One of the most basic materials that is useful in numerous aspects today the most and this is steel. It is, and almost all things are made out of it, such as a crane or even a microwave. Still, have you ever wondered how and why steel is hard and flexible, or why stainless steel is so dense, yet its composition does not change? There is a basic rule behind such a transformation, which happens to be the melting point of steel. Knowing more details about the steel melting point and the stainless steel melting point is very appealing for many reasons related to their application’s purpose. Of such facts, both steel and stainless steel, shall be unfolded, more than Anything else, the different equilibrium structures which the effect of temperature brings shall be discussed, since this influences the field of applications in the use of such material. Whether one is a designer, a process engineer, or simply a theorist, this book will be a refresher or a supplementary reading since it provides such and its applications.

Introduction to Steel and Its Melting Points

Overview of Steel as a Material

Nowadays, without a doubt, steel is found almost in every construction. Its strength permits it to bear strengthening and constructing different things. It is an alloy containing iron as the major component, and the other components are in very small quantities, with carbon may be within 2.1% by weight and 0.0%. characteristic of steel. Some other minor alloys, such as manganese, chromium, nickel, or molybdenum, may also be added in order to obtain certain properties, for instance, anticorrosion, elasticity, hardness, etc.

One thing that can be said about steel is that its melting point is quite phenomenal; it ranges from roughly 1370 degrees Celsius (also known as 2500°F) to 1540 degrees Celsius or 2800 degrees Fahrenheit in lay man’s terms, again, it varies with the alloy used. Carbon influences the melting point of steel, as one can get from the fact that stainless steel with high carbon content is cheaper than that with chromium or nickel added, which has a higher melting point and thus can enhance the performance of the material at higher temperatures.

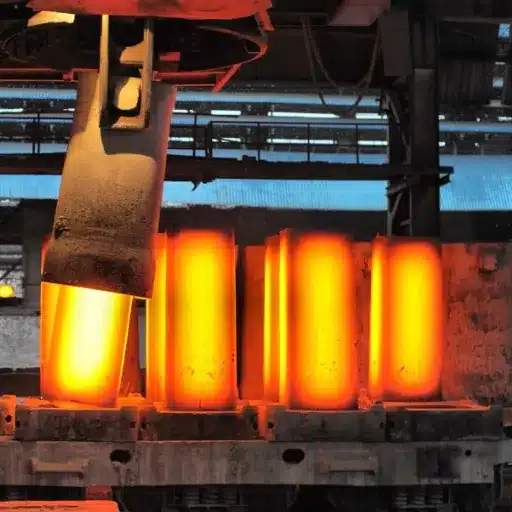

Steel manufacturing is still considered a key sector in many countries. The total amount of manufactured steel has reached its peak in 2022. As cited in the report of the World Steel Association, 1.9 billion tons of steel were manufactured across the globe in the said year. Construction, for instance, as a vast proportion, combines the use of metal structures in buildings with the fabrication of the frames. Dictionary, spare parts of cars, ships, oil, heaters, and houses where construction work is done, use steel moderately. These are taken into account even though steel is regarded as essential. This is not simply a question of the steel melting point. There are other reasons than plasticity. In recent times, the steel sector has improved the variety of processes, such as electric arc furnace (EAF) and many more. The pollution-Reducing Revolution started from companies with electric-driven arc furnaces (EAF) that all use scrap, which promoted the efficiency of steel production.

Manufacturers currently produce many types of steel grades, which can be adapted for various needs, the principal ones usually being carbon steel, alloy steel, stainless steel, and tool steel. As an example, stainless steel is widely used for its anti-corrosion capacity; thus, it is applicable in very rough environments such as hospitals and the food industry, where cleaning should be very easy as well as in the kitchen. On the other hand, there is an HSLA that is ultralight yet very strong, which is applied in such situations.

Understanding the steel melting point in the case of man-made high-performance alloys, how they are manufactured and utilized for priority is an acknowledgment of the need of steel in so many buildings and technologies that stand currently within the society.

The Importance of Melting Points in Industry

Melting points play a crucial role in so many production activities, especially since they determine when a particular substance becomes unstable in heat and hence is useful in more ways than one. For instance, there is the steel mining industry and steel metallurgy that specify such operations as casting, forging, and even machining that are dependent on the steel melting point and the carbon content, usually ranging between 2500⁰ F to 2800⁰ F, i.e., 1370⁰ C – 1540⁰ C. The reusability of materials, given their relatively high melting point in some cases, is also brought about in harsh working conditions, this being the case in most instances of the aerospace, automobile, or power industry.

Furthermore, light metals like aluminum that have the steel melting point of approximately 1220°F / 660°C are favored because they are apt for easier transformations and applications. It is a requirement for the manufacturers to understand the melting points of the consequential materials that they intend to purchase, be it for strength or even malleability.

Similarly, engineering enhanced materials such as tungsten come with complex processes of their own, being the highest temperature material with a melting point soaring at 3410°C (6170°F) that aids in heavy or even conventional heat durable equipements. Within a fraction of a second from these statistics, users understood that this would permit the use of hierarchicalmodelsand predict melting points more accurately, especially considering the material that should be prepared or even manufactured, and in some cases, help cut costs.

Knowing the melting temperature of a material allows the development of different designs of parts and helps protect processes such as welding, smelting, semiconductor fabrication, etc, to which the data on the point of melting is very much relevant for manufacturing. This also provides strategic opportunities to the military-industrial sector, electronics, and all other engineering activities. For instance, if steel is melted and processed, the steel’s melting point plays a vital role in processes such as welding.

Contextualizing the Melting Point of Steel

In essence, the melting point of steel falls within the range of 2500°F to 2800°F, which is approximately 1370°C and 1538°C. This is necessitated by the fact that being a composite of woods and metals, the behavior of such a complex material as steel can alter, and so can its melting point. An example would be an iron alloy, the main component of steel, which is composed of iron and steel and other elements in traces, like manganese, nickel, chromium, etc., whose incorporation in the Interstitial structure of steels may rather tend to contrary interstitial or substitutional alloying of steels irrespective of the steel melting point. We can see such a situation in the case of the addition of Chromium in stainless steel or other steel alloys that have less steel melting point at the same temperature and pressure range, kneading around that particular steel.

Due to the modern advances in the science of steel as a raw material and the technology accessible, the steel melting point is now measurable accurately. Chemistry, along with outside factors that include pressure and the level of impurities, are considerations in dealing with the new steel melting point calculus. This has positive implications such as construction, commercial air lifting, and generation of electricity, amongst others, since the produced specific heat capacities are ridiculously safe during use and efficient.

For example, it is noted that there is no difference in the melting point of performance steels used in high-performance automobiles and ordinary steel structures. Some alloys and works make these steels stronger, but not the other way round. They could be analyzed in contexts of temperature regimens, which are prevalent in turbines, heaters, or pipes that operate at high temperatures.

The knowledge of steel melting point has provided an opportunity to solve problems in many industrial areas, such as those that are able to operate even in extreme conditions, since the level of technological development is sufficient for that.

Understanding the Melting Point of Steel

What is the Melting Point of Steel?

Determining the true melting point of steel is quite a challenge, as the steel melting point can range from 2,500°F (1,370°C) to around 2,800°F (1,540°C), depending on several factors. This is owing to the fact that, being an alloy, which means a mixture of several metals, the components of steel often differ and thus bring about differences in the melting point of such a steel. These are carbon, manganese, chromium, and even nickel. Specifically, in high-carbon content, the steel in such cases will come into a liquid state faster than those low-carbon compositions as carbon content acts to lower the rigidity of the alloy.

There are cases where even the elite grade of stainless steels might have most of the chromium and nickel components in them replaced by other alloying agents that basically improve the utilitarian value or resistance against those temperatures already explained. Similarly, for metals that undergo high-stress operations like tool steels or step-tack alloys, the melting point of such materials will most definitely be influenced by their chemical analysis.

Construction and manufacturing companies that deal with those activities appreciate the steel melting properties the most, for example, welding, forging, or casting. This is due to the fact that all of the above require a certain temperature to be realized. Engineers and manufacturers can offer modification of processes for certain activities, with the aim of being able to sustain every desired temperature research. The available data on steel melting point and new technological advancements in this area is continuously facilitating the exploitation and improvement of material properties.

Factors Influencing the Melting Point of Steel

The temperature at which steel turns into liquid (a melting point of around 1.370 – 1.540º C or roughly 2,500 – 2,800 o F) is determined by the composition of that steel and the degree of alloying obtained. This point of pure carbon steel (steel melting point) could be assumed to be around 2,500-2,8000F (maybe 137°C and above), but this assumption will be put to the question in different groups of steels and not in all alloys.

In regard to alloys, for instance, steel alloys to be precise, it has been previously noted that carbon, for assisting austenite, e.g., forming carbides, and strengthening, may promote the suppression of the M point, among commercial steels. When nickel, chromium or manganese are present, though they offer the protection of the steel from corrosion, make it stronger, such elements may also affect f= its characteristics, for example, its melting temperature.

Thus, research and design are interested not only in the prediction of the thermal response of the steel but also in methods for the manipulation of the depression of this steel, given certain industrial sectors such as aerospace and automotive or high temperature applications which demand the best performance, especially advanced ones.

This organized and stored data helps considerably upgrade the manufacturing processes of high-quality products to new levels.

Temperature: When Does Steel Melt?

Typically, at most times the steel melting point ranges between and within 2500 and 2800 degrees Fahrenheit. This is typically equivalent to above 1370 and 1540 degrees centigrade. This very much depends on what the basic components are. Carbon steel is one of the most prominent types of steel and melts at approximately 2550 degrees F (1400 degrees C). Another category of steel, that is stainless steel, comes out of the steels with more than just the common iron and carbon but also other elements like chromium, nickel, amongst others, for extra corrosion resistance and strength falls within the range of 2,550˚F – 2,970˚F (1,400˚C – 1,700˚C).

There is a reason why such domains as processing, construction, and development, among others, exist and, in most cases, require the melting of steel. The production of steel involves the manipulation of temperature mainly in the production stage, where achieving a certain mechanical or structural stability is the primary goal. Carbon content, as well as the presence of any alloying elements, has a significant influence on the melting and solidification behavior of the metal.

A rheumatoid saline environment, on the other hand, is complicated as it has many fragments suspended in solvent, mainly water, and enhances the efficiency of these conditions. This helps engineers and manufacturers to create innovative steel alloys for applications like civil construction, metal coatings, which are lightweight yet strong and durable enough in their service life for any corrosion, polymerization, or challenge, such as air pressure or any other amount of tension, fatigue, performance temperature or conditions imposed by the use of.

Different Types of Steel and Their Melting Points

Common Types of Steel and Their Melting Point Ranges

As a matter of fact, there are various forms of steel that exist in the market with distinguishing properties and steel melting points as well, because different types of steel employ different compositions. Below are some types of steel with their equivalent melting point.

- Carbon Steel

Excluding all other types of steel, carbon steel has the biggest market share as its melting point is usually in the range of 2, 500°F – 2, 800°F (1, 370°C – 1, 540°C). This range, however, is common to every classification because a higher proportion of carbon will tend to lower the melting point. This type of steel takes a prominent role in infrastructure, the automotive industries, and also piping. - Stainless Steel

Typically, stainless steel incorporates chromium as the main constituent and is notable for its high resistance. The melting point of this steel varied from 2,500 to 2,750°F, which is equal to 1,370 and 1,510°C, in simple words. There is a minor change in these temperatures for 304 and 316 alloy steel from the above ranges because the alloy metals of those 2 steels contain additional constituents, both nickel and molybdenum, among others, for better application in cutlery, surgical, and naval equipment. - Tool Steel

The following steel is specially designed with good toughness and hardness, mainly for metal machining applications, and thus tools steel, most commonly called tool steel, has a steel melting point of about 2,500 to 2,700°F or 1,370 to 1,480°C. Tool grade steels have some constituents such as Tungsten, Cobalt, or Vanadium in order to lower or raise their melting point. These materials are commonly used when making dies or for cutting tools. - Alloy Steel

Manganese, nickel and chromium are examples of additives that are commonly used in alloy steel to offset wear and improve toughness and strength. This steel melts somewhere between 2300°F and 2750°F or 1260°C and 1510°C. In view of its properties, this composition is used in the manufacture of automobiles, construction equipment, and other such industries. - Cast-Iron (relating to the topic)

The latter’s (cast iron’s) melting temperature is lower, that is, nearly 2100⁰F (1150⁰C) to 2200⁰F (1200⁰C), and because of its excessive carbon content, it is often a steel, albeit a carbon one. It, for example, is frequently employed in the manufacture of pipes, auto parts, and cookware.

In fact, there is a combination of factors that influence the choice of one rather than another type of steel over another in different industries and production techniques. These limits – minimum and maximum – are subject to slight fluctuations, as a function of the type and quality of material produced and the degree of processing it has undergone.

Stainless Steel: Melting Point and Characteristics

The substance stainless steel counts as one of the alloy steels or simply alloy steel materials, which perform tasks such as actively participating or/and/or effectively and efficiently hardening. Components such as chromium, most fundamentally and every other element, as the service dictates wears out most of the elements of the alloy in question. The most common use of elements, poly-blended steel has a steel melting point within the range of 2,500 oF to 2,800 oF (1,370 and 1,540 oC). It would be of importance to state that in examples, Dewalt austenitic stainless steels such as the 304 NX, and 316 Position examples Dumbbell weight-free grade, the range of melting temperatures is 2550- 2650°F (1400- 1450 °C). This, however, clarifies the specific reason why and how the maximum temperature of the material is altered, due to a concentration of particular elements of the alloy, for instance, Chromium and Nickel.

Owing to its other properties besides its ability to withstand heat, stainless steel is quite strong and is unlikely to weather even when temperatures continue to increase beyond normal levels. This broadens the applicability of the enclosed Kari, for instance, in medical devices, chemical processing, and construction. As for the rest, it is also good at reminding why it almost always makes most of the toothpicks, which are not meant to be washed often, and they work well in such cases as well. There exist different formulations that call for constant checking of it (composition), as there are steels, some of which even include the duplex and martensitic stainless steels, whose steel melting point appears to be different, yet within the same bounds. These parameters allow for more efficient work.

High-Strength and Alloyed Steels: Variations in Melting Points

Regarding the different compositions of alloying materials used to enhance the quality of steel, there is a huge variance in alloy and high-strength steel melting points. For example, the melting point of carbon steels usually ranges from 2500 °F to around 2800 °F i.e, 1370 °C to 1540 °C. Studies on alloys containing chromium, nickel, molybdenum, or vanadium confirm that the melting range of such steels varies.

On the other hand, steels with content of such elements, known as stainless steels, are in the range of temperature above normal steel melting point because of the communicating presence of chromium and nickel elements. In the case of advanced stainless steels containing nitrogen in correspondingly higher amounts, especially the mechanically tough and multi-functional alloys termed duplex stainless steels which are again in the same range, may vary a bit as a result of increased levels of nitrogen in them.

To enhance performance, tungsten and cobalt that constitute HSS (high-speed steel) allow the tools to remain useful even when they are subjected to harsh conditions. The steel melting point depends on the alloy’s structure, with most compositions having a melting point of 730–1500°C and beyond.

Inclusion of banded elements like titanium and niobium, which are very popular in the field of aerospace and power superalloys, permits continuous applications of the components in better ambient temperatures. This makes it possible to employ some of these superalloys very close to their melting points, which are mostly higher than 2,700 degrees Fahrenheit (1,480 degrees Celsius).

Such levels of temperature and all other related phenomena are necessary for decision-making, including the selection of materials for applications. Or more precisely, and most dearly, while use without engaging every possible type of steel may prove wasteful, should others not out-metal those for which no expense is spared to manage each sorting composition class.

Real-World Applications of Steel Melting Points

Manufacturing: Impact of Melting Points on Production

Steel is an important manufacturing material because it has a high melting point, which is important when considering machinability for the first time in manufacturing. Supposing a low alloy carbon steel can be made to melt between 2500°F and 2800°F (that is, close to 1370°C and 1540°C). The alloy concentration dictates such a temperature range. This temperature allows one to work on the steel using casting, forging, and or welding processes. But stainless steel melting and other similar high-performance steels will be a bit higher, around 2550°F – 2790°F (1400°C – 1530°C), and therefore these steels can be used at such temperatures in turbines or heat exchanger systems.

Handling of steel, concerned with the physical changes like melting and forging, needs to be adjusted depending on the heat exposure levels for efficient production processes. Methods such as induction apparatus and proper temperature measuring programs have enhanced accuracy, thereby resulting in reduced consumption of energy and defects arising from overheating and incomplete melting. Additionally, modern studies suggest that the addition of elements like chromium in steel can increase the associated steel melting point, and make improper more possible with respect to more complex sectors such as space technology and military.

Construction: Importance of Steel Melting Points in Structural Integrity

Concerning the steel melting point, it ought to be mentioned that the general stiffness of the material is governed by such factors as heat and strength requirements, some of which are characteristic of very specific usage outlooks. As we have seen before, steel has a melting temperature in the range of 2 500°F (or 1 370°C) up to a maximum of 2 800°F (or 1 540°C) based on the properties of the material. In buildings, bridges, and even skyscrapers, high steel melting points mean that structures can be made of steel since it will not break down even if it is heated to any of its use temperatures.

Expanding from simple instances of adding other elements into steel such as molybdenum and vanadium, this approach of steel tempering has been the subject of similarly intensive research recently. Example includes the low-alloy high-strength steels, which are quite cheap but also very durable against changes in the weather as well as high temperatures. This study also explains why in some modern buildings, some alloyed steels can be used in fireplace designs and related structures because their geometry can sustain the elevated temperature without reaching the steel melting point, which is 1000 °C.

In addition to this, in regions where there are numerous cycles of earthquakes, such a characteristic of steel turns out to be very useful also because of the capacity of this material to resist rather high temperatures before failure occurs. Research evidence states that 70 percent more loads are carried by these towers than by those constructed with concrete only. This statement demonstrated the ultimate efficiency of the current era absence of any construction operation, without putting in mind the importance strength booths, safety and efficiency.

Metallurgy: The Role of Melting Points in Material Science

The knowledge of a material’s melting point forms the science of material engineering. This is particularly predominant everywhere as it is used in the development of almost every structure and equipment, for instance steel melting point varies in the range of 1370–1510°C depending on its composition. Therefore, this material is best used for all work that has high temperatures for instance, construction work, manufacturing, and transport. On another note, very large projects in the construction industry make use of light materials like aluminum, which is important. However, as a result of the level of heat, an aluminum structure can only withstand a tolerable magnitude; it can only be used for small scales.

The final results from experiments and findings of various studies on science, the behavior of technology, and the like, have recently indicated that materials with a high melting point also tend to be good against high thermal deformation. A good example is tungsten, whose steel melting point is 3422°C and which finds extensive use in aerospace and electricity industries because of such properties. Once this knowledge is understood, then engineers or scientists can look for the materials sought with a considerable degree of accuracy and performance highly appropriate for construction because of wear, among other forms of force.

Advanced computer simulations help to calculate the thermal performance of alloys and composites, providing a perception of how an architecture is able to withstand certain temperatures. It also explains the reason why many parts, for instance, electronic gadgets, are built out of high-temperature-tolerant material because of the urge to reduce the surface area and increase the energy within the gadgets.

For example, melting parts of composition W, E, and I – otherwise said to be steel – or D, L, E, and T are able to be constructed in engineering applications. This is possible because the steel melting point range falls in between 1480⁰C and 1515⁰C.

Reference Sources

-

Al Alloy Melting Behavior and Interfacial Reactions with Steel – An academic paper discussing steel and aluminum melting points, hosted on PubMed Central.

-

Thermophysical Properties of Stainless Steels – A detailed study on the thermophysical properties of stainless steels, available on the U.S. Department of Energy’s OSTI website.

-

Efficiency in steel melting: Ladle development – Research on steel casting and the importance of temperature control above the melting point.

Frequently Asked Questions (FAQs)

What is the melting point of steel?

The steel melting point can still vary based on the steel type and its carbon content in particular. Because of its very high density of carbon, it is much lower compared to vodka, while alloying with several other elements does not change the melting point of steel.

How does the steel melting point vary? In which case is the steel melting point higher?

Some of the stainless steels as AISI 304/316, usually melt at temperatures around 2,550°F -2,790°F (1,400°C –1,530°C), which is the same temperature interval as several steels have. The difference is, nonetheless, the combination of such alloying elements as chromium, nickel and etcetera that all-to-effect inhibit structural alterations, namely concerning corrosion and thermal expansion.

Is steel suitable for applications in high-temperature conditions?

Yes, steel is an excellent material for use in hot conditions because of its high strength and high heat resistance. In addition, alloy steel became especially important as it is reinforced through the addition of metals such as molybdenum, tungsten, chromium, or others that raise the steel melting point to higher values. Its applications in industries such as aerospace and electricity generation have been particularly useful.

Can concepts of simulation be applied to predict the behaviour of steel and stainless steel melting?

The answer is yes, especially due to the fact that there is advanced technology that makes it possible to simulate the steel melting point within various melts of steel and stainless steel, while taking into consideration the chemical components of the alloys and the process of alloying. This helps understand the current material selections better and allows for the improvement of the materials under reasonable conditions.

Why is it necessary to know the steel melting point in industries?

A clear understanding of the structural steel melting point is necessary for a wide variety of applications, ranging from welding and, most importantly, casting. It is because it enables the manufacturerto regulate the temperature within specific limits, thereby preserving the integrity of the material while aiming to produce that particular product.

How does the addition of alloys affect the melting point of steel?

It is for this and several other reasons that steel often contains a percentage of chromium, molybdenum or other elements when used for the manufacture of chemicals, electronics and optics components; these alter the steel’s melting point, improving the efficiency of the HB.