Steel rebar stands as the great building block of construction, giving the strength and durability needed to keep buildings, bridges, and infrastructure standing tall. But with numerous sizes, grades, and specifications on offer, it becomes quite a puzzling matter to choose the rebar suitable for your project.

This comprehensive guide seeks to unravel the world of steel rebar, explaining its sizing system, grade distinctions, and how these factors affect structural integrity. Whether you’re a seasoned contractor or new to the construction scene, this knowledge will help you make sound decisions to ensure your projects have a solid foundation.

Understanding Rebar: The Foundation of Modern Construction

What Is Rebar?

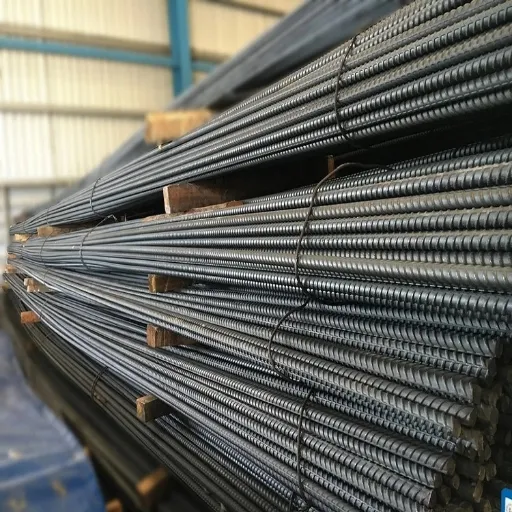

Rebar, short for reinforcing bar, is a steel bar or wire mesh mainly used as a tensioning device in reinforced concrete and masonry structures. Since concrete is strong in compression but weak in tension, the primary role of rebar is to strengthen and hold the concrete in tension.

Key Rebar Statistics:

- 8-10 million metric tons of rebar are produced annually in the U.S. alone

- 60% of all worldwide construction projects incorporate rebar (AISI)

- Well-reinforced concrete structures can last 50-100 years with proper materials and methods

- Global rebar market projected to exceed $130 billion by 2030

Most rebar is made from carbon steel with a textured surface featuring ridges or deformations to create a better bond with concrete. This bond prevents the materials from slipping, allowing them to work together effectively.

The Importance of Rebar in Construction

Rebar serves as a crucial component in modern construction by:

- Providing tensile strength to concrete structures

- Creating composite materials capable of resisting greater loads

- Mitigating structural failure risks under various forces

- Extending structure lifespan in harsh environments

Complete Rebar Size Guide

Standard Steel Rebar Sizes

Steel rebar sizes are standardized to ensure uniformity and reliability across construction projects. Sizes are measured by diameter and expressed in numbers corresponding to the nominal diameter.

| Rebar Size | Diameter (inches) | Diameter (mm) | Tensile Strength | Primary Applications |

|---|---|---|---|---|

| #3 | 0.375″ | 10mm | Light-duty | Driveways, patios, sidewalks |

| #4 | 0.5″ | 13mm | Moderate | Residential walls, beams, slabs |

| #5 | 0.625″ | 16mm | ~27,000 lbs | Foundations, retaining walls, bridges |

| #6 | 0.75″ | 19mm | ~40,000 lbs | Parking garages, multi-story buildings |

| #8 | 1.0″ | 25mm | ~78,000 lbs | Bridges, large retaining walls, high-rises |

| #10 | 1.25″ | 32mm | ~120,000 lbs | Skyscrapers, industrial facilities, marine structures |

Detailed Rebar Applications by Size

#3 Rebar (10mm or 3/8 inch)

- Ideal for light construction projects

- Easy to bend for intricate work

- Perfect for reinforcing lightly loaded structures

#4 Rebar (13mm or 0.5 inch)

- Most versatile size for residential construction

- Provides excellent balance of strength and flexibility

- Common in floor slabs and smaller building foundations

#5 Rebar (16mm or 0.625 inch)

- Widely used in residential and commercial projects

- Medium to heavy load resistance capabilities

- Excellent for foundation work requiring durability

#6 Rebar (19mm or 0.75 inch)

- Designed for larger capacity projects

- Handles heavy vertical and horizontal stresses

- Essential for multi-story building construction

#8 Rebar (25mm or 1 inch)

- Primary choice for heavy infrastructure work

- Exceptional stress resistance capabilities

- Critical for earthquake-resistant construction

#10 Rebar (32mm or 1.25 inches)

- Reserved for massive construction projects

- Highest tensile strength available

- Essential for extreme load conditions

Types of Rebar Materials

1. Carbon Steel Rebar

Most Common Choice: Carbon steel rebar (black bars) is the most widely used reinforcement due to its cost-effectiveness and reliability.

Advantages:

- Most affordable option

- Readily available and standardized

- Suitable for inland, non-coastal construction

Limitations:

- Susceptible to corrosion in high-chloride environments

- May show corrosion signs in 10-15 years in coastal areas

- Requires adequate concrete cover for protection

2. Epoxy-Coated Rebar

Performance Benefits: Epoxy-coated rebar can reduce long-term maintenance costs by 25-40% compared to carbon steel reinforcement.

Key Features:

- Enhanced corrosion protection through fusion-bonded epoxy coating

- Excellent performance in marine and high-humidity environments

- Can extend structure service life by 50+ years

- Cost premium of 20-40% over carbon steel

Important Considerations:

- Coating integrity is critical for performance

- Requires careful handling to prevent damage

- Ideal for coastal highways, parking decks, and marine structures

3. Stainless Steel Rebar

Premium Solution: Stainless steel rebar offers the ultimate corrosion resistance and can last 75-100 years in harsh environments.

Superior Performance:

- Maximum corrosion resistance in extreme environments

- Maintains mechanical properties at elevated temperatures

- Ideal for fire-resistant construction

- Reduces total life-cycle costs despite higher initial investment

Common Applications:

- Critical infrastructure (bridges, tunnels)

- Seawalls and marine structures

- Wastewater treatment plants

- High-temperature industrial facilities

Rebar Grades in the US Market

Standard Rebar Grades

| Grade | Minimum Yield Strength (psi) | Primary Applications | Market Usage |

|---|---|---|---|

| Grade 40 | 40,000 | Light construction, residential projects | Standard applications |

| Grade 60 | 60,000 | Commercial construction, general use | Most common grade |

| Grade 75 | 75,000 | High-stress applications, seismic zones | Specialized projects |

| Grade 80 | 80,000 | Heavy infrastructure, earthquake-resistant | Advanced applications |

| Grade 100 | 100,000 | Skyscrapers, space-constrained projects | Premium construction |

Advantages of Higher-Grade Rebars

- Structural Efficiency: Higher strength allows for smaller cross-sections

- Seismic Performance: Enhanced ductility for earthquake resistance

- Sustainability: Often made from recycled materials with lower carbon emissions

- Long-term Value: Extended lifespan reduces maintenance requirements

Recent Advancements in Rebar Technology

Innovative Rebar Materials

Fiber Reinforced Polymer (FRP) Rebar

- Non-corrosive protection for harsh chemical environments

- Made from glass, carbon, or basalt fibers

- Can reduce maintenance requirements by up to 50%

- Extremely lightweight yet strong

Sustainable Rebar Solutions

- 100% recycled scrap steel manufacturing

- Reduced greenhouse gas emissions during production

- Supports eco-friendly infrastructure development

- Meets increasing global demand for sustainable construction

Smart Rebar Technology

Future of Construction: Smart rebar can extend bridge lifespans by up to 30% through proactive maintenance and reduce long-term maintenance costs by 20%.

Key Features:

- Integrated sensors for real-time structural monitoring

- Detection of stress, temperature changes, and corrosion

- Predictive maintenance alerts

- IoT connectivity for smart city applications

Critical Applications:

- Bridges and highway infrastructure

- High-rise buildings in seismic zones

- Critical infrastructure with failure consequences

- Smart city development projects

Reference Sources

- Camblin Steel: This source discusses common rebar grades in the U.S., such as Grade 40, Grade 60, and Grade 75, and explains their yield strength in ksi (kilo pounds per square inch). Visit Camblin Steel

- BigRentz Blog: This article covers various types of rebar, including Carbon Steel Rebar, Stainless Steel Rebar, Galvanized Rebar, and more, along with their applications. Visit BigRentz Blog

- Endura Steel: This source provides insights into rebar grades, such as 40, 60, and 75, and explains their yield strength in thousands of pounds per square inch (psi). Visit Endura Steel

Frequently Asked Questions

What are the main types of rebar available?

The main types include carbon steel rebar, stainless steel rebar, epoxy-coated rebar, and galvanized rebar. Each type is suited for different construction requirements depending on corrosion resistance needs and environmental conditions.

How do I choose the right rebar size for my project?

Rebar size selection depends on several factors:

- Load requirements and structural demands

- Concrete thickness and coverage

- Type of construction project

- Local building codes and standards

Why is understanding rebar grades important?

Rebar grades determine the tensile strength and yield strength of reinforcing bars. Common grades (40, 60, and 75) are each suited to specific construction needs and load-bearing requirements, ensuring optimal performance and safety.

What standards govern rebar in construction?

Rebar standards are established by organizations such as ASTM International. These standards specify chemical composition, mechanical properties, and dimensions to ensure safe use and optimal performance in construction applications.

How do rebar technology advancements affect construction?

Modern rebar innovations like fiberglass rebar and stainless steel varieties offer enhanced corrosion resistance and improved performance in demanding environments. These advancements help contractors meet modern construction requirements while improving long-term durability and sustainability.

Conclusion

Selecting the appropriate rebar size, grade, and material type is crucial for ensuring structural integrity, longevity, and cost-effectiveness in construction projects. By understanding the various options available and their specific applications, contractors and engineers can make informed decisions that result in safer, more durable structures.

As technology continues to advance, innovations in rebar materials and smart monitoring systems are paving the way for more resilient and sustainable infrastructure development.