Get in touch with us

Leave a message

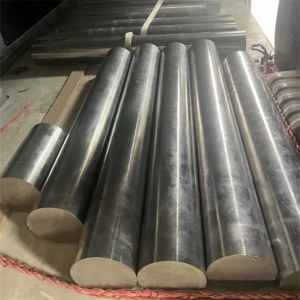

Harness the exceptional performance of our premium titanium alloys, engineered for demanding applications where strength-to-weight ratio is critical. From aerospace-grade compositions to the strongest titanium alloy formulations, our materials offer remarkable corrosion resistance and impressive mechanical properties at a competitive titanium alloy price. With melting points exceeding 1600°C and customizable compositions from commercially pure titanium to advanced Ti element combinations, we deliver the precise metallurgical solutions manufacturers need for aerospace, medical, and industrial excellence.

Titanium Alloy follows standards like ASTM B265 (plates) and AMS 4911 (Ti 6Al-4V), with grades classified by composition and use. From pure titanium (Grades 1-4) to alloys like Grade 5 (Ti 6Al-4V) and Grade 23 (ELI), titanium alloys cater to diverse needs—think titanium alloys for aerospace or industrial applications.

| Type | Composition | Characteristics | Common Grades |

|---|---|---|---|

| Alpha | Ti, Al (5-6%) | High heat resistance, weldability | Grade 6, Ti-5Al-2.5Sn |

| Alpha-Beta | Ti, Al (6%), V (4%) | Strength, formability | Ti 6Al-4V, Grade 5 |

| Beta | Ti, Mo (10-15%), V | High strength, ductility | Grade 19, Ti-3Al-8V-6Cr |

| Commercially Pure | Ti (99%+), O (trace) | Corrosion resistance, ductility | Grades 1-4 |

| Property | Behavior | Key Elements | Notes |

|---|---|---|---|

| Corrosion Resistance | Exceptional in saltwater, acids | Ti, O | Ideal for marine, chemical use |

| Oxidation Resistance | Stable to 600°C | Al, Ti | Suits titanium alloys aerospace |

| Magnetism | Non-magnetic | Ti dominance | Safe for electronics |

| Heat Resistance | Good to 600-800°C | Al, V | Varies by grade |

| Material | Tensile Strength (MPa) | Hardness (HB) | Elongation (%) | Notes |

|---|---|---|---|---|

| Ti 6Al-4V | 880 - 1100 | 330 | ≥ 10 | Strongest titanium alloy |

| Pure Titanium (Gr 2) | 340 - 540 | 160 | ≥ 20 | High ductility |

| 316 Stainless | 515 - 690 | ≤ 217 | ≥ 40 | Less corrosion-resistant |

| Aluminum 6061 | 276 | 95 | ≥ 12 | Lighter, weaker |

Titanium Alloy shines across industries:

Titanium Alloy delivers across high-stakes sectors.

Despite its strengths, Titanium Alloy isn’t flawless:

Titanium Alloy resists corrosion superbly:

Welding Titanium Alloy requires precision:

These ensure titanium alloy composition integrity.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.