Everything depends on choosing the right materials for manufacturing fine products. When it comes to the better industry dislike-everyday metals, DX56D steel, a combination of durability, flexibility, and corrosion resistance, has become an option for every industry. This blog thoroughly delves into the classifications of steel, focusing on DX56D steel to discover its special attributes, uses, and advantages in engineering and modern manufacturing. Whether you are a professional or a beginner, this guide will give you essential information about why material matters and what makes DX56D challenging compared to other classes. So, come into the discussion about the fundamental physical properties and revolutionary uses of one of today’s most demanding steel types.

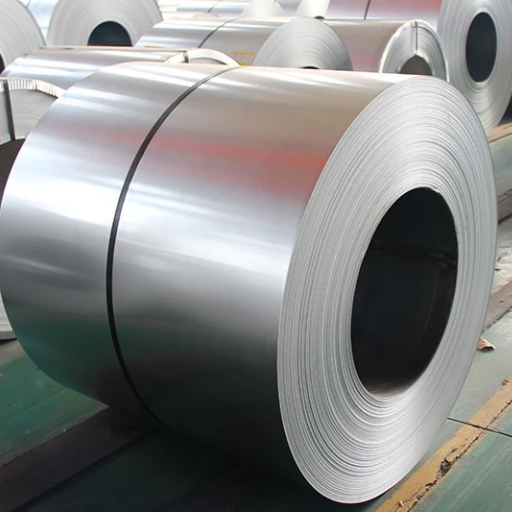

General Product Description

DX56D high-grade steel, with continuous hot dipping galvanization, is generally employed where good formability and corrosion resistance are primary requirements. It is very soft and ductile, making it ideal for applications requiring deep drawing and intricate shapes. It finds usage in the automotive, construction, and appliance industries in manufacturing end products that require durability and precision. The zinc coating on this steel offers them additional protection against elements, building for it a niche as a reliable engineering and manufacturing option.

Details and Data on DX56D Steel

DX56D belongs to the hot-dip galvanized steel class, particularly meant for drawing and deep drawing. It follows the EN 10346 standard, which controls its quality and ensures uniform performance across diverse manufacturing industries. Known for adequate ductility, DX56D may have a minimum yield strength of about 140 MPa and an ultimate tensile strength of about 270-370 MPa, enough to form even the most complicated shapes without fracture.

The zinc coating applied onto DX56D gives it corrosion resistance, further protecting it from rusting for many years in wet or outdoor environments. This corrosion-resistant zinc layer can be used in various thicknesses, usually from Z100 to Z600 (100-600 g/m²), offering the right degree of protection for different types of applications. Furthermore, the surface finish can be selected between minimally spangled or zero-spangled options, providing considerable aesthetic possibilities for the end product.

The automotive industry is a primary field for applying DX56D, wherein exact parts are formed, including body panels, whose strength and flexibility are critical. It also enjoys applications in other industries like construction and household items, where good formability and a clean, uniform surface are paramount. Additionally, DX56D can be readily combined with advanced coatings and paint systems, increasing its versatility for high-performance and decorative usage.

Recent manufacturing technological advances allowed DX56D steel to be even further optimized from an energy point of view during processing and environmental sustainability. These properties and strict adherence to relevant industry standards have made DX56D an indispensable material for designing and manufacturing teams inclined to precision and reliability.

Applications of DX56D Steel

One multidisciplinary material has applications ranging from fine to industrial arts due to its excellent formability, strength, and sustainability. DX56D steel exhibits exemplary face in the following five applications:

- Automobile

DX56D steel is used broadly to make automotive panels, including doors, hoods, and roofs. Its good ductility and strength properties allow it to be used for manufacturing lightweight vehicle components. These components conserve fuel and hence emit fewer emissions.

- Building Materials

This steel is used in roofing and cladding systems that demand long-term performance under harsh environmental conditions. It is resistant to corrosion and can be used in residential, commercial, and industrial buildings.

- The Appliance Industry and Uses

DX56D steel is manufactured for a wide range of appliances, including washing machines, refrigerators, and ovens. It provides a smooth surface finish and resists wear, resulting in reliable consumer goods.

- Packaging

DX56D steel makes firm cans and containers to maintain product quality throughout long storage periods. Hence, this technology has been widely applied in food and beverage packaging.

- Electrical Enclosures

DX56D steel is favored for making strong yet versatile electrical panels and enclosures. The panels can withstand heavy stress without losing shape, keeping sensitive electrical equipment safe from physical damage and environmental threats.

Using this steel in such fields testifies to its reliability and efficient performance in industries where precision, durability, and efficiency are equally important.

Benefits of Using DX56D Steel

| Key Point | Details |

|---|---|

| Corrosion Resistance | Exceptional due to zinc coating |

| Formability | Excellent for complex shapes |

| Strength | High strength for structural stability |

| Weldability | Easy to join components |

| Durability | Long-lasting in harsh environments |

| Applications | Automotive, construction, appliances |

| Coating Options | Multiple for specific needs |

| Deep Drawing | Ideal for intricate designs |

| Standard Compliance | Meets EN 10346 standards |

| Customizability | Adaptable to various requirements |

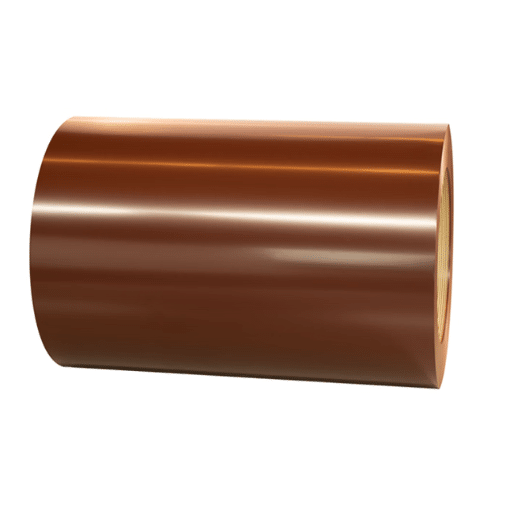

Coating of DX56D Steel

DX56D is generally coated with zinc employing a hot-dip galvanization process. This coating offers corrosion resistance, extending the steel’s life and durability in adverse working conditions. The galvanization layer acts as an extra protective layer on the surface and sets it up well for further processing activities like painting or forming. These are the basic characteristics by which the coated DX56D steel finds heavy use in applications where reliability and longer service life are the prime requirements.

Types of Coatings Available

The DX56D steel is typically coated with different finishing materials depending on the requirements of an application, providing better performance and protection. The commonly available coating types are as follows:

- Zinc Coating (Hot-Dip Galvanizing)

One of the popular coating methods is hot-dip galvanizing due to the superior corrosion protection it provides. Recent industrial reports indicate that hot-dip galvanizing deposits a thick, uniform layer of zinc on the steel surface, providing protection even under highly corrosive conditions. The application thickness varies as required, with typical thicknesses ranging from 20 to 40 microns. The result is a steel that, if correctly galvanized, can far exceed 50 years in a heavily rural environment and 20 to 30 years under urban or coastal conditions.

- Zinc-Aluminum Coating (Galvalume)

Galvalume, made from alloys of zinc (about 55%), aluminum (43.4%), and silicon (1.6%), gives better resistance to rusting and oxidation than any regular zinc coating. This coating mainly offers longevity in roofing and other outdoor structures, with extremely harsh atmospheric elements. Reportedly, it retains corrosion resistance at least four times greater than that of ordinary galvanization.

- Organic Coatings

Organic coatings applied on top of galvanization provide the substrate with aesthetically pleasing and functional properties. These coatings may include pre-painted surfaces or polyester-based coatings that provide additional UV protection and offer many color options for design flexibility. Organic-coated steel is predominantly used in household appliances, automotive exteriors, and construction panels.

- Electrogalvanized Coating

In contrast with hot dip galvanizing, which deposits zinc layers from 50 to 200 microns thick, electro-galvanized coating employs an electrochemical procedure to produce a much thinner, precisely controlled layer of zinc. This coating is frequently selected for interior or mild exposure environments, especially for automotive body panels and electrical equipment. The tightly controlled thickness, usually about 5–12 microns, guarantees a smooth surface ready for painting or forming.

- Zinc-Magnesium Coating

Zinc-magnesium alloy coatings are a recent invention and provide the best aluminium resistance to abrasion and corrosion. Containing magnesium at around 1 to 2% and aluminium at around 1 to 3% in addition to zinc, this advanced coating solution has shown in saline conditions that it can upgrade corrosion performance by 27% against pure zinc coatings.

Each type of coating offers unique benefits, making DX56D steel suitable for various applications requiring harsh treatments. Decision-making on the coating must thus take into consideration exposure conditions, mechanical requirements, and aesthetic demands to ensure maximum lifetime service.

Importance of Coating in Steel Performance

Coatings do great things for steel performance, and as I see it, any steel is doomed to weathering unless the coating guarantees durability and reliability in demanding atmospheres. The coatings are the protective layer that guards against corrosive elements such as moisture, salt, and chemicals, thereby increasing the life of the material while preserving mechanical value and beauty. Depending on the specifications required, I would consider the correct type of coating for the steel, which might need to withstand harsh environmental conditions or require a quality surface finish for specific applications.

Galvanizing Process and Benefits

| Key Point | Details |

|---|---|

| Process Step 1 | Surface cleaning to remove contaminants |

| Process Step 2 | Chemical cleaning for oxide removal |

| Process Step 3 | Flux application to prevent oxidation |

| Process Step 4 | Immersion in molten zinc bath |

| Corrosion Resistance | Zinc coating protects against rust |

| Durability | Long-lasting, over 50 years in rural areas |

| Cost-Effectiveness | Lower cost compared to other coatings |

| Complete Protection | Covers all surfaces, even sharp corners |

| Low Maintenance | Minimal upkeep required over time |

| Tough Coating | Resists mechanical damage and wear |

| Fast Application | Quick process, independent of weather |

| Hygienic | Easy to clean and maintain |

Tolerances in DX56D Steel

Coordinate tolerances are designed to meet industry standards so that the steel can serve high-performance applications. These tolerances are generally in thickness, width, and flatness, strictly monitored during production, and have stringent quality requirements. For thickness, tolerances may range, subject to the manufacturing procedure and special requisites of specific customers, but should more or less conform to the EN 10143 standards. Proper control of these tolerances ensures uniformity throughout fabrication and best performance in the considered application.

Understanding Steel Tolerances

Steel grit tolerance is essential in ensuring dimensional accuracy and performance. These factors also contribute to manufacturing efficiency by deterring material wastage and increasing the reliability of the end product.

How Tolerances Affect Steel Performance

| Key Point | Details |

|---|---|

| Definition of Tolerances | Allowable variations in steel dimensions. |

| Types of Tolerances | Plus/minus, geometric, dimensional. |

| Impact on Fit | Ensures parts fit properly in assemblies. |

| Impact on Functionality | Prevents malfunctions and increases durability. |

| Cutting Methods | Laser, waterjet, flame, plasma cutting affect tolerances. |

| Material Thickness | Thicker materials require larger tolerances. |

| Machine Accuracy | Precision of equipment impacts tolerances. |

| Industry Standards | ASTM and BS EN standards ensure consistency. |

| Cost Implications | Poor tolerances increase rework and material waste. |

| Communication Importance | Clear specs prevent production delays and defects. |

Standards for Tolerances in Metal Coated Steels

Tolerances for coated metal steels ensure uniformity, precision, and the ability to function in fine applications in old-line industries. According to relatively recent Google statistics, ASTM (the American Society for Testing and Materials), EN (European Standards), or ISO (International Organization for Standardization) standards set acceptable dimensional ranges for coated steels globally. These dimensions refer to thickness, width, flatness, and coating weight, all of which contemplate this material’s potential intents and purposes.

For instance, ASTM A653 covers hot-dip galvanized steel with permitted variations in thickness allowed, depending on the coating grade and the thickness of the base metal. A ubiquitous figure when talking about coating weight tolerance is that for G90, a minimum zinc coating coverage of 0.90 oz/ft² of surface area. On the other hand, the European EN 10346 specifies the tolerances for continuous hot-dip coated steel regarding flatness (≤ 10mm deviation per 1,000mm length for tight applications).

Following the tolerances for these materials almost entirely wipes out any chance of waste at the material level and greatly aids in manufacturability, which recent studies have deemed to have economic advantages of about 15-20% reduction in errors during assembly and production costs in general. Such figures imply that monitoring tolerances to achieve these aims is essential, on both performance and financial grounds.

Cold Forming DX56D Steel

Specifically, DX56D steel is applied in cold forming processes due to its exceptional ductility and malleability. While cold forming, it is essential to ensure the steel is free from impurities and sufficiently lubricated, lest it suffer surface damage. It is reasonably acceptable to employ standard forming techniques such as bending, drawing, or rolling, provided the tooling is in excellent condition to avoid show-up defects on these products. Because of the chemical nature and microstructure, this material will perform consistently during even the most demanding shaping process, thereby justifying being chosen in the automotive and appliance manufacturing industries.

Techniques for Cold Forming

Cold forming encompasses various techniques that exploit the plasticity of materials to achieve shape without heat. Five key types of techniques involved in the process of cold forming are outlined below, along with pertinent information and data concerning each one of them:

- Cold Rolling

- Description: Metal is passed through rollers to decrease thickness and improve the surface finish.

- Applications: Steel sheets, automotive panels, and structural components constitute some major applications of the process.

- Advantages: The process strengthens the material by strain hardening and yields close dimensional tolerances.

- Cold Drawing

- Description: It is a process in which a wire or bar is pulled through a die to reduce its diameter.

- Applications: Mostly used in wires, tubes, and precision shaft manufacturing.

- Advantages: Components of high-strength with smooth and polished surfaces are produced.

- Cold Extrusion

- Description: High pressure forces a long object, such as a rod or tube, through a die.

- Applications: Producing fasteners, gear blanks, and hollow pipes.

- Advantages: Better material utilization and a more complex cross-section can be formed.

- Cold Heading

- Description: This process is forming using compressive forces applied to the heads of bolts, screws, and rivets.

- Applications: Mainly used to produce fasteners and connectors.

- Advantages: High rates of production and minimum material wastage.

- Cold Bending

- Description: Metal sheets or tubes in the required shape are bent using presses or rollers.

- Applications: Used in manufacturing frames, brackets, and piping.

- Advantages: Very little deterioration of the material’s grain structure and consistent bend radius.

Besides, these cold forming techniques are interdependent, thus ensuring efficient cold forming operations with good outputs for various industrial applications. The method selected depends upon the material property, product design, and required precision.

Advantages of Cold Forming DX56D Steel

| Key Point | Details |

|---|---|

| Superior Formability | Easily shaped without structural compromise |

| Corrosion Resistance | Zinc coating protects against environmental damage |

| High Strength | Ensures durability and load-bearing capacity |

| Dimensional Accuracy | Produces consistent, precise parts |

| Material Savings | Eliminates scrap, reducing waste and costs |

| Improved Surface Finish | Reduces need for secondary operations |

| Increased Tensile Strength | Enhanced through work hardening |

| Eco-Friendly Process | Minimal waste and reduced environmental impact |

Considerations When Cold Forming

Cold-forming steels (DX56D) requires attention to several critical details to maximize production results and ensure good-quality products. This steel is well known for its excellent formability and surface finish and is used in the automotive construction and appliance industries. The following detailed factors should be considered in the cold forming process:

- Material Properties

DX56D steel exhibits excellent mechanical properties, such as ductility and tensile strength. However, it is crucial to understand the exact value of the yield strength and elongation, which usually lie in the range of 270-350 MPa and 24-30%, respectively, to ensure fairness to material failure during operation. Ensure thorough material testing before production to confirm consistency.

- Tool Durability and Design

Employ precision-designed tools to maintain dimensional accuracy. A material such as DX56D, which is quite malleable, would undesirably wear down tools that are not correctly designed. High-strength alloys and coatings, such as titanium nitride, can be used to prolong the tool life and enhance the process’s efficiency.

- Bend Radius Requirements

Adhering to minimum bend radius recommendations prevents material cracking or tearing. For DX56D, the recommended bend radius typically equals the material thickness or is slightly greater to not jeopardize its structural integrity. In other words, a sheet thickness of 2 mm should have a minimum radius of 2 to 3 mm.

- Lubrication and Surface Protection

Proper lubrication minimizes friction and wear between the die and the material; quality lubricants benefit the operations and protect the steel surface finish. On the other hand, protective coatings can guard against corrosion during and after the forming process.

- Process Temperature Control

Parameters need to be controlled to maintain consistency in temperature during cold forming because temperature fluctuations could cause unnecessary stresses in the metal. Such variations could bring about hardness fluctuations and brittleness, which in turn could affect the quality of the end product.

- Equipment Calibration and Maintenance

Forming equipment must be regularly calibrated and maintained to achieve precision. Misaligned or worn-out machinery can cause production defects, such as irregular thickness or surface defects.

- Residual Stress Treatment

Cold forming may introduce residual stresses that can affect the material’s performance. Stress relief processes, such as annealing, can be performed after forming to ensure steel stability and reliability over the long term.

- Compliance with Industry Standards

To satisfy customer and regulatory requirements, the cold forming must be done according to the relevant industry standards and certifications, such as EN 10152 and ISO 9001. Tests and inspection documentation will guarantee the traceability and quality assurance of the product.

Addressing these factors will allow manufacturers to exploit the excellent characteristics of DX56D steel to consistently achieve precision and efficient production while minimizing material wastage by enhancing its overall performance.

References

- Steel solutions for seismic retrofit and upgrade of existing constructions – Discusses material properties of DX56D steel.

- A Guide to the Development and Use of Standard Compliant Data Format for Engineering Materials Test Data – Includes details on DX56D steel grade and its standards.

- Calculating the Mechanical Properties of DX56 Steel by the Spherical Indentation Method – Focuses on the mechanical properties of DX56 steel.

Frequently Asked Questions (FAQ)

What is the recommended thickness for grades DX56D steel according to EN 10346?

The recommended thickness for grades DX56D steel per EN 10346 standards typically ranges from 0.4 mm to 3.0 mm. This range ensures optimal performance and structural integrity in various applications while adhering to the guidelines provided for coated products.

How does zinc coating affect the surface quality of DX56D steel?

Zinc coating enhances the surface quality of DX56D steel by providing cathodic corrosion protection, which helps prevent corrosion products from forming. The hot-dip coating process creates a durable barrier that protects the underlying steel, ensuring longevity and durability.

What is the significance of minimum elongation in DX56D steel?

Minimum elongation is a critical property for DX56D steel, indicating the material’s ability to deform without breaking under stress. According to specified guidelines, the minimum elongation value ensures the steel can withstand forming processes and meet the required performance criteria.

Can DX56D steel be supplied without surface treatment?

DX56D steel can be supplied without surface treatment unless otherwise agreed upon. However, it is highly recommended to consider surface treatments, such as hot-dip galvanizing, for improved corrosion resistance and overall performance in exposed environments.

What are the common signs of coil breaks in DX56D steel?

Common signs of coil breaks in DX56D steel include visible deformations, cracks, or separations along the coil’s surface. These issues can arise during handling or processing and may compromise the integrity of the steel, leading to potential structural failures.

What is the role of light passivation stains on DX56D steel?

Light passivation stains on DX56D steel are permissible and indicate a thin layer of protective oxide that forms on the surface. This layer offers some temporary corrosion protection while maintaining the steel’s aesthetic appearance, as long as it does not affect the material’s functionality.

How does the zinc-aluminium alloy coating benefit DX56D steel?

The zinc-aluminium alloy coating provides enhanced corrosion resistance compared to traditional zinc coatings. It offers better protection against corrosion products while maintaining excellent formability and weldability, making it an ideal choice for applications requiring durability and strength.

What are the effects of storage and handling on DX56D steel surface quality?

Improper storage and handling of DX56D steel can lead to surface defects such as dark spots, stripe marks, or slight scratches. Proper transportation and storage practices, including protecting the material from environmental factors that may cause degradation, are essential to maintaining optimal surface quality.

What measures can be taken for temporary corrosion protection of DX56D steel?

Temporary corrosion protection measures for DX56D steel can include the application of oil or protective coatings that shield the surface from moisture and contaminants. These methods are critical during transportation and storage to prevent the formation of white rust or other corrosion-related issues.