With its excellent features, 304 Edelstahl stainless steel is one of today’s most common and flexible factory instruments. Its high oxidation resistance and great looks make it the go-to candidate in construction, stainless steel utensils, and removals. This blog will highlight the essential characteristics differentiating 304 stainless steel from its competition, its numerous uses, and what makes the demand skyrocket. After this chapter, readers will be enlightened about why 304 metallurgy is a pillar block in modern design and manufacturing.

What Makes 304 Stainless Steel a Top Choice?

The unmatchable resistance to corrosion is equally advantageous for internal and external uses and allows 304 stainless steel to be exposed to moisture and oxidation without an issue. In addition to this, it contributes to the region’s long-term durability and mechanical needs. Ideal for food and medical use, 304 stainless steel does not contaminate surfaces with chemicals, making it non-reactive and safe. Unlike other expensive materials, 304 stainless steel is visually attractive, easy to maintain, and cost-efficient. All these factors make it one of the most versatile and dependable materials.

Understanding the Composition of 304 Edelstahl

The primary constituent of 304 stainless steel, also known as 304 Edelstahl, is iron, while the key alloying elements are chromium and nickel. Typically, it contains 18 to 20% chromium, which gives it a remarkable corrosion resistance, and 8 to 10.5% nickel, increasing its toughness and ductility. The steel also contains trace amounts of manganese, silicon, and carbon, contributing to its strength, durability, and workability. The composition of these elements makes 304 stainless steel instrumental in manufacturing, construction, and medical use because of its strong and non-corrosive nature.

How Does Carbon Content Affect Performance?

The effect of carbon on the performance of 304 stainless steel is marked, considering its strength, hardness, and corrosion resistance. Higher carbon content increases the material’s tensile strength and hardness, resulting in better wear resistance. However, too much carbon can lower corrosion resistance due to carbide precipitation at grain boundaries, common during welding or elevated temperatures.

Standard 304 stainless steel is made with a carbon content of ≤0.08%, not to exceed the bearing limit. In low-carbon variants such as 304L stainless steel, where carbon is capped at ≤0.03%, general uses acquire enhanced corrosion resistance in marine environments or chemical processing. In contrast to standard 304, lower carbon content helps minimize carbide formation, enabling better durability and resistance to corrosion in critical applications.

Comparing 304 and 316 Stainless Steel

304 and 316 stainless steel are commonly used due to their strength, versatility, and corrosion resistance. Though they have similar features and functions, their composition and performance set them apart, making each suited for different applications. Their differences can be found in their alloying elements:

304 Stainless Steel:

- Composition: 18% Chrome and 8% Nickel l (“18/8 stainless”)

- Characteristics: Good corrosion resistance in food, moderate chemical environments, and mild indoor usage.

- Applications: Used as kitchen equipment, utensils, architectural trim, and storage tanks.

- Limitations: Cannot withstand pitting and crevice corrosion in chlorine and saline environments.

316 Stainless Steel:

- Composition: 16-18% Chromium, 10-14% Nickel, and 2-3% Molybdenum.

- Characteristics: Molybdenum increases chloride, salt water, and harsh chemical resistance, providing durability in extreme environments.

- Applications: Used in marine environments, pharmaceuticals, petrochemical equipment, and surgical instruments.

- Limitations: More expensive than 304 due to enhanced properties and alloyed elements.

Technical Parameters Comparison

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition | 18% Cr, 8% Ni | 16-18% Cr, 10-14% Ni, 2-3% Mo |

| Yield Strength (MPa) | 215 | 290 |

| Tensile Strength (MPa) | 505 | 515 |

| Corrosion Resistance | Good | Superior (especially in saline environments) |

| Cost | Lower | Higher |

If you pick between the two, 304 stainless steel is usually the best option for non-corrosive and low-saline environments due to its cost and performance. Meanwhile, 316 stainless steel has much better applicability for aggressive chemicals, salt water, or even chloride-rich environments due to its molybdenum content, which gives it resistance to pitting and crevice corrosion.

How to Shop with Confidence for 304 Edelstahl?

304 Edelstahl has a variety of applications, so consider your needs and conditions of use before shopping. Make sure you have the right certifications and documentation for your project. Consumer reviews and comparisons can offer better insight into reputable suppliers with clear documentation and reliable customer service. Considering these additional details, you can easily buy the right 304 Edelstahl.

Finding Top Sellers and Highly Rated Products

Your research for reputable sellers dealing with stainless steel 304 Edelstahl requirements for commercial and residential needs shouldn’t start from scratch. Explore the usual places listed on Amazon, McMaster-Carr, and Metals Depot, as they frequently rank among the best markets for stainless steel materials.

- Amazon: Users rate this market as the best among all the others. They have analyzed the grade-selling parts of stainless steel and listed grade 304 as one of the best sellers on Amazon. Their customer feedback allows browsing customers to select their desired grade based on detailed customer feedback, which helps them to judge their desired selection accurately. Their price range is highly competitive, and they tend to deliver efficiently.

- McMaster-Carr: This trusted industrial supply website sells an extensive range of 304 Edelstahl products. Their specifications are usually on point, and a customer service representative will contact you to discuss your requirements personally.

- Metals Depot: Excellent for metal materials, the depot is highly recommended for grade 304 stainless steel as they have it in high-quality sheets, rods, tubes, etc. They never compromise on their quality standards and are also known for efficient shipping services, which always boosts praise.

Don’t forget that these markets offer excellent reviews and descriptions of the products, along with the price, which enables you to zero in on the top sellers with the most value for your specific project.

Reading Seller Feedback for Informed Decisions

While analyzing seller feedback, I look for product quality, responsiveness, and reliability in delivery. For instance, in the reviews for sellers of 304 stainless steel, it is enlightening to notice that customers came back reiterating the importance of grade consistency, accuracy of dimensions, and surface finish. A case in point is McMaster-Carr, whose precision of stainless steel sheets receives accolades, while Online Metals is appreciated for reasonable prices and lower quantities. Metals Depot boasts prompt shipping and well-defined technical details like thickness tolerances and material certification. Important technical details that should be considered are compliance with ASTM A240, thickness between 0.018″ and 0.250″, and 2B or brushed surface finish for specific applications. By analyzing the reviews, I ensure that they do not miss these factors and receive purchases that meet the requirements of the projects.

Understanding Item Specifics for Best Fit

In my search for the most appropriate stainless steel sheets, I narrowed down the options by checking crucial details such as the material grade, which is usually 304 or 316 depending on how corrosive it is, the required finish type, which could be 2B or #4 brushed, and the specific thickness for my application. From the sites I consulted, I double-checked that the material had the proper grade markings and dimensions, so there would not be any standards compliance issues or material waste. I focus on getting certifications alongside proper shipping to ensure quality alongside being provided for timely delivery and guarantee these will be met by suppliers who focus on these features.

What Are the Corrosion Resistance Properties of 304 Stainless Steel?

Stainless steel grade 304 is widely used and known because it has good to excellent corrosion resistance quality, making it applicable in many industries. The high chromium content (about 18-20%) ensures the formation of the protective oxide layer with resistant features against oxidation and rust forming on its surface. Also, nickel (8-10.5%) increases the grade’s property of withstanding acidic and corrosive environments. This grade performs well under mild and moderately aggressive atmospheric conditions, including moisture and some chemicals. On the other hand, this grade may not perform well when exposed for long periods under very saline or acidic settings; for this case, grade 316 would be more suitable since it has higher corrosion resistance.

Why Is 304 Stainless Steel Corrosion Resistant?

304 stainless steel is corrosion-resistant due to its elevated chromium contents, which passively form an oxide layer that protects the surface from rusting and oxidizing. Its exposure to nickel further allows it to withstand varying environments, such as moisture and some chemicals. Combining these elements allows sustained durability in milder to moderately agitated atmospheres. However, more extreme conditions, such as highly saline or acidic environments, may require a different grade of stainless steel, such as 316.

The Role of Chromium and Nickel in Corrosion Prevention

Chromium and nickel are essential in preventing corrosion by improving the contents of stainless steel. Oxidation and rusting can be countered through a passive oxide layer formed by chromium over the steel’s surface. In contrast, nickel improves the integrity and stability of the steel in harsh environmental conditions such as moisture and some chemicals. These elements aim to ensure more durability and enhanced stainless steel performance. However, extreme conditions require other grades.

Applications in Acidic and High-Temperature Environments

Resistant to corrosion and able to withstand high temperatures, stainless steel is ideally suited for use in acidic and elevated-temperature environments. For example, 316 and 316L grades with higher molybdenum concentrations resist pitting and crevice corrosion in highly acidic conditions. In comparison, 310 and 321 grades are structurally stable and oxidatively resistant at high temperatures, with 310 grades reaching 1,100°F (593°C). A few technical details to keep in mind are the maximum service temperature of the steel and its resistance to specific chemical concentrations like sulfuric acid or nitric acid. Sticking to these parameters will result in optimized performance whilst matching the operating environment with the stainless steel grade, which helps ensure longevity.

How Does Mechanical Properties Affect Usage?

The influence of the mechanical properties of the stainless steel in question can be much more pronounced in terms of its full performance capabilities and its applicability in a given use. The capacity to endure mechanical stresses during the operation of stainless steel is impacted by attributes such as tensile strength, yield strength, hardness, and ductility. For example, good ductility and high tensile strength are beneficial when heavy loads need to be sustained and when bending and forming the material are required. Applying the selected mechanical properties assures the reliable and safe performance of the material under the anticipated conditions.

Exploring the Weld Capabilities of 304 Edelstahl

According to my research, 304 stainless steel is appreciated and used in many industrial and business settings because of its good weldability. Most conventional processes, like TIG or MIG welding and even resistance welding, can be used without needing post-weld annealing so long as 304L low-carbon variants are utilized to deal with the carbide precipitation. This means that 304 Stainless Steel can be readily welded, its corrosive resistance and mechanical properties are not affected, and we can use it in different environments.

The High-Temperature Performance of 304 Stainless Steel

From my search, 304 stainless steels have impressive performance at higher temperatures because of their structural stability and oxidation resistance. They can endure scales at 870 degrees Celsius (1598 degrees Fahrenheit) to 925 degrees Celsius (1697 degrees Fahrenheit) for continuous service and intermittent service. Nonetheless, prolonged exposure to higher ends of these temperatures will deteriorate mechanical properties. These indeed great upper temperatures make them helpful in constructing heat exchangers and furnace parts, but operating conditions must be controlled to reduce stress and corrosion.

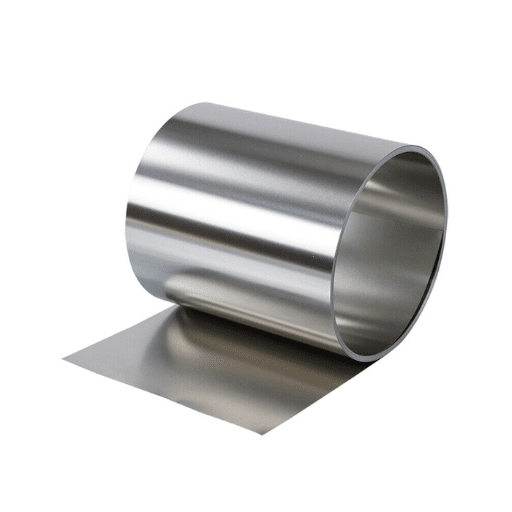

Why Choose Hot Rolled vs. Cold Rolled 304 Edelstahl?

Your unique use case determines whether you opt for hot-rolled or cold-rolled 304 stainless steel, as both have merit. Hot-rolled is the best option for low-value 304 stainless steel projects without strict tolerances or requiring a smooth surface finish. It is prevalent across structural pieces, heavy-duty machinery, and manufacturing processes characterized by intense or abrasive conditions.

In contrast, cold-rolled 304 stainless steel provides higher strength value, enhanced surface finish, and accurate dimensions. Because of its superior aesthetic finish and smaller tolerances, it is ideal for automotive components, appliances, and architectural applications. The last word always depends on how much one is willing to invest in the project without compromising performance and aesthetics.

Benefits of Hot Rolled 304 Stainless Steel

I think the primary characteristics of hot-rolled 304 stainless steel are cost and strength. Being processed at high temperatures, it’s cheaper to produce and works excellent on projects where specific dimensions do not need to be met. Additionally, it delivers reliably in structural applications with good strength and corrosion resistance properties, making it suitable for construction, heavy machinery, and other situations where low surface finish is prioritized.

When to Opt for Cold Rolled Products

For my project’s requirements that need a high level of accuracy, a cold-rolled product is my preferred choice due to its smooth finish and precise surface tolerances. Since these materials are manufactured at room temperature, their dimension and surface quality are significantly improved compared to the hot-rolled alternatives. Cold rolled steed is ideal for automotive parts manufacturing, home appliances, or any high construction grade parts where material appearance and smoothness are paramount.

Technical Parameters:

- Dimensional Tolerances: Typically tighter than ±0.001 inches (varies with the product and supplier).

- Surface Finish: A matte or polished finish is ideal for visible applications, and surfaces with a smooth finish do not require further processing.

- Yield Strength: Due to the cold rolling work hardening, it can sometimes exceed 40,000 psi, depending on the grade; this value varies.

- Thickness Range: Generally from 0.1 inch – 0.25 inch, but may differ according to product specification.

Cold-rolled products ensure superior aesthetics, increased strength, and precise specifications, making them suitable for projects requiring the utmost precision in engineered parts.

References

- What are the (Many) Uses of 304 Stainless Steel? – Discusses its versatility, corrosion resistance, and strength.

- The Benefits of Choosing 304 Stainless Steel – Highlights its structural integrity and resistance to corrosion.

- 304 vs 316 Stainless Steel | Reliance Blog – Explains why 304 is the most commonly used stainless steel.

Frequently Asked Questions (FAQ)

Q: What is 304 Edelstahl Stainless Steel?

A: 304 Edelstahl Stainless Steel, also known as 304 stainless steel, is a widely used alloy in various industries due to its excellent corrosion resistance and high tensile strength. It is particularly popular for its durability and ease of fabrication.

Q: How does 304 Edelstahl Stainless Steel differ from 304L?

A: The carbon content is the main difference between 304 and 304L Edelstahl Stainless Steel. 304L has a lower carbon content, which enhances its weldability and reduces the risk of carbide precipitation during welding, making it ideal for thicker sections like those found in a coil.

Q: What is the chemical composition of 304 Edelstahl Stainless Steel?

A: The chemical composition of 304 Edelstahl Stainless Steel primarily includes chromium (18-20%) and nickel (8-10.5%), along with small amounts of carbon, manganese, silicon, and nitrogen. This composition contributes to its corrosion resistance and mechanical properties.

Q: Can 304 Edelstahl Stainless Steel be magnetic?

A: 304 Edelstahl Stainless Steel is generally non-magnetic in its annealed state. However, it can become slightly magnetic when worked or cold-formed, such as when shaped into a coil.

Q: What are typical applications where 304 Edelstahl Stainless Steel is used?

A: 304 Edelstahl Stainless Steel is used in various applications, including kitchen sinks, tableware, exhaust systems, and mixer taps. Its resistance to oxidation and corrosion makes it suitable for these environments.

Q: How does 304 Edelstahl Stainless Steel compare to carbon steel?

A: Compared to carbon steel, 304 Edelstahl Stainless Steel offers superior corrosion resistance and durability. While carbon steel is more substantial, it lacks the corrosion resistance that makes stainless steel a preferred choice for kitchen and marine environments.

Q: Are there different finishes available for 304 Edelstahl Stainless Steel?

A: Yes, 304 Edelstahl Stainless Steel can be finished in various ways, including a sleek mirror or a matte black appearance, to suit aesthetic and functional requirements.

Q: How can I ensure I buy genuine 304 Edelstahl Stainless Steel products?

A: To ensure the authenticity of 304 Edelstahl Stainless Steel products, shop top sellers and highly reputable suppliers. Check for certifications and verify the UNS number, which should match 304 or 304L for standard products.

Q: Is there a size limitation for 304 Edelstahl Stainless Steel products?

A: No, products can be made in various sizes, including large dimensions like 100mm or more, depending on the application and fabrication capabilities.