheit); they are used in car manufacturing and home appliance industries.

Martensitic Stainless Steel (e.g., 410, 420):

Hard and wear-resistant martensitic steels can be used in the toughest applications. Their operating temperature is usually 0°C to 650°C (32°F to 1,200°F). These steels are suitable for making turbine blades, kitchen utensils, and even surgical instruments.

Duplex Stainless Steel (e.g., 2205, 2507):

Duplex steels are the best of both worlds; their strength and corrosion resistance are both austenitic quality. Their operating temperature limits are -50°C to 316°C (-58°F to 600°F) which is especially true for chemical processing and offshore applications.

Precipitation-Hardening Stainless Steel (e.g., 17-4PH):

At high temperatures, precipitation-hardening stainless steels retain their high strength and corrosion resistance. They perform well in a wide range of -73°C to 593°C (-100°F to 1,100°F) and thus are often used in aerospace and high-end equipment.

Real-World Applications and Scenarios

Use of 316 Stainless Steel in Marine Environments

316 stainless steel is a well-known and widely used material for marine environments because of its superb resistance to corrosion, particularly against chlorides and saline solutions. This specific stainless steel grade has molybdenum added to it in the ratio of about 2-3%, which greatly increases its resistance to pitting and crevice corrosion, two of the main issues in saltwater environments. Nickel is another added component (10-14%) that also helps to make the stainless steel more resistant and versatile in very corrosive situations.

One different thing about 316 stainless steel is that it can survive the ocean for a long time with very little change in the condition of the metal. Studies support the claim that 316 stainless steel has been so passive that it has actually become the benchmark for the other stainless steels regarding how long they will keep their integrity in a salt-water environment. For instance, it can be subjected to salt spray for over 1,000 hours according to ASTM B117 standards without losing its strength, which is one of its main features.

Heat Treatment Processes for Stainless Steel Products

- Annealing

The first step is to heat-up and then later cool-off the metal by applying a little bit of a chemical reaction on it. The purpose of the whole procedure is to make the metal less hard and soft, to open up its pores for easier machining, and to make it less prone to rust. The drawing starts with the austenitic stainless steel (e.g., 304 or 316) which is hardened through welding or cold work and has its ductility restored through annealing.

- Hardening and Tempering

Among the most widely used martensitic stainless steels, for example, Grade 410, and 420, the heat hardening and tempering processes are carried through with the utmost care. They raise the temperature of the steel to around 1,800°F to 2,000°F (982°C to 1,093°C), then they quench it in water very quickly to make it hard and tough at the same time. The typical tempering operation is done at a temperature of 300°F to 700°F (150°C to 371°C) to bring brittle nature down while having strength. The process is crucial for surgical instruments, knives, and turbine blades, among others.

- Stress Relieving

Stress relieving is a process in which the stainless steel is heated to a temperature range of 750°F to 1,050°F (400°C to 565°C) to reduce residual stresses that arise from its parts and the different stages of the manufacturing process such as welding, machining, or casting. It is functioning particularly well for stainless steel components that require high precision, as it ensures that the component will remain the same size and shape and thus minimizes the likelihood that it will become defective.

- Solution Treatment

A solution treatment of the austenitic and duplex stainless steels is to improve their corrosion resistance. The material is heated to a temperature in the range of 1,850°F to 2,100°F (1,010°C to 1,150°C) when it is topmost to be kept for the time needed for complete dissolution of carbides. The cooling is not slow; in fact, it is through water quenching that the precipitation of chromium carbides is prevented, which otherwise might lead to intergranular corrosion.

Reference Sources

-

Marlin Steel Blog

Title: What is the Melting Point of Stainless Steel?

URL: https://www.marlinwire.com/blog/what-is-the-melting-point-of-stainless-steel

This source provides a comprehensive overview of the melting points of various stainless steel grades, making it a reliable reference for technical and industrial applications. -

MRS Steel Blog

Title: Stainless Steel Melting Point: A Comprehensive Guide

URL: https://mrssteel.com.vn/blogs/steel-blog/stainless-steel-melting-point

This guide explains the melting temperature range of stainless steel based on its composition, offering valuable insights for both professionals and enthusiasts. -

Industrial Metal Supply Blog

Title: Melting Points for Metals | Metal Melting Temperatures

URL: https://www.industrialmetalsupply.com/blog/melting-point-of-metals

This source lists melting points for various metals, including stainless steel, and is a trusted resource for industrial and manufacturing contexts.

Frequently Asked Questions (FAQs)

What is the melting point of stainless steel?

Depending on the alloy, the melting point of stainless steel can be between 1400 and 1450 °C for 304 stainless steel, which is an austenitic type. This temperature marks the melting point or, in other words, the point at which the solid turns into a liquid and so melting and casting can be done.

How can one figure out the melting point of stainless steel?

The melting point of stainless steel is determined by its chemical composition especially the contents of nickel and chromium. The melting points of stainless steel grades such as 304 and 316 can be determined by the standard testing methods or can be referred to from the material specifications.

What is the melting point of 316 stainless steel?

The melting point of 316 stainless steel is about 1375-1400 °C. This type of stainless steel, which has the austenitic structure, is recognized for its ability to withstand corrosion and is therefore utilized in chemical and marine industries in parts which are not easily accessible, as well as ordinary steel containers mainly due to its higher melting point.

How the melting point of stainless steel is influenced by the chromium content?

The melting point of stainless steel is largely determined by the chromium content. In general, the more chromium is present, the higher the melting point. Such stainless steels as grade 316 containing 16% chromium are particularly insulated for high-temperature applications.

What Are the Different Melting Points of Stainless Steel Types?

Differentiation in melting points exists among different types of stainless steels. Type 304 stainless steel has a fixed melting point of about 1400-1450 °C, whereas 316 stainless steel has a slightly lower melting range. Awareness of these differences is vital when it comes to picking the right stainless steel for the intended applications.